The wheel bearing is the most important component of any vehicle; it ensures free rotation of the wheel. This structural element is constantly subjected to heavy loads, so it is often made from high-quality materials. However, if used incorrectly or with very high mileage, such a part can also fail.

Auto mechanics recommend changing the wheel bearing in the unit as soon as they notice a malfunction, otherwise the result can be sad, imagine what will happen if the bearing jams at high speed. Let's look at several ways to check a wheel bearing in order to be able to identify a defect in the early stages.

Signs of possible wheel bearing wear

Often the first sign is a hum from the wheel, but this is only the first signal. The field situation develops very quickly and the noise may be followed by a crash. Then the unit cannot maintain speed and falls apart while driving, which leads to a complete wedge and the car becomes uncontrollable. All this leads to failure of the suspension arm and deformation of the axle shaft. As a result, you will have to pay good money for repairs.

Therefore, it is important to be able to correctly identify a malfunction at the first signs and, if necessary, immediately eliminate it. The following signs will be the reason to check the wheel bearing:

- You can hear the wheel axle humming or crunching. More often it occurs when a certain speed is reached, approximately 60 - 70 km/h. When turning, especially at high speeds, the noise intensifies.

- A clear sign is the appearance of vibration along with a hum. It is transmitted both through the steering wheel and to the entire car and is caused by bearing runout.

- During long journeys, the wheel rim overheats. Sometimes the brake caliper overheats.

- Wheel jamming. When driving on a straight road, the car seems to steer to the side. This is caused by a defective wheel bearing inhibiting the rotation of the wheel. The symptoms are similar to an incorrectly adjusted wheel alignment.

To independently diagnose such problems on the go, you need to be able to listen to your car. And this comes with driving experience.

To accurately determine in which hub the bearing is humming, you should understand the causes of breakdowns and the principles of operation of the hub.

Types of hubs and bearings

The wheel bearing experiences the greatest load among all automotive bearings.

, which actually holds the entire mass of the car. The highest load values occur during movement, especially when accelerating and braking the machine. In this case, the bearing is almost simultaneously exposed to axial and radial forces, which places very high demands on its quality.

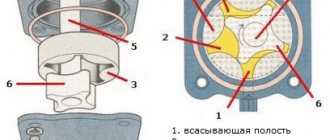

In modern cars, a wheel bearing is always a rolling bearing, which consists of two rings (outer and inner) and a distribution separator, designed to hold on the trajectory and distribute rolling bodies, which are balls, rollers or other parts, along the bearing. Depending on the type of load they carry, wheel bearings are:

- radial;

- persistent;

- radial thrust;

- persistent-radial.

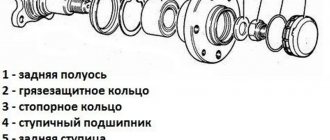

In a modern car, the hub, the design of which is not identical for all models, can be made in various configurations. Thus, in rear-wheel drive models, standard single-row roller bearings are predominantly used, of which there are two on each hub. The design with angular contact ball bearings, which are an integral element of the hub, is becoming increasingly widespread.

In new models with electronically controlled systems, the wheel hub is combined with the ABS system, as well as wheel speed sensors. Such hubs are manufactured completely closed, they are not dismountable and repairable, and their service life is equal to the duration of use of the car.

Causes of wheel bearing failure

In fact, there are several reasons that cause knocking or humming in the hub area. This is how extraneous sounds occur in case of malfunctions:

- steering rod;

- tip;

- ball joint;

- with severe wear of silent blocks.

However, the most common cause is a defective wheel bearing. Therefore, you need to be able to correctly identify the culprit of unpleasant noises.

The hub uses a closed type bearing, this is due to the fact that during operation abrasive materials (dust, dirt, sand, etc.) must not be allowed to get inside it. This makes the design more reliable, but still not eternal. As a result, we can identify six of the most common causes of noise in the hub.

- Great mileage. Caused by natural processes occurring during the operation of any unit. The bearing housing wears out, the grooves for the balls expand over time, play appears and the mechanism begins to knock. It appears after a mileage of 100 thousand km or more.

- Violation of tightness. The housing is equipped with bushings made of rubber or plastic that protect the inside from abrasive materials and moisture, and also prevent the leakage of lubricant, which is necessary for its normal operation. If damaged, the lubricant is lost, which leads to very rapid wear.

- Inattentive driving. If a car at high speeds constantly hits potholes on the road, holes, bumps and the like, this will eventually break not only the hub, but also the suspension.

- Incorrect installation. It happens quite rarely, if during the repair the wheel bearing was pressed in by an inexperienced mechanic or there were violations in the technology, then perhaps it became crooked. In this position, the unit will operate no more than a couple of thousand kilometers.

- Incorrect tightening of the hub fixing nut. The vehicle's technical data sheet describes a clear algorithm for tightening and adjusting the hub. If the torque is exceeded when driving, the unit will constantly overheat, which will reduce its service life.

- Frequent trips into puddles. During operation, the unit heats up; this is a completely natural process. When cold water hits it, the air in the internal space is sharply compressed and thus draws water into the bearing housing through micro-gaps. Moisture causes corrosion of parts, which leads to a crunching sound.

In addition to the reasons listed, there are a number of less significant ones, but also leading to rapid wear and the appearance of extraneous noise. Namely:

- Manufacturing defect. Sometimes found on inexpensive products. Caused by violations in production technology.

- Incorrect wheel offset. Increases the load on the wheel bearing, which shortens its service life.

- Frequent car overload. Even when driving only on good, smooth roads, you should not often subject the car to heavy loads. This also leads to rapid wear of the wheel bearing.

- Large tire radius. More often found on SUVs and trucks. In cases of lateral acceleration, the front wheel bearing will experience additional load.

- Faulty shock absorber. If the suspension systems malfunction, the bearing in the hub will be subject to additional vertical load when driving on bad roads. Therefore, it is also important to maintain the suspension in good condition.

- Brake system defects. Leads to high temperatures on the drum (disc) or in the brake fluid, which will be transferred to the wheel bearing. Which also reduces the resource of its work.

- Incorrectly adjusted camber/toe. If the wheel angle is incorrect, the wheel bearings are subject to additional stress while driving.

All these factors lead to a decrease in the life of the wheel bearing and cause humming and knocking.

In order to answer the question of which hub the bearing is faulty, you need to know what could cause rapid wear of the front hub and what could cause the rear one.

Front wheel hub bearing - what is it?

The front suspension of a car performs a huge number of functions, the main one being to ensure vehicle controllability. For reliability, two bearings are installed between the steering knuckle axis and the hub. They may vary in size, but always have a conical shape.

They are secured to the axle with a thrust washer and a nut. The more you tighten the nut, the tighter the rollers will be pressed. This makes it possible to make very precise adjustments to eliminate backlash.

For the driver, there is one not very convenient factor when operating a car. Due to the lack of standard protection and the possibility of contamination if the integrity of the oil seal is damaged, the wheel hub bearing requires constant attention.

We recommend: Robotic gearbox: should you trust a robot?

Very often, lubricant leaks due to high temperature or is washed out due to frequent interaction of the car with water. Accordingly, road dust and sand get into the hub body. Abrasive debris leads to wear of parts that will have to be replaced.

Checking the wheel bearing

Today, there are 4 most accessible ways to check the serviceability of the hub, available to every car owner. They do not require much time or special skills.

Flatness check

This is the simplest method; you can check the car right in the garage or near the house. First, you should park the car on a flat asphalt or concrete surface. Then grab the top of the wheel being tested with your hand and push it back and forth with all your might, rocking it. If you hear clicks or crackles during the process, then it’s time to change the bearing.

If you do not hear any extraneous noise, but you are not yet sure that the wheel bearing is in good condition, then the car on the side of the problem wheel must be jacked up. After this, turn the wheel by hand; if there is crackling, squeaking or other noise, it means the bearing in the hub is faulty and should be replaced.

On a jacked car, for greater confidence in the serviceability or failure of the unit, the wheel can be loosened in both vertical and horizontal planes. To do this, you need to grab the wheel with your hands by the upper and lower parts and shake it. If there is any play, it will be clearly noticeable. In this case, replacing the bearing is no option.

When performing such work, be careful to prevent the vehicle from falling off the jack.

You can check the front and rear wheel hubs using this method.

Runout check

One additional sign of defects in the wheel bearing will be a push into the pedal during braking. May occur due to impact of the brake disc or hub. Sometimes, when exposed to high temperatures, the brake disc can also become deformed along with the hub. Deviations from the vertical of even 0.2 mm can cause vibration and shock at speed.

The maximum runout tolerance does not exceed 0.1 mm, and sometimes even less - 0.05 - 0.07 mm. Mechanics at a service station check the runout with a dial-type pressure gauge; it is leaned against the plane of the hub and it shows the runout value. If you do not have such a device, you can use a screwdriver.

Checking the hub for runout is carried out in the following sequence:

- remove the wheel from the side being tested;

- Next, the flat screwdriver should be rested on the caliper bracket and applied to the working surface of the brake disc;

- then, using a head with a knob, rotate the wheel through the hub nut;

- if runout is present, it is immediately visible from the traces of scratches left by a screwdriver on the brake disc.

All wheel rims are checked for runout on both sides. If defects are found on the surface of the disk in the form of a scratch from a screwdriver, it should be disconnected, rotated 180° and secured to the hub with mounting bolts. Then repeat the verification process.

If the scratch appears in the same place as during the first test, it means the brake disc is crooked. If a scratch appears on the opposite side, the hub will be crooked.

Checking on a lift

It is better to check front-wheel drive cars using this method. However, it is applicable on all types of cars, even with rear-wheel drive or all-wheel drive.

To do this, the car is driven onto a lift, the engine is started and the wheels are accelerated in gear. Then the engine is turned off, and then you need to carefully listen to how the wheel bearings work while the wheels are stopping. If any bearing malfunctions, there will be a distinct crunch, hum, or vibration from its side.

Checking with a jack

You can also check the hub on a jack. It is better to carry out such operations indoors (garage, hangar, etc.), since extraneous sounds from the wheel will be more clearly heard here. The car is lifted one by one, each wheel is hung out. If you are not sure which side the noise is coming from, it is better to start checking from the rear wheels.

Work order:

- jack up the side of the car wheel being tested;

- when checking the rear side, spin the wheels by hand (for front-wheel drive cars), listen carefully for the presence of extraneous noise;

- checking the front wheels, the engine starts, the clutch is depressed, 5th gear is engaged, and then the clutch is smoothly released.

If the bearing is damaged, a crunching or knocking noise that is not typical for wheel rotation will be clearly audible. After the wheels accelerate, it is better to turn off the engine so that the noise of its operation does not interfere with the detection process.

Replacing the front wheel bearing

Let's look at how the replacement is carried out step by step:

- We turn on the handbrake on the car and put it in gear. We block the rear wheels with stops to prevent the car from rolling.

- Then, without lifting it on a jack, we “tear off” the hub nut. It is usually tightened very well. To prevent the car from rolling, your partner must press the brake at this moment.

- Raise the wheel on a jack and remove the wheel, then unscrew the caliper. The next step is to remove the brake disc from the hub. Further actions can be done in three ways:

- The first is to remove the bearing using a puller right on the spot, without removing the steering knuckle from the car. This method may not be suitable for everyone, because it requires a repair pit or a lifting mechanism. Since there is not much space there and you won’t be able to turn around. However, the advantage is that when replacing the bearing in this way, the camber adjustment is not lost, since the adjustment bolt is not touched with this method. If it is convenient to work in this position, then pull out or knock out the hub and remove the bearing.

- The second option is to screw together the entire knuckle mechanism and, once removed, use a vice and a removable key to replace the bearing. However, with this option, the camber setting is lost. But still this method is the most common among motorists. Before removal, you need to set two marks: one - the strut bolt, and the second - the strut knuckle. When assembly occurs, it is often impossible to achieve accuracy, but the marks make it possible to assemble almost the same way as it was. It is worth noting that if you are carrying out a comprehensive repair of the chassis, namely replacing ball joints, ends and silent blocks, then this method will also be the most suitable and convenient.

- The third involves removing the entire strut, and then using a vice and a removable key to replace the bearing. This is the most time-consuming method, but not everyone is able to use the first two methods for various reasons.

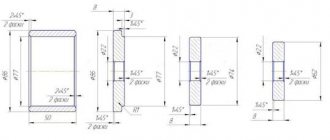

- The next step is to carefully knock the hub off the bearing. Then remove the retaining ring. Next, use a puller to press out the bearing.

- The bearing housing should be cleaned of old grease and debris, then a new bearing should be lubricated and pressed into the steering knuckle.

- Reinstall the retaining ring. We drive the hub into the steering knuckle using the adapter (the applied force when driving should go to the inside of the bearing and nothing else).

This is interesting: Fuse box of the Daewoo Matiz car

And then, in reverse order, we assemble all the mechanisms that were disassembled.

Car mechanics recommend changing the grease in the hub every 20 - 30 thousand km, even without humming, knocking and play. This can save you money on more expensive repairs.

Check while driving

You can also identify a possible defect in the hub bearing while driving; in my opinion, this is the easiest way to diagnose. To do this, you need to drive onto a flat, preferably smooth, section of the road. And ride it at a low speed of up to 50 km/h while taking turns.

During turns in motion, most of the load falls on one of the sides of the car, and accordingly, the hub. When entering a turn, it makes additional noise, and after the vehicle is leveled, the noise disappears. In this way you can determine which bearing is faulty, left or right.

If one of the wheel bearings fails, it begins to make extraneous noise when driving on a straight road while accelerating. The higher the speed, the louder the hum or crackling sound. If such noise is detected, you should not accelerate too much, it is unsafe, especially since bearing wear increases sharply.

Disk temperature

During operation, the wheel bearing heats up, and if there are any defects in it, friction increases, which leads to an even greater increase in temperature. This is a rather indirect sign, but you can also rely on it. A large amount of thermal energy will be transferred to the surrounding metal parts, including the brake disc.

To check in this way, after acceleration, it is necessary to stop the car without using the brake - by simply coasting. Go out and touch the brake disc with your bare hand. A warm disc may indicate a failed wheel bearing.

What if you don't replace a defective wheel bearing?

If, while driving, when accelerating or while cornering, unusual noise appears, you should immediately check the wheel bearings. Continuing to use a car with a faulty hub not only shortens the life of the chassis, but also risks an accident. Negligence can lead to:

- Additional load due to the effect of vibration on the vehicle's chassis and steering. Which leads to a decrease in the service life of all components.

- Reduced traction characteristics and overall efficiency of the machine. Leads to increased consumption of fuels and lubricants.

- Possible boiling of brake fluid. Which can cause partial or complete failure of the brake system.

- When entering a turn, the wheel may “lie down”. It is fraught with complete loss of control, the outcome can be disastrous.

- If the wheel bearing is heavily worn, the wheel may catch a “wedge”. Which will also lead to an accident.

If, after detecting a malfunction of the wheel bearing, for some reason it is not possible to immediately replace it, then when driving you should not drive at a speed above 50 km/h, and it is unlikely that you will be able to drive more than 1000 km with a humming hub.