Knocking, whistling and ringing of the engine. What to fear and what to watch

Today, when on-board electronics have become much more advanced, and the design of power units has become more complex, “listening” to the engine should nevertheless also be given increased attention.

First of all, you should be alerted to a strong knock and even a rumble in the area of the power unit.

It’s even worse when unusual sounds come directly from the cylinder block. Knocks can cause, for example, incorrect clearances in the valve mechanism. As a rule, the frequency of tapping increases in this case with increasing crankshaft speed. However, worn hydraulic compensators can also give similar symptoms. And, by the way, the “health” of compensators directly depends on the cleanliness of the engine oil. So often, by simply replacing the lubricant, for example, with a less viscous one, you can eliminate the problem of parasitic noise, since the lubrication of rubbing surfaces will be more efficient.

The characteristic ringing in the area of the power unit is also caused by incorrect clearances in the valve mechanism. Moreover, this “chime” becomes more rhythmic with increasing engine crankshaft speed. To fix the problem, use a valve spring tester to check the spring tension. In this case, it makes direct sense to take the car for service.

Many car owners are familiar with such an unpleasant accompaniment as a whistle from under the hood. In the vast majority of cases, this is a consequence of a worn alternator belt. As a rule, the problem manifests itself when starting the engine “in cold” or wet weather. It is very likely that the belt has become loose or damaged and needs to be replaced.

Also, the whistling of the generator belt can be caused by oil, water, dirt and grains of sand that have fallen on the surface of the belt. Under load, due to such contamination, the belt slips, hence the unpleasant whistle and squeaks. To make sure the diagnosis is correct, by the way, just spray the belt with WD40 lubricant. If the extraneous noise disappears, the culprit has been found.

However, ringing, grinding and metallic knocks can also be explained by loose engine mounts in the body and even simple damage to the exhaust system. Simply put, a burnt out or punctured muffler can, as they say, “cut.” It is not difficult to detect the damaged area, since a black spot quickly appears near the crack. Most often the problem occurs on pipe bends, along weld seams. In most cases, a complete muffler replacement is required, although sometimes repairing or welding the damage is sufficient.

Finally, so-called attachments can also produce parasitic noise in the area of the engine and exhaust system. For example, the power steering pump, generator, cooling system pump, or air conditioning compressor can shake and hum. The problem is solved by additional fixation.

In any case, if you observe one or more of the symptoms described above in your car, go to the service center. Delay in this case is fraught with serious technical problems and high repair costs.

Source

Engine mounts are a common problem in your car.

Engine vibration is quite strong, even if we are talking about a modern, technologically advanced power unit. Almost all the vibration is taken by the power plant cushions. These are products made of hard rubber that dampen vibration and absorb the main influences. They also make it possible not to transfer impacts to the body and chassis directly to the power unit. If one of the cushions is poorly tightened or fails, there may be a whistling, rattling or ringing sound. The solutions are as follows:

- carry out visual and functional diagnostics of the power unit cushions in order to identify any problems present; this is done in the same way as diagnosing silent blocks in your car;

- Next, check all the fastenings of the airbags, pay special attention to the lower fastenings of the power unit, which usually make a ringing noise when the installation and fastening elements are released;

- It is also worth checking the integrity of the rubber working parts of the cushions in order to obtain information about the performance of the engine cushions installed under the hood of your car;

- the next step is to select and purchase high-quality factory or analog parts for repairs, this will help replace non-working elements and eliminate problems with the car;

- After replacement, it’s worth checking and diagnosing everything again, since replacing the pillow will not always eliminate the sounds that you initially struggled with during the repair work.

It is worth remembering that it is better to change pillows at a service center. To do this, you will have to hang the engine on a winch so that it does not fall off the remaining mounts. After this, the pillow is unscrewed, visually inspected and replaced with a new one. It is important to align the engine correctly down to the millimeter, otherwise vibrations on the body and problems when the car turns sharply to one side cannot be avoided. It is better to entrust work with pillows to professionals.

Grinding, knocking or whistling noise when starting the engine

The appearance of extraneous sounds in the engine compartment during or immediately after starting the engine is a reason to diagnose and check the internal combustion engine. Various deviations from the norm can occur as a result of wear of individual elements of attachments, drives, bearings, pulleys or belts. Also, one should not exclude the possibility of breakdown of the power unit itself and its components. Drivers often notice that when starting the engine when cold, a grinding noise is heard, something creaks in the engine, a whistle appears, etc.

It should be noted that usually many sounds are better heard during a cold start, although in some cases the noise does not go away even after the power unit warms up. It should also be added that in some cases the problem progresses noticeably, that is, the sound gets stronger each time or gradually. In other situations, extraneous noise may not change its tone and intensity over hundreds or even thousands of kilometers.

In this article we will talk about what kind of breakdowns can lead to noise being heard during a cold engine start, as well as how and by what additional signs you can determine the malfunction yourself.

Possible repairs

What to do in this situation? The solution depends on the identified malfunction. A loose drive should be tightened. Kalina cars and other front-wheel drive VAZA models have a tension bolt that allows you to adjust the degree of belt tension.

To carry out the manipulation, loosen the fastening bolts, then tighten the adjustment bolt a few turns, achieving optimal tension. A correctly tensioned drive should bend no more than 1 cm under hand pressure. If this cannot be achieved even with the bolt tightened to maximum, the belt should be replaced.

If the pulleys become oily, the drive should be removed and the inside should be wiped with alcohol or gasoline. Pulleys are cleaned in the same way. If the belt has been in an oily state for a long time, it is recommended to replace it, since fuels and lubricants destroy rubber. Also, current seals and gaskets must be changed.

In cases where the alternator belt whistles “when cold,” repair is not required. It is permissible to slightly increase the belt tension. However, if the whistling noise disappears after warming up, this is not necessary.

If, as a result of diagnostics, it was revealed that the front bearing of the generator is whistling, it is replaced. To do this, remove the unit from the car, dismantle the front cover and, after removing the faulty bearing, press in a new one. This is also done when the pulley is skewed and the generator shaft is jammed.

A grinding noise is heard when starting the engine

If the driver turns the ignition key to the “start” position and at this moment a grinding noise is heard, and the noise disappears after the engine “cages” and starts working on its own, then the most common cause is considered to be a faulty starter.

If, when starting the engine, you hear the starter grinding whether it is cold or hot, then there may be several reasons for such a malfunction.

As a rule, it is necessary to check the solenoid relay, starter bendix and flywheel. The fact is that the bendix may not engage with the flywheel properly, resulting in a crackling sound or a characteristic starter grinding sound when starting the engine.

A whistling sound is heard when starting the engine

A whistling sound at start-up usually comes from the alternator belt or the cooling system water pump (pump). The malfunction manifests itself in the form of a high-frequency squeak or squeal after starting the internal combustion engine, and can also make itself felt already on a warm engine when you sharply press the gas pedal and increase the crankshaft speed.

To check the generator and/or pump, you can take a block of wood, you can also attach a tin can to the end of a wooden stick, etc. Then one end of the bar or stick is applied to the drive area of the generator or pump with the engine running, and the other end of the bar or a tin can attached to the stick is brought to the ear. This solution allows you to more accurately determine the source of noise and localize the fault. By the way, if possible, instead of a homemade device for listening to noise, you can use the so-called car stethoscope (sometimes a medical one is also used).

There is a knocking sound when starting the engine

The appearance of knocking in the engine should be divided into problems with the gas distribution mechanism and the elements of the internal combustion engine itself (crankshaft and CPG, pistons, connecting rods, crankshaft, etc.). Extraneous sounds in the timing area may indicate significant wear of the rollers, defects in the timing belt or chain.

The rollers may whistle, howl, crunch or tap. In some cases, the timing belt rubs against the protective casing. We also note that on motors with a chain, when the chain itself is stretched or the tension is insufficient, the sound resembles a rustling chirping, and popping noises can also be heard. If you increase the speed, such sounds disappear and appear again after releasing the gas. In this situation, the timing chain needs to be tightened or replaced.

On engines with hydraulic compensators, a common cause is failure of the latter or clogging of the oil supply channel to the hydraulic compensator. In this case, the sound is clear, clear, and can be easily heard in the valve cover area. Note that on many cars, after a cold start, the hydraulic compensators knock for several seconds until the engine oil reaches them. This is considered the norm. If the knocking does not go away after the engine warms up, then you need to contact a service center or solve the problem yourself.

Now about knocking in the engine itself. After starting a cold unit, you can hear the pistons knocking in the cylinders. The knock is dull, similar to hitting pottery. The knocking of the pistons is most pronounced at idle, as well as at low speeds under load.

The frequency of the knocking increases parallel to the increase in speed. Axial play of the crankshaft also leads to knocking sounds, while the sound is sharper and differs in that the intervals between knocks are uneven. It can be heard most clearly when the crankshaft speed changes smoothly.

When it comes to connecting rod knocking, a common cause is a problem with the connecting rod bearings. This knocking sound is sharp and can be clearly heard when you press the gas pedal sharply. During diagnostics, a knocking piston or connecting rod can be determined by turning off the spark plug on each cylinder one by one.

Strong and loud tapping

If, during sharp pressure on the gas pedal or under high load, strong knocking sounds with a characteristic ringing echo appear, then most likely this is a consequence of explosive combustion of fuel in the cylinders (detonation).

The main root causes of detonation are considered to be the use of low-octane or low-quality fuel. In this case, the problem will be solved if you add an additive (which increases the knock resistance of gasoline) or add high-quality gasoline.

Also, the source of such a knock can be a very overheated engine or an incorrectly adjusted ignition timing. To eliminate these unpleasant effects, it is recommended to adjust the ignition system and cool the engine.

What else can knock, make noise or whistle in the engine after starting?

As you can see, there are quite a lot of reasons for the appearance of knocks and noises. It should be added that when starting a cold engine, especially in winter, increased noise and chirping can be produced by the injection nozzles themselves on units with a pressure fuel injection system.

In some cases, this does not indicate any malfunction, since after a slight warm-up the noise intensity decreases or the extraneous sound completely disappears. A knock can also occur at the moment of starting in the cold due to heavily hardened ICE cushions (the engine is conditionally driven when the starter rotates slightly forward, and after starting it “bounces” back).

You should also not forget about the air conditioning compressor, especially if the engine is started in parallel with the air conditioning turned on or the climate control is activated immediately after starting. The compressor drive or the compressor itself is often the cause of extraneous noise.

The appearance of unnecessary sounds can also be associated with faulty gearboxes or clutch elements. For example, a hum after starting the engine may well come from a release bearing. It should also be taken into account that on many cars the gearbox is located directly in the engine compartment near the internal combustion engine. If it is the transmission that is humming, then this noise needs to be differentiated separately, since the engine and attachments in this case do not require additional diagnostics.

Source

see also

Comments 49

drop liquid into the fluid and it swallows air! All will pass…

thanks for the advice...i'll try it

I had a cooler riddle. there was a whistle in the summer. at speed. At first I reacted to the brake. then he stopped caring. then on the clutch, then he again didn’t care. then start driving. and again it didn’t matter. turned on the lift. specialists thought the bearing was genes. but the replacement did not help. which is not really surprising. After all, it never responded to gas at all. and the whistle was not like a belt whistling. but like a crooked wheel. I looked at the brakes 10 times. pulled the anthers. Everyone looked at the hubs. didn't find anything. the whistle disappeared with the onset of cold weather) and the car drove off, leaving me wondering if it was a hub, if so, which one? or a bearing in a box? Many people had it on the forums. appeared and disappeared. someone immediately found the reason (by replacing the hub at random). someone changed everything but the whistle remained. From then on I called it (the car) Talkative. there was always something making noise around her)

Unpleasant and incomprehensible sounds under the hood can arise for completely different reasons. There are quite obvious types of breakdowns that are very easy to diagnose. But sometimes even specialists have to spend quite a lot of time on diagnostics when it comes to rather complex and unusual problems. A whine under the hood when starting off occurs when certain rotating parts fail, lose lubrication, or develop certain other problems. But for a more accurate diagnosis, you will need to completely examine the engine compartment of the car, drive the car into a pit and get more important information about what exactly is broken in the car. You should also pay attention to the ringing under the hood when hitting bumps or when starting to move, when the engine experiences slight vibrations. These problems can signal some rather unpleasant breakdowns.

The main suspect is the attachment belt (drive belt).

The engine drive belt is the first thing you should check if you start hearing a whistling or creaking noise from under the hood. This can be either an intermittent or continuous unpleasant sound when the engine is running. As a rule, the serpentine belt makes noise when starting the car in the morning. The whistle usually continues until the car begins to move normally. But what is the reason for this whistling?

neglect to replace drive belts during maintenance , routinely changing only the timing belt or chain, forgetting about serpentine belts. Many car enthusiasts believe that a broken drive belt will not cause big trouble, unlike a broken timing belt, in which the valves can collide with the engine pistons, causing serious damage to the engine.

Therefore, very often car owners do not change drive belts until the last minute. But in some cases this is a mistake. The fact is that on some car models, a broken drive belt in the engine compartment can cause a lot of damage. For example, there are cars where the drive belt can get into the timing drive . In this case, the timing belt may burst, with all that follows (for example, the drive belt may get caught in the drive roller).

Let's sum it up

A difficult task for a car owner is high-quality vehicle repairs. Most likely, the car will not be able to function normally if everything is left without inspection and repair. Ringing and whistling will definitely show themselves in the near future, and you will have to spend much more money on repairing the problem that has arisen than on restoring machine parts today. It is better to react quickly to emerging problems and not wait until they turn into real troubles. One of the best options today is a trip to a service station to diagnose problems with your car.

You can independently conduct a qualitative study of the vehicle and obtain information about which parts are causing problems. Most likely, even with a quick diagnosis, you will be able to understand which components of the power plant or peripheral equipment are causing the unpleasant ringing or whistling. But as the trip continues, completely unpleasant scenarios may arise. Ripping belts or cushions can have extremely expensive consequences. It is better to fix the problems today, paying relatively little money for it. Have you ever had problems with an incomprehensible whistle from under the hood?

The big problem is the pulleys

Replacing the drive belt is usually inexpensive. The belt itself is cheap. The job won't empty your pockets either. By the way, depending on the engine, there are cars that have two drive belts. In this case, you will have to pay twice as much money to replace the belts. Of course, the final cost of replacing belts will be affected by the make and model of the car. On average, prices for replacing drive belts start from 800-1000 rubles. Replacing the belt tensioner roller will also cost about 800 rubles. As you can see, this is not a problem.

The real cost for a car owner begins when it's time to replace the pulleys. The main pulley is mounted on the crankshaft. Fortunately, it wears out very rarely unless equipped with a torsional vibration damper. But if the pulley wears out, prepare a round sum, since the cost of replacing it will unpleasantly surprise you. Most often it is necessary to change the alternator pulley, power steering pump pulley and air conditioner.

Signs of alternator pulley wear

After starting the engine, sometimes the alternator belt does not creak, but after turning on the electrical equipment, a whistling or squeaking noise begins. This may be a sign of wear on the alternator pulley. It may also indicate problems with the alternator and battery. Replacing a generator pulley can cost from 2,000 to 6,000 rubles. By the way, this work already relates to rebuilding the generator. Nowadays, generators are increasingly equipped with a pulley with a vibration damper.

Signs of wear on the air conditioning compressor pulley

The same applies to the air conditioning compressor pulley, which begins to squeak when starting up. When the compressor is turned off, the squeaking noise stops.

Signs of wear on the power steering pump pulley

The power steering pump pulley is the easiest to check. To do this, turn the steering wheel all the way to one side with the engine running, making several deep turns over and over again. Naturally, this needs to be done when the car is stationary. If, when you turn the steering wheel all the way, you hear a whistling or squeaking sound, then it is quite possible that there is severe wear on the power steering pulley or the power steering pump bearing. Also, a similar sound can appear when the belt that transmits torque to the power steering wears out.

The rollers and tensioner may be to blame for squeaks or whistles under the hood. That’s why they always need to be replaced as a set, so that all drive components in the engine compartment serve equally. Also, when purchasing rollers and tensioners, try to purchase parts from the same manufacturer.

Debugg

Once the root causes have been identified, the troubleshooting process can begin directly. We stock up on time and tools. Now that everything is collected, we can begin. It is worth being prepared for the fact that parts will be required.

It is worth noting that for each specific make and model of car, the design features of the repair and location of parts will be different.

Therefore, it is recommended to first review the technological maps and study the design. Moreover, it is best to have a repair manual for the vehicle that will be restored.

Drive belts

Typically, a whistling sound in the engine, especially during a cold start, is associated with belt drives. Thus, a stretched belt slips along the pulley, which creates a characteristic squeak. Often, this effect is characteristic of the timing belt on newer cars. There are two ways to troubleshoot the problem.

The first way is to tighten the belt (only for cars with a belt and a tension pulley). To do this, you will have to dismantle the protective casing that covers the timing belt, and then tighten the drive using a tension roller. Sometimes it happens that the belt is in a very worn condition and requires replacement.

The second way is to replace the belt. Replacing the timing belt is a rather complex and time-consuming task. Therefore, it is recommended to carry out this operation at a professional car service center. Many motorists, unknowingly, when replacing the drive belt, knocked out the valve timing, which subsequently brought with it serious consequences for the power unit, such as major repairs.

For different car manufacturers, the timing of replacing the timing belt will be different, but the average indicator is that the element must be replaced after 40-50 thousand kilometers.

The process of replacing the timing belt is quite simple, but at the same time difficult to complete without knowledge of the design of the vehicle, as well as repair methods. So, let's consider the main provisions for replacing the timing belt:

- To begin with, VTM labels are set. This is necessary in order not to disrupt the valve timing when replacing the belt.

- The camshaft or shafts are fixed on pulleys to prevent rotation. There is a special tool for carrying out this operation, but as practice shows, motorists carry out fixation using improvised methods.

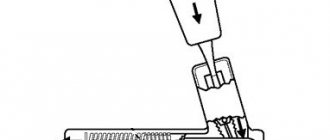

- Next, loosen the belt by unscrewing the tension roller.

- If necessary, on some car models, the crankshaft pulley is removed.

- Remove the belt from the seats.

- Typically, assembly of the unit is carried out in the reverse order. For many American cars, there is a specific sequence for installing the timing belt. Therefore, it is recommended to study the manuals before replacing.

Rollers

Together with the timing belt, the whistling noise may be caused by a worn tension roller. This is because the belt slides over the part, creating a whistling sound. The car rollers are replaced along with the timing belt.

On some cars, the rollers can be replaced without removing the drive belt. It is worth remembering that when changing an element, it is necessary to adjust the tension of the drive belt, because if this is not done, then very soon the whistle will appear again, and the belt will be subject to increased wear.

water pump

Many Lada owners are familiar with the whistling sound that appears after starting the engine when cold and disappears after warming up. This effect was caused by faulty pump parts. In both older and newer car models, the whistling effect can be caused by the water pump.

As with the timing belt, a squealing noise can be caused by a worn water pump belt. On older domestically produced cars, the pump is driven from the crankshaft pulley, while the gas distribution chain operates on a circuit installed directly in the block. For newer cars, the pump is part of the timing belt drive.

Let's consider this variant of the occurrence of a malfunction only for the old generation of vehicles. To eliminate the problem, you will have to determine where exactly it comes from. To begin with, you can change and tighten the drive belt. Tension adjustment is usually carried out using a generator.

Before dismantling the pump and understanding the internal elements, you should pay attention to the condition of the drive pulley. During operation, this part could become deformed and cause a lot of problems. Therefore, first we examine it for deformations and position.

If the whistle does not disappear after changing the belt, then we go even deeper. In this case, it means that the whistle comes from inside the structure. What could make such a sound? Depending on the design features of the car model, a worn bearing or water pump drive shaft may whistle.

What if it's not a belt or pulleys?

Sometimes squeaking and whistling noises are not related to drive belts, rollers, attachment pulleys and tensioners. For example, extraneous noise in the engine compartment can be caused by an engine cooling fan. It is quite possible that the clutch in the fan has fallen off.

Also, squealing can (rarely) be caused by any timing drive components . Usually these are other sounds - buzzing, shuffling sounds or metallic noise. However, if this particular area is the last suspected source of extraneous sounds in the engine compartment, the problem should be corrected as soon as possible. Remember that even a faulty timing belt tensioner can contribute to engine failure.

Source

Timing belt

Let's go further and consider the timing belt as a possible cause of whistling and rattling. Note that the belt itself cannot whistle, but the whistle can come from the rollers and tensioners. Determining that the sound comes specifically from the timing belt is quite difficult. At a minimum, you can start the engine and just listen to the place where the belt is. If the whistle is pronounced and comes from this particular node, then you need to go to the service station. After all, you won’t be able to do anything on your own. As already written above, the problem here is not in the belt itself, but in the system, and simply replacing the timing belt will not achieve anything.

Causes and ways to eliminate whistling from under the hood

Many faults in a car can be determined by sound. When some extraneous noise appears in the form of an incomprehensible knock, grinding, howling or whistling, this may indicate a breakdown of one of the car components. Some malfunctions are quite easily eliminated along with accompanying symptoms in the form of annoying and disgusting sounds. But there are certain signs of breakdowns that appear most often. Most often, a whistle is heard when starting the engine, which can be caused by a number of factors. Moreover, similar unpleasant sounds can occur even when the engine is already running. Next, we will talk about the causes of such phenomena and ways to eliminate them.

The knocking noise occurs when there is no obvious failure of parts

The reasons for this type of knocking are associated with high loads, insufficient oil viscosity, as well as misalignment or jamming of one of the parts. If the engine parts have not yet developed any obvious damage, the unpleasant sound disappears after removing the critical factors. Often, to eliminate knocking, it is enough to check the oil level - insufficient lubrication quite often provokes deformation of parts that cause knocking.

Engine whistling when starting and running

It's always nice to know that your car is in full working order and will not cause inconvenience at the most inopportune moment. However, this does not always happen and many car owners are faced with a number of manifestations of failure of some car parts. This makes people doubt their “iron horse”, and such a car will clearly not add positive emotions. The most common signal of a breakdown is a whistle when starting the engine. Moreover, it is faced not only by owners of old cars, but also by practically new ones that have recently left the dealership.

The reason why a whistle is heard when the engine is running can be a number of different malfunctions in the car engine. Usually this is not so much a dangerous sign as it is annoying. Although, if the engine begins to make such extraneous sounds and the engine whistles more and more, then it is clearly impossible to delay the elimination of this problem. Some ignored faults can lead to expensive repairs and a host of problems.

Belts

One of the main reasons for whistling when starting the engine is the belts of various drives in the engine compartment of the car. Poor tension and wear lead to the appearance of that same annoying whistle, which can intensify with increasing engine speed. Or, on the contrary, it may disappear when you press the gas pedal. In any case, the sound made by the belts is very audible and impossible not to notice.

Why does the engine whistle?

Author: Sochi Auto Repair

During the operation of a car, situations inevitably arise that alarm the driver. One of these problems is the annoying whistle of a running engine. Why does the engine whistle? The problem is not the most serious, but it prevents the driver from concentrating on the road and distracts him from the process of driving.

Drivers often turn to specialists at service stations with the same complaint - a low, annoying whistle that occurs when the gas pedal is pressed, persists while driving, and then slowly stops after the gas pedal is released, and this cycle is repeated every time the pedal is pressed. . Usually only the driver of the car reacts to this whistle.

Why does the engine whistle?

If a car enthusiast understands at least a little about the material part of his car and feels it, he can fix this problem on his own.

The main signs of a whistling engine sound:

- the whistle starts when the gas pedal is pressed;

- the whistle is very quiet and can be heard in the absence of other sounds in the cabin;

- after releasing the gas pedal, the whistle subsides;

- Usually this sound remains unnoticeable for a long time and “appears” somehow completely suddenly;

- such a whistle is not heard outside the car, and passengers do not notice it at all, since they do not feel the connection between the occurrence of the sound and the pressing of the gas pedal;

- In timbre, this sound resembles a “human” whistle and differs significantly from “squealing”, “howling”, “creaking” and “grinding”.

Why does the engine whistle? First, you need to exclude possible sources of the problem with a similar sound. First of all, problems with the brake pads are eliminated, because their “squealing” occurs when you press the brake pedal (or gas pedal + brake pedal).

All problems with belts located under the hood next to the engine are also eliminated.

Belts are the main source of whistling sounds under the hood, but their tone and intensity are completely different. The belts begin to whistle while the engine is warming up. Their problem is slipping relative to the driving and driven rollers.

The moment you press the gas, the belt comes into unison with the rollers, normal operation begins and the whistling stops. It is simply impossible not to notice the whistle emitted by the belt - it is very loud and annoying. The issue of quiet and monotonous sound is also discussed here.

The third possible source of sound why the engine whistles is rollers and bearings. During operation, these parts wear out a lot and begin to “sound,” but they produce sounds of a different type - low, howling. The rollers and bearings begin to “howl” even at idle speed; after pressing the gas, the sound intensifies, but then subsides.

For an experienced technician, the difference between a “howl” and a “whistle” is obvious, especially if a professional is repairing the machine.

After analyzing all the symptoms and options, eventually a good auto mechanic will realize that the source of the problem is the engine intake system.

Eliminating the causes of a whistling engine sound

If a whistling sound is localized at the intake, it is necessary, firstly, to carry out maintenance on the throttle valve - it must be cleaned.

Constant use of the throttle valve leads to severe contamination of the moving parts and, as a result, to “jamming” in certain positions. Because of this, the air, passing under pressure through the damper, begins to whistle. Sometimes, to eliminate the sound, it is enough to simply rinse the damper thoroughly. However, we must remember that in order to properly clean the throttle assembly, it must be removed and completely disassembled.

This is a useful preventive procedure, but it does not always eliminate the whistling.

Therefore, it is necessary to focus on the next device in the intake system - the PCV valve. It is responsible for recirculating crankcase gases. When the engine is running, the air pressure in the crankcase increases due to the movement of the cylinder pistons and heating of the air. Hot air requires additional outlet, otherwise the high pressure will squeeze the oil through the oil seals and any seals. It is impossible to replace the valve with a regular ventilation hole - this may lead to incorrect formation of the air mixture at the inlet.

To understand why the engine whistles and where the whistle comes from, it is necessary to consider the valve design. The valve body has a piston pressed by a spring on the air outlet side. If the engine is turned off, the valve is closed. When the required crankcase gas pressure is reached on the valve, the spring moves, allowing gases to enter the intake system.

If the spring is contaminated with used oil, the valve stops closing completely. Air begins to flow into the resulting gap, producing a quiet whistle.

When you press the gas pedal, the throttle valve opens and air enters the rarefied atmosphere of the intake manifold. It is the vacuum that causes air to be drawn in and a whistle to appear.

When the PCV valve is completely stuck, oil leaks into the intake manifold. The presence of oil stains is a signal to clean the valve.

Simply cleaning the valve will help get rid of the whistling noise.

A simple method for cleaning the valve:

- remove the valve (located on the valve cover or on the crankcase ventilation tube next to the air filter);

- find out what material the valve is made of. If the valve is metal, then any cleaners (aerosols, liquids, pastes) can be used. The main thing is not to scratch the surface. Cleaning sequence: treat the surface, move the valve. Repeat until complete freedom of movement. To clean the plastic valve, do not use too aggressive liquids (the housing may be damaged);

- After cleaning, put the valve back in place.

As a result, after the measures taken, the whistling should stop. If auto mechanics have checked the brake pads, belts, bearings, rollers, and other mechanisms and confirmed their serviceability, then cleaning the valve will help rid the engine of annoying and irritating whistling.

We found out why the engine whistles, as long as our brains don’t whistle!

Did you like the article? Share with your friends on social networks!

Source

What should you do if you hear a whistle coming from under the hood?

We have listed all possible malfunctions in which the motor and its components may whistle when starting the engine or during its operation. To eliminate most of them, the car owner does not need to have any special professional skills. You can handle replacing many belts and rollers, tensioning them, as well as cleaning the elements of the intake system yourself. But if you are not sure that you can cope with such problems, then it is better not to delay them, but contact a car service center to the experts in their field and then you can avoid much more expensive repairs and a lot of unnecessary troubles that can overtake you taken by surprise.

Source

Alternator belt whistles in the rain

Fog, high humidity, rain are ideal conditions for the V-belt drive to whistle. For obvious reasons, moisture gets on the surface of the belt and reduces the frictional ability of the material, as well as on the pulleys. Wet whistles are short-lived, but you shouldn’t relax. This means that the belt has already begun to lose elasticity and should be tightened if wear allows.

In wet weather, the frictional abilities of the alternator belt material are reduced

In any case, belt slipping indicates a malfunction in the belt drive, and rain or splashes are simply an indicator that the belt may need to be replaced soon. To avoid such problems, let the small, cunning Americans from the Hi-Gear company come up with a remedy that can temporarily save you from whistling. Let's say a few words about him.