What is an absolute pressure sensor used for?

What an absolute pressure sensor might look like.

This small device is responsible for measuring absolute pressure. The concept of “absolute pressure” is not used by chance, because the initial reference point for measurements is the state of vacuum, which is taken as an absolute.

After the data enters the ECU, the electronics, taking into account the pressure and temperature in the intake manifold, determines the most suitable air density and its expected flow rate, which is necessary to prepare a fuel-air mixture of the appropriate quality. The control unit, according to the calculated mass of consumed air, issues control commands of the required duration, due to which the injection nozzles are adjusted. Although a pressure sensor is a very worthy replacement for a flow meter, sometimes they are installed together on the unit.

DBP malfunctions

Signs of a sensor malfunction are primarily detected when the vehicle's electronic control unit switches to emergency mode. What does this affect? Firstly, the engine will not work economically, and excessive consumption of gasoline will be revealed. A slight detonation appears, the car's acceleration deteriorates, and the smell of fuel appears from the exhaust system. Further, the engine does not slow down despite long warm-up and reaching operating temperature, and jerks when changing gears.

What should an inexperienced motorist do in such matters? You should know that the DBP in the intake manifold is a fairly reliable element that rarely has any malfunction. Failures should be looked for primarily in the contacts and flexible hoses connecting the fitting and the intake manifold. The first thing to consider is whether the flexible tubing is broken or contaminated. Of course, if the integrity of the tubes is damaged, they should simply be replaced and the contamination cleaned. This all applies to external faults. If there is something wrong with the sensor itself, don’t even try to do anything yourself! The DBP is such a complex device that an illiterate opening will simply destroy it. Here the solution may be to completely replace the device.

How does an absolute pressure sensor work?

Thanks to DBP, it is possible to control how much air flows through the throttle valve. Based on this indicator, an impulse command is generated that determines the amount of fuel required to form a balanced fuel-air mixture. There is a vacuum chamber inside the sensor, from which the air is initially removed. It correlates the pressure in the inlet fitting with the pressure in the vacuum chamber and, according to the resulting difference, creates an outgoing signal. In order for the sensor to detect pressure, a whole chain of actions is necessary:

- The highly sensitive DBP diaphragm is deformed by pressure in the intake manifold.

- The stretching of the diaphragm causes a change in the resistance on the surface position strain gauges; in other words, the so-called piezoresistive effect occurs.

- Voltage fluctuations are observed in proportion to the dynamics of the resistance of strain gauges.

- The method of connecting strain gauges provides high sensitivity, which, thanks to the DBP chip, increases even more, resulting in the output voltage varying in the range of 1-5 V.

- According to the voltage received at the ECU input, a pulse is generated that goes to the injectors. It determines the pressure at the intake valve. In this case, voltage and pressure are directly proportional to each other.

Principle of operation

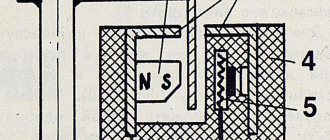

Absolute air pressure sensor circuit

The absolute pressure sensor performs the function of monitoring the amount of air passed through the throttle valve. Knowing it, the system generates an impulse to the injectors, and an amount of fuel enters the combustion chamber that corresponds to the optimal fuel mixture ratio. The operating principle of the absolute pressure sensor is based on changing the conductivity of piezoresistors. To understand the process, let's consider what happens inside the device:

- The diaphragm, which is the sensitive element of the device, is subject to pressure from the input manifold, deforming its surface. On the opposite side of the diaphragm there is a vacuum area. It is because of this that the unit is called an absolute pressure sensor.

- Deformation of the surface of the diaphragm occurs due to stretching. In this case, strain gauges located on the surface change their resistance due to the piezoresistive effect. The voltage changes proportionally to the change in resistance.

- The strain gauges are connected in a “bridge” configuration and therefore have greater sensitivity. The chip located in the sensor increases it even more. As a result, the voltage at the sensor output can take a value from 1 to 5V.

- The output signal is sent to the input channel of the electronic control unit, where it is evaluated and, based on it, a command for the injectors is generated. Moreover, the higher the voltage, the greater the pressure.

Article on the topic: Choosing a rolling jack

Based on the amount of pressure detected, sensors are divided into those used in naturally aspirated engines (determined from 0 to 1 atmosphere), and those used with turbo engines or engines equipped with mechanical superchargers (determined from 0 to 2 atmospheres).

Where is DBP located?

Mounting the DBP on the body.

It has already been mentioned that the sensor must be looked for on the manifold. Let us only emphasize that it is used only on injection engines. This is especially true when the car is equipped with a turbocharged power unit and a compressor.

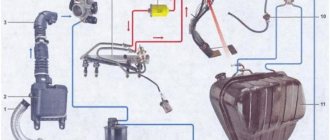

However, in many models its location is somewhat different - in the body part of the engine compartment and it is attached directly to the body. In this case, the inlet fitting and the inlet manifold are connected via a flexible hose. It should be noted that DBP is also installed when the car does not have a mass air flow sensor (MAF).

Sensor location

Mounting the absolute pressure sensor on the body

The location of the MAP sensor may differ for different vehicles. Most often, it is located in the engine compartment and attached to the body. The inlet fitting is connected to the working volume of the inlet manifold using a hose. On engines with turbocharging and compressor, the sensor is attached directly to the manifold. In this case, it also performs the functions of adjusting and measuring excess pressure, which is created by a turbo or mechanical compressor. In such systems, it can be used either with or without an air flow controller. It is worth noting that modern cars often combine an absolute pressure and temperature sensor in one housing. This allows you to create a more accurate control signal transmitted to the electronic control unit, since in this case not only air pressure is taken into account, but also its temperature.

Symptoms of a malfunctioning absolute air pressure sensor

A whole group of “symptoms” can indicate a breakdown of DBP:

- Fuel consumption increases noticeably, which occurs due to the receipt of a signal from the sensor to the ECU about high pressure, the level of which is actually lower. In this case, the electronic unit gives a command to supply a mixture enriched more than necessary.

- The engine dynamics deteriorate, which does not return to normal even after warming up.

- Even in the summer season, white-colored exhausts appear.

- There may be a gasoline smell coming from the exhaust.

- The idle speed does not decrease for a long time.

- Switching is accompanied by sudden jerks or dips.

- An incomprehensible kind of noise, often developing into a hum.

Where is the Lanos absolute pressure sensor located and its part number

All Lanos cars are equipped with absolute air pressure sensors. What this element is needed for and on what principle it works is described in detail in the material. Often, symptoms indicating a device malfunction will lead to the need to have it checked. First you need to find where the DBP is located on Lanos.

The Lanos DBP is located on the engine front panel. Finding it won't be difficult. A chip with wires and a hose are connected to this element. The photo below shows where the air pressure sensor is located on Lanos.

When purchasing the device in question, you need to know its article number. The original MAP sensor has part number GM 12569240. It is not recommended to buy Russian-made devices, as they have a large error, which accordingly affects fuel consumption and engine stability. If you cannot find an original sensor for Lanos, then an alternative solution is to buy a Danish-made DBP “Mechanex”. This is the answer to the question of which one is better to choose.

There are other manufacturers of the elements in question, but when purchasing, consider the cost of the products. The price of a Danish-made Lanos pressure sensor is 1800-2000 rubles, while the Russian prototype costs about 800 rubles.

This is interesting!

When driving a car in mountainous areas, it is recommended to stop periodically so that the ECU can measure the atmospheric pressure.

How to check the absolute pressure sensor

The method for diagnosing DBP depends on the specification of the sensor device, which can be analog or digital. To confirm the functionality of the analog absolute pressure sensor, the following algorithm of actions is required:

- A sensor adapter is connected to the vacuum hose connecting the DBP and the inlet manifold, and a pressure gauge is connected to it.

- The engine starts and idles for several minutes. If the vacuum in the manifold is below 529 mm, it is worth checking whether the hose itself is leaking air. It would be a good idea to look at the sensor diaphragm and make sure there are no flaws in it.

- After taking the pressure gauge readings, you need to disconnect it and replace it with a vacuum pump. Next, you should create a vacuum of 55-56 mm Hg. and stop pumping. It can be considered that the DBP is not damaged when the vacuum remains unchanged for about 30 seconds, otherwise the device will need to be replaced.

When dealing with a digital sensor, you can do this:

- We switch the tester to voltmeter mode.

- We start the engine and determine the position of the power and ground contacts. We connect the wire connected to the output contact of the sensor to the tester. A voltage of 2.5 V or so indicates its serviceability. If the difference with the specified voltage up or down is significant, the device has failed.

- The tester switches to tachometer mode and the vacuum hose is disconnected.

- The “+” probe must be connected to the signal terminal, and the “-” probe to ground. Normally, the device should show 4400-4900 rpm.

- Now you need to connect the vacuum pump to the absolute pressure sensor. Based on the results of repeated changes in vacuum, there should be no jumps in the tachometer and pressure readings.

- When the vacuum pump is turned off, the tachometer should show 4400-4900 rpm, which indicates that the DBP is working properly. Otherwise, the device is faulty.

Operating principle and design of DBP

The absolute pressure sensor on Lanos determines the volume of air passing through the throttle valve. Depending on the amount of air passing and the load on the internal combustion engine, electrical impulses are created that are read by the ECU. Based on the magnitude of the pulses, the fuel-air mixture supplied to the cylinders is adjusted.

The absolute air pressure sensor has a vacuum chamber in its design. Due to this chamber, the pressure in the inlet fitting is compared and a corresponding signal is generated in the form of electrical pulses. The calculation of air pressure is carried out due to the following actions occurring inside the sensor:

- The device is designed with a highly sensitive micromechanical diaphragm that deforms as the pressure on the intake manifold increases.

- Depending on the amount of pressure, the diaphragm stretches. When it is stretched or deformed, the resistance changes on four strain gauges (variable resistor)

- Depending on the resistance value of the strain gauges, voltage fluctuations occur in the circuit

- The high sensitivity of strain gauges is ensured by the use of a silicon chip, so the varying voltage at the sensor terminals is from 1 to 4.9 V

- Depending on the voltage that is supplied to the ECU and detected, a pulse is generated. This impulse is supplied to the injectors, thereby being responsible for preparing the mixture burned in the cylinders

This is interesting!

The higher the pressure indicator, the correspondingly higher the voltage value at the sensor terminals.

When the engine is not running, the pressure in the intake manifold will be the same as atmospheric pressure and amount to 101 kPa. It is at this moment that the sensor determines the amount of atmospheric pressure. When the engine starts, the throttle valve closes, which helps create a vacuum and create a pressure of about 30-33 kPa. With the damper open and the engine running, the pressure will be compared with atmospheric pressure and equal to 101 kPa. Pressure fluctuations occur when opening and closing the throttle valve.

| Output voltage at DBP terminals | |||

| Height above sea level | Barometric pressure | Output voltage | |

| m | mmHg | kPa | IN |

| 0-610 | 760-707 | 100-94 | 3,3-4,3 |

| 611-1524 | 707-634 | 94-85 | 3,0-4,1 |

| 1525-2438 | 634-567 | 85-76 | 2,7-3,7 |

| 2439-3048 | 567-526 | 76-70 | 2,5-3,3 |

From the principle of operation of the absolute pressure sensor on Chevrolet, Daewoo and ZAZ Lanos, it is clear that this element plays an important role in preparing the mixture. If the element operates with an error or does not function at all, the fuel assembly will be saturated and contribute to an increase in fuel consumption.

Video on the topic

Related publications

- Power steering: what is it in a car

- What is mono injection and how does it work?

- RHH: what is it?

- Injector and carburetor: what is the difference and which is better?

Leave a review

Cancel reply