It is a well-known fact that the engine life of one owner can differ significantly, both up and down, compared to exactly the same power unit for another on a similar model. Let us note right away that this difference is usually due to several main reasons, which not every driver knows about.

As a rule, drivers operate their car in a convenient and familiar manner, little thinking about the fact that some common mistakes and misconceptions can quickly develop into the need for a major overhaul of the internal combustion engine.

In this article we will talk about what factors have the most serious impact on the life of the engine, as well as what car enthusiasts need to do in order to maximize the life of the engine.

Running in a new engine or a motor after a major overhaul

Most often, the service life of a new engine and the quality of its further operation are determined by the driver himself during the break-in period. This is most true for new cars.

A popular myth that is actively spread by managers at car dealerships is that today the internal combustion engine does not need to be further broken in. The argument is that modern engines are very different from the developments of the last century; they have high quality processing, assembly, fitting and tuning of all parts and assemblies. Moreover, there is a belief that the car was run in right at the factory.

Please note that if you are buying an ordinary civilian car, and not a sports car like a Ferrari, Nissan GTR, Bugatti Veyron or Lamborghini, then no one has specifically tested such a car in the factory. The maximum you can count on is the so-called “cold run-in”.

To put it simply, the whole process consists of cranking the internal combustion engine without starting it to grind in parts and check the power unit. In some cases, factories do not even carry out such a procedure for a new engine coming off the assembly line. Taking into account the above, it becomes clear that the car needs to be run in, and this is done by the owner himself after purchase.

Despite the fact that the quality of workmanship and precision during the production of internal combustion engines have recently increased greatly, the general principle of operation of a piston engine has not changed. This means that the parts still need to be broken in. The piston rings are ground in, a “mirror” is gradually filled into the cylinders, etc.

Of course, you don’t have to adhere to the break-in regime and the engine will still be out of at least the warranty period. The above-mentioned car dealership managers are well aware of this, for whom it is much more profitable for you to come to them again after the end of the warranty for a new car.

It is also important to remember that even from the very beginning of operation, even a new, but incorrectly run-in engine may lose some power and throttle response, consume more oil and fuel, etc. This is not a warranty case; at the initial stage, you will only be able to notice the difference in comparison with another similar car.

However, further problems will progress more intensively, as premature wear of the CPG will affect it, and the overall service life of the engine will ultimately be significantly reduced. To prevent this from happening, you definitely need to know how to run in a new car and engine or a restored power unit after a major overhaul.

Optimal gear selection

Too low or maximum speeds contribute to a reduction in the life of the internal combustion engine.

For example, driving uphill in this mode is a blow to the engine's life. To maintain a given pace, the speed is usually switched to a lower speed and the gas pedal is depressed. This causes detonation, and you can hear the same “fingers” knocking.

It is optimal when the tachometer needle shows average values. You must switch to the required gear in time, focusing on road conditions, speed limits and other factors.

Correct selection and timely replacement of engine oil

Proper maintenance of the power unit is one of the most effective ways to prolong the operation of the engine and not experience serious problems during its operation. Such maintenance, first of all, should mean replacing the engine oil and oil filter.

- First of all, you need to start with the correct selection of lubricant. The oil must be of high quality and meet all the requirements and recommendations of the engine manufacturer.

At the same time, when choosing, you should pay attention to seasonality, that is, use a lubricant whose SAE viscosity corresponds to real operating conditions. For this reason, in some cases it is separately recommended to additionally adjust the oil change taking into account the season (the so-called summer and winter oil).

For example, if the summers in the region are very hot and the winters are cold, then in the summer, all-season oil with a viscosity index of 5W40 or 10W40 is poured, and with the onset of cold weather, a mandatory transition to 5W30 is made.

- The oil needs to be changed according to regulations. In this case, it is also highly desirable to take into account the individual characteristics of vehicle operation. The fact is that so-called “severe” operating conditions require the driver to further reduce the service interval.

Such conditions include the following features:

- If the car mainly drives around the city at low speeds and low revs.

- Frequent and short trips are important for a car.

- The engine, especially in winter, does not warm up properly and does not reach operating temperatures.

- The vehicle sits in traffic jams for a long time, the engine often works a lot at idle;

- A trailer is regularly towed, cargo is transported, etc.

As you can see, if we add to this the low quality of fuel in the CIS, and there is no way to influence this, then we can safely say that the majority of cars on our roads are operated precisely in those conditions that manufacturers consider difficult.

For this reason, the oil change interval indicated in the technical repair and operation manual is every 10 or 15 thousand km. or 12 months (whichever comes first) can be considered a very average indicator. In practice, it is optimal to change oil and filters every 8-9 thousand km. for synthetic ones, 7-8 thousand km. for hydrocracking, 6-7 thousand for semi-synthetic and 4-5 thousand for mineral motor oils.

If the load on the unit is constant and very high, the engine is forced or equipped with a turbocharger, for such internal combustion engines the issue of changing the oil and reducing intervals is even more acute.

Also, the lubricant must be changed at a shortened interval several times when there are emergencies or any other reasons that may affect the service life of the engine oil itself (for example, antifreeze or fuel got into the pan, there is an active ingress of gases from the combustion chamber into the crankcase, etc. .d.). Reducing the interval is necessary to flush the lubrication system with fresh engine oil.

- It is very important not only to change the oil promptly, but also to change it correctly. It is necessary to drain the waste only in the traditional way (hot oil flows out through the drain hole in the pan, and not using vacuum suction through the oil filler neck during express changes).

Fill in fresh lubricant strictly according to the level, not allowing the oil level in the engine to exceed or fall above the recommended level. Remember, both high and low oil levels negatively affect the life of the internal combustion engine.

You also need to constantly monitor the oil level, since some engines (even when new) can waste lubricant due to design features. Such consumption is not a malfunction, but requires the driver to periodically check the level in the pan.

On many engines, even a slight decrease in the oil level leads to a significant increase in the degree of wear of the internal combustion engine. In other words, if the driver does not take into account the features of his engine, this usually has a bad effect on the resource of the unit.

Let us add that if the level drops from replacement to replacement, then in order to maintain the required amount of lubricant, you should have a supply of engine oil for topping up. It should be borne in mind that it is prohibited to mix oils of both different brands and products of the same manufacturer with different oil bases, viscosities, tolerances, additive packages, etc.

Replacing consumable parts

Filters, spark plugs and other consumable parts must be replaced in a timely manner to eliminate the possibility of reducing engine life.

Turbo engines and naturally aspirated internal combustion engines require a constant flow of air, which is part of the fuel-air mixture. Such air must be clean and free of any debris, which is ensured by an air filter, the replacement of which is regulated. Although the peculiarities of car operation make their own adjustments. Mostly the filter is replaced every 10 thousand km.

The next important “consumable” is spark plugs. They must not only be checked and changed on time, but also chosen correctly. Spark plugs must match the specific internal combustion engine. If this is not the case, the resource of the unit will suffer due to impaired sparking.

Correct operation of the cooling system, electronic control and power supply of the internal combustion engine

Not only the stable operation of the internal combustion engine itself, but also the service life of the unit depends on the efficiency of various systems. It often happens that the engine is running relatively normally, but malfunctions occur in the fuel supply, electronic control or cooling systems. Some drivers simply do not notice problems due to lack of experience, others simply ignore the problem and delay diagnosis.

You need to understand that any deviations from the norm are a reason for an immediate visit to the service station. Otherwise, even minor faults can cause more serious breakdowns in the future. In other words, ignoring even minor problems leads to a reduction in the overall life of the unit.

- For example, problems in the cooling system often cause the engine to overheat. At the same time, overheating does not always have to be critical. If a significant increase in temperature immediately disables the internal combustion engine, then local overheating usually goes unnoticed, but also causes significant damage to the power unit.

Let us also add that in some cases, a malfunctioning thermostat can lead to the engine constantly remaining cold and not reaching operating temperature. In such a situation, the internal combustion engine operates far from under optimal conditions, the gaps are increased, and the fuel burns incompletely.

We also recommend reading the article on how to break in a diesel engine. From this article you will learn about the features and nuances of running in the specified type of motor.

Taking into account the above, it is necessary to promptly change antifreeze or antifreeze, flush the cooling system, monitor the cleanliness of the radiator, periodically check the tightness of all pipes and connections, and make sure that the cooling system fan, pump and thermostat are working properly.

- If we talk about the electronic engine control system, the main problem is the failure of the ECM sensors. If the breakdown is serious, a “check” lights up on the dashboard, the engine may run intermittently, etc.

It should be borne in mind that in many cases the “check” does not light up, however, the incorrect operation of certain sensors leads to problems with mixture formation. Running the engine on a rich or too lean mixture negatively affects the life of the internal combustion engine.

Another cause of problems with mixture formation may be the electronic “brain” of the ECU. Typically, the controller itself rarely fails, which cannot be said about cases where chip tuning was carried out, the control unit was reflashed, fuel maps were corrected, etc.

- As for the power supply system, special attention needs to be paid to the injection nozzles. Violation of the spray pattern as a result of their contamination can lead to very unpleasant consequences for the engine.

The injectors must open and close in a timely manner; leakage and fuel overflow are not allowed. Otherwise, the engine may run intermittently; excess fuel enters the engine crankcase, diluting the engine oil. As a result, the lubricant loses its properties, and engine parts begin to wear out intensively.

To extend the life of the power unit, periodic cleaning of the injector (nozzles) is necessary, as well as computer diagnostics of the car engine. This approach allows you to detect deviations in the operation of the sensors in a timely manner, avoid problems with mixture formation, and also maintain the injectors in working condition.

Interesting

The world in which car owners live is full of legends and rumors. Quite a lot of them are devoted to the reliability of car engines. For example:

- there is a legend about an engine that does not break down;

- many car enthusiasts can talk for hours about engines they know with mileage of more than 1 million km;

- There were “reliable” rumors that the American company Rolls-Rouce produces engines, inside of which a flask with abrasive material breaks after a certain mileage. As a result, the power unit instantly fails and cannot be repaired.

Quickly identify and resolve problems

The appearance of any extraneous sounds, knocking or vibrations during engine operation is a signal that malfunctions may occur in the motor or attachment. In some cases, the problem is solved by replacing belts, rollers, pulleys, engine support cushions, etc. In others, diagnostics and repairs are necessary for the motor itself.

It is important to know that a break in the timing belt or timing chain will immediately damage the power unit. The fact is that when a break occurs on many internal combustion engines, the valves bend, and other consequences may also appear.

For this reason, it is necessary to change the timing belt and rollers strictly according to the regulations. The chain drive also needs maintenance, although less frequently. Experts recommend performing a preventive inspection of belts for damage or stretching at each scheduled maintenance. As for replacement, the timing chain on some engines needs to be changed at 100-150 thousand km, and the timing belt along with the rollers is usually changed every 50 thousand km.

- Let us also add that the norm for a responsible driver is to check the level and condition of technical fluids at least once a week. In the case of internal combustion engines, the oil level is usually checked, as well as the coolant level in the expansion tank.

At the same time, the smell and type of lubricant, as well as the coolant, are assessed. No obvious color change, staining, foaming, emulsion, etc. are allowed. It should be noted that the appearance of minor or intense leaks through pipes, covers, seals, seals or gaskets is a reason to stop operating the internal combustion engine and inspect the engine at a service station.

Engine life - what is it?

In specialized technical literature, the engine life is defined as the period of its service until the first major overhaul. The need for repairs and wear can be determined by a number of signs. These include a decrease in power by 20-30%, the appearance of any extraneous sounds, knocking, compression changes, increased fuel consumption, and excess engine oil consumption of more than a liter per hundred kilometers.

There are several factors influencing the acceleration of wear. Among the main ones are the use of low-quality oil and fuel, and changing the oil at the wrong time. This also includes untimely replacement of the air and fuel filters.

Reasons affecting wear include delaying minor repairs to mechanism elements.

In addition, improper operation can lead to accelerated wear. In rare cases, wear is affected by manufacturing defects.

However, proper care in accordance with technical regulations can extend the service life by 10-15%.

Warming up the engine before driving, optimal driving mode and correct gear selection

Let's start with warming up, since this issue gives rise to a lot of controversy. First of all, experienced drivers who are familiar with carburetor cars are accustomed to the fact that such a car needs to be warmed up before driving. Moreover, warming up was necessary at any time of the year. This procedure was taken for granted by everyone for one simple reason - until the engine warms up, it is simply impossible or extremely difficult to drive normally.

With the advent of the injector to replace carburetor injection, the situation changed. In this system, fuel is evenly supplied to the cylinders, all processes are controlled by the ECU, and the unit operates smoothly regardless of the temperature of the internal combustion engine. Let us add that after the tightening of environmental regulations and standards, the manuals for modern cars usually indicate that there is no need to warm up the engine while idling.

In other words, it is recommended to start driving immediately after starting, and the unit itself will quickly heat up while driving. Please note that such recommendations are mostly needed to save fuel and protect the environment. The resource of the power unit is relegated to the background. Without going into details, internal combustion engine parts consist of metal and various alloys. As you know, metals expand when heated.

It is not difficult to guess that engineers design the engine in such a way that the optimal operating mode for the engine is to fully warm it up and reach operating temperatures. Only in this mode can the power plant be loaded, since after warming up the clearances return to normal, the engine oil liquefies, etc.

If we take into account that some parts inside the engine heat up faster, while others are subject to heating a little later, then one important conclusion can be drawn - without preheating, it is extremely undesirable to increase the load on the internal combustion engine, especially in winter.

At the same time, the power unit should not be allowed to operate for a long time in idle mode, which is also difficult for the engine (low pressure in the lubrication system, etc.). It turns out that the compromise is that preheating at idle is necessary, but you should not wait for the internal combustion engine to reach operating temperatures completely. Once the arrow of the coolant temperature indicator begins to rise, you can start driving.

However, before reaching operating temperature, you should not load the engine, raise the speed above 1/3 of the maximum (about 2-2.5 thousand rpm), move in higher gears, use engine braking, accelerate sharply, etc. Driving should be calm and smooth until it warms up completely.

- Now let's talk about speed and gear selection on cars with a manual transmission or in those models where the automatic transmission allows the driver to control the transmission manually. First of all, any engine does not “like” extremes, that is, too high or low speeds.

If the motor is constantly turned to the cutoff or closer to the red zone, then the load on all its components will be maximum. This will not add any conditional “health” to the unit. At the same time, at low speeds the pressure in the lubrication system is low; often in this case the driver uses the unit in tight driving mode.

This mode means that the car is moving, for example, up a hill, in high gear and low revs. To maintain a given pace, the driver does not switch the speed to a lower one, but simply presses the gas pedal harder. At this moment, detonation occurs in the internal combustion engine, you can hear the sound of “fingers”, etc.

It is important to remember that the specified driving style under tension and at low speeds also greatly impacts the resource of the internal combustion engine. To increase the service life of any engine, it is optimal to keep the tachometer needle in the middle range, promptly switching to the desired gear depending on road conditions, driving speed, engine load and other individual factors.

Warming up the engine

The move away from carburetor internal combustion engines has led to the fact that warming up the engine is no longer considered necessary. The injection system ensures a uniform supply of fuel to the cylinders with control of this process by the ECU. As a result, normal engine operation does not depend on its temperature.

It follows that the movement of the machine is possible without preheating the unit. This is explained from a technology point of view, the need to preserve the environment and fuel economy, but not by the resource of the internal combustion engine. Meanwhile, any engine is metal, and it is known to be subject to expansion. Some engine parts heat up faster, while others heat up more slowly.

This suggests a conclusion: it is advisable to load the internal combustion engine only after preheating, regardless of the time of year, although in winter this is more important.

Refusal to use additives in oil or fuel

Today you can find a huge number of additives and additives, the manufacturers of which promise to improve the properties of lubricants and fuel, flush the engine or fuel system from contaminants, protect internal combustion engine parts from wear, etc. Also included in a separate group are the so-called “repair” compounds that eliminate leaks, restore elasticity to gaskets and seals, and allow sealing of cracks and other minor defects.

As practice shows, the benefits of using such solutions are very questionable, especially when we talk about additives to the engine lubrication system to protect internal combustion engine parts, flushing oils, “five-minute” flushes and other similar liquids. The fact is that high-quality motor oil already contains the entire necessary package of additives.

It must be taken into account that any additive somehow changes the properties of the poured lubricant. For this reason, the use of “repair” compounds (for example, to eliminate coolant leaks from the cooling system or oil leaks through oil seals) is allowed only in emergency situations. In other words, such additives can only be used to get to the repair site under your own power.

If there is such a possibility, it is better to deliver the car to the service station using a tow truck or in tow. As for various “nano” additives that protect engine parts from wear, it is better not to use such products.

How to increase engine life: simple secrets to long engine life

It is a well-known fact that the engine life of one owner can differ significantly, both up and down, compared to exactly the same power unit for another on a similar model. Let us note right away that this difference is usually due to several main reasons, which not every driver knows about.

In this article we will talk about what factors have the most serious impact on the life of the engine, as well as what car enthusiasts need to do in order to maximize the life of the engine.

Regular replacement of consumables

In order for the power unit to work as long as possible, it is also worth mentioning the mandatory and timely replacement of the so-called consumable parts. These include fuel, oil and air filters, spark plug wires and the spark plugs themselves, brake pads, etc.

First of all, both naturally aspirated and turbocharged car engines need a constant flow of air. Air is an integral element of the fuel-air mixture, which burns in the cylinders. In addition, the air must be clean, that is, debris and small mechanical particles must not be allowed to get into the engine, as defects will appear inside the internal combustion engine.

To solve the problem, an air filter is installed in the intake system. If this filter becomes dirty, then the amount of air in the mixture may decrease, the engine will run on a rich mixture, fuel consumption will increase, carbon deposits will form in the cylinders, etc.

To prevent this from happening, the air filter needs to be changed. The frequency of replacement is stipulated by the regulations, however, it is always necessary to make allowances for the degree of air pollution and dust in a particular region, the characteristics of vehicle operation (for example, frequent driving on dirt roads, off-roading), driving style and other conditions. As a rule, in the CIS, drivers change the air filter every 10 thousand km.

- Now let's move on to the ignition system. An important element of this system are the spark plugs. Spark plugs should be checked regularly and changed on time. In this case, special attention should be paid to the selection of candles.

The fact is that the internal combustion engine manufacturer provides for the use of one type or another for different engines. They can be ordinary, with one or more electrodes, and differ in physical dimensions, heat rating and a number of other parameters.

Simply put, spark plugs need to be precisely selected for a specific engine using special catalogs offered by the spark plug manufacturer. Errors in this matter can lead to disruption of the processes of spark formation and combustion of fuel in the cylinders. Naturally, the life of the unit from driving on unsuitable spark plugs may be reduced.

As for high-voltage power wires, it is usually advisable to change these elements every 20-30 thousand km. This approach is the key to stable operation of the ignition system, a powerful spark and, as a result, effective ignition and complete combustion of the fuel and air mixture in the cylinders.

Ways to increase engine life

Engine oil

One of the most important points is timely oil changes.

You should fill in the oil recommended by the car manufacturer. You also need to take into account seasonality, using oil of different viscosities: in summer - 5W40, 10W40, and in winter - 5W30.

In the harsh Russian realities, it is advisable to change the oil every 8-10 thousand kilometers. Or at least once a year, remembering that even expensive high-quality oil loses its properties after this period.

The following operating features reduce the regulated replacement period:

- driving around the city at low revs at low speed;

- short trips over short distances;

- frequent idling in traffic jams, prolonged idling;

- In winter, the engine does not warm up enough and is not brought to operating temperatures;

- the car operates under overload conditions, for example, transporting heavy loads.

It is important to monitor the level with a dipstick, checking at least once a week, since insufficient fluid significantly increases wear.

In addition, the oil should also be changed correctly, using only the traditional draining method.

Quality fuel

Use only the type of fuel recommended by the vehicle manufacturer. Information can be found in the instructions or on a sticker located on the inside of the gas filler door.

The use of low-quality gasoline with a low octane number affects the detonation process. Carbon deposits form, the engine overheats, valves and pistons fail.

Also keep an eye on the fuel level; experts do not recommend driving with the light on. Try to keep the tank at least half full.

Coolant

Must meet the vehicle manufacturer's requirements. Monitor the coolant level, do not replace with water. Only high-quality antifreeze can provide an optimal level of cooling and maintain the system in working order.

Riding mode

Driving in abnormal modes significantly reduces the life of the car's heart. This includes driving at high speeds, sudden starts, braking, and driving too slowly.

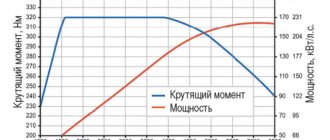

The middle range is optimal, when the tachometer needle stays at 2-2.5 thousand revolutions, and timely gear shifting.

Also avoid prolonged warm-ups and idling, which increases wear.

Experts advise going to the highway about once a week, giving the engine the opportunity to accelerate, burning off accumulated deposits and carbon deposits.

Timely elimination of engine malfunctions

The appearance of extraneous sounds, knocking, unpleasant odors, leakage of liquids and other uncharacteristic symptoms should immediately alert you. Often the failure of one part entails disruptions in the operation of the entire mechanism, leading to expensive repairs.

Running in the engine

The engine is new or needs to be run in after a major overhaul. The mechanisms require running-in and lapping. Control the number of revolutions, avoid increasing 3000 rpm, move smoothly, without sudden braking and starting.

The duration of the running-in is 1500-2000 kilometers. Neglecting the break-in rules is fraught with a decrease in car power, an increase in oil and fuel consumption, and ultimately - general engine wear.

Read the instructions

Knowledge of mechanisms and components, their location, and maintenance procedures is important for beginners and professionals, as technologies change and improve from year to year. Maintenance in accordance with the regulations is the key to long and uninterrupted operation.

Avoid using oil and fuel additives

Any additives and additives that are not recommended in the vehicle’s operating instructions have dubious merits. This is especially true for additives in oils and washes, since a good oil already contains everything necessary.

Unregulated additives change the composition of the fluid already present in the system, which leads to unpredictable consequences.

Regular replacement of consumables

The service life of the engine is significantly increased by timely replacement of consumables: air, oil and fuel filters, spark plugs and wires.

The air filter provides a flow of clean air, participating in the combustion process of the fuel-air mixture. Filter contamination reduces the amount of incoming air, the engine does not receive the necessary mixture, increasing fuel consumption, forming carbon deposits and reducing service life.

Timely replacement of spark plugs and high-voltage power wires (after 20-30 thousand kilometers) ensures uninterrupted operation of the ignition system.

Helpful advice

The main rule of a motorist is the timely completion of the necessary types of work in accordance with the regulations and operating conditions. It is important not to neglect regular technical inspections in specialized centers where the necessary equipment is available. In addition, you should purchase spare parts and consumables without chasing cheapness, choosing only high-quality and appropriate car models.

A dirty oil filter leads to a decrease in service life. If the fuel filter is not replaced in a timely manner, it can lead to a complete stop of the engine.

Useful tips

As you know, any problems in the fuel system lead to unstable engine operation. Debris and impurities in the fuel also cause certain harm to the internal combustion engine. To prevent the entry of various contaminants, several fuel filters (coarse and fine filters) are installed in the system.

In most cases, these elements do a good job of cleaning, but this does not always happen. More specifically, the habit of driving with an almost empty tank and rolling out the remaining fuel causes a reduction in engine life.

The fact is that sediment and dirt accumulate at the bottom of the gas tank during operation, and condensation can also collect. Over the course of several years, quite a lot of such garbage can accumulate. It is quite obvious that when driving with an empty tank, debris actively gets into the fuel filters and clogs them. Moreover, some contaminants pass through the filter element and enter the combustion chamber, forming deposits inside the internal combustion engine.

To prevent this from happening, you must always keep the fuel level at least half the tank. This will preserve the fuel pump and extend the service life of the filters; in cold weather, the amount of condensation will decrease, and the risk of unwanted impurities getting from the gas tank into the engine will also be reduced.

What is a bully?

Scuffing is the mutual damage to the friction surfaces when they operate without clearance. There is no gap, which means lubrication stops. Further movement in the absence of lubrication leads to micro-welding of the protruding elements of micro-roughness. The disruption of these particles leads to a further increase in temperature. In the case of a cylinder, this further increases the diameter of the piston due to thermal expansion - the scuffing increases. The phenomenon can continue until the piston completely jams. The result is destruction of the piston, connecting rod, cylinder block and, possibly, the crankshaft. It's time to go for another engine.

Seizure in the cylinder.

Seizure in the cylinder.

Retracted piston.

Retracted piston.

WHERE DOES SCORING FORM? |