Rules for choosing a cross

This is what the part looks like

On VAZ 2106, auto mechanics advise changing the crosspieces as a set. In some cases, 3 crosses are replaced at the shank. The best parts are made in Germany. Products from the following manufacturers are installed on the VAZ 2106.

- Trialli with oiler. Made of steel and uniformly hardened over the entire surface. Such parts can withstand significant dynamic and statistical loads.

- Kraft. Made from anti-corrosion stainless steel alloy. The manufacturer provides a warranty on the part.

- Weber, GKN and other foreign manufacturers. The disadvantage of such products is the need to adjust the retaining rings.

- Domestic products. Plus - affordable price.

Replacing the crosspiece on a VAZ 2106 car involves dismantling the cardan. To do this you will need an inspection hole or a jack. Removal and installation are carried out using keys “12”, “13”, “27” and a hammer.

The suspension bearing is installed using a tension puller and an old flange. The release spring is disconnected from the bracket using pliers, then it is dismantled. The cardan is jammed with a screwdriver. Unscrew the nuts and remove 1 end of the cardan. The plank and plate of the suspended structure are dismantled. The cardan is removed. The location of each part is noted so that the balancing of the shafts is not disturbed. The retaining rings are dismantled. Using a puller or vice, remove the bearing. If an anvil is used for this, then the cover of the 2nd bearing should not rest against the plane of this device.

The VAZ 2106 cardan is turned over 180°. Similar actions are carried out with the 2nd bearing. If the process is carried out without a puller, then the blows are made on the crosspiece or on the 2nd part of the cardan (with a transverse crosspiece). The bearing is pulled out of the fork. The transverse cross is disengaged. The puller is installed on the 2nd pair of bearings.

https://youtu.be/https://youtu.be/MhbHBuPffrs

_

Replacing the driveshaft crosspiece in a VAZ 2107 2105 2106 with your own hands.

Today we will learn with our own hands how to quickly and correctly replace the driveshaft crosspiece on VAZ cars of the classic family, such as VAZ 2107, VAZ 2105, VAZ 2106, etc.

We drive into the inspection hole, as in our case, or lift the car on a lift. Unscrew the 4 bolts on the cardan shaft:

We unscrew the two bolts on the suspension bearing (a 12 or 13 wrench, depending on which bolt you have):

We dismantle the cardan. We wrap the splined part with a clean rag to prevent sand and other dirt from getting there. We tap through the mandrel:

We pull it out using pliers:

We select a suitable mandrel and press out the old cups through it:

The last part is knocked out with a hammer. We clean the seats from sand and dirt with a metal brush, carefully clean all the grooves with a screwdriver, and lubricate them. Installing a new driveshaft crosspiece:

We use round-nose pliers to install new locking rings (they come complete with a new cross):

We check the work by rocking it in each direction. The crosspiece should rotate equally left and right, up and down. If one of the sides rotates worse, then when you put the driveshaft on the car you will feel vibration. One of the sides rotates tighter, so we remove the retaining ring from this side and grind it down with sandpaper to make it a little thinner:

After turning and reinstalling, the flange began to move easily in each direction, it can be easily moved with a finger. At the same time, we check the suspension bearing, twist it, make sure there is no noise or play, the rubber band should be intact and not torn.

When replacing the middle crosspiece, mark the cardan with the half-cardan with chalk so as not to confuse it. The removal process is identical to the rear crosspiece:

The video shows the process in full. Before installing the cardan, lubricate its splined part with nigrol.

Step-by-step installation of the part

Before installation, the crosspieces are checked and lubricant is applied to the parts. For lubrication, use “Fiol” or another substance of similar effect. The bearing housing is inserted into place, the forks are pressed into place. Then the retaining rings are installed. They hit the forks with a hammer. All gaps existing between the bottom of the bearing and the ring disappear. To check the free movement of the main part, use a feeler gauge. The stroke should not exceed 0.04 mm. Otherwise, a larger diameter ring is installed.

The rings come in 5 sizes, each with its own color. If the thickness of the part is 1.5 mm, then the product is not painted.

Disassembling the cardan to remove the cross

Replacing the crosspiece involves installing a new outboard bearing. This procedure is carried out after dismantling the cardan and crosspiece. Then unscrew the front shaft nut. The puller is fixed to the fork. Using a hammer, the fork is moved and pressed from the splines. The outboard bearing fixing bolts can be unscrewed with a 13 key.

The main part is knocked out of the shaft. Reassembling the cardan is carried out in the reverse order. If the above process is carried out without dismantling the cardan, then an assistant will be required.

Lada 2106 “Red Garnet” › Logbook › Replacing crosspieces

Good day to all!

Yesterday we replaced the universal joint crosspieces. Due to noise during gear shifting. As it turned out, the bearings on the crosspiece were worn out.

How to determine crosspiece wear

If, when lowering the pedal, when shifting gears, or during sudden acceleration or braking, you hear a knocking sound in the cardan drive, vibration of the axle, this indicates severe wear of the crosspiece and bearings. It is urgent to carry out work to replace these worn-out parts. You can, of course, ignore the symptoms, but then there is a high probability that the bearing will collapse and the cardan will fall out someday right on the road. The gearbox may also be damaged.

You should have the following tools at hand: open-end wrenches 12 and 13, a copper or aluminum adapter, compression pliers, a hammer, a socket wrench 13 and 27. If it becomes necessary to replace the outboard bearing, you will need a tension puller and an old flange of the elastic coupling.

Removing the cardan on a VAZ 2106 Sequence of actions when removing the cardan

Using round nose pliers or pliers, disconnect the tension spring from the body bracket and remove it.

Mark with paint the joint between the gearbox flange and the cardan (this will be useful during assembly). Having jammed the cardan with a screwdriver so that it does not turn, unscrew the self-locking nuts (there are four of them) with a No. 13 wrench.

After the nuts are unscrewed, one end of the cardan can be easily removed.

The relative location of the elastic coupling flange and the cardan should also be carefully noted.

Bend back the 4 locking tabs on the seal ring near the elastic coupling.

Carefully move the cage towards the cardan (together with the seal).

Using a 13mm socket, unscrew the two nuts and remove the safety bar.

Using a 13mm wrench, unscrew the two nuts and remove the plate of the outboard bearing, secured to the body through rubber washers, from the studs that secure it to the body.

Remove the cardan shaft from the splines of the flexible coupling flange and remove it.

Which crosspiece is better to install?

Car service specialists say that if the time has come to change the crosspiece, then it is better to change them as a set, both of them. In fact, this is not always the case. The front crosspiece, as a rule, lasts much longer than the rear one. Sometimes three crosspieces are replaced at the shank, but at the outboard bearing the crosspiece remains fully functional.

Experts advise not to “kill the ears of the cardan”, and not to change the crosspiece unless necessary.

When purchasing, you should not save on cost, it will be more expensive. Quite good crosspieces made in Germany are of high quality and come complete with retaining rings, which come in very handy if the “original” ones break during disassembly.

Trialli reinforced crosspieces (with an oiler at the end of the tenon) - made of high-carbon steel, uniformly hardened over the entire surface. Withstands high static and dynamic loads. The improved seal design provides reliable protection from sand and dust to the bearing units.

The crosspieces (with oiler) are made of a special stainless steel alloy that is resistant to corrosion. The manufacturer guarantees high quality based on multi-stage control during the production process.

Crosspieces from Weber, GKN, etc. The only disadvantage of imported crosspieces is that the retaining rings often need to be adjusted.

Installation of crosspiece VAZ 2106

First, you should check the presence of lubricant in the new crosspiece on the inner surface of the bearing housings and the spikes of the crosspiece. If necessary, lubricate the crosspiece bearings with Fiol. Place seals and plastic plugs on the crosspiece. Insert the spider spikes into the fork. Place the bearing housings and press them into the fork holes. The bearing should go deeper than the groove for the retaining ring. Install retaining rings. Tap the forks with a hammer (preferably one with a plastic striker). The gap between the bottom of the bearing and the retaining ring is eliminated under the influence of impacts and gaps will appear between the ends of the crosspiece studs and the bearing housings. Use a feeler gauge to check the axial free play of the crosspiece - it should not exceed 0.04 mm. If the axial stroke is greater, replace the ring with a larger diameter. Retaining rings are available in five sizes. For clarity, each size has its own color. Rings with a thickness of 1.5 mm are unpainted, 1.52 mm are dark brown, 1.56 mm are blue, 1.59 mm are black, 1.62 mm are yellow. Check the balancing of the cardan drive and the ease of rotation of the hinge forks.

Lada 2106 “Red Garnet” › Logbook › Replacing crosspieces

Good day to all!

Yesterday we replaced the universal joint crosspieces. Due to noise during gear shifting. As it turned out, the bearings on the crosspiece were worn out.

How to determine crosspiece wear

If, when lowering the pedal, when shifting gears, or during sudden acceleration or braking, you hear a knocking sound in the cardan drive, vibration of the axle, this indicates severe wear of the crosspiece and bearings. It is urgent to carry out work to replace these worn-out parts. You can, of course, ignore the symptoms, but then there is a high probability that the bearing will collapse and the cardan will fall out someday right on the road. The gearbox may also be damaged.

You should have the following tools at hand: open-end wrenches 12 and 13, a copper or aluminum adapter, compression pliers, a hammer, a socket wrench 13 and 27. If it becomes necessary to replace the outboard bearing, you will need a tension puller and an old flange of the elastic coupling.

Removing the cardan on a VAZ 2106 Sequence of actions when removing the cardan

Using round nose pliers or pliers, disconnect the tension spring from the body bracket and remove it.

Mark with paint the joint between the gearbox flange and the cardan (this will be useful during assembly). Having jammed the cardan with a screwdriver so that it does not turn, unscrew the self-locking nuts (there are four of them) with a No. 13 wrench.

After the nuts are unscrewed, one end of the cardan can be easily removed.

The relative location of the elastic coupling flange and the cardan should also be carefully noted.

Bend back the 4 locking tabs on the seal ring near the elastic coupling.

Carefully move the cage towards the cardan (together with the seal).

Using a 13mm socket, unscrew the two nuts and remove the safety bar.

Using a 13mm wrench, unscrew the two nuts and remove the plate of the outboard bearing, secured to the body through rubber washers, from the studs that secure it to the body.

Remove the cardan shaft from the splines of the flexible coupling flange and remove it.

Which crosspiece is better to install?

Car service specialists say that if the time has come to change the crosspiece, then it is better to change them as a set, both of them. In fact, this is not always the case. The front crosspiece, as a rule, lasts much longer than the rear one. Sometimes three crosspieces are replaced at the shank, but at the outboard bearing the crosspiece remains fully functional.

Experts advise not to “kill the ears of the cardan”, and not to change the crosspiece unless necessary.

When purchasing, you should not save on cost, it will be more expensive. Quite good crosspieces made in Germany are of high quality and come complete with retaining rings, which come in very handy if the “original” ones break during disassembly.

Trialli reinforced crosspieces (with an oiler at the end of the tenon) - made of high-carbon steel, uniformly hardened over the entire surface. Withstands high static and dynamic loads. The improved seal design provides reliable protection from sand and dust to the bearing units.

Kraft crosspieces (with oiler) are made of a special stainless steel alloy that is resistant to corrosion. The manufacturer guarantees high quality based on multi-stage control during the production process.

Crosspieces from Weber, GKN, etc. The only disadvantage of imported crosspieces is that the retaining rings often need to be adjusted.

Installation of crosspiece VAZ 2106

First, you should check the presence of lubricant in the new crosspiece on the inner surface of the bearing housings and the spikes of the crosspiece. If necessary, lubricate the crosspiece bearings with Fiol. Place seals and plastic plugs on the crosspiece. Insert the spider spikes into the fork. Place the bearing housings and press them into the fork holes. The bearing should go deeper than the groove for the retaining ring. Install retaining rings. Tap the forks with a hammer (preferably one with a plastic striker). The gap between the bottom of the bearing and the retaining ring is eliminated under the influence of impacts and gaps will appear between the ends of the crosspiece studs and the bearing housings. Use a feeler gauge to check the axial free play of the crosspiece - it should not exceed 0.04 mm. If the axial stroke is greater, replace the ring with a larger diameter. Retaining rings are available in five sizes. For clarity, each size has its own color. Rings with a thickness of 1.5 mm are unpainted, 1.52 mm are dark brown, 1.56 mm are blue, 1.59 mm are black, 1.62 mm are yellow. Check the balancing of the cardan drive and the ease of rotation of the hinge forks.

Here is the result. =)

All that remains is to install the cardan in place =)

Source: www.drive2.com

VAZ 2106 replacing the crosspiece yourself

The photo shows the universal joint of a VAZ 2106

Note: The driveshaft is a mechanism that transmits torque from the gearbox to the wheel drive. Used in a variety of vehicles. The main feature is a cardan transmission, invented by Gerolamo Cardano, which allows the transmission of torque between two non-parallel axes. The main working part of the cardan transmission is the crosspieces. They most often require replacement. The VAZ 2106 cardan contains two identical crosspieces. Our instructions will help you replace the VAZ 2106 crosspiece yourself; the replacement is quite simple and will allow you to save on car service costs.

How to diagnose wear on crosspieces

Replacing the crosspiece in a VAZ 2106 is carried out after diagnostics:

- When, during rapid acceleration or braking of a car, when changing gears, a knocking sound from the cardan transmission or vibration of the axle is heard, all this indicates wear of the crosspiece and its bearings. There is an urgent need to replace the VAZ 2106 crosspiece, which has become unusable.

- If you don’t pay attention to these signs in time, then the result will be destruction of the bearing and the cardan falling out directly onto the road. The axle gearbox and the underbody of your car can also be damaged.

Buy a “VAZ” crosspiece, do not forget to purchase spare retaining rings (if they are not included in the kit), because old rings, as a rule, become deformed or break.

Tool required for replacement

Replacing the driveshaft crosspiece of a VAZ 2106 requires the following tools:

- Two open-end wrenches 13 and 12

- Socket wrenches 27 and 13

- Copper or aluminum extension

- Hammer

- Compression pliers with thin jaws to remove circlips

- Two mandrels for pressing out the cardan cross bearings.

- Universal puller

- Ticks

- Chisel

- Large screwdriver

We remove the cardan

Replacing the VAZ 2106 crosspiece with your own hands is not possible without removing the cardan from the car. So:

- We remove the cardan on a lift or inspection hole. Unhook the handbrake cable spring.

- Using a chisel, we apply marks at the junction of the cardan and the gearbox flange. Using a 13mm wrench, unscrew the nuts (there are four of them). Use a large screwdriver to secure the cardan shaft from rotating.

- Remove the rear end of the cardan.

Disconnect the cardan from the bridge

- Use a chisel to mark the position of the cardan and flange of the rubber coupling

Mark the position of the cardan and flange with a chisel

- Then we bend the locking tendrils of the seal ring near the rubber coupling

- We move the cage with the seal together towards the propeller shaft

- Using a 13mm socket, unscrew the nuts and take out the safety bar

- Supporting the cardan, unscrew the nuts using a 13mm wrench and remove the plate securing the outboard bearing from the studs. It is attached to the body using rubber washers.

- We pull the cardan out of the slots inside the rubber coupling flange and take it out

It is first recommended to watch how to replace the crosspiece of a VAZ 2106 video.

Replacing the crosspiece, outboard bearing of the propeller shaft on a VAZ Classic

see also

Clutch release bearing: principle of operation, symptoms of malfunction

- 202 0 154k

Lubricant for crosspieces

- 89 4 86k

Replacement of the rear axle axle bearing of VAZ 2101 - 2107

- 82 18 90k

Strut support bearing

- 93 1 118k

Balancing the driveshaft

- 34 0 45k

This photo report demonstrates in detail the replacement of the crosspiece, as well as the outboard bearing of the propeller shaft on classic car models VAZ 2101 , 2102 , 2104-07 .

If you come to the conclusion that this procedure will be necessary, you should check them carefully before purchasing replacement parts. When purchasing a suspension bearing, make sure that it has elastic rubber and a smooth ride, since when installing a bearing with tight rubber on the cardan, vibrations on the car body cannot be avoided and the rubber itself will wear out faster in this case. The bearing should also rotate without snagging.

Which suspension bearing and crosspiece should I install on the VAZ Classic?

The original number of the outboard bearing is 2101-2202080, the average price is 330 rubles.

- SEVI 3103 — 426 rub.

- Trialli RM0133 — 471 rub.

- Master-sport 2101-2202080-ST-PCS-MS — 506 rub.

The original number of the cross is 2101-2202025, the average price is 260 rubles.

- Trialli CC506 — 212 rub.

- Toyo TU-51L — 350 rub.

- Zommer 21012202025 — 210 rub.

The parts needed for replacement are the bearing, spider and snap rings.

The set of tools is as follows: open-end wrenches for 12 and 13, socket wrenches for 13 and 27, pliers for removing retaining rings, a puller and an elastic coupling flange for replacing the outboard bearing, as well as a hammer and an adapter made of aluminum or copper.

Let's move on to removing the driveshaft from the car. Unscrew the nuts securing the propeller shaft to the rear axle shank.

First, using a 13mm wrench, unscrew the two bolts securing the suspension bearing to the transverse support.

After the cardan has been removed, not all of its parts need to be marked, so that in the future it can be assembled according to the applied marks in order to avoid its beating and vibration.

We change the cross. Using pliers, remove all retaining rings.

The cardan shaft must be installed in such a way that the crosspiece is suspended. Using a hammer and a mandrel, knock out the cup of the cross. A puller for cardan shaft crosspieces will allow you to do this faster and safer.

We unfold the cardan and take out the cup.

We repeat the same with the remaining cups of the cross, after which the eyes of the propeller shaft are cleaned of dirt and rust, as are the grooves for the retaining rings.

Remove two cups from opposite sides of the crosspiece and tuck the crosspiece into the eyes. Carefully, so as not to scatter the needles from the cup, move it to one side and put the cup on.

Using a soft metal adapter, we seat the cup until a groove for the retaining ring appears. Having installed the retaining ring, turn the cardan over. Carefully move the cross to meet the cup and put it on, in the same way we seat it until a groove appears. We install the retaining ring. The second part will be a little more difficult to assemble. The crosspiece has been replaced.

We are replacing the driveshaft outboard bearing. After removing the crosspiece, insert the splined end of the cardan into the flange of the elastic coupling.

From the other end, using a 27mm wrench, unscrew the nut securing the universal joint fork to the front shaft.

Use a puller to tighten the hinge fork.

after which we remove the outboard bearing from the shaft, for which you can use a puller after cutting off the outer ring of the outboard bearing. Or just try to knock him off the shaft. That's all, assembly is carried out in reverse order.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

Replacing the driveshaft crosspiece on a VAZ 2106

- We first mark the relative positions of the parts (cardan joint forks) so as not to disturb the factory balancing of the cardan shaft during assembly.

- Then we mark the locking rings and their seats in order to install them in their standard places during assembly. Remove the retaining rings (four from each hinge).

We take out the locking rings

- We press the bearings out of the hinge fork using mandrels of a suitable diameter.

- Since the bearings are not pressed in completely (the joint cross rests against its fork), we remove the bearing using pliers

- We disconnect the cardan joint by moving its crosspiece in the direction of the removed bearing, slightly turn the crosspiece and remove it from the hinge fork.

- Press the opposite needle bearing out of the hinge fork.

- We carry out steps 3 and 4 for other needle bearings and remove the cross.

- We do the same with the second cross if necessary.

As you can see, replacing the crosspiece on a VAZ 2106 with your own hands is not particularly difficult.

If necessary, replace the intermediate bearing

- Unlock the nut securing the front shaft fork. We unscrew it and press the fork using a puller from the front shaft.

- Remove the dust deflector from the front shaft.

- Screw the nut onto the threads of the front shaft so that it is flush with the shaft itself

- We compress the intermediate shaft support (we apply force to the inner race of the bearing) and unscrew the nut.

- Remove the support along with the bracket from the propeller shaft

Tip: Remember the position of the arms - the long and short support bracket relative to the driveshaft (it is better to mark the position of the support bracket relative to the driveshaft).

- We unscrew the bolts securing the bracket to the support, remove all the washers and disconnect the bracket from the intermediate shaft support.

Advice: Disassembling the intermediate support requires special tools and certain skills, therefore, it is recommended to change the intermediate shaft support assembly.

Defective parts

- We thoroughly clean the parts with a brush before inspecting them.

- To cull the cardan transmission elements you will need: a bore gauge, a dial indicator.

- Since we have removed the cardan and disassembled it (albeit partially), we check the integrity of the welds. Drive shaft splines so that they do not contain wear marks

- For the rear cardan shaft, we check the presence of balancing weights, the condition of the seams and measure the diameters of the fork holes for the needle bearing. Dents of pipes and misalignment of the holes of the cardan forks are not allowed.

Important: Be sure to measure the diameter of the holes in the universal joint forks, where the needle bearings go, so that it does not exceed 23.825 millimeters. Measurements are made with a dial gauge.

- We check the condition of needle bearings, oil seals, their cages and spider spikes for damage and significant wear.

Note: A clear sign of a defect in the studs, upon detection of which the entire joint is replaced, are longitudinal dents left by the bearing needles.

- At the same time, check (while the cardan is removed) the condition of the rubber coupling of the cardan.

- The presence of cracks, mechanical damage or detachment of rubber from steel liners is not acceptable.

- We check the intermediate support for deformations. Cracks or ruptures of the elastic clip, as well as peeling of the rubber, are not acceptable. Replacing the defective support assembly

- We check the intermediate support bearing, rotate its inner race in two directions, while pressing it against the outer race (the inner race should rotate smoothly). We check the bearing seals for mechanical damage.

- We replace all defective parts.

We assemble the cardan in the reverse order, taking into account the features given below:

- Before installing the front shaft fork, lubricate the splines of the fork and shaft with grease.

- When installing the front shaft fork, tighten the nut securing it with a torque wrench 8.1-10 kgf•m (79.4-98 N•m) and tighten the nut with a chisel.

- When installing the oil seal race, the oil seal itself with the flange onto the front driveshaft splines, we fix the oil seal race by bending its three “tendrils”.

- Using an oil syringe, coat the splined part of the front driveshaft. Remove excess grease with a rag. We unscrew the grease nipple and screw in the plug in its place.

How to replace the driveshaft crosspieces on a VAZ 2101-VAZ 2107?

Note! If you decide to change the crosspieces, then we also recommend sending the outboard bearing for replacement; when purchasing it, make sure that its rubber is elastic (Do not take a bearing with hard rubber under any circumstances), so that the bearing rotates without jamming and without snagging, if so bearing, find it and purchase it, how to change it, read the article entitled: “Replacing an outboard bearing on a car”!

1. First, you will have to remove the shaft itself from the car, removing it will not be difficult, but just before doing this, be sure to mark its position relative to the gearbox and relative to the box, because when you reinstall the shaft, it will have to stand exactly the same as and was installed earlier, otherwise the balancing of the shaft will be disrupted and when the car starts, strong vibration will be transmitted to the body and increased wear of the driveshaft parts will occur (And how to remove it was described in detail in the article entitled: “Replacing the driveshaft shaft on the car").

2. After the driveshaft is removed from the car, take a marker or punch or use them to make marks on the forks of the universal joints (If they were not made previously), now pry them off using a special tool. pliers, all four retaining rings (see photo below, before prying them off, we recommend that you remember at least a little how the rings were positioned, or even better, make marks as shown in the small photo; when installing new rings, they will need to be installed in approximately the same way) and start removing the crosspiece.

3. To remove you will need heads or special ones. mandrels for pressing out the bearings of the crosspieces and a hammer, placing something under the lower part (so that the propeller shaft forks are suspended), knock out the crosspiece together with the bearing down and tilt it, pull it out of the hole in the fork, thereby the forks will separate and you will only have to knock out the crosspiece from the last one forks.

4. It will be more difficult to knock it out of the last fork, also by placing the head and putting something under the bottom (To have the fork suspended, see the photo below), try to knock it out from above and tilt the cross, remove it from the bottom hole like this on the small one photos shown.

Note! The other crosspiece, which is located in the place where the cardan clings to the gearbox, is removed in the same way, don’t be afraid to remove the crosspieces at all, they are replaceable, so you can do whatever you want with them, knock them out, saw them, and so on, the main thing is not to damage the forks to the cardan shafts and then everything will be fine!

5. Installation of the crosspieces begins with the fact that you will need to remove two cups from them and then the crosspiece will become much more compact and can be easily inserted into the fork; after inserting these cups, these cups are installed in their place using a soft metal hammer and a spacer, you need to drive the cups until the groove is clearly visible into which the retaining ring is installed, when everything is completed, do the same with the other two cups and install another fork (the main thing is to orient everything according to the marks) and by the way, when installing the cups and their When removing, be careful, because there are balls inside them that cannot be scattered, as it will be very difficult to put them back in (see small photo).

Note! During all the work, this kind of problem may arise: The crosspieces cannot be removed due to the fact that they have become sour (Rusted), you can fight this with the help of kerosene, just wet the parts with it or something like that liquid and rub it with a metal brush, this will help and by the way, when the crosspieces are removed, clean their seats with a brush, especially those places where the retaining rings are installed, this is a must!

Additional video clip: Visual instructions for replacing the driveshaft crosspieces are shown in the video clip located just below:

Purpose of the VAZ 2106 cardan cross

When a car is moving, the axles of the vehicle are not always on the same straight line. They change their position relative to each other and the distance between the axes also changes. On the VAZ 2106, as on many other cars, torque from the gearbox to the rear axle is transmitted through a cardan, at the ends of which crosspieces (hinges) are installed. They are the main link of the cardan transmission, which connects the gearbox and the drive gear of the rear axle gearbox. Another important function is assigned to the universal joint crosspiece - the ability to dampen possible deformation of the universal joint due to the constant movement of all its elements.

What are cardan crosspieces made of?

Structurally, the universal joint is made in the form of a cross-shaped part with needle bearings, seals and covers, which are fixed with a stopper.

Cross

The cross itself is a product with perpendicular axes in the form of spikes, supported by bearings. The material used to manufacture the part is high-alloy steel, which has high strength. Such properties allow the crosspiece to withstand heavy loads for a long time.

Bearing

The outer part of the bearings is a glass (cup), the inner part is a spider spike. The movement of the cup around the axis of the tenon is possible thanks to the needles located between these two elements. To protect the bearing from dust and moisture, as well as to retain lubricant, boots and cuffs are used. In some designs, the end of the crosspiece tenon rests against the bottom of the cup through a special washer, which is a thrust bearing.

Stopper

Bearing cups in the holes of forks and flanges can be fixed in different ways:

- retaining rings (internal or external);

- clamping strips or covers;

- punching.

On a VAZ 2106, a retaining ring secures the bearing cup from the inside.

Which crosspieces to put on the “six”

If you listen to the opinion of service station specialists, they recommend replacing both universal joint crosspieces, even if only one of them fails. But not everything is so simple. The crosspiece located at the front of the driveline travels much longer than the rear one. There are situations when a part in the shank is changed three times, but near the outboard bearing there is no need to replace it. When choosing crosspieces for your car, you should not chase a low price, since repairs will ultimately cost more. Let's look at some hinge manufacturers that you can trust with your choice:

- Trialli. Made of high carbon steel and evenly hardened over the entire surface. The product is able to withstand high impacts of dynamic and static nature. The seal has an improved design, which increases reliability and protection against dust and sand getting inside the bearings.

Before purchasing and installing a universal joint, be sure to consider the size and shape of the cups. Attention should also be paid to the hinge pins. They should not have any burrs, marks or other defects. For domestic cars, it is better to give preference to crosspieces with a grease fitting, i.e., serviceable ones, which will allow you to periodically renew the lubricant in the bearings. The seals must not have any defects, such as visible tears or manufacturing defects.

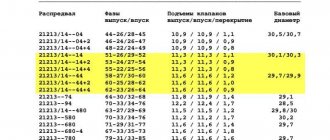

Table: parameters of the universal joint for the “classic”

| Number | Application | Dimensions DxH, mm |

| 2101–2202025 | Cardan crosspiece VAZ 2101–2107 | 23.8x61.2 |

| 2105–2202025 | Cardan crosspiece VAZ 2101–2107 (reinforced) | 23.8x61.2 |

Signs of faulty crosspieces

The VAZ 2106 crosspiece, like any other car part, has a certain service life. Theoretically, the service life of the part is quite long, about 500 thousand km, but the real figures are 10 times less. Therefore, replacement has to be carried out after 50–70 thousand kilometers. This is due not only to the quality of the parts, but also to our roads and the intensity of vehicle operation. Lack of periodic maintenance of crosspieces only brings the need for their replacement closer. The following characteristic signs indicate that there is some problem with the hinge:

- blows and knocks;

- chassis vibrations;

- squeaks when driving or accelerating.

Clicks and bumps

Often problems with crosspieces appear when the seals are damaged and dust, sand, dirt and water get inside the bearings. All these factors negatively affect the service life of the product. When the joints wear out, clicks will be heard when changing gears while moving, impacts at a speed of about 90 km/h, and a crunching or rustling sound will also appear. If metallic sounds occur, it is recommended to twist parts of the cardan, for example, by placing the car on an overpass. If large play is detected, the crosspieces will need to be replaced.

When diagnosing the gap in the crosspieces, the gearbox must be in neutral gear.

Video: play of the cardan cross

If clicks appear in the cardan area on my car, but I am sure that the crosspieces are still in good condition and should move, then, most likely, there is simply not enough lubrication in the hinges, for which they need to be injected. If clicks appear, I advise you not to delay maintenance, since the bearings will break and it will no longer be possible to do without replacing the crosspiece.

Creaks

The cause of squeaks in the area of the driveshaft is usually associated with souring of the crosspieces. The problem is clearly noticeable at the beginning of the movement and when driving at low speed, while the car creaks like an old cart.

The malfunction occurs when the hinges are not maintained, when the bearing simply cannot cope with its task. Sometimes, after removing the cardan, it is discovered that the crosspiece does not move in any direction at all.

Video: how the cardan cross creaks

Vibration

Malfunctions in the form of vibration with the universal joints can occur when moving forward or in reverse. The problem can be present with both old bearings and new ones. In the first case, the malfunction is caused by jamming of one of the hinges. If the vibration persists after replacing the crosspiece, then a low-quality part may have been installed or the installation was performed incorrectly. The crosspiece, whether old or new, should move in any of the four directions freely and without jamming. If you have to exert little effort when moving the hinge by hand, you can lightly tap the bearing cup; it may not be seated properly.

Replacing the VAZ 2106 universal joint

The cardan crosspieces must only be replaced, since the bearing needles and the outer and inner parts of the race wear out, which leads to the formation of play. This indicates the impossibility and inappropriateness of restoring the part. If characteristic signs indicate that the cardan joints need to be replaced, you will need to dismantle the shaft itself, and then begin repairs. For the upcoming work you will need the following tools and materials:

- open-end wrench 13;

- head 13 with a knob or ratchet;

- copper or aluminum extension;

- hammer;

- compression pliers with thin jaws;

- universal puller;

- chisel;

- new crosspiece;

- lubricant “Fiol-1” or “CV joint-4”;

- large screwdriver.

Removing the cardan

On the VAZ “Six” the driveshaft is mounted to the rear axle gearbox, and closer to the gearbox the driveshaft is held by an outboard bearing. Removing the shaft from the car is carried out as follows:

- Unscrew the cardan mount with a 13 key.

Removing the cross

After dismantling the driveshaft, you can immediately begin disassembling the crosspiece:

- We mark the universal joint forks to avoid disturbing the factory balancing during assembly. To apply marks, you can use paint (pictured below) or hit it lightly with a chisel.

- We remove the retaining rings using special pliers.

Installing the crosspiece and cardan

We install the hinge and shaft in the following order:

- We remove the cups from the new cross and insert it into the eyes.

Video: replacing the cardan cross on a VAZ 2101–07

The cardan crosspieces are filled with lubricant from the factory. However, when replacing a product, I always syringe the hinge after the repair. There will be no excess lubrication, and its lack will lead to increased wear. For crosspieces, it is recommended to use “Fiol-2U” or “No. 158”, but in extreme cases “Litol-24” will also do. Although I know car owners who use Litol for both crosspieces and spline joints. When injecting, I pump the lubricant until it begins to come out from under the seals. According to the regulations, the hinges must be serviced every 10 thousand kilometers.

You don't have to be an experienced auto mechanic to replace universal joints. The desire of the car owner and step-by-step instructions will help identify the malfunction and carry out repairs in a garage without making mistakes.

Replacing the VAZ 2101 driveshaft crosspiece - installation

- You need to remove both cups from the cross.

- Install the cross into the eyes.

- Slowly, moving it to the side, put on the cup, while making sure that the needles do not fall out of the cup.

- It is necessary to squeeze the cup until it forms a groove for the retaining ring, to do this, use a soft metal attachment.

- Install the locking ring, turn the cardan very carefully, while moving the cross forward towards the cup, and put it on. Squeeze the cup and install the retaining ring.

Replacement of the cross - completed! I believe you have succeeded, if I missed anything I hope you will find the answers in the informative photos. Thank you for your attention, try it and you will definitely succeed!

How to change the crosspiece 2106 with your own hands

In the article you will learn for what purposes the 2106 crosspiece on the cardan shaft is needed, as well as how to replace it with your own hands. The Six is one of the few cars that can be repaired independently, without the help of specialists at service stations. Unfortunately, everyone tries to earn as much as possible, and mechanics are no exception. Along with replacing the crosspiece, they will force you to install a new driveshaft, and this significantly increases the cost of service. Moreover, you can also run into “black” craftsmen who will include in the cost of repairs those items that were not actually completed. But we have moved away from the topic of conversation, let's still look at how a car is repaired.

Replacing the crosspiece of a VAZ 2106 - nothing is easier

So what does the cross do? With its help, it becomes possible to bend the driveshaft. Pay attention to how the rear axle flange and the gearbox shaft are located relative to each other. That's right, the axis of the second one is located higher, therefore, you need to somehow cheat in order to transmit the rotation. The driveshaft must “break” in two places so that movement from the gearbox to the rear axle is transmitted without any problems. In addition, the center of gravity of the entire propeller shaft must be such that axial runout does not occur. Don’t forget about the VAZ 2106 suspension bearing; it is used to attach the shaft to the bottom of the car. If it is destroyed, the axial runout increases, which leads to failure of the crosspieces.

To repair the driveshaft you will need the following tool:

- Open-end and ring wrenches for “12”, “13”, “10”. The latter can also be an end one.

- Pliers.

- Flathead screwdriver if necessary.

- Puller for retaining rings.

- Puller for crosspieces.

- Hammer and wooden spacer.

The procedure is quite simple, it will not take much time:

- Place the car on a flat surface, place stops under the front wheels, and lift the rear with a jack. If there is a hole, overpass or lift, these procedures do not need to be performed.

- Using a 10mm wrench, unscrew the two bolts that secure the suspension bearing to the bottom of the car. You shouldn’t remove them right away; it’s better to do it at the end, just before removing the cardan.

- Hold the head of the bolt that secures the cardan and rear axle flanges to each other with a 12mm wrench. Unscrew the nut with the head to “13”.

- Loosen the bolts securing the outboard bearing and apply several sharp blows to the shaft to knock it out of the rubber coupling.

- Using a puller, remove the rings and apply sharp blows to the driveshaft through the spacer with a hammer. In this case, the crosspiece 2106 should literally fly apart - the glasses will fall out of their seats.

- Before installing a new crosspiece, be sure to clean the seat under it and apply a small amount of lubricant. Do not hit the glass, as this will lead to the destruction of the needle bearing. It is very difficult to collect.

- First, install the VAZ 2106 crosspiece on the driveshaft, then on the flange. Or in reverse order.

The middle cross, located at the outboard bearing, changes in the same way. Before installing the cardan, make sure that the retaining rings are installed correctly and that they will not fall out of their grooves with the slightest force. Please note that the new rings that come with the kit may be thicker than the groove for them, so you will have to use old ones. And most importantly, before starting work, it is advisable to outline the location of the propeller shaft relative to the gearbox coupling and the rear axle flange. If an imbalance occurs, an extraneous hum and high vibration will appear.

Driveshaft VAZ 2106

The cardan transmission consists of two tubular shafts connected to each other by a universal joint, an elastic coupling and an intermediate support. The front driveshaft is made of a thin-walled pipe, with splined ends welded to both ends. A flange is placed on the splines of the front tip, which is fastened to the flange of the secondary shaft of the gearbox with six bolts through a rubber coupling. The alignment of the connected shafts is guaranteed by the centering ring 15, pressed onto the end of the secondary shaft, and the centering sleeve, pressed into the flange of the propeller shaft.

Replacing the cross

Sequence of actions when replacing crosspieces

The cardan has been removed. Once again, we emphasize that it is necessary to mark the relative positions of the parts with paint or a chisel, so as not to disturb the balancing of the shafts. Using pliers, remove the retaining rings.

Install the puller and press the needle bearing into the puller cup. If there is no puller, you can fix the driveshaft in a vice or place it on an anvil, but so that the opposite bearing cover does not rest against the plane of the anvil or the vice. While carefully tapping the cap of one of the bearings (a drift with a hammer), follow the opposite one.

The bearing should extend 1/3 of the way.

Turn the cardan 180 degrees and begin a similar operation to press out or knock out the second bearing. If the work is carried out without a puller, please note that you need to hit not on the cover, which already protrudes half a centimeter, but on the cross itself or on the second part of the cardan on which the cross member is held. After the second cover appears above the surface with the same protrusion half a centimeter, you can remove them using cobra pliers or, resting a screwdriver on the edge of the bearing housing, knock the pressed bearing out of the fork.

Release the cross member from its engagement.

Install a puller for the other pair of bearings.

Experienced car owners often do not remove the cardan to replace the rear crosspiece, but only unscrew the cardan from the axle. To do this, you need an inspection hole and, preferably, an assistant. If you have little experience in car repairs, it is better not to resort to this method.

Installing the clutch basket follow the link.

Malfunctions

If a howling or whistling sound occurs while the vehicle is moving.

Check the condition of the vehicle's propeller shaft support bearing.

The cardan shaft is out of balance; this can be due to mechanical damage, distortion, or a build-up of dirt on the surface of the shaft.

Severe wear or damage to the centering sleeve of the flexible coupling flange and the centering ring of the transmission secondary shaft.

Wear of the support bearing or increased clearance in the bearing, which led to the formation of whistling and howling of the cardan shaft.

The bearings of the cardan joints are worn out and may become jammed.

There is an imbalance in the cardan shafts.

Insufficient lubrication of the spline joint, check and lubricate if necessary, use LITOL-24 lubricant.

Perhaps the problem is in the elastic coupling, or rather, the flange seal ring has weakened.

What to do if a lubricant leak occurs?

Wear of the seal or loosening of the seal ring of the flexible coupling flange. It is also possible to loosen the nuts securing the elastic coupling.

Severe wear or mechanical damage to the universal joint seals.

In the front propeller shaft, the spline clearance has been greatly increased.

Severe wear and, as a result, a fairly increased gap in the bearings of the cardan joints.

Deformation of the cardan shafts is also possible.

Suspension bearing

To replace the crosspiece and suspension bearing on cars you will need: open-end wrenches 12 and 13, socket wrench 13 and 27, an aluminum or copper adapter and a hammer, compression pliers for removing the retaining rings, a tension puller, an old flange of an elastic coupling. You will need a puller and flange if you are replacing the driveshaft outboard bearing.