What kind of variator is installed on the X-Trail

The T31 and T32 models of this SUV have Jatco CVT gearboxes of type RE0F06A or RE0F10A (JF011E).

They are highly reliable and can operate in almost any conditions, even with high-power power units. The service life of such variators is also pleasing. The Nissan manufacturer assures that the CVT will cover 100,000 km without problems before the first serious maintenance. However, in order for the device to work as long as possible, you should not forget about timely maintenance.

When the Nissan X-Trail T31 variator is used in compliance with all requirements, it demonstrates excellent performance. In this case, replacement of the main components will not be required. They just don't wear out. You just need to change the chain annually and go for car diagnostics every 6 months.

CVTs of any car are designed in such a way that the V-belt drive is the basis of the entire structure. Using a stepper motor, the distance between the pulleys is adjusted. As a result, the gear ratio of the gearbox changes. Planetary gears are used to adjust the reverse gear.

The main parts of the body include:

- pulleys;

- steel belt;

- CVT solenoids and valves;

- planetary gears;

- reverse clutch and "Drive" mode;

- control block;

- high pressure pump.

In general, the variator is very similar to the drive of the most ordinary bicycle, which has driven and driven “sprockets” connected by a chain. In cars, pulleys are used instead of sprockets, and a belt is used instead of a chain.

The gearbox pulley is connected to the motor-clutch. In this case, the steel belt creates a force so that during operation the secondary shaft pushes the primary one. The belt itself is made of steel tape and special elements.

Nissan X-Trail variator design

CVTs Nissan X Trail T32 and T31 have the following device. The design is based on a V-belt drive. The gearbox ratio changes due to the correction of the distances between the driving and driven pulleys - this is done by a stepper motor. The CVT box also includes planetary gears; they regulate the reverse gear.

Main components of the body:

- variator pulleys;

- steel belt;

- solenoids, box valves;

- planetary gears;

- reverse clutch and Drive mode packages;

- control unit;

- high pressure pump.

In a simplified form, a variator has much in common with a bicycle drive, with its driven drive sprockets connected to each other using a chain. But in cars, sprockets are replaced by pulleys, and the chain is replaced by a belt.

The gearbox pulley connection comes with the motor-clutch. During operation, the secondary shaft pushes out the primary shaft; the force for this is created by a special belt. The belt consists of a steel belt and a set of segments.

Review of the Nissan X-Trail CVT

Story

Continuously variable transmission is by no means a new idea, and was known back in the Middle Ages. In particular, Leonardo da Vinci reflected it in his drawings. And the CVT box embodies these ideas in a modern, high-tech design.

They started installing the Jatco variator on the Nissan X Trail about 10 years ago, and since then the manufacturer, car service centers and motorists have already accumulated solid experience in operating these boxes, repairing and eliminating various problems.

Box device

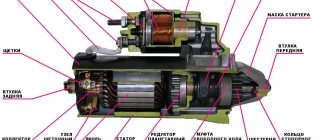

The Nissan variator is based on the principle of V-belt transmission: the box contains pulleys consisting of two cones, connected by a special belt, which is responsible for transmitting torque. The gear ratio of the box changes by changing the distance between the driving and driven pulleys, which is done by a special stepper motor of the box. In addition, the CVT box includes planetary gears that are responsible for engaging reverse gear.

Hidden within the body of the Jatco CVT transmission are several key elements:

- variable speed pulleys;

- a steel belt connecting them;

- box valves and solenoids;

- planetary gears;

- clutch packages for reverse gear and Drive mode;

- high pressure pump;

- control block of the box.

In an extremely simplified way, a variator can be compared to a chain bicycle drive, where there are driving and driven sprockets connected by a chain, only instead of sprockets there are pulleys, and instead of a chain there is a box belt.

The input pulley of the box is connected to the engine in the form of a clutch, always operating in mode D. During operation, the secondary shaft of the box is pushed by the primary shaft due to the force transmitted by a special belt.

The box belt consists of many steel segments connected to each other by a dense steel tape.

Important: the transmission belt is a pusher. This means that the force transmitted by it from the primary pulley pushes the secondary one, rather than pulling it along with it.

It is assumed that the box belt is subject to little wear, since the steel is very strong and does not compress. The entire belt element of the box works as one steel body transmitting torque.

If the gear ratio needs to be changed, the transmission control module (TCM) changes the distance between the transmission pulleys, resulting in:

- the primary gearbox pulley rotates more slowly - the gear is downshifted;

- faster - increases.

If you need to switch to reverse, the planetary gear of the box is engaged (in normal driving mode it is passive). At the same time, the ability to change the gear ratio by the gearbox is blocked for safety reasons - to avoid accidental acceleration when reversing.

It is extremely important to create high pressure in the box to avoid belt slippage and damage to metal surfaces. For these purposes, special technological methods and special transmission fluids are used.

The nominal pressure developed by the oil pump of the box is 55 bar, and the maximum possible is up to 60. The CVT box uses several regulators that provide the following indicators:

- maximum 4 bar – for the lubrication and cooling system of the box;

- up to 10 bar – for the torque converter unit;

- up to 15 bar – for gearbox clutches.

How does the Nissan X-Trail variator work?

The principle of operation of the Nissan X-Trail T31 and 32 variator is to move a metal belt inside the CVT along a tangent to a pair of shafts. To change the gear ratio, the diameter of these elements is adjusted. The primary transmission shaft is connected via a clutch connected in the D position. The input pulley influences the secondary pulley and pushes it out through a belt, structurally consisting of a set of segments (material steel).

The surfaces between the pulleys change under the influence of the control module. Thanks to its correct operation, the belt on the input shaft rotates slower or faster depending on what speed is being simulated. As a result of changing the position of the control shaft, the model gives the required coefficient.

Characteristics of the Nissan X-Trail variator

The improved version of the CVT RE0F10A gearbox differs from older versions in lightweight variator pulleys and the use of a single-piston drive shaft. Engineers increased the pressure of the drive pulley circuit to 60 kg per centimeter.

Other advantages of the variator:

- improved external processing frequency;

- reducing the risk of adhesion and foaming of the transmission.

The nominal pressure that the pump develops is 55 bar, the maximum possible is 60 bar. Regulator indicators:

- 4 bar – for the lubrication and cooling system;

- up to 10 bar – on the torque converter unit;

- up to 15 bar – box clutch.

The range of gear ratios has been expanded, the hydraulic control system has been redesigned. To reduce losses, the pressure can be adjusted on the driven and driving pulleys independently of each other (previously it was only possible at the same time). There is a chain drive in the structure of the device.

Pros and cons of the Nissan X-Trail CVT

Advantages of X-Trail CVT transmissions:

- A simple box in terms of design that simplifies maintenance and diagnostics of the unit.

- Open access to the gearbox makes it easy to change the oil.

- CVT is equipped with magnets, they are mounted in pallets and attract metal shavings.

- There is no need to warm up the liquid when starting, there is an additional heater for the lubricating part.

- Increased service life of the Nissan X Trail T31 variator, largely due to the use of a single-piston shaft, which reduces the weight of the pulleys and the degree of their wear.

- The presence of an air radiator reduces the degree of adhesion and foaming of the transmission fluid, and prevents overheating of the box.

- Smooth, fast acceleration due to the lack of gears.

Important! Compared to a manual transmission, cars equipped with CVTs consume more or less gasoline when compared to a conventional automatic.

Flaws:

- sensitivity to incorrect operation;

- expensive repairs;

- failure of the entire system if one sensor breaks down.

If the operating conditions are observed, there will be no unnecessary problems. More about them later.

General characteristics and weaknesses of Nissan XTrail T31 CVTs

According to representatives of official Nissan centers, the Nissan XTrail T31 model with a CVT transmission has become a striking example of an “all-terrain vehicle” that demonstrates good cross-country ability and handling in difficult conditions. The demand for the car was indirectly confirmed by massive sales of pre- and post-restyling versions of crossovers.

The potential resource of the CVT 7 transmission installed on the first T31 models is about 200 thousand km. However, in practice, this figure varies within 80-100 thousand km, after which partial or complete repair of the Nissan X Trail CVT is usually required. The most vulnerable point of the CVT 7, according to reviews from car owners, is the pulley bearings. Taking on the bulk of the load, these elements quickly wear out, as evidenced by the appearance of a monotonous hum.

The pulleys themselves and the rotation transmission belt between the shafts also do not demonstrate a high safety margin. Their condition is largely determined by the degree of wear of the bearings. As the latter become unusable, the tension of the belt decreases, which begins to slip without transmitting torque to the shafts. Malfunctions and breakdowns of the functional elements of the variator are indicated by “triple movement” of the engine, manifested by vibration and malfunctions in the operation of the power unit.

CVT 8 type CVTs installed on later XTrail T31 models, unlike their predecessors, demonstrate a longer service life and resistance to aggressive driving style. After technical improvements, the weight of the unit has decreased, and the oil pump has become more compact. In addition, due to improvements, the friction of the belt on the pulleys was reduced by 40%, which made it possible to ensure a longer service life of these parts. The potential resource that this Nissan X Trail T31 variator has is designed for approximately 250 thousand km.

Reliability of the Nissan X-Trail variator

Nissan X-Trail CVTs are reliable and can last longer than the stated period if the operating rules are followed. Factory defects reduce the working life; parts wear out faster than they could.

An aggressive driving style and the habit of driving also significantly reduce the service life of the CVT gearbox. When starting abruptly from a standstill with the roar of the engine and slipping, the belt begins to slip, scratching and damaging the metal. During high-speed driving, chips get into the oil, do not have time to settle on the filter box, and immediately get into the working mechanisms and channels. This leads to transmission failure.

How to check the CVT on a Nissan X-Trail

The operating principles of the Nissan X-Trail T31 and 32 CVT gearbox consist in moving a belt clutch made of metal alloys into the CVT in the direction of the tangent shaft pair. In order to correct the transmission data, the current diameter of the elements is modified. The primary type transmission shaft is connected by a coupling. The input pulley acts on the secondary, pushing it out with a strap. The surfaces in the intervals from pulley to pulley change under the influence of the modulus. Thanks to this design, the belt rotates at the desired speed.

Advantages of the CVT transmission X-Trail T 31 Nissan:

- frequency of processing refined to ideal;

- reducing the likelihood of adhesion and foam formation by the transmission.

The pump develops pressure up to 60 bar. The range of gear values is expanded, the hydraulic control system has been repeatedly improved and brought to almost perfection. Failures of the Nissan X-Trail variator are possible at any period of operation, although the operating time of the box declared by the manufacturer is at least 100 thousand km. After this period, scheduled repairs are usually required.

Important! Provided regular timely maintenance, repair of the X-Trail variator will not be required soon. It is advisable to test it from time to time and check the circuit every 12 months.

The procedure for checking the variator on the Nissan X-Trail will be described below. The main signs of failure, which indicate a problem and require in-depth diagnostics, are as follows:

- slipping when moving along perfectly smooth roads;

- the indicator activating the emergency lights began to work when it shouldn’t;

- The vehicle reduces engine speed, and the transmission hums;

- there are difficulties with gears, levers jam or shift with great difficulty;

- The power of the car has decreased significantly, the driver squeezes the gas, but the engine does not work, but hums loudly;

- vibration in the selector is disturbing, which can occur from time to time or constantly;

- jerking began when moving the gearbox selector.

The main causes of problems are incorrect operation and ignoring the basic principles of variator maintenance.

How to check CVT?

Of course, when buying a used Nissan with a full guarantee, you won’t be able to diagnose the condition of its components, but you need to make every effort to do this. The X-Trail variator needs to be checked in three ways:

- Pay attention to the oil in the box.

- Check in motion.

- Listen to the sound of work.

The oil in a Nissan variator should be light in color, have a normal level and not emit a burnt smell . But even if the clarity of the liquid is acceptable, take a closer look. Make sure that there are no foreign particles, lumps, clots, or streaks in the oil.

Black oil in the variator

You'll be lucky if you manage to check the Nissan in all modes - from minimum to maximum . If the X-Trail accelerates to peak speed without jerking or dips, then the variator is normal. But not every seller will agree to such tests, and they cannot be carried out everywhere. If there are jerks during acceleration, the oil pump valves jam, causing the lubricant pressure in the channels to jump.

Oil pump JF016E

A hearing test will complete the picture. A normally operating Nissan X-Trail variator should not produce any extraneous noise; the maximum that can come from it is a quiet and even sound . If clicking or whining is present, the CVT will soon require repair. A sound similar to the humming of old bearings indicates that the pulleys are worn out.

The absence of signs is reassuring. But it should be remembered that service life depends on driving style and proper use. For careless drivers, the CVT X-Trail can die even after fifty thousand miles.

Design and principle of operation

First, let's look at the device and operating principle of a CVT gearbox. If you don’t know what a CVT transmission looks like and how to distinguish it from an automatic transmission, then the second type of transmission is installed only on SUVs equipped with diesel engines. In addition, CVT gearboxes are equipped with additional knobs for shifting and downshifting. There are no other visual differences.

Nissan X Trail cars of 2007, 2008, 2010, 2011 and other years of production are equipped with two types of CVT transmissions. This could be model RE0F06A or RE0F10A, which developers began installing on newer cars. The second option is characterized by the use of lighter pulleys and the use of a single-piston shaft.

During production, the designers increased the pressure level in the drive pulley circuit to 60 kg/cm. The external machining frequency has also been improved, which helps prevent the adhesion of working lubricant. In Nissan X Trail CVTs 141, 144, 169 l. With. a more expanded range of gear ratios is used, while the developers have completely modernized the hydraulic control system.

In terms of their design as a whole, the X Trail CVT gearboxes in the T31 and T32 bodies of 2012, 2014, 2015 and other years of production can be simplified compared to the design of a bicycle chain drive. A CVT uses a metal belt that runs over the surface of two shafts. To change the gear ratio, the diameter of these elements changes. The primary shaft of the transmission is connected by means of a clutch connected to position D. The input pulley acts on the secondary one, pushing it with the help of a belt, which is structurally composed of many steel segments.

In accordance with the vehicle control mode, the surfaces between the pulleys change under the influence of the control module. Thanks to its proper operation, the belt can rotate on the input shaft more slowly if a reduced speed is simulated, or faster if it is increased. By changing the position of the shaft, the control module can achieve any ratio.

Life time

Now let’s look at the average service life of a new CVT transmission in a car produced in 2021, 2021 with an engine capacity of 2 liters. The official manual states that the CVTs of these cars last on average at least 100 thousand km before the first scheduled repair. Such a resource is possible with proper operation of the gearbox and timely replacement of transmission fluid, which the manufacturer recommends every 6 months.

If maintenance is performed on time, the reliable X Trail CVT will last much longer. It is only necessary to periodically check its performance and at least once a year diagnose the condition of the circuit.

How to warm up the variator

In winter, owners of CVTs are faced with the problem of warming up, but who knows that it is prohibited to use gas in a parking lot to warm up the oil in the CVT. During this operation, the chain wears out as quickly as possible and metal dust ends up in the same bearings. The updated x-trail has automatic heating of ATF fluid. What to do on the old model you ask. The instructions for warming up the variator are quite simple. Move the selector to position D or R and hold the brake pedal without moving for 15 - 30 seconds. In this simple way, the oil in the variator warms up faster. After warming up, drive with minimal load and the variator will surprise you with an increased resource.

CVT x trail in hot weather and under load

If you bought an x-trail with a variator, you should know that this model has its own cooling radiator. You need to check it periodically and keep it clean. There are minimal problems in the city. If you need to climb a long hill or you are simply stuck, there is a possibility of overheating of the variator, as well as the rear-wheel drive clutch.

Common problems and their solutions

Failed variator cone

Before checking and repairing the variator, familiarize yourself with the signs of its breakdown:

- when driving on a flat surface the car slips;

- an indicator for activating the emergency operating mode appeared on the control panel of the car in the cabin;

- the vehicle reduces engine speed, while a hum is heard from the transmission;

- there are problems when changing gears, the lever does not shift at all or shifts but with difficulty;

- the car’s power decreases, the driver presses the gas pedal, but the car’s engine does not gain speed, but only hums louder;

- vibration has appeared in the area of the gearbox selector; it may be present constantly or periodically;

- Jerks appear when the driver switches the gearbox selector to another position.

Improper operation and maintenance leads to problems in the operation of machines and the need for repairs. In their reviews, X Trail owners often share that after changing the transmission oil, the gearbox hums and the car jerks or does not move at all. Let's look at the faults typical for the transmission of Japanese SUVs.

Noise from the depths of the box

This occurs due to wear and destruction of the box bearings. When this happens, the driver hears a hum emitted by the box. This usually happens after a mileage of about 50 thousand km, and can only be eliminated by replacing damaged elements.

The box bearings can become unusable if wear products (metal shavings and other foreign impurities) enter the system. Therefore, it is advisable to change the oil in the box within the prescribed time frame.

Important: it is advisable to replace the belt along with the box bearings for preventive purposes.

Consequences of destruction of box bearings:

The car lost its dynamics and accelerated worse

This indicates old oil in the box that has not been changed for a long time. There is only one remedy - change the fluid in the transmission as soon as possible, completely flushing the system and cleaning the box from wear products (metal dust, shavings).

The box has gone into emergency mode

This can mean a wide range of problems - from transmission oil leaks to physical damage to CVT components. You need to make sure that there is oil in the box, and then try to find a car service specializing in CVTs for a full diagnosis. The box may need to be repaired or even replaced.

Common breakdowns and methods for eliminating them

Here is a list of symptoms that indicate abnormal CVT operation:

- the car begins to slip on a flat road (without dirt or snow);

- on the X-Trail instrument panel, the gearbox emergency mode light came on;

- the car slows down, while noise is heard from the box;

- the speed does not change or is difficult to change;

- the car's power disappears (when you press the gas pedal, the engine hums as if in neutral);

- box vibration (systematic or periodic);

- When changing gears the car starts to jerk and jerk.

Noise

A common CVT failure is bearing failure. If they have already exhausted their service life, the driver will hear noise or hum from the box. This problem does not arise earlier than after a mileage of 50 thousand km. How much is it? Replacing elements at a service station will cost no less than 35 thousand rubles (about 10 thousand hryvnia).

CVT Nissan X-Trail disassembled

There are a number of reasons why bearing noise occurs. This may be wear products entering the variator system. In this case, you should not rely on the two oil filters with a magnet that are equipped with your CVT. Because they will not prevent metal dust from entering the transmission fluid.

Some “craftsmen” advise reducing the frequency of ATF replacement to 30 thousand km in order to avoid destruction and increase the service life of bearings. But, early fluid replacement (after 30 thousand kilometers instead of 50 thousand) does not affect the service life of the bearings.

Power Loss

If a problem arises, then you have never changed the oil in the automatic transmission or have done it for a long time. Then you need an urgent replacement of the fluid with a complete flushing of the system. It is important here to get rid of all wear products in the variator, otherwise the car will continue to lose “traction” on the road from time to time. How much chips and dust are in the gearbox, you can see the fluid draining from it.

Emergency mode

First, check if there is oil in the car. There may be a transmission fluid leak, and its absence in the automatic transmission will lead to complete failure of the unit. Then you will have to shell out a tidy sum to buy a new CVT.

X-Trail under the hood

Riding jerkily

If you notice jerking while driving at a constant speed, this may indicate another problem. In particular, on one kilometer of road the car jerks 1-2 times for no reason. These jerks are felt while driving in cruise control mode. Typically, problems arise with the hydraulic valve, which are best resolved at a service station with specialized equipment. How much repairs will cost depends solely on the type of damage.

Diagnostics of the Nissan X-Trail variator

Diagnosis of the Nissan X-Trail T31 or T32 variator comes down to following the following recommendations. First you need to get behind the wheel and drive off. If the start was smooth, without extraneous noise, everything is in order with the Nissan CVT package. Growling and noises indicate that the package is not working correctly - it is not a fact that it is completely faulty, but there are defects. You will need to check:

- variator oil level;

- smell and color of the liquid.

The motorist or service station employee takes out the dipstick and evaluates the shade of the oil. Ideally, the technical fluid should be light-colored, without dark spots, streaks, or other impurities. The aroma of burning is unacceptable.

Important! Taking into account the condition of the car (heated or cooled), the oil level will change. A hot engine contains more fluid than a cold engine.

Now you need to drip the liquid from the dipstick onto a white blank sheet of paper. Assess the presence of compactions and black spots on the drop. If they exist, we can talk about various types of malfunctions and the need for a more thorough check of the X-Trail variator.

It is imperative to inspect and test the CVT box - no cracks, nicks, or chips. The measuring tool will allow you to accurately assess the unevenness and distortions of the Nissan variator. You need to understand that if there are chips or nicks, cracks may soon appear in the working parts of the mechanism, and the variator box will begin to gradually deteriorate. All this leads to the fact that the Nissan X-Trail T31 variator twitches, the mechanism jams and jams.

The next point that needs to be clarified as part of the diagnosis is the current state of the speedometer. If the unit is not working, the reason may lie in the transition of the belt part to the emergency position. When the car is moving at low speeds, belt deviation will go unnoticed, but for racing this situation is deplorable. The main unpleasant consequences are sudden emergency braking and breaks in the working parts of belt drives.

To understand the causes of vibration of the Nissan X-Trail variator and the occurrence of other problems, you need to:

- Warm up the car while driving.

- Disconnect battery power consumers.

- Insert the keys into the lock and activate the “ON” position. Repeat the “OFF-ON” switch several times, leaving the device in the on position.

- Turn on the ignition, wait for the light bulb to light up, then turn it off.

- Press the brake pedal. Activate the “drive” mode for the selector.

- Turn the ignition back on, release the brake pedal, and move the selector knob to position L.

- Depress the gas and brake pedals, move the selector to “drive”, release a couple of pedals.

At this point, the self-diagnosis of the Nissan X-Trail variator can be considered complete. If the emergency mode is not deactivated, it is worth checking the Step Motor windings at the variator box connector in the area under the battery. Through this connector you can access all electronic internal components.

Maintenance of the Nissan X-Trail variator

Maintenance work for the Nissan X-Trail variator includes:

- Diagnostics – computer testing accurately shows faults and weak points. If the oil has a burning smell or is dark in color, an in-depth check is needed.

- Routine repairs - transmission flushing, radiator replacement, line flushing.

- Oil change. You only need to fill in the original product, since counterfeits have the wrong composition and can negatively affect the operation of the transmission. It is best to change the filter device along with the lubricant. Be sure to monitor the level to avoid overflow. If there is more lubricant than required according to the specifications, the pressure inside the box will increase sharply. The plug will begin to squeeze out, and consumables may leak.

The lubricant level must be carefully monitored; if it is low, the box will fail quickly. Recovery will be impossible.

Service

Briefly about the nuances that need to be taken into account when servicing the X-Trail model with CVT.

Diagnostics

To identify malfunctions in the operation of a CVT transmission, it is advisable to use computer diagnostics using a laptop and special software. The error codes obtained as a result of the test must be deciphered and the breakdown determined.

It is necessary to carry out a more detailed diagnosis of the CVT transmission if the oil in it is too dark or there is a burning smell coming from it. As a result of the repair, the unit will also need to be flushed. If the diagnostics showed the presence of wear products in the gearbox, then the radiator unit will need to be replaced and its lines flushed.

The “Service, Repair, Diagnostics Nissan” channel in its video showed the process of diagnosing and repairing a CVT transmission in the X Trail.

Changing the oil and filter

What nuances should be taken into account when changing the lubricant:

- If you are performing the procedure for changing transmission oil in a garage, then use only the original CVTF+4 product for filling. According to the manufacturer, the use of other lubricants may lead to transmission malfunctions. Experts recommend replacing the filter device when changing the lubricant.

- Be careful when adding liquid so as not to overfill it. If the lubricant level is higher than normal, this will lead to an increase in pressure in the gearbox. As a result, the car owner will be faced with the problem of squeezing out the plug and hole, which will cause leakage of consumables. With such a problem, squeaks may occur in the operation of the transmission, but due to the good sound insulation of the vehicle interior, the driver will not hear them.

- Always monitor the lubricant level in the system. If the gearbox operates without lubricant due to a leak, it will fail within half an hour when running dry. Restoring the unit will not be possible.

The Automatic Transmission Repair Technology channel in its video showed how you can independently restore the functionality of the CVT transmission in a Nissan X Trail.

Nissan Xtrail CVT repair

Nissan X Trail CVT repairs should be carried out by professional technicians. Problems with electronics are indicated by the Service required light, a glowing notification in the Slow Down panel (will appear if the temperature indicators for the use of working fluids are exceeded).

Important! Nissan X-Trail should be tested at the first suspicion of a malfunction. Otherwise, the breakdown will get worse over time.

If the problem is caused by the motor system, strong jerks will bother you during the trip. Other probable causes of their appearance are damaged motor mounts (only replacement will help). The cause of the noise is the failure of the bearings, which will also have to be replaced.

You will have to remove the Nissan X-Trail variator if there are mechanical problems - it will not be possible to understand what the reason is without analysis. In case of failures in the control system, the pan and hydraulic units are dismantled and serviced. It is also advisable to check pulleys and belts and replace them in case of excessive wear. Minor damage to the pulleys can be sanded out. Repressing the bearings should not be done - it is fraught with deformation of the housing and pulleys.

The housing landing valve can be restored. It breaks down due to iron dust, which gets on the working surfaces in large quantities. The best way to solve the problem is to replace the pump. The torque converters are repairable, the differential bearings only need to be replaced. After repairs, it is advisable to flush the box cooling system.

Nissan X-Trail CVT repair

Problems with electronics replacement driver immediately. They are indicated by a lit Service required light and a notification on the Slow down control panel (appears when the temperature standards for the operation of working fluids are exceeded).

Important! Comprehensive high-quality diagnostics of the Nissan X-Trail variator is needed at the slightest suspicion of a malfunction. Driving with an incorrectly functioning gearbox is the cause of failure of the engine and sensors.

When problems are associated with the engine system, pronounced jerking occurs during operation of the variator. Another reason is the destruction of the motor mounts, which will need to be replaced. Noises occur due to failed bearings. It is necessary to check all systems and components (hubs, suspensions, transmissions), repair and replace them if necessary.

Replacing the X-Trail variator

There are situations when you shouldn’t even try to repair the Nissan X-Trail CVT gearbox. Restoring the variator will require considerable expense, but it still won’t last long. This is especially true for complex models, where even a professional cannot give a guarantee.

When choosing between replacing an old unit with a cheap contract CVT and replacing it with a more expensive new device, it is worth choosing the second option. It’s just extremely difficult to find a good used copy in working condition, the probability is no more than 10%. However, today CVTs for the X-Trail can be purchased from independent suppliers who offer such boxes at very reasonable prices. To find them, you can explore the club services of Nissan or the brand you need.

As an example, we can cite the fact that for a complete restoration of the Jatco JF015E CVT gearbox you will have to spend about 150,000 rubles. Whereas a new copy for the X-Trail can be purchased for 200,000 rubles. Therefore, there is simply no point in taking risks by investing that kind of money in repairs.

To overhaul the variator, it will take about 120,000–150,000 rubles. For comparison, restoring a standard hydromechanical automatic requires 1.5 times less. The most expensive parts of a variator are the pulleys and steel belt. Basically, they are to blame for the fact that the price of repairs is so high. At the same time, a good specialist will not hide the fact that after the X-Trail CVT gearbox is restored, it will not last long. The warranty is only given for a year or 20 thousand kilometers.

Buying a contract unit will be much more profitable than completely restoring the X-Trail CVT. Repairing the latter can cost twice as much. However, buying a used unit is always risky. Sometimes the design of the unit is such that no repair will give the desired result. And, of course, the service life of such a device will not be long, unlike a new variator. This is why many service centers simply refuse to deal with used devices.

The elements of the X-Trail planetary gearbox only wear out significantly in rare cases, even if the CVT gearbox has been in use for a long time. Wear of these elements usually occurs as a result of improper operation. Thus, the clutches in the planetary gearbox of the X-Trail variator may stop functioning for one reason - due to severe overheating.

When you decide to turn to specialists, choose a service with a good reputation. A workshop that works with the dealer and parts manufacturers is also an excellent option. There are also services that have their own replacement stock of restored CVT gearboxes with a guarantee. In addition, these sites can help you find new devices at an affordable price. In this case, replacing a failed Nissan X-Trail variator with a restored one will cost 110,000 rubles, and repairs will cost 150,000.

You can also replace the variator in the X-Trail yourself. You just need to perform a series of actions in a certain order.

To replace the variator you will need:

- screwdrivers;

- spanners;

- hammer;

- heads with a knob;

- plastic clamps.

If there is an inspection hole, you can start working:

- First of all, the front part of the X-Trail should be raised with a jack, while simultaneously disconnecting the wheel drive and mountings. The transmission needs to be removed.

- After unscrewing the plug, you need to drain the used oil.

- Using a screwdriver, you need to unscrew the bolts and remove the transfer mechanism cover.

- Next you need to remove the roller bearing and gear.

- Remove the shaft along with part of the housing.

- To get to the internal components of the gearbox, you need to unscrew and remove the side cover.

- Then you need to remove the two gears and, carefully unscrewing the bolts, pull out the gear and the oil pump cover. In this case, the entire process needs to be recorded, or better yet, photographed so as not to forget how the parts and assemblies are located.

- The next step is to remove the oil pump shaft. If necessary, you can immediately replace it with a new one.

- Having shifted the gearbox to the other side, unscrew the fastenings of the other cover.

- You need to remove the casing by prying it off with a screwdriver. As a result, the main components of this transmission will be visible. These are two pulleys and a steel belt.

Nissan CVTs: are they reliable?

CVTs have a number of undeniable advantages over other types of transmissions. They utilize the engine's traction capabilities more effectively, providing fuel efficiency and lower levels of harmful emissions. But the average car enthusiast is much more concerned about other indicators - reliability and service life. Let's talk about them using the example of the most popular variators from Jatco.

CVTs have a number of undeniable advantages over other types of transmissions. They utilize the engine's traction capabilities more effectively, providing fuel efficiency and lower levels of harmful emissions. But the average car enthusiast is much more concerned about other indicators - reliability and service life. Let's talk about them using the example of the most popular variators from Jatco.

Jatco is one of the world leaders in the production of automatic transmissions and CVTs. Its continuously variable units are installed on cars of many manufacturers, although Jatco is the brainchild of the Nissan concern and is 75% owned by it.

There are many cars in Russia with Jatco CVTs - and the mileage is already high. It's time to delve into their track record and trace their evolution with an emphasis on resource, reliability and weaknesses.

Let's focus on the families of CVTs of the last two generations, officially presented on our market. They are the ones that work on popular cars of the penultimate and current generations.

Automotive news from around the world

The “Spikes” sign: a necessity or another traffic police scam?

Duster 2021: new body, photos and other details

BMW M5 2021: official details about restyling

Our analysis is based on statistics from official and independent technical centers, which helped assess the feasibility and cost of repairing CVTs of specific models, as well as the availability of spare parts.

A new valve body for the third generation CVT family (CVT8) costs about 55,000 rubles. Along with it comes a disk with individual calibrations for each solenoid, which must be registered in the unit control unit.

Models JF010E and JF011E belong to the so-called tenth family. This is a typical representative of the second generation of Jatco CVTs. The younger model JF011E is paired with naturally aspirated petrol engines 2.0 and 2.5, and the older model JF010E is paired with 3.5 engines. Structurally, they are identical, the only difference is the reinforcement of various elements for higher torque. The JF011E variator was installed on Nissan Qashqai and X‑Trail, as well as the Mitsubishi Outlander of the last two generations. The JF010E unit was used, for example, in the Nissan Murano (Z50 and Z51), as well as the Teana sedan (J31 and J32).

The tenth family does not have characteristic sores. The average resource of these CVTs is 150,000–200,000 km. Towards the end of their life, there is a general critical wear of the elements - cones and belt, cone bearings and their seats in the housing, valves in the valve body and oil pump.

The new valve body for Jatco CVTs of the second generation is noticeably more expensive than for the third. For example, for JF010E it will cost 70,000 rubles. This is eloquent confirmation of the excessive simplification of the design of a critical component and the reduction in the cost of its production.

Contrary to popular belief, the oil pump pressure relief valve is not a weak point. At least it serves no less than other parts of the variator. Wear of the valve seat in the pump body is caused by metal dust getting onto the contact surfaces. As a result, it begins to jam, and the pressure in the hydraulic system goes beyond normal limits. However, this is already a consequence of mechanical wear of other elements of the variator. Metal dust, even before attacking the oil pump, manages to damage the valve body and its solenoids. This causes excessive pressure dispersion in the hydraulic system, which leads to increased wear of the belt/cones pair. But this does not manifest itself clearly until the pressure relief valve gets tired. Therefore, proactive treatment of the oil pump alone when the first symptoms of CVT malaise appear is only a slight delay in major repairs.

CVTs of the tenth series are repairable. Complete restoration costs approximately 150,000–180,000 rubles. Officially, Nissan supplies either a new valve body or an assembled variator for spare parts. However, some original spare parts can be obtained separately on the market, and other elements can be successfully repaired. You can also order a new variator on the market through suppliers at a reasonable price - for 200,000–230,000 rubles. Moreover, this applies to models from other families, even the newest ones. Such offers can be found, for example, through club services.

“Attachments” to the valve body from the JF010E variator: wiring harness, solenoids, sensors and a stepper motor. All this, if necessary, can be used as high-quality second-hand elements that do not require registration in the unit control unit.

During repairs, the belt is replaced with a new one, and worn cones, depending on the degree of damage, are ground or replaced with used ones in good condition. Processing cones is a very responsible matter. Using the example of CVTs from other manufacturers, we can safely say that such repairs often do not last long. However, in relation to Jatco CVTs it is more justified. Competent servicemen entrust grinding to specialized enterprises (factories).

But repairing hydraulic units, as in the case of other CVTs, is impractical. Unless you replace a couple of faulty solenoids with working used ones or new ones.

Original cone bearings are available as spare parts. And their worn-out seating surfaces in the variator semi-housings are reanimated by installing cast iron sleeves. This work is also entrusted to factories.

Models JF010E and JF011E are considered quite reliable compared to similar CVTs from other manufacturers. However, if you compare them with their first generation predecessors (RE0F06A series), which had an excellent reputation, the picture becomes less rosy. It turns out that second-generation CVTs have reduced their service life by almost half! This is reflected in the general tendency of the modern automobile industry to simplify (in a bad sense) successful designs and reduce the cost of production. For example, from the nature of wear of various elements it is clearly visible that lower quality metal was used in second-generation variators

The latest model JF015E belongs to the CVT7 family. Jatco does not classify it as a specific generation.

Automotive news from around the world

Volkswagen Touareg 2021: all the details about restyling, equipment and characteristics

Toyota Land Cruiser Prado 2021: new body, configurations and prices, photos

Ford Focus 2021 in a new body: first render and characteristics

JF015E is a separate development designed exclusively for small-volume naturally aspirated gasoline engines. This variator is installed mainly on Renault-Nissan cars with 1.6 engines, for example on Nissan Juke and Qashqai, Renault Kaptur and Fluence.

Cones from model JF010E with minor wear are brought back to life by grinding. This procedure requires expensive equipment and highly qualified technicians, otherwise the repaired part will not last long.

Oil pump from variator JF017E, manufacturer - KYB (Kayaba). Almost the same is installed on the younger model JF016E and even on units of the previous generation (JF010E and JF011E). It is noteworthy that the pressure reducing valve in the pump is the same for all.

The main design feature of the JF015E is the presence of a two-stage planetary gear. At speeds up to 100 km/h the first stage is activated, above - the second. This design made it possible to significantly reduce the size of the cones and, accordingly, the overall dimensions of the variator. This idea was good on paper, but in reality it turned out to be a design that kills itself.

Due to the ill-conceived nature of many decisions and savings in production, CVT parts subject to natural wear and tear die several times faster. In addition, even the elements of the planetary gear suffer, which is generally not typical for continuously variable units.

A repair pressure reducing valve of a larger diameter for an oil pump costs about 2,000 rubles. The photo shows a copy produced by Sonnax (USA). For such repairs of the oil pump they will charge approximately 5,000 rubles.

Bearings for Jatco are supplied by NSK. These products are freely available on the aftermarket. A set of three main cone bearings costs 13,000–14,000 rubles.

Automotive news from around the world

Import of used foreign cars 2021: changes

Jatco JF011E/015 variator will be installed on Lada

Owners will be forced to get rid of old cars from 2019

The characteristic wear of the lateral contact surface of the belt plates is clearly visible to the naked eye. This consumable for Jatco CVTs is made by Bosch. Depending on the model of the unit, the belt costs from 20,000 to 30,000 rubles.

Due to the low quality of the metal, the cone bearings and their seats in the variator housing quickly wear out. Metal shavings spread throughout the hydraulic system, clogging the valve body solenoids and the oil pump pressure relief valve. The oil pressure goes beyond the permissible limits, and the variator quickly gives up.

The internal elements in the cones that ensure their movement also wear out actively. Because of this, even more chips enter the hydraulic system.

On average, the JF015E rarely lasts more than 100,000 km, and the first bells are heard already at 20,000–30,000 km. Repair is most often impractical. Even independent service stations rarely undertake it. The only reasonable option is to buy a new CVT.

Automakers often underestimate the importance of the CVT cooling system. Some cars (for example, the current Murano) do not have a full-fledged radiator, and on others it is located in the wrong place - in front of the front left fender liner. There it actively becomes clogged with dirt and rots. Moreover, this applies to both fresh and older models. The refusal to install a radiator on the “pre-reform” Outlanders of the current generation led to the fact that the JF011E variator began to overheat often. As a result, the manufacturer admitted the mistake and returned the heat exchanger.

Sufficient cooling system performance is extremely important for the health of the CVT. Fortunately, there are various sets of radiators on the market at reasonable prices. Some kits are designed for installation in a standard place - in front of the fender liner, while others - for example, in front of a pair of engine and air conditioner heat exchangers. Depending on the car model, turnkey installation of a radiator costs from 9,000 to 13,000 rubles.

The tenth family was replaced by the CVT8 series. These are third generation CVTs. On our market it is represented by models JF016E and JF017E. Despite a complete generation change, the new CVTs are built on the basis of their ancestors.

The JF016E variator replaced the “old man” JF011E and inherited its engine range. Among its carriers, for example, are the new generation Nissan Qashqai and X‑Trail. The JF017E and JF010E series swapped places in the same way - the new CVT was installed under the hood of the fresh Nissan Pathfinder and Murano , as well as the Infiniti QX60 / JX35.

The third generation units differ from each other more than their predecessors. Strengthening the elements of the JF017E variator to handle higher torque required the use of a pin belt (the so-called chain), while the JF016E retained the usual plate belt.

The heart of the JF017E variator: cones and a pin belt (the so-called chain). There are some minor nicks on the cones, so they will be sent for grinding. Pin belts for Jatco are made by LUK; they cost about 20,000 rubles.

The design basis of the CVT8 family is twofold. At one pole is the hardware from the tenth series that has been simplified in order to reduce the cost of production, and at the other is the excessive complication of the control system. Both of these led to a noticeable, one and a half to two times, reduction in the service life of the units. However, CVT8 CVTs remain maintainable. The cost of their full restoration is even lower than that of representatives of the tenth family, and usually does not exceed 150,000 rubles.

The valve body is the most demanding unit of the CVT8. The manufacturer saved as much as possible on the “iron” base and removed the stepper electric motor, which on CVTs of the tenth family controlled the oil pressure to change the gear ratio in the cones. The design of the valve body was changed, using additional solenoids of a new type. Moreover, here too the manufacturer was greedy, choosing solenoids that were cheaper to manufacture and had different output parameters. Therefore, with a new variator or valve body there is a disk with individual calibrations for each valve. If you do not register them in the unit control unit, the variator will not work correctly or the car will not move at all.

Automotive news from around the world

Windshield repair kit

FuelFree fuel saver

Smart receiver for car PIONEER SPH-10BT

It is natural that such a sophisticated hydraulic unit does not always work properly for a long time. The oil pressure in various modes goes beyond the permissible limits, and a chain reaction starts. Due to belt slippage, metal dust spreads throughout the hydraulic system and kills the variator.

Repairing a faulty valve body is impossible. It will also not be possible to use used/new solenoids or the assembly, because the appropriate calibrations cannot be found. During disassembly, you need to buy a valve body together with a variator control unit, and they must be from the same car.

Otherwise, the repair features for the CVT8 and the tenth family are the same. For example, models JF016E and JF017E use almost the same oil pump, so it is possible to replace a worn pressure relief valve.

The policy of routine maintenance has long been an ambiguous situation. Jatco requires mandatory periodic oil changes in its CVTs, and automakers often claim that the fluid is designed to last the entire service life of the units. On this issue, representatives of dealerships and independent technical centers are unanimous: the oil needs to be updated. Jatco recommends doing this every 60,000 km under normal operating conditions, and even shortening this interval under severe operating conditions. This approach is guaranteed to extend the resource.

Jatco CVTs use two oil filters. When changing the oil, just rinse the coarse filter located in the pan. Depending on the variator model, a disposable fine paper filter is located in a mounted heat exchanger or in a separate housing at the end of the unit. Service technicians advise using only original oil. All Jatco CVTs are very sensitive to the inevitable mixing of fluids with different additive packages.

When the variator begins to mope (jerks, kicks appear, acceleration dynamics drop), it is useless to change the oil in it in the hope of correcting the situation. Typically, such symptoms indicate significant mechanical wear of the elements and the need for repair. At the same time, all sorts of emergency modes of operation of the variators are activated when things are already really bad (for example, the belt has started slipping). It is important not to delay your visit to the service. Timely treatment sometimes significantly reduces the final cost of repairs, since some elements can be saved.

The evolution of Jatco CVTs confirms a general sad pattern: each new generation becomes less reliable. The only consolation is that most of the CVTs from this company are repairable and new units are still available at reasonable prices.

Other articles to read:

- Jatco JF011E/015 variator will be installed on Lada

- Why does the automatic machine “jerk” when switching?

- Lada cars will be equipped with new Japanese gearboxes