Types of Engine Oil Pumps

Oil pumps are not the same in different car engines. Thus, they can be regulated or unregulated. The former can be adjusted by changing their performance to ensure optimal pressure in the system. Devices of the second type do not have this capability; pressure-reducing valves are used to ensure pressure stability.

Structurally, pumps for pumping oil are divided into rotary

and

gear ones

. In rotary devices, oil is pumped by rotor blades, and in second devices, it is transferred by gears.

The gear oil pump may have:

- External engagement with adjacent gears;

- Internal gearing, in this scheme the gears are placed one inside the other.

Having approximately the same performance characteristics, the devices differ in size, since internal gear systems have smaller dimensions.

Rotary pumps

They are also called cam rotors, as they are based on the principle of displacing liquid of a special shape by cam rotors (see Fig. 3). Looking at the photo, you may get the impression that this is the same gear pump, only it has gears with large rounded teeth as the working part. This is not entirely true - here the teeth do not carry the load, which is transmitted by special gears. Thus, the rotary mechanism is much more complex than a gear mechanism, but is less subject to wear and is more durable.

Rice. 3 – Rotary oil pump

In addition to three-cam rotor forms, there are also two-cam, four-cam, and also special shapes - segmented.

Design features of oil pumps with gears

These pumps are simple. They consist of a small number of parts, including:

- driven and driving gears;

- drive unit;

- suction and discharge channels.

Oil pump device.

Gears are mounted in the device body, transferring oil from the suction to the discharge channel, from where it is distributed throughout the system. The performance of such equipment depends entirely on the frequency of operation of the crankshaft. If the pressure becomes excessive, to reduce it it is necessary to dump some oil from the system into the crankcase. This operation is carried out automatically using a pressure reducing valve that responds to increased pressure. It should be noted that it is impossible to manually adjust such an engine oil pump.

Rotary type

The device combines internal (leading) and external (driven) rotors in a housing. Engine oil is taken up by the blades of the drive rotor and, passing through the discharge cavity, is supplied to the channels of the engine oil system. The device of a non-regulated oil pump is shown above, so its operating principle requires the presence of a pressure reducing valve.

Adjustable pump

The adjustable rotary oil pump is equipped with a movable stator and an adjusting spring. Rotating inside the outer rotor, the inner rotor captures oil from the suction cavity, redirecting it under pressure to the discharge area. The volume of pumped oil depends on the rotation speed of the inner rotor and on the volume of the cavity between the inner and outer rotor, which is connected to the movable stator. By changing the volume, we can adjust the performance of the oil pump.

Design features of rotary oil pumps

As a rule, a rotary-type oil pump consists of a small number of parts, including:

- suction and discharge cavities;

- external and internal rotors;

- drive shaft.

Oil pump operation

with rotors is based on the interaction of two rotors. In unregulated designs, the oil that is drawn in is transferred into the system by rotor blades. If the pressure becomes excessive, the pressure relief valve opens and excess oil is released.

What makes them adjustable is the presence of a movable stator. It has a special adjustment spring, by tightening or twisting it you can change the volume of the chamber with the rotors, due to which the overall pressure in the system also changes. Thanks to the stator, it is possible to achieve stable pressure in the lubrication system, regardless of how intensely the crankshaft rotates.

The adjustable oil pump design is also not complicated, but allows for much greater efficiency of the lubrication system.

Advantages of variable oil pumps

Today, adjustable oil pumps are considered much more acceptable than unregulated ones, because they have a number of significant advantages, including:

- about a third less power taken from the engine;

- less oil wear due to reduced frequency and speed;

- the oil foams less.

That is, an adjustable oil pump allows for smoother oil circulation and a longer interval between oil changes, which makes it a more preferable equipment.

Rotary oil pumps

They are more advanced and complex than the gear ones discussed above, and represent a stator, inside of which a rotor is eccentrically fixed, having from 2 to 14 - 16 plates along the longitudinal axis. As the rotor rotates, the plates adhere to the stator under the action of springs or centrifugal force, creating a vacuum in the area of the supply pipeline and pumping liquid into the area of the discharge pipeline.

During operation, rotary pumping mechanisms have proven themselves to be reliable, easy to maintain and repair.

Piston oil pumps

They develop much higher pressure compared to their predecessors. As the name implies, the operating principle is based on a piston, which, moving in one direction along the axis, sucks oil into the cylinder. When the piston changes direction, the working fluid under pressure enters the discharge pipeline.

- Depending on the complexity of the design and purpose there are:

- Manual - usually this is a one- or two-piston simple mechanism, which is used as a backup in various hydraulic systems.

- Radial piston. Their design includes a stator and a rotor eccentrically fixed inside it, with pistons located around the circumference. As the rotor rotates, the cylinders alternately pass through the suction and discharge cavities, the pistons perform reciprocating movements, sucking or pumping oil. This design is capable of creating pressures up to 100 MPa.

- Axial piston - in them cylinders with pistons are located parallel or at a slight angle relative to the axis of rotation of the rotor.

Signs of a faulty oil pump

Like any other system with moving parts, the oil pump can fail.

Malfunctions in the oil system will be indicated by an oil pressure lamp.

.

The reasons for this may be various factors, including:

- decrease in oil level in the crankcase;

- breakdown of pressure monitoring devices;

- use of low-quality oil or oil unsuitable for this pump;

- oil filter clogged;

- breakdown of the safety or lubrication valve;

- clogging of the oil pump itself and other problems.

Signs of problems with the lubrication system include:

- decrease in oil pressure;

- increase in its consumption.

This will be indicated by a warning light on the dashboard.

It should be noted that if the oil pressure decreases, you must immediately stop using the car and begin to find out the causes of the problem.

Replacing the oil pump is only necessary in rare cases!

The service life of the oil pump is so long that most vehicle owners will never have to replace it (a few hundred thousand kilometers is the rule). In some cases there may be a dangerous defect. Poor oil quality, contamination due to leaks in the cylinder head or dirt penetration may lead to the need for replacement. In addition, design or operational faults of some car models mean that the oil pump needs to be replaced.

Today, few cars still have a pressure gauge, but there is always a warning message that the oil pressure is too low. If such a warning is received from the on-board diagnostic system or the oil level indicator comes on, the engine must be turned off immediately. If you continue driving, you can expect significant collateral damage within a very short time, which may result in engine failure. If the oil level is too low and the low pressure is not the cause, the oil pump may fail. Further signs of a bad oil pump may include unusual noises and leaks from the engine.

How do rotary type oil pumps work?

The design of rotary pumps includes:

- external rotor;

- internal rotor;

- oil;

- discharge cavity;

- suction cavity;

- drive shaft.

Rotary pumps are structurally composed of a driving and driven rotors, which are also called an internal and external rotor. These rotors are located inside the housing.

If we consider an unregulated rotary pump, then the oil sucked with its help is transported into the system through the rotor blades.

When the pressure increases, the pressure relief valve is automatically turned on. An adjustable rotary oil pump, unlike a non-adjustable one, has a movable stator with an adjusting spring in order to provide constant pressure regardless of the crankshaft speed.

It will also be interesting: Wheel locks: which anti-theft bolts are better

Constant pressure is maintained with the help of this movable stator by changing the volume of the cavity between the rotors, turning the stator in the required direction.

Why is an adjustable oil pump better than a non-adjustable one?

- less power is lost from the motor (by about 30%);

- the oil retains its properties longer, since the frequency and number of revolutions are lower;

- The oil doesn't foam as much.

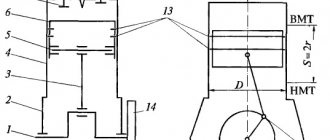

Operating principle of gear oil pump

The driven gear is fixed to the axis, and the drive gear is driven into rotation by the drive shaft. Rotating gears take oil through the suction channel, where it flows through the oil receiver from the crankcase. Next, oil under pressure enters the discharge cavity, from where it is distributed through the channels of the oil system. This is exactly how a simple gear pump works.

The performance of the oil pump directly depends on the speed of rotation of the crankshaft. But increasing the pressure in the system above normal will lead to squeezing out the seals and increasing mechanical losses. Therefore, excess oil is released by a pressure relief valve, which opens when the design pressure is exceeded. You can study in detail the design and principle of operation of the valve, which allows you to dump oil back into the intake cavity, from the article “Oil pump pressure reducing valve”.

1- intake gears; 2- valve; 3-lock spring.

Kinds

Based on the method of gear engagement, pumps for pumping liquids are divided into units with internal and external gearing.

The arrangement of units with gears in gears allows the oil pump to be driven directly from the crankshaft. The operating principle helps to reduce the overall dimensions of the housing without loss of performance. Therefore, it is unregulated oil pumps with internal gearing that are most often installed on modern cars.

Types of oil pumps based on design

The design of oil pumps varies, so based on these features, there are the following types:

- rotary pumps - in such pumps, lubricant is transferred using rotor blades;

- Gear pumps - they transport oil using gears.

Gear pumps are as follows:

- with internal gearing - when one gear is located in another;

- with external gearing - when two gears are located one next to the other.

The performance of these pumps is the same, but the sizes are different - an internal gear pump is smaller than a pump with external gears, since one gear is located in another.

How does a gear type oil pump work?

This type of pump consists of:

- drive shaft;

- driven gear;

- drive gear;

- suction channel;

- driven gear axis;

- discharge channel.

Inside the pump housing there are gears (driver and driven). These gears transport oil through the discharge port from the suction port into the system.

The higher the crankshaft rotation speed, the faster the gears spin and the greater the performance of the gear pump.

In the case when the pressure of the injected lubricant is greater than what is permissible for a given pump model, then a certain amount of oil is transported into the engine crankcase or into the suction cavity thanks to a pressure reducing valve, which operates automatically with an increase in pressure in the system. In general, gear oil pumps are a non-adjustable type of pump.