Design Features

The pressure of the fuel in the rail is controlled using a pressure gauge connected using a special fitting, the hole for which is provided in its design. In the normal position, the fitting is closed with a plug that protects its threads from contamination. The pressure in the ramp is monitored during inspections of the technical condition of the vehicle.

To improve fuel atomization, in some engines the fuel rail design provides for the possibility of preheating it. Also on the ramp there are fittings for supplying and draining fuel.

Fuel rail pressure: how to check, what it should be, symptoms of a malfunction

Diagnosis of the fuel system cannot be completed without checking the pressure in the fuel rail. If there are problems with the fuel supply, this will affect the overall operation of the engine: its start-up, acceleration, idling and other modes. The driver can check the pressure in the fuel system rail independently; no special diagnostic equipment is required; a simple pressure gauge is sufficient. In this article we will look at how to check the pressure in the fuel rail.

When to check fuel rail pressure

If problems arise in the fuel system, with a high degree of probability they can be associated with rail pressure.

The following main malfunctions can be identified that indicate the need to check the pressure in the fuel system:

- The car began to consume significantly more fuel;

- The engine operates unstably at idle, including stalling;

- The motor is tripping;

- Engine exhaust contains high CO content.

The malfunctions listed above are also typical when a number of other problems occur. In particular, before checking the pressure in the fuel rail, it is recommended to make sure that the electronic control unit is working properly.

Fuel Rail Operation

To inspect and troubleshoot the fuel rail, it may be necessary to remove it from the engine. In this case, the fuel supply is turned off, after which the fuel supply hose is disconnected. Then the drain hose is removed, which allows you to remove the ramp from the body by unscrewing the mounting bolts with a wrench. Next, the injectors are removed with extreme caution, the fittings of which are prudently closed with protective plugs. After inspection and elimination of identified defects, the ramp is mounted on the engine in the reverse order.

Source

Ramp manufacturing and operation

The material for the manufacture of the fuel rail is alloy steel, which protects the internal cavity in contact with the fuel from corrosion. After manufacturing, the ramp undergoes mandatory testing for its ability to withstand excess pressure.

To check the ramp for defects, it is sometimes necessary to remove the device from the engine. First, the fuel supply is turned off, and then the hoses are disconnected. Next, remove the drain hose to remove the ramp from the body by unscrewing the mounting bolts with a wrench.

Then you will need to remove the injectors with utmost care so as not to damage the structure. The fittings are first closed with plugs for protection. After a technical inspection and possible defects, the ramp is repaired. Then it can be used again.

The fuel rail is an essential element in the vehicle system. Therefore, it is extremely important for drivers to know the principle of its operation and periodically monitor its operation. If malfunctions are identified, it is strongly recommended not to use the vehicle until repairs are carried out.

What is a fuel rail?

The fuel rail (or fuel rail) is a special tube that serves to supply fuel and distribute it between the injectors. The fuel in the rail is under pressure.

Initially, in the era of carburetors, such an element was not provided for in the design of automobile engines - there was no need to supply fuel under pressure. With the development of technology and the improvement of gasoline engines, this element migrated from diesel cars and became an unchanged part of the design.

Features of the device and advantages of the Common Rail fuel system

The Common Rail fuel system is used exclusively in diesel engines and is considered the most progressive at the moment. Compared to other schemes, it provides more economical fuel consumption, increases the environmental safety of the car, has a low noise level, but most importantly, it creates a higher supply pressure into the combustion chamber. How the Common Rail injection system works and what the principles of its operation are will be discussed further.

What is a Common Rail fuel system?

Literally, the term Common Rail is translated into Russian as a common highway. The main design feature of this system is the presence of a fuel rail, in which fuel is accumulated before its further supply to the diesel engine injectors. Due to this feature, such systems are also called battery-powered. It was first introduced by Bosch in 1996.

Common Rail fuel system design

Structurally, the Common Rail system is divided into low and high pressure circuits and consists of the following elements:

- Fuel booster pump. It supplies diesel fuel from the tank to the pressure line.

- Fuel filter equipped with a valve for preheating at low temperatures.

- Auxiliary fuel pump. Performs fuel pumping from the injection line.

- Mesh filter.

- Temperature sensor. Fixes the level of fuel heating in the system.

- Fuel injection pump (high pressure fuel pump) - the most often used is a distribution type pump.

- Dosing valve. It regulates the amount of fuel entering the ramp.

- Diesel fuel pressure regulator. Necessary to maintain specified fuel pressure in the high pressure line.

- Fuel rail or battery. In fact, it is a tube along the length of which the injector mounting fittings are located.

- Pressure meter. Located in the high pressure line. It records and transmits relevant data to the engine ECU (electronic control unit).

- Reducing or bypass valve. Allows you to maintain the pressure in the return line at the level of 1 MPa, which ensures proper operation of the injectors.

- Fuel injectors. There are two types: electrohydraulic or piezoelectric. The former are controlled by an electromagnetic valve, while the latter are equipped with piezocrystals, which can significantly increase the speed of their operation.

More than 70% of all diesel engines produced today are equipped with Common Rail fuel systems.

Features and principle of operation

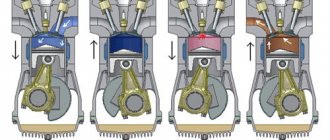

The operating principle of this type of fuel system is based on the separation of the processes of creating high pressure and direct diesel injection. From the fuel tank, fuel is pumped into the system by a low pressure pump. At the same time, it passes through filters, where it is cleaned of impurities and various contaminants. Through the low pressure circuit, diesel fuel enters the injection pump, which has a mechanical drive. He, in turn, pumps fuel into the ramp, where it accumulates until injection. This allows you to constantly maintain the desired pressure level, regardless of the current operating mode of the engine.

Receiving data from the system sensors, the engine ECU determines how much fuel the injection pump needs to supply to the fuel rail. After this, the fuel dosing valve opens, which enters the battery. The fuel is under a given pressure level maintained by the regulator.

Sectional diagram of a common rail system injector

As soon as the required volume of diesel is pumped into the ramp, the ECU sends a command to open the injectors corresponding to the engine operating cycle. During one cycle of operation of such a system, multiple injections are carried out, consisting of three stages:

- Preliminary - necessary to increase the temperature and compression in the combustion chamber, which speeds up the process of self-ignition. At idle, two pre-injections can be performed, while the speed increases - one, but at full power there is no pre-injection.

- The main one is directly responsible for the operation of the motor.

- Additional - necessary to increase the heating temperature of the exhaust gases, which ensures the combustion of soot and reduces the volume of harmful emissions into the atmosphere.

Modern diesel engines can have from 7 to 9 injection phases.

Advantages and disadvantages of the Common rail system

Initially, the pressure level created at the fuel rail was 140 MPa. Starting from the fourth generation, the system made it possible to achieve values up to 220 MPa. Such progress has made it possible to achieve an increase in the volume of fuel injected into the engine cylinders in one cycle, and, consequently, to increase the power of diesel cars.

Battery fuel systems use a whole range of sensors to take into account:

- pressure in the main pipeline;

- crankshaft rotation speed;

- air flow, gas pedal position;

- fuel and air temperature;

- lambda probe data.

The signals coming from these sensors enable the ECU to optimize the operation of the diesel engine as much as possible. Compared to injection pump systems with pump injectors, the maintainability of Common Rail is higher due to its simpler design.

Among the disadvantages of the Common Rail system is the need to use higher quality fuel. Since such engines use structurally complex injectors, their service life is lower. It is also very important to ensure complete tightness. So, for example, if an injector breaks down, its valve will constantly be in the open position and the fuel system will stop working.

The advent of the Common Rail fuel system was a real breakthrough in the production of diesel engines. It made it possible to apply high environmental standards for diesel engines of all classes, which are actively being implemented in developed countries.

(5 4,40 of 5) Loading...

You may also like

Source: https://TechAutoPort.ru/dvigatel/toplivnaya-sistema/common-rail.html

Features of design and location

The main task of the fuel rail is the delivery and distribution of fuel between the engine injectors. In this case, as already mentioned, the fuel must be kept there under pressure. In order to ensure a long service life, the fuel rail is made of special corrosion-resistant steel.

The design of most fuel rails provides a special fitting for connecting a pressure gauge. which controls pressure. In addition, a separate valve may be located on the fuel rail to drain fuel during repairs and maintenance.

The fuel rail is located on the engine intake manifold and is securely bolted. The injectors can be connected to the ramp either directly or through outlet pipes.

Fuel rail and its removal process

One of the most important elements of a vehicle's fuel system, the fuel rail, serves as a fuel distributor through a pressure valve to the injectors. This element was used on diesel units; later, the ramp began to be used on gasoline engines, as well as fuel injection pumps. It is simply impossible to imagine a modern engine without this part.

A fuel rail or rail is a section of a hollow tube with ends closed on both sides and outlets for connecting smaller diameter pipes through which fuel is supplied to the injectors.

In some cases, the injectors are attached directly to the ramp. The fuel rail is used in almost all multipoint injection systems, although in some designs the fuel is discharged to the injectors from the regulator body.

Design and location of the fuel rail

Typically, the ramp is installed on the engine intake manifold. In addition to the outlet pipes, the ramp has a hole with a shut-off fitting for connecting a pressure gauge, which controls the fuel pressure. To prevent contamination, it is closed with a threaded plug. Most often, the ramp is made of seamless steel pipe that can withstand high pressure. In the case of a diesel engine equipped with a common rail system, this pressure can be very high.

The main purpose of the fuel rail is to supply fuel and distribute it to the injectors.

When removing fuel injectors from the rail, extreme care must be taken. One wrong move can lead to the need to replace the injector.

When the injection pump operates, fuel enters the supply line located in the block head. Once in the ramp, the fuel moves towards the farthest cylinder. Some injection system designs provide for heating the fuel with the heat generated by the engine during operation. Warming up improves atomization.

Fuel rail operation issues

If for some reason the fuel rail needs to be removed, you must proceed with extreme caution, as there is a high risk of damaging the injector nozzles and connector contacts. Under no circumstances should dirt be allowed to get into open channels and pipelines, since after assembly it will inevitably get into the injectors and the matter will end, at a minimum, with washing them.

During maintenance, the holes must be closed with plugs. Before removal, the fuel rail can be cleaned using a can of injector cleaner. Under no circumstances should the ramp be placed in flushing solvent without disconnecting the injectors.

The fact is that all the holes in the fuel rail are equipped with rubber sealing rings, which will fail if placed in an aggressive environment.

Operation process and main malfunctions

Due to the simplicity of the design and the materials used, the fuel rail has a very long service life. The main type of malfunction is loss of tightness, which leads to a drop in pressure and fuel leakage. The causes of malfunctions may be mechanical damage or the natural aging process. This is especially true for the junction points of the ramp with other elements of the fuel system. Troubleshooting occurs through a thorough visual inspection.

It is best to remove/install the fuel rail in a car service center - since in this case there is a higher probability of complying with the technological process. When handling the fuel rail, special attention should be paid to the connection points - do not allow contaminants to get inside the rail and do not wash it in aggressive environments (so as not to damage the sealing elements of the connections).

You need to select a fuel rail only in the original catalog. And when pricing and choosing analogues, you need to pay special attention to high-quality and proven brands.

Source