A popular tool for modifying a car is covering the body with film. This method is increasingly attracting drivers with its availability and low price. Before gluing the film on a car, you need to study the instructions and prepare all the necessary tools and materials.

- Types of films for car wrapping

- Car surface preparation

- Materials for car wrapping film

- Methods of covering a car with protective film

- How to cover a car with dry film with your own hands?

- Film on a car using the wet method: how to glue?

- How to glue film to headlights?

- Results

You can cover your car with PVC of any color and type, just use your imagination. With a little patience, you can complete this task yourself.

To do this, the article discusses:

- types of film coatings for car bodies;

- their popular brands;

- instructions for wrapping the body and optics of a car with your own hands.

Conditions for filming

The car or its individual parts should be covered with film in a dry, clean and warm room. When working outside in cold weather, it is impossible to properly glue the material to the surface. Most likely, he won't hold on. The same applies to excessive humidity. And dust and dirt that gets under the sticker on the street or in a poorly cleaned garage will lead to its poor-quality application and rapid peeling. It is not advisable to apply materials to freshly painted body parts. About a month should pass from the moment of painting. The exception is touch-up of small chips and scratches.

Pasting carbon fiber plastic

The method of gluing plastic is no different from the methods of gluing metal surfaces of a car. It can be either dry or wet: the choice depends only on the experience of the car owner and the availability of a partner.

Plastic panels in the cabin, covered with carbon fiber

There is only one important point that the car owner must remember: it is the plastic parts of the interior that should be covered with carbon fiber. You cannot cover parts made of:

- polypropylene (aka PP);

- acrylonitrile butadiene styrene (aka ABS).

To date, the use of these materials in the automotive industry is gradually declining because they are harmful to health. Nevertheless, many manufacturers still use them (Koreans and Chinese are especially guilty of this). Applying the material to parts made of ABS or PP leads to a chemical reaction, as a result of which the service life of the PVC base is reduced by 3–4 times.

How to choose a film

Now there are many films of various colors and with all kinds of decorative effects. Materials can imitate carbon, be matte or mirror, have different designs and patterns, 3D or 4D images. You can order stickers with an individual design. Sometimes this is necessary for car branding, for example, for working in a taxi or any company.

Most car wrap films are made from vinyl. Good quality products are easy to apply and easy to remove. They have a long service life of at least five years. These are materials from the brands 3M, Arlon, Hexis, KPMF, Oracal and other American and European manufacturers. Their disadvantages are the relatively high cost and a large number of fakes. Therefore, you need to buy products from places with a good reputation.

Many adhesive materials from China and South Korea are short-lived and of low quality. They can successfully serve for a couple of years, or even less. Such stickers are difficult to remove from the surface and may leave marks and damage to the paintwork. Sometimes they do not stretch well when glued, tear and quickly begin to peel off. Chinese products can develop noticeable defects even with minor mechanical or chemical exposure, for example, after a regular delicate body wash. Their only advantage is their low price. But those who value the condition of their car and want it to have a beautiful appearance should not skimp on film and take the cheapest varieties. And what design to choose is a personal matter for everyone. But you should not buy materials with a strong mirror effect or imitating the colors of special vehicles. This is prohibited by traffic rules and unsafe.

Scope of application

The most commonly used film is vinyl film. It is used for various purposes - in baths, kitchens, living rooms and even children's rooms. The safety of its use and beneficial properties allow you to update the design of your home, office, etc. The variety of colors will satisfy any, even the most fastidious, buyer.

A type of vinyl film is carbon-effect film. Carbon film is used to change the appearance of the car. Its versatility allows you to stick the film on the outside of the car and update the interior. On the one hand, carbon film is economical, durable, and on the other hand, it is easy to remove. Therefore, if you get tired of the color of your car, you can easily change it at low cost.

Let's look at how to properly glue vinyl and carbon film to plastic.

How to prepare the body

In order for the adhesive coating to adhere well and last for a long time, the car body must be carefully prepared before applying the adhesive. Preparation stages:

- Washing the body with car shampoo, drying or wiping it.

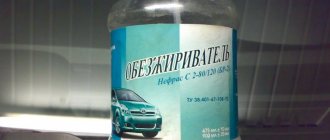

- Carefully inspect the surface to identify damage and difficult-to-clean contaminants. If there are traces of tree buds, bitumen or glue or similar stains on the body parts, remove them with alcohol or a special product. Do not use aggressive solvents that can damage paint and varnish. If there are large chips, scratches and dents, repair them. Otherwise, the sticker will not fit well, and corrosion may form underneath it.

- It is advisable to polish the body if the car is not new. After polishing, the material will adhere better and last longer. And it will be much easier to remove it.

Do not apply stickers to items with areas of rust, peeling paint, large chips or scratches to the primer or metal. To avoid more severe damage to the paintwork and corrosion, it is better to repair defects on your own or at a car service center. Sometimes it is allowed to stick film materials onto unpainted, primed surfaces.

Advantages and disadvantages

Body coating is acquiring more and more positive aspects than disadvantages.

Advantages:

- In addition to scratches and chips, dents are hidden. After pasting, the unevenness will be visible from a certain angle.

- The coating protects against weather conditions (sunlight, rain, hail), mechanical defects.

- When using transparent film, covering can be done on headlights and mirrors, which will keep them in their original condition for many years.

- If properly maintained, it can be used for up to 7 years without restoration.

- Changing the style according to the wishes and capabilities of the car owner.

- Affordability.

- Large assortment of colors and shades.

Disadvantages appear when working with cheap materials and poor quality preparation:

- Deformation of the coating.

- Burnout, possibility of peeling off when exposed to direct sunlight.

- Surface roughness.

Another point is that if the color of the material and the color of the car do not match, you will have to redo the documents for the car and introduce a new tone.

How to glue car vinyl

To apply vinyl film you will need the following tools:

- Stationery knife;

- Scissors;

- Dry and soft rags;

- Rubber spatulas;

- Soapy water or window cleaner;

- Degreaser;

- Masking tape;

- A hair dryer is better than a construction hair dryer, but you can also use a regular household one;

- Film of the chosen design in sufficient quantity.

If you plan to cover the entire car with the material, then a sedan will need 17-20 meters of film, small hatchbacks - 13-15 m, crossovers and station wagons - 18-23 meters, and for SUVs you will have to buy about 23-30 m. When pasting one or several elements, measure their sizes and, based on this, buy film. For those who apply it for the first time, it is better to take it with a reserve in case of damage to the product. For beginners, it is better not to take coatings with a complex pattern, since it is impossible to glue it evenly without experience.

Before application, you need to mark the material by applying it to the body parts to be pasted. Using scissors or a stationery knife, cut out the stickers of the desired size and shape. Before gluing, prepare the necessary tools and materials, as well as the room itself. It should be dry and warm. If the garage is dark, take care of additional light sources. Insufficient lighting can affect the quality of the result. It is advisable to work with an assistant.

There are two main ways to apply vinyl to a body. This is wet and dry. The first one is suitable for novice masters, as it allows you to correct flaws. But gluing with this method may take a little longer than working with the dry method. Therefore, it is chosen by people with experience.

Wet vinyl wrapping

If a car enthusiast does not have experience in gluing car vinyl, it is better to use the wet method. It takes a little longer than dry, but it allows you to correct mistakes.

This method will require a bottle with a spray bottle and an aqueous solution of soap or washing powder. You can use window or dishwashing detergent. For gluing, it is advisable to use good quality elastic film. Pasting is done like this:

- Spray soapy water or soap onto the surface.

- After removing the transport layer, apply the film to the body panel.

- Press the sticker to the surface, leveling it with your hands and a spatula.

- Warm up the front side of the product with a construction or household hairdryer.

- Starting from the center, carefully press the film to the part towards the edges. Make sure that there are no air bubbles or moisture left underneath.

- Treat the edges of the sticker with a primer for film materials so that it sticks better.

- Cut off any excess pieces of film if any remain.

- Wipe the surface with a rag or napkin, pressing the coating slightly.

It is not recommended to wash the car for a week after such tuning. Therefore, the method is not suitable for those who often have to drive on bad and dirty roads or, for example, taxi drivers who often have to stop at a car wash. But, if significant rainfall is not expected in the near future, this method can be suitable for almost everyone.

Dry vinyl wrapping

The dry method requires experience and skill in applying vinyl film. It makes it practically impossible to correct gluing defects and does not require the use of soapy liquid. Pasting is done according to the following algorithm:

- Place the film on the part, remove the backing sticker and smooth it with a spatula or your hands.

- Heat the sticker with a hairdryer and smooth it out with your hands and a spatula so that there are no air bubbles left inside.

- Secure the edges of the coating with special glue.

- Remove excess pieces of material with a utility knife or scissors.

If you are not confident in your abilities or are afraid of ruining the car, it is better not to try to wrap it yourself using any of the methods, but to turn to professionals.

Wet method

For those new to film wrapping, the wet method will be easier and faster.

Procedure:

- You need to cut a piece of film to the required size, taking into account a turn of 8 mm on each side. In large areas, it is allowed to leave folds up to 5-6 cm.

- The surface is degreased with a soap solution and washed with clean water.

- If there are uneven spots and scratches, then before applying the sticker you need to restore the structure of the surfaces using a primer or automotive putty. It is important to consider the following: if the primer dries in 5-7 minutes, then the putty takes up to several hours, and then it must be sanded with fine sandpaper.

- Afterwards, a soap solution is applied again - the carbon fiber will be attached to it. In order for the film to fit tightly, you must check that there are no contaminants left. And to apply the soap solution evenly, it makes sense to use a spray bottle.

- The film must be applied to the surface, having first removed the backing from it, and pressed step by step onto the paintwork, smoothing with a soft polymer spatula or felt squeegee.

- For fixation, the front part is heated with a hair dryer. The final gluing process should begin from the center of the element, gradually moving to the edges.

Maintenance of a car covered with vinyl film

Vinyl does not require serious care, but to extend its service life you should follow simple recommendations:

- You should not wash your car for the first seven days after wrapping it;

- For a week after applying the coating, do not drive at very high speeds or on bad roads;

- Wash the car with high-quality car shampoo and not very hot water;

- Do not use abrasive polishes or rough brushes to care for coated surfaces;

- Do not leave the car in the sun for a long time. Any film can burn out.

Removing vinyl film

It may be necessary to remove car vinyl if it is damaged, for example, after an accident, even a minor one. Sometimes stickers are intentionally damaged by vandals or otherwise damaged. The drawing may become boring or the owner of the car will stop working for a taxi or another company, and the logo on the body will become irrelevant. In such cases, the film should be removed. This can be done at a car service center or yourself. If the vinyl is removed correctly, there should be no traces left on the paintwork. To remove the film you will need the following tools:

- Plastic squeegee;

- Plastic scraper;

- Hairdryer - construction or household;

- Rags;

- Soap solution.

The film is removed like this:

- Heat the surface with the sticker with a hairdryer.

- Use a scraper to pry off the coating from one corner.

- While heating the material, tear it apart with a squeegee and remove it with your hands.

After removing the film, traces of glue and other defects may remain on the body. You can remove them with a soap solution or white spirit. Aggressive solvents are not recommended. Sometimes body polishing may be required.

Paintwork damage repair

Vinyl material not only does not hide defects in the car body, but can also make them more noticeable (especially if it is a matte finish or carbon film). When choosing auto vinyl over painting a car, you must understand that the preparation must be no less thorough.

Particular attention should be paid to areas of corrosion, since the corrosion process will continue under the film, which will very quickly lead to peeling or swelling of the car vinyl.

If the car body is in satisfactory condition, it is often enough to hide large chips and deep scratches. If the damage is not too severe, you can do without puttying and priming. Otherwise you need:

- degrease the damaged area, clean with P120 abrasive. Corrosion areas must be treated with a rust converter and then primed with epoxy primer;

- fill the defect with universal putty;

- sand the putty first with abrasive P120, and then with finishing abrasive P320;

- prime the putty areas with acrylic primer;

- clean the soil with abrasive P320 at the initial stage and P600-P800 at the finishing stage.

We did not describe each of the processes, since we have already devoted separate articles to filling and priming your car.