Many car owners, when a squeak or squeak appears when they press the brake, ask themselves what caused this sound? Having started to figure out where it came from, it turns out that it was just the brake pads squeaking. Arriving at a car service center, you can hear an unequivocal verdict - “The brake trims are of poor quality, they need to be replaced.” But what to do if the strips were purchased from a dealer, and the sets of pads purchased there did not raise any complaints before?

Experts say that brakes squeak or whistle due to poor quality pads only in a third of cases. A reasonable question arises - what else could be the cause of their grinding? Let's look at all the reasons for this phenomenon.

First, let's look at what factors affect the front or rear (disc) brakes when squeaking occurs.

Why and when we encounter grinding

Sticking of the friction lining to the disc for a split second and its subsequent breakdown generates vibrations. The human ear perceives them as a whistle, hence the complaint that the brakes squeak when braking on a car, the class of which, by the way, can be absolutely any.

If we compare the degree of harm from squeaking and the consequences of a tight clutch, then the second is more dangerous to health. But squealing is hard to come to terms with morally. Every now and then it gives me a headache.

In 80% of cases, the symptom occurs after changing the pads. It happens that even the “originals” whistle. Those who have not looked beyond the rim for a long time or have entrusted this matter to inexperienced service workers are also faced with this fact. In humid weather, grinding noise is also possible.

Other causes of squeaking

Sometimes small gravel gets between the disc and the casing while driving. It can also contribute to the squealing noise produced by the brake components.

Drum brakes also sometimes whistle and squeak. Many Russian cars and foreign cars have rear drum brakes. When a whistling sound appears in this type of brake design, the reasons are the same as in the disc design. But there are also differences due to the characteristics of the device.

If the disk system linings are too dusty, the dust is removed outward and does not remain on the surface of the linings. And in the case of a drum structure, dust settles inside on the parts and drum. Clean the elements from dust and the brake whine will stop.

If your car's brakes squeak and whistle, remember our tips and eliminate the causes. To do this, just remove the wheels, drums and look at the brake elements.

Brake squealing when braking can have a different nature, but in any case it is a cause for concern. Squealing brakes is a fairly common problem among motorists, which requires special attention. By following our advice, you can do without the services of a service station and find problems yourself. Let's try to understand the reasons for such difficulties and how to eliminate them.

Why even new pads squeak when braking smoothly?

The whole difficulty is that the reason can only be found by brute force. If a defect appears immediately after replacing the friction linings, you have to think only about the fact that they have not gotten used, about problems with their quality, or about the absence of anti-squeak plates on the back of the part. If no one serviced the brake system the day before, inspect all components:

- Pads. Some models are equipped with “squeaks” - special metal brackets attached to the side of the product. When the friction part wears critically, the metal comes into contact with the disc, and we get a squeaking sound.

- Brake discs. They wear out and often unevenly. Allowable end runout is no more than 0.020 mm.

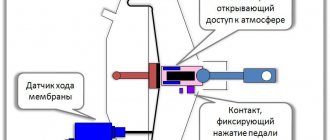

- Caliper. Wedging of the working cylinders and the entire structure on the guides is not allowed. Torn anthers must be replaced, fingers must be lubricated with a special compound that is resistant to high temperatures.

There is no need to carry out an inspection if the disk has been exposed to water, sand or has become corroded.

You can do nothing, as in the case of the alternator belt whistling in the cold after driving through a puddle, or perform a series of long, smooth braking. This will help dry the part or remove dirt from it. For example, repeat the cycle three times: acceleration to 80 km/h and smooth deceleration to 20 km/h. If the pads squeak when braking after a recent wash, get ready to find a turner or go to the store. Cold water falling on a hot disk leads to improper hardening. As a result, it wears unevenly and runs out.

For your information. Ceramic parts tend to squeak when cold. They have a slightly higher setting temperature than conventional brakes, so the whistle goes away after a few brake applications.

Types of pads and classification

Brake pads are plates with a friction lining. The shape of the lining follows the place of contact with the disc - straight, or the drum - arcuate. The linings are fixed to the body of the pad using glue or metal rivets; The fixation method does not in any way affect the effectiveness of the brakes. Recently, manufacturers have begun to place wear sensors on brake pads.

Despite the fact that manufacturers try to make the alloy composition as unique as possible, most automobile pads contain ceramics, synthetic rubber, organics and mineral bases and modifiers in their structure. The large list of materials used is based on the fact that the pads are subject to significant heating and must not be damaged or lose frictional characteristics in extreme conditions.

In some cases, brake pads heat up to 1000–3000 degrees Celsius.

The first signs that it is time to change the brake pads can be determined by the quality of braking, squeaks and unnatural vibration. The pads are more susceptible to destruction under the influence of water, antifreeze and brake fluid. Brake pads must be replaced in pairs; distinguish front and rear brake pads. Typically, it is the front ones that are subject to greater loads and wear out 3-4 times faster than the rear ones.

Motorists distinguish several types of pads, regarding the material of manufacture:

- Metal. According to reviews, they perfectly withstand high temperature loads. However, they are quite noisy and are most often used on racing cars. Contains steel or copper compounds.

- Organic. The chemical composition includes Kevlar, rubber impurities, glass fibers and organic carbon compounds. Most often used for quiet driving, since such pads are very vulnerable to temperature loads. Among the advantages, car enthusiasts cite low noise levels and a gentle effect on the elements of the braking system.

- Semi-metallic. The structure contains about 70% metal and 30% inorganic compounds. Manufacturers most often use a friction modifier as an additional additive. According to their characteristics, they have a fairly high heat transfer, however, they wear out very quickly.

- Ceramic. They are considered among motorists to be the most efficient, but also the most expensive. They consist mainly of ceramic fibers and non-ferrous metals. Among the advantages: the most gentle effect on discs, low heating and excellent wear resistance.

To choose the best option for yourself, you should not chase price, but quality and compliance with your needs. Purchasing ceramic or metal pads for a fabulous sum will not bring any benefit if the driver prefers a calm driving style.

Naturally, like any other parts, pads can be divided according to the quality of the manufacturer. There are three groups: the highest category, aftermarket and third category. The first usually includes original components. The second class includes manufacturers who allow themselves to deviate by approximately 10% from standard documentation and manufacturing technology. The third category is small manufacturers, little-known companies, products of low quality and low prices.

You can determine the quality and manufacturer by carefully looking at the product labeling. The country where the pads were certified is usually coded before the conformity indicator.

Organic brake pads

The friction layer of such parts includes various materials of organic origin. It can be rubber mixed with glass, fiberglass, carbon compounds, etc. Such elements have a minimum content of metal components (no more than 20 percent).

Pads with organic linings will cope perfectly with moderate driving of a passenger car. At low speeds, a slight pressure on the brake pedal is enough to activate them.

The advantages of these modifications include softness and quietness during braking. This property is ensured by the minimal presence of abrasives. The disadvantages of such pads are their significantly shorter working life compared to other analogues. The friction layer in them is soft, and therefore wears out much faster.

Another disadvantage of organic pads is that they do not tolerate high heat. For this reason, they are installed on budget vehicles, which are not particularly powerful. Most often, such elements will be installed on small cars.

Semi-metallic brake pads

This category of pads will have a higher quality friction layer. They are used in most cars in the budget and mid-price segment. The lining of such a block will consist of metal (up to 70 percent depending on the manufacturing technology). The material is bonded with a composite substance, which gives proper strength to the product.

Useful: Which alarm system with auto start is better?

This modification is widely used in mechanical means. These pads will be equipped in a passenger car, crossover, small truck, van, SUV or car participating in amateur sports competitions.

The advantages of semi-metallic linings include an increased working life (compared to an organic analogue). This layer also has a high coefficient of friction, withstands intense heat and cools quickly.

The disadvantages of such products include the formation of more dust (more information on how to remove graphite deposits from transport disks is described here). Compared to their organic counterparts, semi-metallic pads produce more noise during braking. This is due to the fact that it will contain a large number of metal particles. To operate effectively, the pads must reach operating temperature.

Ceramic brake pads

The price of such pads will be higher than all those listed earlier. This is due to the fact that their quality is much higher. Ceramic fiber is used as a friction layer in these elements.

The advantages of ceramic pads are excellent responsiveness of the brake pedal. They have a wide range of operating temperatures, although their efficiency in cold temperatures is low. They do not contain metal particles, so these brakes do not make much noise during operation. Ideal for sports cars.

Despite the obvious advantages over the linings mentioned above, the ceramic analogue is not intended for installation on slow transport. They are especially not recommended for use in trucks and SUVs.

So that the motorist can independently determine what material is used to make the pads, manufacturers apply special markings. Markings can be colored or lettered.

The color classification indicates the maximum permissible temperature. This parameter is as follows:

- Black color - used in regular budget cars, as well as models in the mid-price segment. Ideal for daily travel. The product will be effective if it heats no more than 400 degrees.

- Green friction layer - overheating is allowed to a maximum of 650 degrees.

- Red trims are already products for entry-level sports cars. The maximum permissible overheating is 750 Celsius.

- Yellow block - used on professional racing vehicles that participate in events such as circuit racing or track racing. Such brakes are able to maintain their effectiveness up to temperatures of 900°C. This temperature range may be indicated by blue or light blue.

- The orange pad is used only in highly specialized racing vehicles, the brakes of which can heat up to one thousand degrees.

On each pad, in addition to information about the manufacturer and certification, the company can indicate the friction coefficient. This will be a letter sign. Since this parameter changes depending on the heating of the lining, the manufacturer can apply two letters. One indicates the coefficient of friction (CT) at a temperature around 95°C, and the second - about 315°C. This marking will be located next to the catalog number.

Here are the parameters each character corresponds to:

- C – CT up to 0.15;

- D – CT from 0.15 to 0.25;

- E – CT from 0.25 to 0.35;

- F – CT from 0.35 to 0.45;

- G – CT from 0.45 to 0.55

- N – CT from 0.55 or more.

Having basic knowledge about this marking, it will be easier for the driver to choose the right quality pads suitable for specific operating conditions.

What to do to make new brakes stop squeaking when braking the car at low speed

Actually, if nothing was done before the grinding noise appeared, then this is a call to at least inspect the area around the calipers. Where to look has already been discussed; these cases do not require additional comments. An interesting list of actions in relation to fresh pads, which after installation began to squeak. Replacement immediately is not an option, this is a last resort method.

Lapping in

Give the friction linings time to grind in. After several hundred kilometers of city travel, their working surface will be in full contact with the disk, and this is a reason to stop the whistling, but not the only one.

In relation to pads, the term “molting” is relevant. The fact is that the product includes organic products of the oil refining industry - resins. Overheating, the latter turn into gas, and a gas gasket appears between the friction part and the disk. The effect is similar to hydroplaning of car wheels.

High-quality products undergo “molting” once or twice and only when heated. “When cold,” they do not creak, unlike low-grade models. By the way, the latter's burn-in knows no limits - they will squeak all the time.

Sports pads have their own specifics. If you do not burn through, the brakes on the car will constantly whistle even when braking at low speed. Baking consists of several series of accelerations and decelerations with breaks. The main goal is to overheat the pads to the point where there is smoke in the area of the wheels:

- Stops smoothly from 60 km/h to 0 km/h. Repeat 5 times.

- Drive 1 km without braking.

- Slow down from 80 km/h to 0 km/h. Do it 5 times.

- Drive 2 km without stopping.

- Perform steps 1-4 again.

- Cool the brakes during 5-10 km of non-stop driving.

Unusual cases of grinding noise on the front and rear wheels

The route map is designed for standard circumstances, when squeaking appeared on old pads during soft braking or immediately after replacement. What to do if everything was fine in the summer, but with the advent of cold weather a squeal appeared? Or what to do if a squeaking noise appears even when the brake pedal is released? Look for answers in a special selection:

- The brakes began to squeak in the cold. During a thaw, moisture may settle on the discs. If the process is regular, lubricate the back side of the pads.

- Whistle even when the brake is not pressed. Overhaul the brake calipers. Make sure that they move freely along the guides and that the working cylinders do not jam.

Note: constructive measures aimed at preventing whistling

A microscope is not needed to examine engineering tricks. They are of a purely technical nature. We have already talked about one of them - anti-squeak linings on the back of the products. Find out about other means of combating vibration below:

- Bevels and slots on the friction layer move resonant vibrations to higher frequencies.

- The slots perform a role similar to bevels + remove dirt from the contact patch.

- Anti-vibration plates dampen vibrations relative to the piston and caliper bracket.

- Specially curved elements on the back of the pad fit tightly into the working cylinder, which helps to avoid noise in many braking modes.

- Wire brackets dampen vibrations of the friction part along the guide.

- Damping bushings are installed on one of the caliper guide fingers to absorb vibrations.

Eliminating squeaking brake pads.

Can't cope with the terrible whistle or squeaking of brake pads? Or maybe you are annoyed by the terrible sound when braking and you don’t know what to do about it? Have you just, very recently, changed your brake pads, but as a result of this, an unpleasant squeak or whistle appeared when braking? Don’t be upset, friends, in fact, you can fix everything yourself.

Before moving directly to the description of a method that will help you get rid of squeaking brakes, we would like to note the following that not a single auto mechanic will help you make a completely silent brake system. In either case, when you press the brake pedal hard, you will hear a certain squealing sound from the brake pads or brake drums. However, in most cases, it is still possible to get rid of an unpleasant squeak or whistle in this mechanism. You can read more.

Poor quality pads

If you hear a whistle when braking, and the pads have recently been replaced with new ones, then their quality is not up to standard. When rubbing with a disk, they crumble and become covered with dust. In this case, it can be argued that the material of the pads does not combine well with the material of the brake discs.

Pads are made from different friction materials. The layer involved in friction includes metal shavings: brass, copper and steel. These elements cause this nasty squeaking noise during braking.

It usually disappears if you replace the pads with quality products. It cannot be stated unequivocally that the sound in the form of a whistle is the cause of defective friction linings. They simply do not match the composition of discs or drums.

What causes your brakes to squeal?

Modern brakes consist of metal brake discs that are sandwiched between two pads coated with a friction material. When the discs, caliper and brake pads are or are in perfect condition, the entire system works properly and when you press the brake hard, you will not hear any unpleasant squealing sound. Yes, we do not argue that when braking sharply, any driver hears the squealing of the brake system, but it will remind them more of the sound of a correctly tuned violin than the same playing of a Scottish bagpipe by a non-professional.

Just as for the normal sound of all musical instruments, a tuner is needed, so for the normal adjustment of the brake system, you need a specific professional auto mechanic who, in the event of a brake malfunction, will be able to adjust the brake system of your car to optimal operation.

How to reduce squealing brake pads?

One of the most effective ways to get rid of squeaking or whistling when braking is to change the pads to others that use a different friction material. True, as many people know, it will be problematic and difficult to purchase non-original pads that will match and therefore work better than the original pads, but, nevertheless, this is possible today.

Please remember that the more expensive the pads, the more expensive their friction coating, on which their successful operation depends, that is, whether an extraneous sound will appear during braking or not.

Also, you can reduce the squeaking or whistling of brakes when braking in another way, namely, by lubricating the pads with a special compound(s). Dear friends, we do not recommend that you use for this purpose various oil compounds and WD-40 with them, which are used to reduce the friction of the friction coating of the pads with the brake disc, since all this can affect the effectiveness of the braking itself, which will certainly reduce your own safety.

In addition, before installing non-original pads, you can first remove all the metal burrs that are on the pads using sandpaper, and then paint all the ends with fire-resistant paint. This way you can achieve a reduction in excess gaps between the friction coating and the surface of the brake disc.

In particular, before directly installing the pads into the caliper, lubricate the guides themselves with graphite lubricant.

If, after preparing the pads and lubricating the guides in the caliper, the squeaking of the pads has not disappeared and still continues to torment you on the road, then please check the brake discs for wear, thereby measuring the thickness of the brake discs and the uniformity of their wear.

If the brake discs are in perfect condition and the brake pads are prepared in accordance with our recommendations, and the whistle still appears when braking, then it would be better to replace these pads with other new ones, namely, buy original pads for the car directly from the dealer.

Remember, dear motorist friends, that by purchasing any spare parts for a car other than from a dealer, you risk purchasing counterfeit products that will not last as long as real original spare parts.

Normal brake noises

Many brake pads squeal or squeak during the first few braking sessions after the car has been parked overnight. As a rule, the squeak goes away after the brake pads heat up and do not drive away the moisture that has accumulated overnight.

Have you probably encountered grinding brake pads in rainy and damp weather in the morning? This is normal because a thin layer of rust has formed on the brake discs overnight due to moisture.

Previously, asbestos was used as a friction material on pads. Unfortunately, as a result of the study, doctors proved that asbestos can cause lung cancer and therefore decided to abandon the use of this material to cover brake pads.

Currently, alternative materials that are less hazardous to human health are used as friction materials. Thus, in recent years, the use of a combination of metal and ceramics as a coating has become increasingly popular. This is due to the fact that in recent years the automotive industry has been developing towards reducing the weight of all vehicle components. Therefore, reducing the weight of the braking system is an important task for all automobile companies.

But due to the use of new friction coatings, an unpleasant creaking (squealing) sound, etc. may appear when the car is braking. This is a small price to pay for increasing the power of modern cars by making all parts of the vehicle lighter.

Also, do not confuse the squeaking of brake pads when they have reached 80 percent wear. Let us remind you that most brake pads begin to squeak when the friction layer is almost worn out. This is done so that the owner of the car knows without diagnostics when it is time to change the pads to new ones.

Why do brake pads whistle? (2 photos)

Why brake pads whistle: wear and grinding in

Let's consider the main factors and reasons that can influence the appearance of squeaking when braking.

- Poor quality friction layer. If the car has new pads, but you can hear a squeaking sound, this may indicate their low-quality friction layer: they gather dust, crumble and simply do not fit the brake discs. An unpleasant sound when slowing down may appear due to particles of copper, brass or steel shavings that are used in the production of elements. The whistling and grinding noise disappears after replacing the pads.

- Lapping. If the squeaking occurs from the first days, as soon as new brake bars were installed, then it may take time to break in. The culprit for the sound may be impurities that get onto the pads during production.

- Wear of planks. When the friction layer is completely worn out, friction between the brake disc and the metal base of the pad begins. This also occurs due to improper fastening of the mechanical strip wear sensor.

Causes of squealing brake pads: defects and weather

There is another group of reasons that influence the occurrence of pad whistling during braking.

Drum brakes

In this topic, it is worth highlighting in a separate paragraph the question of why drum-type brake pads squeak.

In many domestic and foreign-made cars, rear brakes are still installed of the drum type. When creaking bars occur in such brakes, the main reasons coincide with the factors causing similar sounds in disc brake systems. But there are also differences caused by design features.

When the strips become dusty after replacing disc brakes, the bulk of the dust from the friction material falls out and does not clog the surface of the pads. And if the friction linings in drum brakes become dusty, then all the dust settles inside the mechanism on the inside of the drum and the surface of the pads.

This is what causes the squeaking noise when the car slows down. In this case, in order to remove the creaking sound, you should periodically clean the surface of the planks from plaque with sandpaper.

BEHIND THE STEEL

You have to use the brakes in the city cycle more than once or twice a day - if you hear unpleasant piercing sounds, driving turns into torture. How to make the pads silent?

It is customary to pay primary attention to the operation of vehicle systems responsible for traffic safety. That is why, when a whistle or a squeak is heard when braking, the driver certainly tries to find out the reason for its appearance. In the end, this sound is just annoying.

However, solving this problem is not so easy.

Simply incompatible

The pads are not always to blame for the appearance of extraneous sounds, because they work “in close contact” with the discs. The sound quality depends on the compatibility of the friction lining and disc materials. The same pads can completely suit one car owner and greatly irritate another with their squeaks. Ideally, the components of the friction pairs should be manufactured by the same manufacturer: this minimizes the risk of “incompatibility”. But there is still no guarantee that the brakes will work quietly.

Wear - critical

Those who are used to calling in for service only when the car breaks down have probably encountered this situation: the pad lining is completely worn out, braking occurs with a metal plate (base) on the disc. More often than not, this is caused by ignoring timely diagnostics and maintenance. But don’t rush to just install new pads - perhaps one of the pistons is jammed, as a result of which

and increased wear occurs. It is easy to determine the malfunction: other pads in such cases are in a much more efficient condition.

Of course, sounds when braking have nothing to do with its effectiveness. However, we can say that squeaking does indirectly affect safety: it provokes the driver to use the brakes less often and makes him nervous every time he presses the pedal. So, if getting rid of loud brakes does not require a lot of money and time, it is better to deal with them as quickly as possible.

Reason No. 1: incorrect installation of pads at a service station

The loud whistle of new or almost new pads in many cases is a consequence of the manual work of the craftsmen. The replacement procedure is very simple, but even in it they manage to make mistakes.

Firstly, the back side of the pads must be lubricated with a special anti-squeak paste. As a last resort - copper. The paste prevents squeaking from developing, thickens over time, and dampens resonant vibrations, so that even if the discs are damaged, the sound becomes quieter. It must be applied in a thin layer so that it does not get on the piston (it is lubricated with a separate lubricant). Most services neglect this procedure and simply skimp on lubricants.

Secondly, some types of cars (for example, old Mercedes, Audi) have a barely noticeable bevel on the piston. It was specially made to get rid of squeaking and to remove dust from the disk. Naturally, 99% of mechanics don’t look at the manual for a specific car, thinking that everyone’s pads change the same way, and don’t even know about the orientation of the piston.

Thirdly, the pads are simply placed in one place. They forget to install a plate or spacer, they install larger pads, which, when worn, form a lot of abrasive, leading to squeaking. If the wheel gets very hot, that means it is so.

Some unfortunate craftsmen also tear off the protective anti-squeak layer from the back of the block, mistaking it for a protective film.

There is only one verdict here - change it from a specialized specialist, or independently according to the instructions (there is nothing complicated here).