Niva VAZ 21213 car engine: characteristics, malfunctions and tuning

The light SUV VAZ 2121 Niva is one of the most popular modifications of the Volzhsky Automobile Plant. The most popular of the engines on Niva were modifications 21213 and 21214. The difference between these power units is the presence of an injection system and a modified combustion chamber. The Niva gasoline engine has proven itself to be a fairly reliable power unit, which, with proper maintenance, can run about 300 thousand kilometers without major repairs.

Specifications

Motor specifications:

| PARAMETER | MEANING |

| Years of manufacture | 1194 – present |

| Weight, | 117 kg |

| Cylinder block material | cast iron |

| Supply system | injector |

| Type | in-line |

| Engine displacement | 1.7 |

| Power | 81 horsepower at 5200 rpm |

| Number of cylinders | 4 |

| Number of valves | 2 |

| Piston stroke | 80 |

| Cylinder diameter | 82 |

| Compression ratio | 9.4 |

| Torque, Nm/rpm | 125Nm / 3000 |

| Environmental standards | EURO 4 |

| Fuel | AI 93 |

| Fuel consumption | 8.3 /100 km combined cycle |

| Oil | 5W-30 |

| Oil volume | 3.75 |

| When replacing, pour | 3.5 liters |

| The oil change is carried out | 15 thousand km |

| Engine life - according to factory data | 200+ |

Peculiarities

The VAZ 21213 four-cylinder eight-valve petrol engine has a displacement of 1.7 liters.

The power of the power unit is 81 horsepower with a torque of 125 Nm. Engines 21213 in their latest generation were equipped with an injector and ran on high-octane 93 gasoline. The cast iron cylinder block ensured maximum strength for this power unit.

The use of numerous automatic engine control systems made it possible not only to change the traction performance of this engine, but also significantly improved fuel efficiency. Niva in suburban mode consumes 8.3 liters of gasoline per 100 kilometers when driving at cruising speed.

Starting from 2014, Niva cars with a diesel engine are also offered to customers.

The Niva engine with an overhead camshaft is equipped with a chain drive, which significantly simplifies the service of this power unit. The chain drive does not require replacement of the tensioner or any adjustment during operation of the motor. We also note the presence of hydraulic compensators, which relieves the car owner of the need to carry out the procedure for adjusting the valve clearance. All maintenance work on this engine can be performed by the car owner himself, without contacting branded service stations.

Tuning

There are several ways to increase the power of a Niva engine. We will tell you in more detail about these methods of tuning the VAZ 21213.

- Deep engineering tuning of the Niva engine with crankshaft replacement and cylinder boring. This kind of work allows you to increase the working volume of this engine to 1.95-2.1 liters. Accordingly, when adjusting the injector, the VAZ 21213 engine receives power of about 100 horsepower.

- Chip tuning of the Niva engine allows you to get about 10 additional horsepower at minimal cost. In this case, the work does not pose any difficulty. You just need to select the appropriate chip tuning and reprogram the engine control unit. The advantage of this option is the complete preservation of engine life.

- Installation of turbines and compressors on VAZ 21213 engines. In this case, we can recommend that you use compact turbines with a pressure of no more than 0.5 bar. At the same time, the injector is reconfigured and the oil and fuel pumps are replaced. It is necessary to understand that such work should only be performed by a specialist who knows the features of the VAZ 21213 engine.

Also interesting: Extra horses: dangerous and senseless chip tuning of naturally aspirated engines - KOLESA.ru - automobile magazine

Note that installing a turbine and boring the Niva engine invariably negatively affects its service life. Therefore, the car owner needs to weigh the pros and cons, and only after that perform tuning of the Niva engine.

Flaws

Niva engines have excellent technical characteristics and have proven themselves to be quite reliable power units. At the same time, it should be understood that, like all other VAZ power units, they are not without drawbacks.

The disadvantages of this motor include:

Such problems often appear after a mileage of 100,000 kilometers. Car owners need to closely monitor the condition of the cooling system.

Often, problems with the pump and thermostat lead to overheating of the power unit. The result of such overheating can be the appearance of cracks in the cylinder head, which in turn leads to coolant entering the oil. The VAZ 21213 engine in this case requires complex and expensive repairs.

Let's sum it up

So, which is better - a Niva carburetor or an injector? For off-road use and for the city, the second option is definitely better. An injector is a more reliable and practical system. There are far fewer problems and headaches with it, as evidenced by numerous reviews from owners. The engine starts easier and responds better to the gas pedal.

Read news about the new Niva

- "Golden Niva-2021"

- Winch for a field in Novosibirsk: 500 products: free shipping, 28% discount [go]

- Installing PTF Chevrolet Niva - Automagazine MyDucato

- Replacing the wheel bearing Niva Chevrolet: front hub and axle shaft

- Chevrolet Niva bolt pattern: diameter of the holes in the Chevy Niva, what is the bolt pattern of wheels and rims in the Chevrolet Niva, radius 15 and 16

- Chevrolet Niva and standard key fob. VAZ forum

- There is an opinion: test Lada 4×4 Urban 5 doors.

- Haval H5 test: five pros and four cons of the Chinese SUV

Malfunctions

| FAULTS | CAUSES AND REPAIRS |

| The appearance of a characteristic knock at the bottom of the engine. | This indicates problems with the main bearings. The car must be towed by a tow truck to a service center and the appropriate repairs must be carried out. |

| The appearance of a pronounced knocking sound with a metallic sound. | The reason for this is problems with the bearing rods and piston pins. It should be said that operating a car with such problems may subsequently lead to the need for expensive major repairs. |

| Engine troubles at low speeds. | There may be several reasons for engine tripping: first of all, it is the use of low-quality gasoline. It is also possible that carbon deposits may appear in the combustion chamber. In rare cases, problems are observed in the operation of the injection system. Repair in this case is carried out only after a comprehensive diagnosis. |

| Loud knocking sound when the engine is not warmed up. | This may indicate the beginning of camshaft wear. This problem is typical for power units whose mileage exceeds 100,000 kilometers. It is necessary to carry out appropriate diagnostics and then replace the camshaft. |

Technical characteristics of engine 21213

VAZ 21213 is a 1.7 liter petrol 4-cylinder 8-valve carburetor engine. The engine was created on the basis of 2121 and taking into account the developments of the VAZ 2107 unit. Engineers partially changed the original design to achieve better ergonomic characteristics of the Niva’s internal combustion engine:

In addition to increasing the cylinder diameter to 82 mm, VAZ developed new pistons and a crankshaft for the 21213 engine. We replaced the outdated Ozone carburetor with the Solers, the most popular and successful model in the early 90s. Improved ignition and cooling systems.

To lubricate the 21213 engine, oil is selected depending on the climate:

The manufacturer indicates the preferred brands of oils: Lukoil, ESSO, Rexol, Yar-Marka, Norsi, Shell, etc.

Technical characteristics of the VAZ 21213 engine

Meaning

Despite the factory-specified service life of engine 21213 being 80 thousand km, in practice the engine lasts 150 thousand km before overhaul, provided that high-quality fuels and lubricants are used and moderate operation.

Based on the 21213 engine, the 21214 unit with an injector was developed. The technical characteristics of the motors are identical. The designs differ in the power supply system, timing drive and the presence of hydraulic compensators. According to environmental requirements, the injection version meets the Euro-3 standard.

pros

Which is better - Niva carburetor or injector? Among the advantages of the carburetor Niva, it should be noted:

- Simple design of the power system. In the event of a breakdown, you can fix the problem yourself.

- Cheap service.

- Unpretentiousness to fuel quality. Many Soviet Nivas can easily “digest” even 76-octane gasoline.

- Lack of many sensors.

It would seem that the answer has been found to the question of which is better - a Niva carburetor or an injector. However, a carburetor engine has more disadvantages. Among them:

- Low reliability. Every season you need to adjust the carburetor and carry out its maintenance.

- Dependence on air temperatures. In winter, the spark plugs could easily be overfilled, making starting impossible until the spark plugs were subsequently unscrewed and dried. Also, in winter, due to condensation, the float often “stuck”. And in the summer the fuel pump often got hot.

- Greater fuel consumption.

- Less productivity. To unlock the potential of the engine, it was necessary to spin it up to high speeds.

No matter how simple and maintainable this power system may be, it requires a lot of attention. Over the course of a year of operation, you will have to rebuild the carburetor several times. A modern car enthusiast is unlikely to be happy with this situation (especially adjusting the carburetor or drying spark plugs in 20-degree frost).

Which is better - Niva carburetor or injector? This question interests many car enthusiasts. Here are the advantages of the injection Niva:

- Stable operation of the internal combustion engine. Thanks to the presence of IAC, owners have forgotten what floating speed is. For carburetor engines this was a real disease.

- Great performance. The fuel-injected Niva responds more quickly to the gas pedal.

- Less fuel consumption. We have already seen this by looking at the technical specifications. With the arrival of the injector, consumption decreased by 20 percent.

- Excellent starting in any weather. The injection engine does not flood the spark plugs, and in the summer the fuel pump does not overheat. The latter is submersible and is cooled by gasoline, as it is located in the tank.

- Reliability. Since there is no carburetor, there is no need to regularly tune it, change jets and clean it. The maximum that the owner of an injection-powered Niva can do is clean the throttle valve, but this procedure is by no means mandatory. It is recommended to do this only if the car selects high idle speeds.

What are the disadvantages of the fuel-injected Niva? There aren't many of them. Since more electronics have been added to the system, owners may experience faulty control sensors. If the car begins to consume a lot of fuel, it is worth looking at the mass air flow sensor. If the engine does not maintain normal speed at idle, the IAC may be to blame.

And if the engine refuses to start, the contact may have come loose from the crankshaft position sensor. But fortunately, these problems don't happen that often. And you can diagnose them with a simple multimeter by measuring the resistance or contact voltage of one of the sensors. Thus, breakdowns mainly concern only electronics. The mechanical part does not raise any questions.

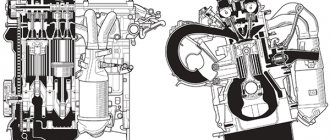

Description of the motor device 21213

The basis of the VAZ 21213 engine includes:

The main difference between the 21213 engine and its predecessors was the increased cylinder diameter - 82 mm versus 76 and 79 mm. The center-to-center distance of 95 mm remains the same, and allows the block to be bored to a diameter of 82.8 mm. The design of the water jacket has changed. The working volume has increased by 100 cm3, but the engine dimensions have remained the same.

To install the crankshaft in the BC there are 5 supports: one each on the front and rear walls, 3 more on the ebb. The crankshaft parameters provide a piston stroke of 80 mm. The crankshaft is cast from cast iron and consists of 4 connecting rods and 5 main journals. The connecting rod journals have oil channels. The necks are separated by cheeks with counterweights. In previous VAZ engines, balancing counterweights were found only in the outer and central cheeks. The axial movement of the shaft is limited by thrust half-rings.

The piston group for the 21213 engine was developed anew. Pistons 21213-1004015 are cast from aluminum and reduced to a single mass of 347 g. The piston class (A, B, C, D, E) is determined by the outer diameter in increments of 0.01 mm. The shape of the piston is conical in height and oval in cross section. The hole for the pin is 22 mm, offset by 1.2 mm from the piston axis. The finger is locked with rings. There are 3 rings installed on the piston skirt:

The connecting rod 21213-1004045 is forged from steel and processed together with the cover. A steel-bronze bushing is pressed into the upper head of the connecting rod. To fasten the connecting rod, M9x1.0x56 bolts are used.

The aluminum BC head is designed for the VAZ 21213 engine and is designed for compression from 10 bar. Installing a head from other motors may cause it to break. Cast iron seats and guide bushings for 4 intake and 4 exhaust valves are pressed into the head. The valves operate from the camshaft cams. The gap between the valve stem and the cam is adjusted with a bolt.

The camshaft 21213-1006010 is made of cast iron and rests on 5 journals. The jaws are bleached to increase wear resistance. Axial movement of the shaft is limited by a thrust flange.

The timing belt is driven by a double-row bush-roller chain. In addition to the camshaft, the chain drives the oil pump. The drive is regulated by a semi-automatic tensioner with a shoe and damper. To prevent the chain from falling off when removing the camshaft sprocket, a limiter is provided next to the crankshaft drive sprocket.

Systems

The power supply system in the Niva 21213 engine is a 21073 Solers carburetor. The carburetor unit is two-chamber, the throttle valves operate sequentially. When the first chamber is 2/3 open, the throttle of the second chamber is engaged. At idle, the economizer turns on. The carburetor device includes:

The ignition system in the 21213 engine is non-contact. The system is controlled by a switch using distributor signals. In general, the system is classic, without any special features.

Cooling of the motor occurs according to a typical scheme: liquid circulates through the water jacket in the BC and the block head. The pressure is created by a centrifugal pump connected by a belt drive to the crankshaft and generator. The radiator fan impeller works on suction, so in winter the radiator has to be covered with cardboard.

Design Features

The 21213 engine was created from the working version 2121, taking into account new developments for the VAZ 2107 engine, which were never completed. The main differences from the Niva internal combustion engine are:

- new design pistons;

- changing the parameters of the cylinder head and connecting rods;

- crankshaft modernization;

- camshaft modification;

- use of Solex carburetor modification 21073;

- improved lubrication system;

- original design of the chain tensioner shoe.

Pistons 21213

Crankshaft

Chain tensioner shoe

A detailed description of the components is contained in the manufacturer's manual. To reduce costs, designers mainly used parts of engines already in production that were already in mass production at the time of 1994:

- standard cylinder block, from 2103, height 214.58 mm, cylinder center distance 95 mm;

- crankshaft - taken from 2103 with a crank radius of 40 mm, equipped with additional counterweights, oil channels are drilled in the connecting rod journals, and their diameters are increased by 0.02 mm;

- the cylinder head was used from 21011, but the combustion chambers were enlarged (30 cm3 each), the height was ground down to 111 mm;

- timing valve mechanism – used from 2101 without changes;

- Timing chain – bush-roller double-row from 2103.

Cylinder head 21213

Factory boost provided a power of 81 hp. s and a torque of 126 Nm, but the manufacturer left a potential of about 45 - 60 hp. With. At the same time, he recommends improving the intake and exhaust tracts with your own hands without boring the cylinders and turbocharging the engine.

The main feature of the lubrication system is the presence of plugs to accumulate and then remove dirt from the oil.

What cars was the power unit installed on?

Tolyatti engineers designed the 21213 internal combustion engine to replace the 2121 for all-wheel drive off-road vehicles. The engine is found in AvtoVAZ SUVs and minivans:

Engine 21213 was installed on the export right-hand drive model Niva 21216.

The most common engine failures

ICE 21213 has typical problems of VAZ engines:

The disadvantages of the 21213 engine include repair features. If the wear of the cylinders exceeds 0.15 mm, then boring is permissible only for the repair dimensions of the pistons, increased by 0.4 and 0.8 mm from the nominal value. Exhausting the limit threatens to completely replace the pistons and cylinders.

Regrinding of the crankshaft journals is possible with a diameter reduction of 0.25; 0.5; 0.75 and 1 mm. The limitation is due to the repair dimensions of the liners. If the axial clearance of the crankshaft increases by more than 0.35 mm, the part must be replaced.

Advantages and disadvantages

At the time of its creation, ICE 21213 had the following advantages over earlier versions:

- trouble-free carburetor - does not require frequent adjustments, when adjusted by a specialist, it ensures gasoline consumption at the level of injection injection;

- improved performance - in addition to power/torque, speed and throttle response have increased;

- several repair sizes of ShPG - major repairs can be performed several times without purchasing a new unit.

The disadvantage is the excessive noise during operation of the internal combustion engine, high consumption of fuel and lubricants and antifreeze. Currently, instead of standard elastic cylinder head gaskets, metal packages with a long service life can be used. However, machine grinding of the surface of the head and block, respectively, will be required.

Users note among the disadvantages of the motor the low quality of the factory assembly. For example, the connecting rod pin bushings are pressed in incorrectly - with a cut in an arbitrary direction. And these parts experience maximum loads at dead spots, so in the literature it is recommended to press them either at 45 degrees or in a horizontal direction, which will increase the service life of this consumable.

Price of new and contract engine 21213

Drivers of Niva with engine 21213 note the affordable price of spare parts and the car as a whole as one of their selection criteria. A new fully equipped engine with a factory warranty will cost 70,000 rubles. For comparison, the price of the injection 21214 is from 85,000 rubles.

A used engine costs 2 times less: 30 - 45,000 rubles. There are models for 10-15,000 rubles, but their condition, as a rule, requires repair.