Belt drive is the most common method of transmitting rotation to the generator rotor. The method has been used for a long time and differs from others in its simplicity: only two pulleys on shafts that are connected by a belt.

The belt itself is responsible for a lot. It is he who is responsible for transmitting rotation from pulley to pulley. You should be aware that one part of the belt is tighter than the other. It is the difference between these tensions that determines the traction force and its coefficient.

The belt provides precise transmission and is quiet in operation. High-quality products are able to withstand long-term loads, smooth out shocks and jerks. They are compact, take up little space, but simultaneously operate several important components of the car: generator, pump, air conditioning compressor and power steering pump.

The generator rotor must rotate constantly. This is facilitated by the belt connection to the crankshaft. The pulleys, which are screwed onto the generator and crankshaft shafts, are connected by a belt, which must be flexible.

The “whistle” of the belt is similar to a disgusting clang. It is caused by the belt slipping. The sound of such a whistle is unpleasant and can be heard at a great distance. Of course, you should not drive in such a situation.

Why does the alternator belt whistle and how to eliminate the whistle?

In most cases, there is one reason for the appearance of a whistle, squeak, squeak or squeal from under the hood of a car - the alternator belt or timing belt is whistling.

On modern cars, in addition to the generator, the drive belt can also rotate the pulleys of the power steering, air conditioning compressor, engine cooling pump and other attachments. The reasons for whistling may vary. For example, a whistling alternator belt in wet weather can be caused by moisture getting on the belt and pulleys. And if the generator belt whistles when cold, this may be due to thickened lubricant in the generator bearings or tension rollers.

In this article we will talk about why the alternator belt whistles, what to do in such cases, and how to eliminate the drive belt whistle yourself.

The whistling may appear for a while and then disappear (for example, the whistling of the alternator belt when the engine is cold, during rain or when the air conditioner is turned on), or it may be constant. What to do and where to start looking for the cause of the whistle?

Self-diagnosis

Cracking sound when starting the engine when cold: what is the cause of the malfunction?

In some cases, the cause of an unpleasant whistling sound of the belt is its stretching. In such a case, you can solve the existing problems by slightly tightening the belt. A characteristic whistle may also appear if oil or antifreeze gets on the drive.

During self-diagnosis, the car owner will need to check the belt and its wear; if there are abrasions and cracks, it is best to replace the drive. If there are contaminants on its surface, they should be removed, observing the subsequent operation of the belt and the absence of unpleasant sound.

The pulleys may also be dirty; it is necessary to clean the grooves, restoring their alignment. If serious groove wear is already observed, then replacement of the pulleys is required.

In rare cases, the tensioner fails and is recommended to be replaced with a new one. In such a case, you need to contact the service and repair the car engine in a specialized workshop.

Self-repair and replacement of the alternator belt is possible if the car owner has relevant experience. In the past, it was indeed possible to change the belt on VAZ cars or relatively old foreign cars yourself, significantly reducing the cost of contacting a specialized service center. However, today modern motors have a complex design, so if such an unpleasant sound appears, you should immediately contact the service center.

Let's sum it up

The appearance of an unpleasant whistling sound from the alternator belt indicates its wear, after which the car owner needs to contact a service center as soon as possible or replace the drive themselves. Such an unpleasant sound can appear either constantly or in certain conditions, for example, in cold or high humidity. Most often this is mechanical wear and damage to the belt, but in some cases the pulleys or tensioner may fail.

27.08.2020

Why does the generator belt whistle (reasons for whistling)

Many car enthusiasts believe that the whistling of the alternator belt appears only because it is worn out or sagging, but this is not entirely true. It is not always possible to eliminate whistling by replacing the old belt with a new one or “tightening” it. Often the causes of whistling may not be obvious.

In order to understand how to eliminate the whistling of the generator belt, you must first understand why it whistles (squeaks, creaks), and what are the reasons for the appearance of these sounds.

During operation, the alternator belt, like other vehicle drive belts, is subjected to prolonged high loads. With its help, torque from the engine crankshaft is transmitted to the generator and other attachments.

Most drive belts in automobiles are wedge-shaped, which provides greater frictional force where they contact the pulleys. They are called V-belts. The same belts that have several wedge-shaped tracks (the so-called “streams”) are called poly-v-belts.

V-belts are available with and without teeth. It is believed that belts with teeth work better at breaking, do not break and slip less often.

Now we have come to the answer to the main question - why does the alternator belt whistle ? It's very simple - in 99% of cases, the whistle appears due to the friction of the belt on the pulleys and tension rollers as a result of slipping! That is, if the belt cannot turn the pulley of a generator or other equipment, then it simply slips, making an unpleasant sound similar to a whistle, squeak, squeak or squeal.

Therefore, you need to look not for the cause of the whistle, but for the reasons that cause the belt to slip. And there can be five main reasons:

In addition, the appearance of a whistle can be influenced by such factors as humidity and ambient air temperature, the technical condition of the generator, air conditioner, power steering and other equipment driven by the generator belt.

Purpose and types

The main purpose of the alternator belt, as the name suggests, is to transmit rotational motion from the engine crankshaft to the generator for the operation of the vehicle’s electrical system as a whole.

In most cars, the purpose is even broader. Sometimes it rotates the pump (water pump), the air conditioning compressor clutch, the power steering pump, and other rotating mechanisms of the car.

Why is it that in all cars a belt drive is chosen to transmit rotational motion from the crankshaft to the generator, if there are more reliable and durable ones, for example, a gear drive?

Belt drive has several significant advantages:

- simplicity;

- the ability to perform kinematic connections over long distances;

- Perhaps the main advantage is the protective functions.

The protective function of the belt drive is that if the generator (compressor, hydraulic booster, pump) jams, the powerful torque of the engine crankshaft will not destroy the generator and other components. The belt provides slippage. At worst, it will simply break, but the other nodes will remain intact.

The following requirements apply to generator belts:

- reliability (service life is usually at least 30,000 km);

- elasticity, the ability to maintain tensile strength during changes in temperature and humidity throughout the entire service life;

- good anti-slip properties;

- resistance to aggressive agents.

In order to meet these high requirements, manufacturers use different types and technologies for the production of alternator belts:

- wedge - to provide a larger area of contact with the pulley, lateral resistance to slipping;

- poly V-belts - to increase the properties of V-belts;

- toothed poly-V-belts - to increase the flexibility of V-belts;

- woven covering of the non-working area - to increase service life.

A modern alternator belt from an official manufacturer is a high-tech product using high-quality materials. However, no matter how high quality it is, during operation it wears out and its linear dimensions increase

.

While the engine is running in the engine compartment, its operating temperature can vary in the range from – 30 to + 100 degrees. This also causes a change in the geometric dimensions of the alternator belt. To maintain the tension force at a constant level, tension regulators are used.

In cars of the 80s, tension control was often done by changing the geometric position of the generator. In this case, one side of the generator was fixed permanently. The second mount had a groove.

Video - why the alternator belt whistles when cold and how to solve the problem:

If the tension weakened, the second fastening was loosened, the generator was moved using the device, tightening the generator belt, then the fastening bolt was clamped again. A little inconvenient, but no additional rollers, rods or other components.

Currently, three types of tensioners are used:

- roller with eccentric

(the central bolt is loosened, the eccentric bolt is rotated to achieve the required tension, the central bolt is clamped); - a roller with a screw rod

(does not require two keys, tension adjustment is simpler, although the design itself is less reliable); - dynamic tensioners

(self-adaptive, do not require adjustment during operation).

There are car models in which there are no elements for regulating the tension of the alternator belt at all. In this case, it is especially important to select a product from a recommended manufacturer according to the instruction manual.

How to eliminate a whistling alternator belt

You can get rid of the generator belt whistling by eliminating the reasons that cause it to slip on the pulleys.

If there are signs of belt slipping, accompanied by an unpleasant whistle, we suggest eliminating it in the following order:

For information on the optimal degree of tension of your car's alternator belt, refer to its operating instructions.

An indirect sign of pulley misalignment is the poly V-belt jumping from track to track and sliding off the pulley.

And so, if the generator belt has not stopped whistling, but it is intact, clean, well tensioned, and the pulleys rotate smoothly and smoothly, then you can try to correct the situation using another method:

If all of the above did not help and the belt whistle has not gone away, then the problem lies either in the quality of the belt itself or in the equipment that is driven by it: tension rollers, generator, power steering pump, air conditioning compressor, etc. Perhaps the grease in the bearings has simply thickened or they have failed, or perhaps the reason is much more serious, so in this case it would be better to seek help from a car service specialist.

You can try to temporarily eliminate the whistling noise using special auto chemicals, so-called conditioner-tensioners for drive belts. This, of course, will not solve the problem, but the whistling will disappear for a while.

A cheap way to get rid of belt squealing without using expensive sprays

The first thing we need to do is make sure that the whistle is actually coming from the belt. If you hear an unpleasant whistle constantly, then it is clearly not a belt, but possibly a pump or some kind of bearing (most often a generator bearing). The belt whistles only when there is a load on the generator, for example, when turning on the amplifier of a powerful audio system or during a sharp increase in speed (over-throttle).

You can once again verify this in the following way: warm up the car engine, sharply press the gas pedal and immediately release it. During such a re-gas, the belt slips on the generator pulley, producing an unpleasant squeak or whistle.

If you are convinced that the belt is tensioned as expected, but the whistle does not disappear, then we need to increase the belt friction. Ordinary drivers who do not have sufficient experience buy special V-ribbed belt conditioners for these purposes. This is a spray that is sprayed onto the working surface of the belt, increasing its friction with the pulleys.

Such sprays really help, but their effect is temporary, and the whistling will soon appear again. Moreover, such V-belt conditioners are quite expensive. For example, the popular and beloved Hi-Gear Belt Dressing spray costs from 450 rubles and above.

Few young drivers understand that by paying so much money for a spray, they can also damage the car. Since the spray composition is liquid and does not evaporate quickly enough, it can flow down the pulley onto the bearing (for example, a generator bearing) and quickly damage it.

Also, the consistency of this spray always remains sticky and never completely dries out. As a result, dust and dirt will begin to adhere to the surface of the belt, which we have treated with a conditioner spray, which will further reduce belt friction.

Therefore, we will not use all these newfangled features and auto chemicals, but will simply read the composition of the spray to once again make sure that we are paying for air. And their composition is very simple: isopropyl or methyl alcohol and coniferous tree resin, which manufacturers proudly call a special additive, hiding the real name of the component. It is the resin dissolved in alcohol that gives the effect of increasing friction. But resin with alcohol gives a sticky surface on which dirt accumulates, worsening belt friction.

All these disadvantages are absent in the simplest method, using ordinary soldering rosin. Yes, yes, the resin of coniferous trees is nothing more than rosin. We will not dissolve it in anything, but use it in the form in which it is sold in stores. In any hardware store you can buy a block of rosin for only 20 rubles. Do you feel the difference in the cost of the main component and the sprays sold? As a rule, everyone in the house who has ever worked with a soldering iron has rosin.

We need to rub the working (inner, in contact with the pulleys) surface of the belt with a regular piece of rosin. Then, turn the starter a little so that the raw part of the belt becomes available to us. We will also carefully rub it with a piece of rosin. We will do this until we have processed the entire belt.

Dry rosin improves belt friction even better (remember violinists who rub their bow with rosin before playing the instrument) and does not have all the disadvantages of commercial conditioners. The surface of the belt becomes clean and dry; dust and dirt do not stick to it over time, which worsens the friction of the belt.

I have long been convinced that the majority of auto chemicals sold are nothing more than ordinary old-fashioned recipes, which new-fangled brands bottled in beautiful bottles and sold at outrageous prices. Therefore, I recommend reading the composition of this chemistry more often in order to save money and make your own chemistry from components available to everyone, for mere pennies.

Source

How to lubricate the drive belt. The best lubricant for alternator belt against whistling

Drive belt conditioner allows you to get rid of the whistling noise that they sometimes create and extend their overall service life. This product softens the hardened rubber layer, reduces the intensity of its wear, and also creates a layer on the surface with a high coefficient of friction.

However, it is necessary to understand that using a conditioner for rubber drive belts is only a temporary measure, and in order to eliminate the squeaking and/or its insufficient tension, it is necessary to solve the problem radically, that is, tighten the slack with a tensioner or replace the belt.

How to choose a conditioner for drive belts

There are several simple rules, and if you follow them, it will be easier to decide on the choice of belt conditioner.

- Scope of use . Many manufacturers produce universal products that can be used to restore not only traditional rubber V-belts or multi-V belts, but also similar products made from other materials. Restoration of leather, fabric, synthetics. Such products are good for everyday use, but the wider the spectrum of action, the less well it will cope with the belt of attachments in a car.

- Compound . Typically, the compositions of drive belt restorers are approximately the same for most manufacturers. Therefore, when studying the composition, it is necessary to pay attention to whether the product will harm individual materials, and even more so the human body (can it be allowed to come into contact with the skin or the respiratory system).

- Packaging volume . Considering that many drive belt conditioners have a short lifespan, you also need to look at the packaging volume. In addition, you need to consider how soon you plan to tighten/replace the belt, and accordingly, refuse to use the air conditioner.

- Value for money . Since all regenerating conditioners have approximately the same efficiency, it is best to buy products from the middle price category.

- Manufacturer . The market is represented by dozens of different similar products, so it makes sense to pay attention to the product descriptions, as well as reviews about the product.

How to eliminate the squeaking of the alternator belt with your own hands?

The generator belt squeals: what to do if you have no experience in repair work. This article will help you deal with this problem, as it will explain the causes of the squeaking noise and provide recommendations for resolving the problem.

If the alternator belt creaks, then this sound hurts the ears not only of the driver and passengers, but even passers-by. When such sounds occur, the thought arises that the reason is in the strap and it needs to be replaced urgently, but this is not always the case. Therefore, before rushing to replace it, you should understand the cause of the squeak.

A generator is present in any car; its purpose is to provide electricity to all car systems. Continuity of rotation of the device rotor is ensured by a belt drive between the crankshaft and the generator. Due to friction with the pulley or slipping of the rubber product, a whistle occurs. Pulleys and belts may differ for different vehicle devices, but the principle of their interaction is the same. The cause of the squeak is the friction of parts from each other. Therefore, the whistle often occurs when the belt is loose and it slips along the pulley.

The cause of the squeaking of the alternator strap may be:

In the cold season, a squeak may occur when starting a cold car. The belt is a rubber product; in the cold it hardens and loses elasticity. As soon as the material warms up, the whistle disappears. The cause of the whistling may be increased humidity. In this case, nothing needs to be done, since the whistle disappears as the surface dries.

Fixes

What to do if you hear a squeaking sound from the generator belt? You shouldn't change it right away. Sometimes there is a whistle, but the resource of the consumable has not yet been exhausted and it can be further used. Therefore, if extraneous sounds occur, you should inspect the belt drive and find out where the squeak comes from. To diagnose, open the hood and inspect the strap for:

Replacement should be done if the surface is worn out, there are cracks, assemblies, or frayed edges. If traces of oil, coolant or other contaminants are found, you can try cleaning the surface. Contamination prevents the product from stretching and moving evenly. If they cannot be removed, the consumable must be replaced.

The cause of a whistling noise in the generator belt drive may be wear of the bearing in the tension roller or generator. To diagnose the serviceability of the tension roller, you need to dismantle it and check for defects and play. If any malfunctions are found, parts must be replaced.

You should buy only original products, this can guarantee that they will last the required period.

The following factors influence the service life of components:

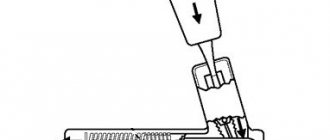

The most common cause of whistling is poor belt tension. To check it, you need to press the product between the generator and crankshaft pulleys somewhere near the middle.

Checking product tension

The deflection should be in the range from 6 to 8 mm. If the tension is not correct, it needs to be adjusted. If the tension is poor, the unit does not produce a full charge. To tension you need to do the following:

Generator mounting nut

Move the unit towards the engine compartment

After the tension adjustment procedure, you need to check the operation of the unit. Before starting the engine, you need to turn on several devices powered by the generator, for example, a heater, air conditioning, and high beams. If everything is in order, then there is no whistle and the charging level is at the proper level.

To improve the operation of the belt drive, you can lubricate both surfaces of the rubber product with special liquids, for example, Hi-Gear and VeryLube conditioners. With their help you can also get rid of squeaking, but they give temporary results. Regular use of conditioners extends the service life of belts by 1.5-2 times.

Thus, if you hear a whistle when starting the generator, you should not rush to a car service center. You can solve the problem yourself. It is important to correctly determine the cause of the whistling, and solutions are described in the article.

“Eliminating alternator belt whistling”

This video shows how to get rid of strap whistling using special liquids.

Source

Fixes

What to do if you hear a squeaking sound from the generator belt? You shouldn't change it right away. Sometimes there is a whistle, but the resource of the consumable has not yet been exhausted and it can be further used. Therefore, if extraneous sounds occur, you should inspect the belt drive and find out where the squeak comes from. To diagnose, open the hood and inspect the strap for:

- integrity of the part;

- degree of wear;

- presence of traces of working fluids on the surface;

- displacement of the pulley line, they must be strictly on the same line;

- degree of tension of the product.

Five main reasons why a generator whistles

Below is a list of the most common causes of alternator belt whistling:

The provisions listed above are the main ones. But this does not mean that there cannot be other reasons. The most important thing is to respond to the problem in a timely manner and take immediate measures to eliminate it, then you will forget how the generator belt whistles.

An unpleasant high-pitched whistle periodically coming from under the hood of a car indicates a problem with the belt drive. As a rule, a loud squeak is heard when starting the engine or when pressing the accelerator pedal. Moreover, at idle speed and during uniform movement, the sound does not appear. In most cases, you yourself will be able to determine why the alternator belt whistles “when cold” and when the engine “spins up”. There are several reasons, and half of them can be eliminated by the car owner.

Why does the driver hear a whistle?

When the power unit operates in a car, the belt, along with other drive belts, experiences maximum loads.

Most of the drive belts installed in the machine have a wedge shape, which provides a greater frictional force in the place where the part contacts the pulleys. Such elements even have appropriate names - V-belts.

These same products, but having several paths at once, called streams, are called polywedges.

Generator belts can be with or without teeth. It is generally accepted that products with teeth have a longer service life, since they wear out and slip less often.

So why is there a whistle? In 95% of situations, the manifestation of an unpleasant whistling sound occurs due to the friction of the belt on the pulley if slippage occurs. It turns out that when the belt is unable to turn the pulley, then it slips. This action is accompanied by a sound resembling a whistle.

The motorist should not look for the cause of the sound, but for faults that cause the belt to slip.

There may be several of them:

- Weak and, conversely, very tight tension of the generator belt. Over time, the belt may stretch. The main reason for this is wear and tear of the lower part of the part. The car owner will only need to tighten the connection point. However, it is important to remember not to tighten it too much. In the longest section, the blade should have a stroke in the range of 8 - 10 millimeters. A belt that is too tight can also cause a squealing noise. It is no secret that extremely tight tension does not allow the pulleys to rotate normally. This situation often occurs in winter. The squeak disappears from the moment the engine reaches operating temperature and the belt takes its previous shape.

- Poor quality or temporary wear of the belt. Often, the material used in the production of the belt itself is not the same material applied to the outside of the product from Chinese manufacturers. When the top layer wears, the belt makes a squeaking sound. If the wear is too great, then even the next tension will not help eliminate the problem with the belt whistling. When cracks appear on the product or traces of major destruction can be visually detected, the problem can be corrected by replacement. There is no point in delaying this issue, since such a belt can break at any time.

- Contact with the pulley or belt of technical fluid used in the operation of the machine, for example, oil, washer fluid and even plain water. Problems with whistling appear most often due to contact with engine oil. The belt loses its previous grip and slips with the appearance of a characteristic sound.

- Malfunction of the tension roller or generator bearing. A technical problem with the bearing can cause an unpleasant sound emitted by the hanging belt. The owner of the car will only need to replace the bearing. This structural unit also has special tension rollers. This part is a type of bearing that can begin to seize over time. Because of this problem, the movement of the belt drive is disrupted, the belt rubs heavily against the pulley. In this situation, the belt will show signs of severe wear. The car owner must inspect the mechanism, remove the belt and check the play of the rollers.

- Axle mismatch between pulleys. The appearance of a nasty whistle may be due to misalignment of the line between the two pulleys. The pulleys must be positioned strictly on the same axis, and even a slight slope can cause a whistle.

There are several pulleys in a car. The first is located on the crankshaft, and the second on the generator. With constant use of the car, the pulleys wear out. A small pulley is installed on the generator; on the crankshaft, on the contrary, the largest one is installed. Most of the load will go on the small pulley. Some automakers make a small alternator pulley from not the most durable materials. Therefore, wear of the teeth on this part is a matter of time. In addition, situations often occur when damage occurs on the track itself, for example, after an impact.

In any case, the car owner will need diagnostics and replacement of damaged parts.

You will also be interested in:

The alternator belt whistles - what to do in this case?

The method for eliminating alternator belt whistling directly depends on the technical reasons for its occurrence.

Tension check

To check the tension of the generator belt, pressure P is usually applied to the section in the middle of the longest run (see Fig. 1). The amount of drawdown h should be from 5 to 10 millimeters.

Strong tension (less than 5 millimeters) leads to rapid wear of the belt, bearings or bushings of the generator. Weak tension leads to slipping and whistling, and can cause incomplete charging of the battery and other problems in the operation of electrical equipment.

This problem can be resolved by adjusting the tensioner. If the adjustment limits are not enough, the alternator belt should be changed.

Video - whistling due to tensioner misalignment:

To check the structure of the working area of the product, it is necessary to provide good lighting and access to the rubber surface. Sometimes experienced specialists rub the surface of the belt with chalk, then microcracks will be more noticeable.

The fabric base of the non-working surface is also checked. If there is damage, breaks, chips on the working surface, deep microcracks, such a product must be replaced.

How to lubricate a generator belt to prevent it from squealing

There are a number of special auto chemical products on the market that can help solve this problem.

The ingress of foreign liquids, especially oil, is the most common cause of a whistling alternator belt.

There is a proven repair method - wetting the belt with alcohol or, as a last resort, an inactive solvent mixed with water in a ratio of 1 to 2 (to ensure fire safety). Never use pure gasoline

Then you can let the engine run a little (a minute or two) so that the solvent lubricates the pulleys and rollers, since they can be sources of oil. Then you should find the source of the oil and fix the problem.

Pulley check

Distortion of pulleys is possible after an accident or repair of vehicle components. In a generator, the pulley may become dislodged as a result of wear on the rotor bushing. In this case, repair of the generator is necessary.

You can determine the skew visually by looking along the direction of movement of the belt drive.

The quality of pulley fastening should be checked immediately after routine or repair work on any components involved in the rotational movement of the generator belt.

Checking bearing wear

Wear of the bearings of the generator or pump, hydraulic booster, or rollers can cause these units to jam and cause a whistle. Sometimes the sound of a worn pump bearing caused by a leaking oil seal is mistaken for belt whistling.

This can be determined by antifreeze leakage in the pump area. You can only check whether the bearings are jammed by removing the belt. Next, check the “ease” of rotation of all pulleys and rollers (with the exception of the crankshaft).

Jamming of the generator is also possible, but this problem can also be identified by the lit battery light on the dashboard. By the way, this warning can also occur when the belt slips.

Specific reasons

Let's go over the specific reasons for the alternator belt whistling. Such problems arise only on certain cars and this is often due to the design features of the drive.

But we note that specific problems are only one of the causes of whistling, and you should not forget about the general ones.

Ford Focus 2

First, let's take the above-mentioned Ford Focus 2. On this car with 1.4 and 1.6 liter power units, the designers did not use a tensioner, considering that the attachment itself would do a good job of tensioning the belt. And this is true, but for now it is new and unworn.

During operation, the drive gradually stretches and this stretching on the Ford Focus 2 cannot be corrected in any way, since there is no tension roller.

Therefore, the whistling of the alternator belt on this car often appears due to insufficient tension of the element, and this problem can only be eliminated by replacing the product.

READ ON THE TOPIC: How to replace the Ford Focus 2 alternator belt.

On the same car, but with 1.8 and 2.0 liter engines, a tension roller is structurally provided, but on the restyled Focus 2 models there is a rather interesting technical solution - there is a roller, but it does not have a tension mechanism (instead there is a regular bracket, which the part is attached to the engine).

It turns out that there seems to be a roller, but it is useless, and when the belt is stretched, its tension will decrease and a whistle will appear. But this problem is completely solvable - pre-restyling models use a roller with a tension mechanism, which can be installed on the restyled version.

Otherwise, the reasons for whistling of the generator drive and working equipment on the Ford Focus 2 are the same as for other cars - dirt, ingress of technical fluids, wear of equipment bearings, etc.

Hyundai Tucson

Hyundai Tucson has its own specific problems, these include:

- The surfaces of the belt and pulleys are not worn in (the sound appears after replacing the first element). The whistle disappears on its own as the products rub against each other);

- Incorrect installation - the belt on this car is located along a complex path and covers many pulleys and rollers, so when replacing it is very easy to confuse the laying path and place the flexible element incorrectly;

- Worn bearing of the additional guide roller (parasitic).

If we add standard problems to this, then establishing the cause of the whistle on the Hyundai Tucson is not so easy.

Reno Logan

Reno Logan also has its own specific design features of the generator drive, which may cause a whistle to appear.

The first of them is the use of 6-groove pulleys, while the belt itself is 5-groove, and here when replacing it is very important to put it on correctly, otherwise the line of its position will be violated, in fact, a skew will appear, which is why a whistle will appear.

At the same time, with different numbers of attachments, the drive is installed in its own way.

On models equipped with power steering, the outer groove of the pulleys should remain unclaimed (the belt should be moved closer to the engine and components).

But in versions with power steering and air conditioning, on the contrary, the rivulets on the inside of the pulleys are not used.

The second feature is the absence of an automatic tensioning mechanism on models equipped with power steering. Therefore, on these Logans, when a whistle occurs, first of all, you should check the belt tension and, if necessary, tighten it.

Lada Priora has no specific reasons for the whistling of the generator drive, they are all common, but there are design features that are important to consider.

This car not only does not have an automatic belt tensioning mechanism, but also to adjust the tension you need a special key that turns the eccentric element, which is why the tension occurs.

POPULAR WITH READERS: The heated rear window does not work, we look for and fix the problem

If we take earlier versions of the VAZ, for example, 2114 or 2110, then their belt drives only the generator, so even the tensioner is not used (tensioning is done by displacing the generator itself). There are no specific reasons for whistling in these cars, they are all standard - incorrect tension, dirt, bearings, etc.

But on even earlier models - 2107 or 2108, the use of a V-belt alternator can be considered a feature. This type of drive is considered more reliable, but in terms of flexibility it is much inferior to a poly-wedge (multi-strand) drive, which is why it is not used on modern cars.

On these cars there is one specific reason for the appearance of a whistle - wear on the working surfaces of the pulleys. As a result, the belt sinks very deeply into the groove, which causes it to jam, accompanied by a squeal.

Causes of problems

If you have encountered a similar phenomenon, you have probably noticed that the belt begins to make an annoying squeak at moments of greatest load. The whistling sound accompanies the friction of rubber on metal as a result of slipping of the belt drive. In 90% of cases, this indicates wear of the belt, which is a consumable item and needs to be periodically replaced (interval from 20 to 60 thousand km, depending on the make of the car).

Now more about the reasons for slippage:

Practice shows that low-quality products and fakes whistle even at maximum tension. As experienced drivers say, the material contains more soot than rubber.

Whistling often occurs for other reasons that do not depend on the quality and technical condition of the belt:

In the design of some cars (for example, Chevrolet Niva), a belt drive additionally rotates the shafts of the air conditioning compressor, water pump and power steering pump. If the oil seal or bearing of any of the listed units fails and lubricant gets on the pulleys, the belt will begin to slip and squeak.

Reasons why friction occurs and a squeaking sound is made

So, for what reasons does the alternator belt whistle? We will now try to talk about this. According to many motorists, the main reason for the appearance of third-party sounds is wear of the element. However, this is not true in all cases.

As stated above, this is only partly true; we will talk about other reasons further:

- Often the problem with extraneous sounds is that the pulley on which the strap is placed is dirty with some kind of lubricant. This could be either motor oil or any other lubricant that got there accidentally during any repair work. As a rule, this problem occurs not only during startup in wet weather, but at absolutely any time. When the lubricant gets on the element, it ceases to provide normal adhesion functions to the surface of the pulleys. As a result, an unpleasant sound appears.

- Another reason is component sagging. When starting in wet weather this is most noticeable. By the way, this problem is one of the most common, so when it comes to whistling, motorists are always advised to check the tension or condition of the belt.

- If the element is too tight, it will be at its stiffest, which can also lead to noise. If this is the case, then the strap will not be able to transmit sufficient rotation to the pulley, as a result: all elements that rotate with the strap will make a whistling sound. As a rule, car owners encounter such problems in the cold season, because if the strap is hard, then in cold weather it will shrink even more.

- Another reason is bearing wear. If this component is worn out, then the consequence may well be the appearance of third-party sounds when starting the motor, since the bearing itself is part of the drive structure.

- And, of course, the last reason is the wear of the strap itself, which occurs when its service life is exhausted.

How does Alternator Belt Spray work?

Today, several manufacturers produce products for treating drive belts. One of the most popular and widespread is Keilriemen Spray from Liqui Moly. Products from other manufacturers have approximately the same composition and operating principle.

V-belt spray has several actions at once.

Thus, these products eliminate belt slippage and extend their service life. But sprays can only be used for V-belts. Timing belts cannot be treated with the agents in question.

Reviews

Motorists overwhelmingly respond well to V-belt sprays. The most common points noted in reviews are:

- these means really eliminate the squeak, even if the belt was already very worn and slipped with minimal load on the generator;

- some belts soften after processing, while others remain the same texture, but a sticky layer with a high coefficient of friction is formed on their surface;

- As an express solution, the product is the best option when it is not possible to quickly replace the belt.

Among the negative reviews, the most often noted is the contamination of the pulleys, the belt itself and attachments with a black sticky substance, which can only be washed off with solvent or gasoline. Therefore, the spray must be applied carefully and directly to the belt. You should also first check the belt tension. Applying the product to a loose belt will only give a short-term effect and will not be able to eliminate slipping for a long time.

You can recognize a certain type of malfunction in a vehicle by its characteristic sound. The most common problem, which even a driver without experience can identify, is the whistling of the alternator belt. Many people believe that if an unpleasant whistle occurs, it is necessary to immediately replace the belt. However, there are a large number of other reasons why the belt whistles and it is not at all necessary to replace it. Therefore, before replacing the belt, the driver must conduct diagnostics that will allow him to find the exact cause of the squeak.

Liquid for increasing the elasticity of the alternator belt

In car stores you can find many different “chemicals”, among which there is a special product for generator belts. Most often it is performed in the form of an aerosol, and its purpose is to protect the belt from cracking and increase its elasticity. Such products really have a beneficial effect on the alternator belt, and in many cases (with increased wear or poor belt tension) they allow you to get rid of its whistling.

Manufacturers of generator belt fluids recommend applying their products not only when the whistle appears, but also for preventive purposes earlier, to increase the service life of the element. Some packages with such “chemistry” indicate that it can double the service life of the alternator belt with regular use.

( 424 votes, average: 4.48 out of 5)

Source

How can I replace belt conditioner?

The products listed above are professional conditioners and generator belt tensioners (drive belts), which were developed for this purpose. However, many car enthusiasts, in order not to buy such products, use other available compounds. In particular, many are interested in the question of whether it is possible to lubricate drive belts with silicone grease or the well-known WD-40 spray?

As practice shows, these compounds can indeed be used to lubricate engine drive belts, but there are a couple of nuances here. The first is that the duration of their action is extremely short. In particular, the squeak will be eliminated for literally a few hours, or at best, days.

This is due to the fact that silicone lubricant , like WD-40 , softens the rubber, but leaves a greasy film on it that lasts a very long time. Accordingly, with their help you can get rid of rubber tanning, which leads to whistling, and displace moisture.

In the long term, it is not worth using silicone grease or a Vedashka. The fact is that due to constant forced softening, the rubber will soften excessively, and this will lead to stretching of the belt, reducing its service life and its complete failure!

There is another “folk” method for increasing the friction coefficient of a belt without increasing its tension force. So, for this they use rosin diluted in ethyl alcohol. The powder is dissolved in alcohol (used for soldering electronics). The solution should have a medium consistency, not very liquid, but not thick either. Next, this same solution must be applied to the inner surface of the belt. The method has been tested for years, and it eliminates the squeaking for several days. However, like the above remedies, rosin can only be used as a temporary means of eliminating extraneous noise.

Why does the belt whistle when cold?

The problem of whistling when cold can have several varieties. A squeak or whistle does not appear when the engine starts, but after a couple of minutes. This problem is easily diagnosed, since after the engine reaches operating temperature, the sound disappears.

The reason for the non-standard behavior of the belt is also hidden in its slippage. The torque transmitted from the crankshaft is not sufficient to spin the pulley. There are several reasons for this problem:

- Inaccurate selection of bearing lubricant for the generator. Due to the compaction of the lubricating fluid consistency at low temperatures outside, the generator pulley is not able to function as usual until the machine’s power unit warms up. At engine operating temperature, the lubricant will defrost and the unpleasant sound will disappear. The solution to the problem will be for the car owner to purchase a lubricant option that is more resistant to temperature changes outside the window.

- Weak tension. This situation is identical to the previous one. Until the engine reaches the required operating temperature, due to low tension, the belt is not able to perform its functions at the required speed and will slip.