Lada Granta cars are equipped with a clutch of the same system as the Lada Kalina. Reliable, correct operation of the clutch ensures correct gear shifting and allows the car to move smoothly. If the system malfunctions, the car moves jerkily, and the driver experiences problems when changing gears. The problem can be resolved by replacing the clutch with a new one. You can do this yourself with a special mandrel for centering the clutch disc and some repair skills.

Replacement is carried out in the following order:

- The car is placed on a lift and the gearbox is removed;

- If there is no need to change the basket, marks are made on the flywheel with a center punch;

- The six bolts that hold the basket in place with an “8” key are unscrewed;

- The basket is removed from the flywheel and the driven disk;

- Next, the release bearing is removed. To do this, use a flat-head screwdriver to remove the spring that holds the bearing;

- The release bearing and clutch are removed from the guide sleeve;

- The spring holding the release bearing is removed;

- If there is a need to change the clutch fork or its bushing, use a screwdriver to pry off the rubber boot;

- The fork bushing is pulled out from the clutch housing;

- The clutch fork is removed from the seat and removed from the clutch housing by lifting it up. If the need arises, we replace it with a new one;

- The clutch is assembled in the reverse order of removal. Before this, all removed parts must be washed with kerosene;

- Next, “CV joint-4” lubricant is applied to the bushing guide and the splined part of the input shaft;

- All removed parts of the clutch housing are installed in the reverse order of removal;

- To center the clutch, you need to use a mandrel that is inserted into the hole in the end of the crankshaft;

- After this, the driven clutch disc is placed on the mandrel, with the side where the hub protrudes larger directed towards the gearbox;

- Next, the basket is installed;

- We align the marks made before disassembly and tighten the bolts;

- The centering mandrel is removed and the gearbox is installed in place.

After replacement, you should check the operation of the clutch drive. If everything is done correctly, gears will shift without crunching and clearly, and the car will move smoothly, without jerking or beating.

This completes the replacement of the clutch on the Lada Granta. This work is not difficult to perform, but if you have absolutely no experience in carrying out this type of operation, then it is better to do it with a person who has already replaced clutches on cars.

Why has the clutch pedal become stiff?

If the car is completely new, then the so-called drive wedge may have occurred.

This is the easiest fault that you can adjust yourself. But if we are talking about an older car, then perhaps the problems are more serious and affect the entire unit. Most often, such problems occur due to poor performance of the diaphragm spring. It is possible that the fork is jamming or the bearing being pressed out is jammed. Cable scuffing often occurs. The driven disk itself may also become jammed.

If the car is in use for a long time, then cracks may appear on the drive fork. You also need to understand that over many years of driving a car, a large amount of dirt could simply accumulate in this unit.

Sequence of actions when removing and replacing the Lada Granta clutch with cable drive

- After removing the manual transmission (the process is described above), we mark the location of the basket and flywheel with marks. In the event that we do not plan to replace the basket or pressure plate. The decision is made by the repairman based on the diagnostic results.

Removed manual transmission

- Unscrew the bolts and remove the basket with the pressure driven disk.

Cart with disc

Note to the driver!!! We loosen the tightening of the bolts evenly, according to the diagonal principle, one turn of the key.

- Remove the discs from the clutch basket.

Removing a disc from the bin

- We carry out troubleshooting of parts, adjacent mechanisms and elements.

What to pay attention to when troubleshooting:

- cracks, breaks in parts;

- depressions of more than 0.2 mm;

- check for cracks on the diaphragm spring;

- We inspect the support rings; there should be no signs of wear, visible or obvious defects on them;

We replace worn elements with new ones as necessary.

How to replace a release bearing - step-by-step instructions

The entire bearing replacement process is outlined below, supported by photographs for greater clarity. To replace you will need: a new release valve (suitable from Priora, but you will have to trim the “ears”); pit or lift; set of tools.

1. Work is performed on an inspection pit or on a lift. We unscrew everything that may interfere with hanging the box (protection, hanging cables, etc.).

2. Unscrew the bolts securing the box and disconnect it from the motor.

3. We hang the box on ropes without removing it completely and without disconnecting the CV joints.

4. Remove the retaining spring, then remove the faulty bearing from the guide bushing.

Reassembly is performed in reverse order; during assembly, do not forget to lubricate the shaft on which the release bearing sits. If the replacement process is not described in sufficient detail for you, you can read a more detailed report

Replacing the release bearing Kalina 2, 1118, Cross, Sport

To make a replacement you will need to put your car on a pit or a lift. Repairs are also possible if you have reliable supports and a jack. It is worth noting that without a pit or lift, the replacement method without removing the box, which is described at the end of the article, is suitable.

How to remove the gearbox and release bearing on Kalina 2 (1.4-1.6 8kl) with your own hands

Replacing the release bearing on a Lada Kalina begins with dismantling the gearbox; this process is described in detail in step-by-step instructions with photos/videos. Perform the operations in order.

- Open the hood of the car and immediately remove the battery.

- Next, remove the air filter by unscrewing the clamp and disconnecting the fastenings to the body.

- The clutch cable is located behind the battery; you need to unscrew the nut and disconnect the cable from the fastener.

- Now disconnect the plug of the speed sensor wire, it is located behind the “engine”, in the area of the pipes.

- Next, find the upper bolts securing the gearbox to the engine and unscrew them.

- The last operations on top of the gearbox are unscrewing the starter and its terminals, as well as disconnecting the clutch cable and electrical wiring.

- Remove the front wheels and tighten the hub nuts. We disconnect the protection (mud flaps) under the wing.

- Immediately disconnect the terminal of the reversing lights wire.

- Nearby there is a suspension beam, first twist the rear nut with a 24mm wrench.

- Now we move on to the ball joints, loosen the nuts and remove them on both sides.

- On the same side of the manual transmission we find the oil drain plug, unscrew it and drain it into any container.

- Between the manual transmission and the engine there is a clutch protective cover. To remove it, unscrew the nuts around the perimeter.

- Let's move on to dismantling the gearshift mechanism. First, unscrew the two bolts and remove the cover.

- Then unscrew the screw that secures the linkage connection.

- The next step is to remove the wheel drive shafts from the gearbox on both sides.

- Let's return to the suspension. On the manual transmission side, it is necessary to unscrew the bolt securing the lever, and also disconnect the extension.

- Next, to remove the gearbox and replace the release bearing of the VAZ Kalina, unscrew the lower bolts securing the gearbox to the engine, as well as the front cushion. Before doing this, be sure to install a support under the engine.

- As a result, the housing of the high-speed unit (MKPP-2181) will be completely disconnected from the mating units, and it can be dismantled. First, use a sharp, wide screwdriver to separate the assembly from the engine.

- Then we manually dismantle the assembly. It is advisable to use a special telescopic stand or ask a partner for help, since the gearbox is not light. After removal, we proceed to replacing the release bearing on the Lada Kalina with our own hands.

How to change the release bearing on Kalina - step-by-step technology

The clutch release bearing for Kalina 2, 1118, Cross, Sport (including 8 valves) is located in the crankcase (see photo at the beginning of the article), to remove the old “releaser” follow the instructions.

- First, use a screwdriver to remove the coupling spring, after which the VP will be removed from the shaft without difficulty.

- Next, inspect the fork, check for smoothness, absence of radial and axial play, as well as runout. If the fork is in working condition, then check the input shaft on which the VP is located: splines, seating surface. No nicks, cracks, or corrosion are allowed.

- After checking the unit, if the condition is normal, the coupling should be replaced. In reverse order, put the coupling on the shaft (the ear should mate with the fork without distortion). Secure the spring and check the smooth operation of the mechanism.

- When the new clutch release bearing is installed on Kalina, you can begin installing the box. The operations are performed in reverse order. To lift the gearbox to the power unit, it is recommended to use third-party assistance or a telescopic transmission stand.

How is the clutch adjusted?

So, how to properly adjust the clutch? The clutch of the modern VAZ model family has a clutch cable, along with which there are ratchet mechanisms in the structural unit. These cables do not provide for any clearance, which in theory does not imply the need for adjustment. However, the manufacturer insistently recommends performing periodic adjustment procedures on this mechanism.

To perform the adjustment on these cars, including the Lada Granta, you should stock up on a ruler (a caliper is also suitable) and a screwdriver.

The sequence of manipulations looks like this.

- Open the hood of the Lada Grant and install the clutch cable in its original position. To do this, move its lower edge forward until it stops. By moving the cable, you can feel the force created by the return spring. We do not pay due attention to this aspect and continue this manipulation.

- Taking a ruler or the same caliper, we measure the distance. The photo clearly shows the segment to be measured: between the beginning of the fork and the cable lead. For correct measurements, you will need to keep the cable in a stationary and certain position. The ideal measurement result would be 27 mm. When clutch adjustment is required, the actual parameter will differ from the stated standard. To achieve the required value (27 mm), rotate the cable lead.

- Having completed this action, insert the cable end into the groove of the fork, and then release the retained element. Please note that there is no gap.

- This completes the procedure. Now we move on to pressing the pedal multiple times to make sure the unit is functioning correctly. After completing a set of presses, we once again measure the distance along the cable and, if discrepancies appear, perform repeated adjustments.

The need to adjust the cable on Lada Granta, Kalina or Priora occurs regardless of its condition (new or has already spent a certain amount of service life).

When does the need for adjustment occur?

In such cases:

- when there are jerks from the start that are permanent;

- when an attempt to engage a gear is accompanied by a blow;

- if the pedal is stuck.

These are the most striking symptoms indicating the need for adjustment. Ideally, the level of the pedal should coincide with the brake. In this case, the full pedal travel is 125 - 135 mm. Practice shows that the stroke can be exceeded by up to 160 mm.

To properly adjust the pedal assembly, you will need to stock up on two wrenches with suitable parameters.

- Loosen the locknut holding the cable. It is located on the engine compartment side.

- Now use a wrench to rotate the second locknut to achieve the correct clearance.

- Upon completion of the process, be sure to tighten the first nut to the required torque.

Attention! If the pedal is adjusted with its position below the brake, then the moment the clutch engages will occur when the pedal itself “lifts” from the floor. When the level is above the brake pedal, seizure will occur at the end of the stroke.

We remind you that efforts should be made to achieve a uniform level in the pedal assembly (the author of the video is Time R).

How to check the clutch?

The clutch is checked using already proven and reliable folk methods, and only by them. Naturally, in addition to disassembling the clutch. We are talking about how you can check the clutch of your car yourself, and then decide whether you need a more in-depth diagnostic with dismantling the clutch mechanism.

So, let's start checking the clutch on the main points.

Clutch slippage. Those. again we are talking about wear on the driven disk when it is not fully pressed against the flywheel, which means there is no full clutch.

- We put the car on the handbrake and start the engine;

- engage a higher gear: 3rd or 4th;

- slowly depress the clutch and “give” the gas;

- When the handbrake is adjusted, the car engine should stall. If this does not happen, then it is time to think about replacing the clutch disc.

The clutch “drives” , i.e. it doesn't turn off completely. This malfunction is accompanied by difficult gear shifting, or extraneous noises and sounds when changing gears. And the gearbox is hardly to blame here. Checking the clutch.

- the engine is idling;

- Depress the clutch pedal completely and engage first or reverse gear;

- If the gear is engaged with uncharacteristic effort, and at the same time you hear extraneous sounds, then the driven disk does not completely move away from the flywheel, i.e. the clutch “drives”;

- you need to pump the hydraulics and adjust the free play of the clutch pedal;

- check again, if nothing has changed, then it’s time to go to a car service for a more in-depth diagnosis of the clutch.

Using these simple methods, you can independently check the clutch before it fails at the most inopportune moment. Timely diagnostics, and even better - correct operation, will increase the life of the clutch, or take timely measures to eliminate malfunctions.

Tips, tricks and useful repair videos

1. Follow general recommendations for transmission operation to increase service life.2. Service life is 80-100 thousand pedal cycles, do not press or hold the clutch unnecessarily.3. Before installation, generously lubricate the new VP.4. Removing a manual transmission is a time-consuming operation (2 hours), so it is recommended to immediately troubleshoot the disk, fork, flywheel, and also replace the cable if necessary. 5. Do not purchase spare parts at the car market or other dubious retail outlets.6. Watch useful videos on repairing, replacing clutches and more!

1. Clutch Lada Granta and its possible malfunctions

2. Adjusting and replacing the clutch cable on a Lada Granta

3. Operations for adjusting the clutch cable Lada Granta

4. How to eliminate squeaks and clicks in the Granta clutch pedal

Lada Granta clutch and its possible malfunctions

The car has a clutch from the Lada Kalina model. The clutch is a flywheel on which a basket is attached. The basket constantly presses the clutch disc, and it is due to this that torque is transmitted to the gearbox from the engine. When you press the clutch pedal, a metal cable connected to the clutch fork is stretched. The petals of the basket are wrung out and stop pressing the disk towards the flywheel, while no torque is transmitted from the engine.

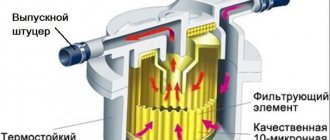

Here is a drawing for reference only, with the design of the Lada Granta clutch.

Clutch and its drive: 1 - metal clutch drive cable; 2 — cable sheath; 3 — lower tip of the cable sheath; 4 — protective cover; 5 - leash; b - fork lever; 7 — bearing guide sleeve; 8 — clutch release bearing; 9 — clutch casing; 10 — pressure spring; 11 — pressure (drive) clutch disc; 12 - flywheel; 13 — friction linings of the driven disk; 14 — driven disk; 15 — damper spring; 16 — torsional vibration damper; 17 — driven disk hub; 18 — spring; 19 — toothed cable tip; 20 — housing of the automatic cable length adjustment mechanism; 21 — spacer sleeve; 22 — cable sheath bracket; 23 — clutch housing; 24— gearbox input shaft

The clutch does not need adjustment throughout its entire service life.

Clutch malfunctions of Lada Granta

The table below shows possible clutch malfunctions of a Lada Granta car and methods for eliminating them. For more detailed information about the operations carried out to repair the machine’s clutch, see the individual articles in the category.

Adjusting and replacing the clutch cable on a Lada Granta

On a Lada Granta car, the clutch is disengaged and engaged by changing the position of the clutch paddles. The petals are pressed out using the clutch bearing, which is moved by the clutch fork. The clutch fork, which is actually a lever on an axle, is driven by a metal clutch cable. This article provides information on replacing and adjusting the clutch cable on a car.

Tools required to replace and adjust the clutch cable: 8 mm wrench, ruler, flat-head screwdriver

Clutch box design "Lada-Grants"

On this car, this unit is no different from the one installed in the Lada-Kalina. This is a mechanism consisting of a flywheel on which a special basket is attached. It must constantly press the disc with the friction linings. Thanks to this, torque begins to be transmitted to the transmission.

When we talk about a cable-type clutch on a Lada Grant, in this case it means that when the car owner presses the pedal, the cable that is connected to the clutch fork is tensioned, and special petals stop pressing the disc. Accordingly, the torque from the power unit is no longer transmitted to the gearbox.

There is only one clutch disc on the Lada Grant. This unit itself is a friction unit, equipped with a diaphragm-shaped spring. The clutch is combined with the gearbox in one housing.

Finalization

Purpose: install a gasket between the clutch cable and the gearbox fork

Procedure:

- Remove the clutch cable end from the fork.

- Unscrew the cable end, having previously measured the length of the free threads.

- Remove the clutch cable boot.

- Remove the rubber insert from the cable stop (photo No. 1).

- Instead, install a round washer made of porous rubber (diameter 32-35 mm, hole 12-13 mm) (photo 2).

- Cut a piece of rubber measuring 20x70 mm, 2.5-3 mm thick.

- Glue it (for example, with “Moment” glue) to the plastic cable stop (one turn), secure with electrical tape 1.5 turns.

- Insert the cable into the bracket on the gearbox and put on the boot.

- Screw on the tip, leaving a couple of millimeters less free threads on the stud (since the new gasket is thicker than the factory part).

- Place a 2 mm foam rubber spacer between the cable tip and the fork lever.

- Adjust the clutch pedal.

As a result: the effect was noticeable immediately. Now the rattling can only be heard with the windows open. After modifying the clutch cable fastening, the car drove more than 15 thousand km, the gearbox noise was within normal limits. Increased vibrations and noise are noticed only at a temperature of -20 o C, when the rubber gaskets become hard. The author has posted sound files (engine acceleration-braking mode at 1500-2000 rpm in 3rd gear), which shows what the noise was from the gearbox before and after modification. Site users can download the file:

Preparation for repair

To remove and subsequently replace the clutch, prepare a set of tools consisting of:

- center punch;

- extension cord;

- funnels;

- heads (8, 10, 15, 17, 19 and 30 mm);

- high head (13 mm);

- heads Torx E12 and Torx E14;

- Phillips and flat screwdrivers;

- pliers;

- curved spanners (8 and 13 mm);

- straight spanners (17 and 19 mm);

- two adjustable stops;

- metal brush;

- ratchet wrench;

- caliper;

- stands;

- hammer;

- jack;

- balloon wrench;

- torque wrench;

- centering mandrel.

In addition, you will need to apply certain parts and consumables. So, you will need CV joint-4 lubricant, a guide pin M12×1.25 mm, transmission oil, wood blocks, a technical container, a hose, rags and the clutch itself.

Preparatory stage before replacing the clutch on the Lada Grant

Necessary tools, materials:

- set of car keys, sockets, ratchet;

- extension;

- calipers;

- additional lighting;

- screwdrivers with a set of bits;

- mounting blade;

- pliers;

- hammer;

- metal brush;

- hydraulic (mechanical) jack;

- cylinder and torque wrench;

- graphite-based lubricant “CV joint-4”;

- container for draining waste;

- 6 liters of gear oil;

- clutch assembly;

- wooden spacers;

- rags.

How to replace the cable in the clutch mechanism?

How to properly replace a clutch cable? Below are detailed aspects of the instructions to successfully replace the cable.

- First, we begin to unscrew the cable nut from the bracket, which is located under the dashboard. We perform this action using the key set to “8”, after which access to dismantling the bracket stop appears.

- We disconnect the locking bracket, which is located on the “finger”.

- Next, remove the body of the compensation device (use a screwdriver).

- We remove the fluoroplastic bushing from the pedal pin.

- We visually monitor the assembly element for wear. If such “artifacts” are present on the surface of the bushing, then we definitely replace it by pre-treating it with grease.

- We dismantle the cable seal, which is mounted in the technological hole of the frontal shield of the body (in the photo it can be seen from the engine compartment).

- Pull the cable end as you move until it is removed from the fork groove.

- Using the key “17” we “defeat” the nut by means of which the cable tip is held on the corresponding bracket of the transmission unit. To prevent the tip from turning, we use an additional key.

- Now we proceed to dismantling the cable end, after which we remove this element from the hole. The cable itself can also be removed.

- Having completed the indicated manipulations, we begin the installation of a new unit.

- First, we pass the cable into the previously designated hole in the front shield.

- We treat the bushing with a special compound and fix the wear compensation element on the corresponding pin.

- Now we attach the cable directly to the pedal and return the previously removed seal to its place.

- We move on to installing the tip on the LADA Granta transmission bracket. Screw the retaining nut with the required torque (do not overdo it).

- We remember the need to tighten the leash.

- We continue the installation procedure by moving the lower tip in the forward direction until a feeling of stop occurs.

- We hold the tip in the designated position and at the same time measure the distance that was illuminated by us earlier (more specifically: in the “leash-fork” section). If the parameter is incorrect, rotate the leash until the optimal value appears.

- We remember the need to lubricate the body of the leash before installing it in the knot. The surface in contact with the fork must be lubricated.

- The final action is to press the pedal to its full value multiple times. Then we again make a control measurement in the “fork – leash” sector and, if it deviates from the regulations (27 mm), we make a re-regulation. This completes the clutch cable replacement.

Do-it-yourself clutch installation on a Lada Granta

- Using a mandrel, we install the driven disk, basket, and centering pins.

- We fix the basket to the flywheel with three bolts. We tighten the bolts evenly according to the diagonal principle with a force of 37 N.m. We use a torque wrench.

- We remove the frame and install the manual transmission.

- We fix the clutch drive on the manual transmission.

- We adjust the distance from the plastic bushing to the drive fork. It should be equal to 27 mm. We adjust the key value to “10”.

We measure 10 mm

Replacing the clutch cable

To replace the clutch cable, you will need to perform the following manipulations sequentially:

- unscrew the nut that secures the cable to the pedal assembly (it is located under the panel);

- remove the stopper from the braid pin;

- then use pliers to remove the locking clip;

- then remove the pedal axle;

- remove the pedal bracket spring;

- Use pliers to remove the tip stop;

- release the pedal from the cable end;

- Next, you need to remove the cable sheath seal from the engine compartment;

- pull the end of the cable connected to the fork towards you, and then remove it;

- dismantle the tip driver;

- dismantle the guide bushing;

- to complete the work, it will be necessary to pull the cable through the hole located between

- engine compartment and car showroom.

Before installing the cable, it is lubricated, and a small amount of machine oil is poured between its shell and itself. Install the cable, carrying out actions similar to its removal in the sequence directly opposite to dismantling.

Release bearing Gearbox 2181, Clutch release clutch Gearbox 2181 - replacement in Lada Granta

Well, I was struck by the death of the release bearing with a mileage of 23 thousand km, also known as the clutch release clutch of the gearbox 2181. Judging by people's reviews, this bearing does not last more than 30 thousand km. In the evening everything was fine. The next day in the morning, while squeezing the clutch, I noticed that it was somehow not being pressed correctly, I thought, maybe it seemed, and after 20 - 30 km the clutch disappeared altogether.

With the car running, I could not turn on the first and rear, 3,4,5 turned on with difficulty, and after a while they did not turn on. But with the car turned off, all transmissions were switched on. Having opened the hood, I pulled the clutch fork, it dangled as desired in different directions, i.e. was not fixed. Having reached the garage under my own power (25 km), I began to find out the reason. I disassembled and removed everything unnecessary that interfered with removing the box. We unscrewed and separated the box from the engine and supports, hung it by the CV joints (in this position it is problematic to install it later, it is better to read a repair book). The problem became immediately clear - the release bearing had died. Among other release bearings, I chose a roughly similar one - the Priorov one, but it still needed to be installed somehow, and for it to still work. In the 2181 gearbox there is a release fork similar to a fork from a cornfield, based on this I decided to also buy a release bearing spring from a cornfield (or from a VAZ 2101) that secures the bearing to the fork.

on the left - Grantovsky, on the right - Priorovsky bearing

action plan

+spring

hanging the box

modified Priorov bearing sits on the shaft

The spring is installed in the bearing groove and fixes the fork on the other side, i.e. the fork is clamped by a spring, if something is not clear, then read the manual for replacing the release bearing in the field.

Well, that’s all, actually. I put the box back, assembled everything, and connected it. Works great. Don’t forget to lubricate the shaft where the bearing sits and the splines with a lubricant like lithol, but not too much because if you overdo it, then when the shaft rotates, lubricant can splash onto the clutch disc, and it will slip. After these procedures, the clutch pedal became a little softer, and the gears shifted better. I drove more than 100 km, everything is fine, time will tell how long it will last. Well, everyone decides for themselves to change the original 2181 release bearing every 30tkm or less, or install another one with modifications. The release bearing should last for the entire service life of the clutch, i.e. operating time to failure is at least 800 thousand “off-on” cycles of the clutch, which is equivalent to a car mileage of 100,000 km, and a bearing that falls apart up to 30 thousand km.

Why did it happen so?

Perhaps the automatic requests do not belong to you, but to another user accessing the network from the same IP address as you. You need to enter the characters into the form once, after which we will remember you and be able to distinguish you from other users exiting from this IP. In this case, the page with the captcha will not bother you for quite a long time.

You may have add-ons installed in your browser that can make automatic search requests. In this case, we recommend that you disable them.

It is also possible that your computer is infected with a virus program that is using it to collect information. Maybe you should check your system for viruses.

If you have any problems or would like our support team, please use the feedback form.

How to replace the clutch on a Lada Granta?

- On the Lada Granta, the process should start from the engine compartment

- Under the hood, you need to remove the air filter and air duct so that they do not block access to the gearbox. However, you can remove anything, as long as it’s convenient for you.

- Now unscrew the starter from the engine

- Unscrew the clutch cable from the gearbox

- Now we remove the engine protection under the car

- Remove the clutch housing cover. Draining the oil from the gearbox

- Disconnect the front suspension arms from the steering knuckles, unscrew the torque rod

- Disconnect the reverse wire and speed sensor

- We take the CV joints out of the gearbox one by one. The main thing is that the differential gears do not become out of sync. To do this, insert special plugs into the differential.

- We unscrew the gearbox torque rod and the rocker. Before doing this, you need to mark the position of the adjusting bolts so that after the repair you do not have to adjust the rocker again

- If the ignition coil is in the way, remove it

- We place any strong and stable support under the gearbox.

- Unscrew the gearbox from the engine and remove it

- Now you can unscrew the clutch basket and driven disc

- We replace them with new ones, center the position using a special plastic device that fits onto the crankshaft and assemble everything in the reverse order. To make it easier to understand, watch the video on how to replace the clutch on a Lada Granta with your own hands.

- After assembly, we adjust the clutch cable so that the free play of the clutch pedal corresponds to those recommended by the manufacturer

- During this repair, you can replace the release bearing and lubricate the clutch fork. These parts are located on the gearbox itself.

The release bearing (VP) is a ball bearing that is installed in a special clutch with a spring and moves along the input shaft bushing. The part is used to press the clutch disc and remove the flywheel from engagement with the gearbox. The release bearing (Kalina VAZ 1118, Priora, Granta), like the clutch, periodically fails after a long mileage or improper operation and maintenance. If a clutch malfunction occurs, the gearbox will need to be removed for repairs, but there is a method in which the Kalina release bearing is replaced without dismantling the gearbox . Many VAZ 1118 owners often ask the question “How much does it cost to replace a release bearing on a Kalina?”, we can say with confidence that in a car service this repair will cost about 3,000 rubles. Replacing it yourself according to these instructions will take you 3-4 hours, so the choice is yours.

The article outlines a guide to replacing the clutch release bearing on a Lada Kalina with removing the gearbox, and also shows a method without removing it. Additionally, information is provided on the selection of spare parts, numbers, prices, and sizes. The material is accompanied by numerous photographs, as well as supporting videos, including on replacing the clutch on Kalina. This instruction is suitable for owners of Lada Priora, Lada Granta, VAZ 2110-2115 cars.

Clutch installation

Before you begin assembling the clutch, you must wash each removed element in kerosene. Then apply a thin layer of CV joint-4 lubricant to the guide sleeve of the release bearing and to the spline of the input shaft. The installation of parts begins with the release bearing, after which the clutch fork, spring and bushing are installed.

Next, the clutch is centered using a special frame inserted into the hole in the crankshaft end, while the driven disc is placed on the frame so that the protrusion located on the hub faces the gearbox. After this, the clutch basket is installed, and the centering frame is removed. Then you will need to install the gearbox in its proper place.

After installation, check and monitor the gear shifting process; they should turn on clearly, without clearly audible extraneous crunching sounds. In addition, ideally the car will move away without jerking.

What to pay attention to

There are certain signs that the clutch on the Lada Grant has failed and measures need to be taken. It is worth paying attention that if the car has just been purchased, the pedal will be pressed quite easily. If this requires great effort, then this is the first evidence that the clutch needs to be adjusted or replaced.

It is also worth paying attention to the appearance of extraneous squeaks at the moment when the driver presses the pedal. In addition, it should not twitch when the car owner does not touch it.

Most often, car enthusiasts are faced with the fact that the pedal travel becomes too tight. It is worth considering in more detail the reasons for this problem.

Replacing the clutch on a Lada Grant (robot)

The process of prevention and replacement is similar to that described above. Provided the recommendations are followed, the repairman will not have any problems with the installation.

The main task is not to damage the upper actuator when dismantling/installing the automatic transmission. To make disassembling the automatic transmission easier, first remove the subframe cross member. We lower the two engine mounts, remove the automatic transmission, and replace the clutch. When finished, assemble the structure in reverse order.

Do-it-yourself Lada Granta clutch adjustment: video instructions

Lada Granta is one of the most popular cars in Russia made after 2010. The advantage of a car is its affordable price, which is a decisive factor for the majority of residents of our country. In addition, Granta is quite cheap to maintain, unpretentious and reliable, which many other AvtoVAZ models cannot boast of. Granta is considered one of the most successful VAZ models in the recent history of the manufacturer.

However, any car needs care, and the Lada Granta will be no exception. The clutch is a system that requires increased attention in any car. However, sooner or later problems also happen to him. In this case, you will need to replace the cable or simply re-adjust the clutch on the Lada Granta. Today we’ll talk about the design features of the car, and also look at some methods that will help you solve the problem yourself.

Features of clutch on Grant

Unlike older models, the VAZ-2190 is equipped with an automatic clutch adjustment system. This unit is monitored by a special sensor, so car enthusiasts have much less hassle. If you hear all kinds of clicks from the machine, then the system is working. However, the system is not always effective. In particular, it will not help you in the following cases:

- If the pedal fails.

- If the clutch is not fully depressed.

Selection of components

The clutch life on Grants depends on the operating conditions in which the car is located, and therefore can have significant differences. When using the car sparingly, the clutch is changed after 100,000 km. One of the most common types of clutch installed by the Volzhsky Automobile Plant is LUK clutches.

As a rule, clutches are sold in the form of kits, which include a clutch disc and basket, as well as a release bearing. The approximate cost of clutches for Granta starts at 2,000 rubles and can vary significantly in a particular region.

To purchase an original kit and not a counterfeit, buy parts only in specialized retail outlets, based on real customer reviews, or order the kit directly from the manufacturer (for example, using the Internet). Sometimes clutches are assembled from components made by different manufacturers.

When to change and how to check the clutch - its service life may have come to an end

Good day, dear car enthusiasts! Each of us is always concerned about how long this or that part or car system will last. It `s naturally. Especially considering the quality of some products, the “skills” of workers, etc.

This issue fully concerns the car’s clutch. Very often on motorist forums there is a serious question about when to change the clutch, and how to know when the time has come to replace it. So let’s try to figure out together what the actual service life of the clutch is, and whether it exists at all.

Is there a certain clutch resource?

Whether or not you will be upset when you find out that the manufacturer does not indicate specific figures for clutch service life. If, for example, in the brake system, it is clearly stated that the thickness of the brake disc should be such and such, then why is this not applicable to the clutch?

The fact is that clutch wear depends on many reasons, and first of all, of course, on how the driver changes gears and in what mode the clutch is used.

And while clutch disc thickness cannot be measured the same way brake disc thickness can be measured with a caliper, there are ways to measure it. There are two of them.

- The first way to measure the thickness of the clutch disc is with a special measuring gauge. This method does not require dismantling the clutch; it is performed on a lift. But you are unlikely to use it.

- the second method is simpler to implement and allows you to determine the wear of the clutch disc in order to replace it. Replacing the driven disk is a procedure provided by the manufacturer, because The driven disk is a consumable part. The check is carried out as follows: with the engine running, you need to put it in high gear, accelerate it, and if the car does not stall, this means that the driven disk is worn out and requires replacement. It must be remembered that such a check of the thickness of the clutch disc is not technologically correct, but it is effective and allows you to determine the condition of the disc extremely accurately.

As already mentioned, the life of any clutch is determined by its operating conditions. Without going into technical details of the interaction of clutch parts, you should understand that basically the life of the clutch and the wear rate of the discs depend only on the driver.

A clutch of the same quality and manufacturer can last 5,000 km for one driver, and 100,000 for another. Participation in drag racing, frequent slipping, abrupt starting at high speeds, ingress of foreign liquids and objects, unqualified installation and adjustment clutch - all this reduces the life of the clutch.

Review of Manufacturer Prices

| Manufacturer article number | Price, rub.) | Resource (Thousand km) |

| Set of wheels LADA 2190-316010001 | From 3100 | 85 — 105 |

| —/— 2190-31601000 | —/— | —/— |

| —/— 302050901 | —/— | —/— |

| —/— 302052223 | —/— | —/— |

| —/— 302052307 | —/— | —/— |

| LADA 21810160118001 clutch | From 650 | 80 |

| LADA 21090160119000 input shaft guide | From 750 | 75 — 80 |

| LADA 21010160121500 fork support | From 150 | 75 – 95 |

| LADA 21810160120001 plug | From 800 | 85 – 95 |

| Connecting spring fork and clutch 21010160118800 | From 350 | 85 — 95 |

*prices are current as of October 30, 2018.

Features of correct adjustment of the unit

Quite often, clutch-related problems are solved by standard adjustments. However, such measures must be carried out based on the recommendations of specialists and experienced car owners. First of all, you need to turn off the engine. After this, just press the pedal several times and listen to the sounds. If no grinding or creaking is heard, then the adjustment continues.

If the Lada-Grant clutch pedal gets stuck or it moves jerkily, then its position needs to be adjusted. First of all, you need to completely squeeze it out with your hand. It is better not to use your foot, as in this case it will be much more difficult to feel minor jamming or, conversely, jerking at the moment when the lever returns to its original position.

If you manage to find out that the pedal twitches a little, then you need to arm yourself with a ruler and determine the distance from the floor to the pedal, or rather, the part that protrudes outward. After this, while continuing to hold the measuring device, the car owner must press the lever and wait until it returns to the same position. If the values on the ruler diverge or the distance is more than 14.5 cm, then in this case you need to make adjustments. It is worth noting that the full pedal travel should not be more than 146 mm. The cable guide cannot move in relation to the fork lever by more than 2.7 cm.

Finding the reason

One of the owners of a Lada Kalina (VAZ 11194) decided to check where there was such noise from the transmission in the cabin. With the help of spot wiretapping, he was able to find out that some of the vibrations from the gearbox are transmitted to the cabin through the clutch cable. This was confirmed by a simple experiment:

- raised the front wheels

- turned on first speed

- raised the speed to 4500-5000 rpm

- Reduced the speed to 1500 rpm using the brake pedal without releasing the gas pedal

Then, the same thing was done with the clutch cable disconnected from the gearbox fork. The familiar sound of “hrrrrr.” "disappeared. The sounds were recorded in an mp3 file (before the pause - with a cable, after - without it). Site users can download the file:

To download files you need to log in to the site.

Conclusion : the clutch cable is a transmitter of vibrations from the gearbox fork.

A similar situation may occur on Lada Grant and Priora cars.

Signs of clutch wear

| Sign | Cause and remedy |

| Incomplete engagement of the clutch (slips) | Replacing discs, cleaning clutches |

| Incomplete shutdown (leading) | Prevention of the clutch mechanism |

| Periodic jerks | Clutch cable wear, clutch replacement |

| Vibration, beating when shifting to higher gears | The flywheel is bent, the gripper teeth are worn out. Replacing the flywheel and related consumables |

| Noise, creaking, grinding noise when activated | Damper spring wear, replacement with a new one, drive lubrication |

| Pedal free play is increased, exceeding 2 -3 mm | Tensioning the cable, replacing with a new one |

| You can hear the smell of burnt friction linings | Dismantling the clutch block, replacing worn elements |

| Increased fuel consumption | Flywheel worn, teeth damaged |

| Reduced acceleration dynamics | Replacing clutches |

How do I replace the clutch assembly or its components?

Many are also interested in the question of how the clutch is replaced. Next, we will consider the features of replacing a disc or other elements in the clutch units of Lada Granta, Prior and Kalin. Choosing a clutch is not difficult, since the market is represented by many offers. This aspect is influenced not only by individual preference, but also by the price factor.

The disc replacement process is identical, regardless of the modification of the designated VAZ models, including the Lada Granta. Having decided on the choice of element, we proceed to the direct replacement procedure.

- The initial action will be to dismantle the LADA Granta transmission unit.

- If you plan to reinstall the pressure plate (basket), you will need to first mark the location of the flywheel and housing. This manipulation allows you to save balancing and install the disk in a position identical to the element previously located here.

- Next, we mount a special bushing (mandrel) into the central hole of the pressure element. If such a mandrel is not observed, then it is possible to dismantle the assembly without it, but you will need to hold the driven disk during removal in order to prevent it from falling out.

- To eliminate the risk of the flywheel turning, we arm ourselves with a locking component (screwdriver or mounting blade).

- We unscrew the 6 bolts that hold the basket on the flywheel. The action should be characterized by uniformity and without completely removing first one screw, then the second, etc.

- Now we remove the casing together with the driven disk.

- Having detected the presence of damage on the surface of the assembly elements, the next step is a complete replacement of the clutch.

- We focus special attention on the degree of wear of the friction linings on the disk in LADA Granta. When it is discovered that they are oiled or the rivets are deepening, we urgently replace such an element. We check the rigidity of the damper springs. If they are found to be damaged, the disk must also be recycled. We inspect the disc for runout. If its value exceeds 1 mm, then this fact means the part is unsuitable for use.

- We inspect the pressure element and the flywheel, especially the plane of their contact. Areas with scuff marks, signs of overheating and wear are strictly unacceptable.

- We study in detail the condition of the disc spring, on the surface of which traces of the indicated defects are also unacceptable. The contact points of the petals of this part to the bearing device (“release”), which carries out the process of disengaging the clutch of the disc with the flywheel, must be in a single plane. No defects are appropriate in this case, and the discrepancy should not exceed 0.8 mm. If this parameter is not maintained, then a complete replacement of the clutch is necessary.

- Don't forget to inspect the spring support rings. It also excludes the presence of any defects.

- When, based on the completed set of testing manipulations, the fact of the need to replace certain elements of the clutch assembly or the entire assembly structure has been identified, then before starting work it will be necessary to monitor the characteristics of the movement of the driven disk along the corresponding section of the transmission unit shaft. If, during movement, the fact of jamming, jamming, or other aspects that do not allow free movement of the disk emerges, then these negative factors must be eliminated without fail. When achieving such a result is not possible, you should resort to replacing the entire list of defective parts.

- When carrying out the installation procedure, it is imperative to take into account the issue related to the correct installation of the driven disk in relation to the pressure component of the basket.

- First, we center the disk, using the mandrel we previously designated for these purposes. This will require careful consideration to ensure the element is positioned correctly in relation to the flywheel.

- Now we fix the basket directly to the flywheel using the bolts indicated here. We proceed by analogy with the dismantling procedure in terms of ensuring reliable retention of the flywheel from the risk of turning.

- Do not forget about the correct tightening of the basket fixing bolts. The procedure involves an algorithm of actions with uniform screwing of each of the fasteners. It is impossible to fully tighten one particular bolt, since such an action may cause the basket to skew, thereby causing incorrect operation and uneven wear of the clutch elements.

- The next step involves removing the previously installed mandrel from the corresponding recess in the center of the flywheel.

- After this, you can attach the transmission unit to the engine block.

- Now we mount the lower end of such a part as the clutch cable to the corresponding bracket on the gearbox housing, after which we carry out the previously indicated adjustment. Do not forget to install the compensation device in its original position, which will allow you to return the clutch cable to its original position. This procedure is necessary so that the compensation device, shifted to its lowest position, can signal to the owner that the disc is worn out. Replacement of the clutch cable in the LADA Granta has been completed.

Clutch replacement instructions

Now it’s time to tell you how to replace the clutch disc on Lada Granta, Kalina and Priora cars. Which clutch is best to buy is a matter for every motorist. Here everything depends not only on preferences, but also on financial capabilities, as we said earlier. On our resource in this section you will find reviews of several brands, after analyzing which you can decide which device is best to install on the Lada Kalina or Priora. Replacing the disc is carried out according to the same principle on Lada Kalina, Grant, and Priora.

So, if you have decided which clutch is best to install, then let’s start replacing:

- First, you need to dismantle the gearbox from the Lada Granta, Viburnum or Priora. In the event that you plan to install the same pressure plate that you had, then before starting work, mark the location of the flywheel, as well as the housing. This is done in order to maintain balance and set the disc in the same position. Also install a special bushing (mandrel) into the hole in the pressure pulley. If you do not have such a bushing, then you can dismantle the device without it, but during removal you should hold the driven pulley, as it may fall out.

- Using a screwdriver, hold the flywheel to prevent it from turning. You need to unscrew the six screws that secure the device's pressure pulley housing to the flywheel. Do not unscrew one screw at a time; it is recommended to do this evenly, moving from one screw to another.

- Dismantle the device casing along with the pressure pulley. You can also dismantle the driven pulley with the bushing installed in it.

- If you notice that any of the elements have cracks or other mechanical damage, then these components need to be replaced. You should also check how worn the friction linings are. If the linings themselves are oily, the rivet retainers are loose, or the rivet heads are even slightly recessed, the driven pulley must be replaced. It would also be a good idea to check how securely the damper springs are secured. If they are broken, the disk will also need to be replaced.

- The next step will be to diagnose the driven pulley. If no defects were identified during a visual inspection, then you will need to diagnose its runout. If the runout indicator is more than one millimeter, then it will also be necessary to replace the pulley. Attention should be paid to diagnosing the working surfaces of the pressure shaft and flywheel, in particular, we are talking about the friction plane. Make sure that there are no defects, signs of wear, or scuffing, and there should be no signs of overheating. If components and mechanisms are found to be defective, they will need to be replaced.

- Next, pay attention to the condition of the so-called disc spring of the pressure shaft; as in other cases, signs of wear, defects or cracks are not allowed on it. The places where the spring petals come into contact with the bearing device for turning off the mechanism must be located in the same plane. Of course, there can be no talk of any defects; if wear is present, it should be no more than 0.8 mm. Otherwise, you will have to replace the entire pressure pulley assembly. If the rivets are loose, you will also have to replace the entire disc. Then it is also necessary to diagnose the condition of the spring support rings. As you understand, any cracks and mechanical damage are excluded, otherwise the pressure shaft is replaced as an assembly.

- If you understand which clutch is best to install, then before installing the device you need to check how well the driven shaft moves along the primary transmission pulley. If you notice that there are jams during movement, then any defects must be eliminated. If this cannot be done, then the parts will need to be changed.

- During installation, take into account the fact that when installing the driven shaft in the place where the pressure element is mounted, the part of the hub that protrudes must be directed towards the pressure spring. When installing the device, you must first install the driven pulley. Use a special bushing or do it as carefully as possible.

- After these steps, the pressure shaft housing is secured with three bolts, and screws are also installed with which the casing is attached to the flywheel. As during dismantling, the flywheel should be held with a screwdriver to prevent rotation. As you remember, you cannot tighten one screw at a time; this must be done gradually.

- The final stage will be dismantling the bushing installed in the disk and installing the gearbox. You need to mount the lower end of the clutch cable to the transmission, after which its initial adjustment is carried out. As for adjustment, we already wrote about it at the beginning of the article. But before restoring the original position of the cable, the wear compensation device should be reset to its original state. This is done because if the disk is completely worn out, the compensator device will be located in its lowest state.

The request returned an empty result.

You can understand that such a procedure for replacing a disk is quite labor-intensive, so not every car owner will be able to cope with it on their own. If you have doubts, it is better to seek help from specialists.

Clutch adjustment methods

There are two methods for adjusting the clutch. When regulating it in the first way, you must:

- pick up the tip, after which it is pulled forward to the maximum possible value;

- Use a caliper to measure the distance between the leash and the fork, normally it is 27 mm;

- If you find any problems, adjust the length of the cable by tightening the thread;

- Next, you should press the clutch three times and make sure that it functions normally.

If problems arise, take new measurements with a caliper (the distance from one extreme point to the other cannot exceed 146 mm). If this indicator is exceeded, a new cable must be installed.

The second adjustment method is an alternative, thanks to which you can adjust the clutch without a caliper. The beginning of alternative adjustment is no different from adjusting the clutch in the first way. When the leash is snug against the fork, you depress the clutch three times, then open the hood to make sure that the leash is pressed to the metal as before? One of the mandatory conditions for adjustment is the complete absence of movement of the fork or its minimal mobility (not exceeding 2 mm).

Each car owner can use both the first and second methods, since the automatic adjustment system still will not relieve him of the obligation to periodically carry out the work described above. Remember - even with a properly functioning cable, you still need to open the hood of your car at least from time to time.

Don’t forget one more recommendation from experienced car owners: to make adjustments, don’t wait for obvious problems to appear in the clutch. It is best to carry it out regularly (once every 10,000 km), because adjustment will help you protect yourself from clutch problems. And when carrying out this procedure again, do not forget to also evaluate the condition of the cable. If cracks or thinning are found on it, it is recommended to replace the part immediately.

Sources

- https://FB.ru/article/465967/stseplenie-ladyi-granta-obzor-vozmojnyie-neispravnosti-i-otzyivyi

- https://evrasia-today.ru/skolko-hodit-stseplenie-na-grante/

- https://vaz-remont.ru/kak-zamenit-vyzhimnoj-podshipnik-na-lada-granta-svoimi-silami/

- https://Vaz-Lada-Granta.com/dvigatel-korobka/zamenit-tros-stsepleniya.html

- https://cartore.ru/153-kogda-menyat-sceplenie-srok-sluzhby-i-kak-proverit.html

- https://new-granta.ru/sceplenie/

- https://remont-avtovaz.ru/instrukciya-po-zamene-scepleniya-na-lade-grante/

- https://www.spike.su/index.php/%D0%92%D1%8B%D0%B6%D0%B8%D0%BC%D0%BD%D0%BE%D0%B9-%D0% BF%D0%BE%D0%B4%D1%88%D0%B8%D0%BF%D0%BD%D0%B8%D0%BA-%D0%9B%D0%B0%D0%B4%D0%B0 -%D0%93%D1%80%D0%B0%D0%BD%D1%82%D0%B0.html