The front suspension of Gazelle cars is spring; a massive cast beam is installed on the front axle.

The connection between the beam and the steering knuckles is a pin connection; the pins turn together with the knuckles in bronze bushings that are pressed into the knuckles. The suspension itself is highly reliable, but only if it is regularly lubricated. Replacing the kingpins on a Gazelle with normal care is required after 70-120 thousand km, but if the suspension is not tightened, large play in the connections may appear after 20 thousand km.

Replacing kingpins on a Gazelle with your own hands. Let's learn and do

Anyone who has studied their native roads well will eventually need to replace the king pins on their Gazelle.

The majority of people prefer to carry it out with their own hands - anyone who has a similar domestic car has probably managed to know it inside and out and is unlikely to have the desire and money to entrust the car to some, albeit good, foreign masters from car service centers. A hint that the kingpins require replacement is a knocking sound and characteristic shaking in the suspension. To make sure that this is the case, you need to hang out the suspected wheel, grab it from above and below and try to swing the ramp in a position towards you/away from you. There is play, which means that either the king pins or the wheel bearing are damaged. A further check will be to turn the wheel outward and inspect the movements of the fist as it continues to swing. The frequency of changing pivots is affected not only by the roads, but also by the driving style (the more aggressive it is, the faster the suspension breaks), the degree of wheel wear, and the regularity of injections.

Replacing the kingpins on a Gazelle with your own hands is not a very complicated process. When you are used to servicing your car yourself, it won’t take too much time. Read more about how to do the work in our next article.

When to think seriously about renovations

As practice shows, replacing the pins is required when there is significant play that occurs on the steering knuckle. Determining the malfunction is quite simple - we hang the front wheel and, holding it at the 6 and 12 o'clock positions, make sharp jerks up and down. If play is felt, it means that the kingpin has exhausted its service life and needs to be replaced. A visual confirmation of the problem can be obtained by turning the wheel outward and shaking it - it is very problematic not to notice the excessive movement of the fist in relation to the front beam.

A number of factors can underlie such a problem, but most often the root cause is the following:

- Aggressively overcoming problem areas of the road;

- Malfunctions of wheels and steering tips;

- Lack of timely maintenance, including injecting;

- Incorrect tightening torque of the bearings on the front wheels.

Work order

Since you will need to disassemble the entire assembly, it is worth checking the accompanying elements at the same time.

- First of all, the oil is drained from the bridge, unless you want to go to the bathhouse for a long time and wash off everything that will be filled with it;

- The front end is hung out, reliable supports are placed under it (in the form of special metal spacers, wooden blocks) and the chassis is dismantled;

Subtleties of the process

If you have not worked on the kingpins of your Gazelle before, we will share the work of more experienced craftsmen. Firstly, when purchasing a repair kit you need to be extra vigilant: from time to time you come across kingpins with a smaller cross-section than needed. It is better to go shopping with a micrometer so as not to return for a replacement (which, by the way, may be refused). Secondly, when purchasing kingpins, pay attention to the bearings - they should be in a thick lubricating composition and rotate without the slightest crunch.

And so that replacing the pins on a Gazelle with your own hands is needed less often and proceeds without difficulty, do not forget to clean the screw groove on the bushings and introduce lubricant into it. It is precisely because of the clogging of this channel and the lack of oil on the bushings that removing the kingpin often takes more time than all other procedures - it turns sour from water and dirt so that it has to be knocked out by soaking, heating and swinging a sledgehammer.

Kingpins for Gazelle

The pivot joint has been used in mobile equipment for a very long time - it was used in carts and horse-drawn carriages. The pivot suspension is installed on Volga and UAZ cars, on GAZ 53/3307, KAMAZ, ZIL trucks.

Repair kits are sold for suspension repairs on Gazelle cars; the standard set includes four bronze bushings and two kingpins. The industry is also producing repair kits of a new type, in which the bushings are replaced with needle bearings. The price of a repair kit with bronze bushings is in the region of 900-1700 rubles; there are no problems with the spare parts themselves - they can be bought at almost any specialized auto store.

Auto stores also sell complete sets, which include:

- wedges (2 pcs.);

- spherical bushings (2 pcs.);

- kingpins (2 pcs.);

- rubber seals (2 pcs.);

- plug gaskets (2 pcs.);

- bronze bushings (4 pcs.);

- washers;

- nuts

Often, car owners of GAZ commercial vehicles are interested in how much it costs to repair king pins on a Gazelle. It should be noted that the work itself of replacing the pins (PS) is quite labor-intensive and requires considerable physical effort and time. Prices for repair work in car repair shops are different; the price depends on the level of the service station, region (location), and degree of complexity of the replacement. The point here is that in advanced cases (when the suspension has not been lubricated for a long time), the pins practically do not come out of their seats, and then you have to completely remove the front beam assembly and use a gas torch during disassembly. The cost of a ZSh for a Gazelle car on average starts from 2-2.5 thousand rubles for one side, the replacement price can reach up to 10-12 thousand rubles.

Replacing kingpins on a Gazelle with your own hands

Due to the fact that ZSh is not cheap, many commercial vehicle owners do such work with their own hands. Here we will look at how to change the king pins yourself with or without removing the suspension itself. First, let's look at how to do the job without removing the beam.

We disassemble and perform it in the following sequence:

- We place the car on a flat area; it is not necessary to use a pit or a car lift, but it is very desirable to have a concrete floor. In any case, the base must be rigid, otherwise the machine will simply fall through and be pressed into the ground;

- loosen the bolts of the front wheels, jack up each side, place supports (traces) on both sides. In a word, we hang out the “front” of the Gazelle;

- unscrew the two caliper bolts, which are located on the inside of the brake disc, and use a screwdriver to press the brake cylinder to release the pads;

- fold the caliper on the brake hose to the side;

- disconnect the caliper bracket;

- unscrew the bolts securing the plugs of the pivot joint (top and bottom);

- knock out the wedge;

- We take a piece of iron rod of suitable thickness and use a sledgehammer to knock out the kingpin from top to bottom. Very often the kingpin boils tightly in the body of the front beam, so it is sometimes simply impossible to knock it out in place. When the front suspension is not removed, the wheel arch prevents you from swinging a sledgehammer normally; the distance for swinging is not enough.

If you have a gas burner, you can warm up the connection properly, and perhaps the kingpin will move out of place. Having removed the steering knuckle from one side, we perform exactly the same operation with the other fist.

The steering axle (knuckle) can be disassembled after dismantling, but this is not at all necessary.

We clamp the removed trunnion in a vice, and knock out the upper and lower bronze bushings from the body one by one. Since the bushings are not needed, they can be knocked out in any way, the main thing is not to damage the seat under them. You can take an iron flat screwdriver or a bit, flatten the sleeve from one edge, and then it will fall out of your fist on its own.

Having knocked out both old bushings, we install new parts in place, hammering them into the seats of the steering axle using a sledgehammer. It is not recommended to beat as in the picture below; it is better to push the bushings into place through a spacer.

Having installed the bushings in place, we use a round file to approach them from above,

then we unfold them with a 25 mm reamer.

Here it is very important not to loosen the bushing - after passing the reamer once from top to bottom, you need to try on the kingpin in place. Ideally, the kingpin should fit into its seat very tightly, with a hammer (lightly tapping). It is normal that the pivot pin fits tightly; it will wear out very quickly as the vehicle operates. But loosening here is unacceptable, in this case play will quickly appear, and soon the suspension will again need repairs.

Instead of a simple reamer, you can use an adjustable reamer or a ball; keep in mind that the diameter of the ball should be 24.7 mm, no more. If the bushing is pierced with a ball with a diameter of exactly 25 mm, play will appear in the pivot joint almost immediately.

Before turning the hole with a reamer or ball, the bushing must be lubricated (motor oil, lithol can also be used). Having installed the bushings, we put the steering knuckles in their places. There are usually no problems with assembly; the most important thing in the ZSh is to disconnect the steering knuckles from the beam.

How to remove old hinges

Regardless of the type of hinge, the basic dismantling operations are the same. To replace or adjust the kingpins, you will need a level area. In addition, you will need:

- jack and safety stand;

- a set of socket and open-end wrenches;

- Screwdriver Set;

- set of sockets and ratchet;

- torque wrench;

- a powerful wrench and extension made from a piece of pipe;

- clean rags;

- wheel chocks;

- low stool;

- assistant or assistant.

It is important! If you are going to change or adjust the king pin, you should carefully read the safety rules and always follow them:

- never leave the car on a jack, always use a safety stand, which is sold in any car store, or a wide, flat block of wood;

- Be sure to support the wheels with wheel chocks;

- never carry out any work under the car alone - if something goes wrong, an assistant will be able to call for help or help you independently;

- do not drink alcohol, do not use narcotic or psychotropic substances before repairing your car.

Step by step guide

We have divided the entire process into separate operations that must be performed sequentially. This will help not only in disassembling the steering knuckle, but also in reassembling it after installing new or adjusting old hinges:

- Place the car on a level surface and apply the handbrake.

- Support the rear wheels with wheel chocks, then loosen the front wheel bolts and jack up that side.

- Place a safety stand under the car and remove the wheel.

- Unscrew the two bolts and remove the plate holding the pads, then pull out the pads.

- Unscrew the two bolts and remove the caliper bracket.

- Unscrew the two bolts, then remove and hang the brake caliper so that the hose is not strained or pinched.

- Unscrew the screws securing the brake disc and carefully hitting the back side with a piece of wood, knock it off the hub.

- Unscrew and unscrew the steering tip nut and remove the pin using a puller.

- Disconnect the ABS wire.

- Unscrew the bolts holding the plug at the end of the hub and remove it.

- Unscrew the 6 bolts securing the axle and remove it, the CV joint and the axle shaft from the steering knuckle.

- Unscrew the 5 bolts securing the ball joint to the axle flange and remove the wheel rotation limiter.

- Then remove the ball joint, place it on the table and clean off any dirt.

- Unscrew the 6 bolts securing the ball joint oil seal and remove the oil seal.

Removing ball joints

Unscrew the grease fitting or the bolt installed in its place and the 4 nuts securing the bipod to the steering knuckle. Using a hammer, lightly tap the bipod in the area of your fist to move it out of place. Remove the 4 cone washers, then remove the bipod and the shims underneath it. To remove the hinge parts, you will need a special puller, which can be made from a U-shaped profile 5 mm thick. The profile width is slightly larger than the diameter of the outer part of the kingpin. In the center of the puller, drill a hole whose diameter is 1–2 mm larger than the diameter of the hole for the grease fitting. Then take a 5-7 cm long bolt with a suitable thread and nut.

Screw a nut onto the bolt, then place the puller over the outer part of the hinge and screw the bolt into the plug through it until it stops. Tighten the nut until the bolt is completely pulled out of the outer part. If there is no such puller, you can try to pull out the hinge by screwing a bolt with large washers into it and squeezing the washers out with two pry bars, but this method is less effective. Then remove the ball and pull the ball joint out of the steering knuckle, then pull out the inner part of the joint in the same way. Thoroughly clean the places where the pins are installed to remove any remaining old grease.

Dismantling other types of hinges

The remaining types of kingpins are removed in the same way:

- Unscrew the upper kingpin nut, then hit the kingpin pin through a soft metal spacer to make it easier to unscrew the clamping sleeve.

- Using a special key (it is found in many sets of new king pins, and can also be bought at any auto store), unscrew the clamping sleeve.

- They pull out the finger.

- Unscrew the bolts of the rear plate of the steering knuckle and pull out the ball joint.

- Use a screwdriver to pry up and pull out the bearing shell or plastic/bronze cup.

- Thoroughly clean the liner and pin areas of old grease.

Installation of new kingpins

New ball joints are pressed in using a puller for replacing cylinder head guide bushings or a puller for replacing wheel bearings. You can use other pullers that will ensure that the upper and lower parts of the joint are fed strictly parallel to the channel in the ball joint and steering knuckle. Having installed the king pin in the ball joint, fill the space under the ball with Litol or a higher quality lubricant.

The rest of the hinges are installed like this:

- Insert new cups or liners into the ball joint, aligning the protrusions on them with the slots in the support, then slightly recess them by inserting the pivot pin into them and lightly hitting it with a hammer (it is advisable to use a spacer made of soft metal so as not to damage the threads).

- Fill the liner with lubricant.

- Insert the ball joint into the steering knuckle.

- The upper and lower fingers are inserted.

- Tighten the clamping bushings evenly on both sides. Tightening torque 70–100 Nm. After tightening the bushings, the ball joint should rotate with a force of 10–15 Nm.

It is important! Regardless of the type of joint, when installing and tightening, it is necessary to ensure the same distance from the ball joint to the steering knuckle at the top and bottom. Measure the gap using a caliper. The maximum gap difference is 0.2 mm.

Having installed the kingpin and secured the ball joint in the steering knuckle, lubricate the surface of the support with Litol or a better lubricant and install the oil seal, securing it with a metal ring and bolts. Then reassemble everything in the reverse order to what was used during disassembly. Don't forget to adjust the camber and toe.

Adjusting the kingpins

If there is a slight play on the front wheels caused by wear on the hinges, then on machines with ball kingpins, check one or more spacers located on the steering knuckle under the bipod, as well as under the plate that holds the lower kingpin. As a result of this, the bipod will press harder against the fist and provide a more reliable fixation. On machines with other types of kingpins, it is necessary to unscrew the top nut and tighten the clamping sleeve until the play is eliminated.

Removing the Gazelle front beam

If you can’t knock out the pins in place, you have to remove the entire beam. We do it this way:

- in the same way as in the option considered above, remove the wheels and hang up the front axle of the car;

- Disconnect the brake hoses from the calipers on both sides;

- remove the brake calipers;

- dismantle the front shock absorbers;

- disconnect the steering rod along with the lever from the long beam;

- on each of the two sides we disconnect the four nuts securing the beam to the springs;

- roll out the beam and remove the steering knuckles from it.

Next we produce ZSh. With the suspension removed, it is very convenient to knock out the kingpins even with a heavy hammer, and with a very sharp strong blow and a large sledgehammer, almost any “dead” kingpin can be moved from its place.

How to check play in Gazelle king pins

There are certain signs by which you can understand that play has appeared in the king pins on the Gazelle:

- uneven premature wear of the tire tread occurs;

- a knock appeared in the suspension;

- The car doesn't listen well to the steering wheel.

Checking the suspension for play is quite simple; to do this, you need to hang the car on a jack and rock each wheel from top to bottom. If play is felt (more than 2-3 mm), it is necessary to get up without repairs.

The Gazelle is a very durable car, and even with play in the suspension it can drive for quite a long time. But it is extremely undesirable to operate a car with broken bushings; there may be bad consequences:

- if the seat for the bushings in the front beam breaks, then the beam itself will have to be replaced, but it is not cheap;

- the tires will wear out quickly and you will have to change the wheels;

- Riding a Gazelle with large gaps is dangerous, you can get into an accident.

What does a king pin look like and what is it?

The part can be conical or cylindrical; fastening is done in different ways, in several units.

This is what the king pin looks like

Let's find out the reasons why you should change the king pins on a Gazelle. If you regularly check the steering knuckle play, you can change the unit in a timely manner. The procedure is as follows: the front wheel is hung out, in 12 o'clock format it is pulled by hand, pointing up and down.

Having felt the play, look at the bearing of the existing wheel, the kingpin.

While on the road, we simply turn the wheel outward, loosen it - we determine the standard for moving the fist relative to the front beam. After making a long trip on broken roads, we inspect the wheels of the car. It is better to make a replacement when repairing steering tips or assessing wheel balancing. Take a closer look at the assembly when the bearings on the front wheels are tightened.

How to care for your Gazelle pendant

The factory instructions specify the frequency of lubrication of the suspension on the Gazelle - after 15 thousand km, but experienced drivers advise filling the pin joints with lubricant approximately every 5-8 thousand km. Lubrication significantly extends the service life of the pins; with regular injection, parts can last up to 150 thousand kilometers without repair. It is not difficult to lubricate the connections; the main thing is not to be lazy about doing it.

We perform injection as follows:

- install the car on a pit or lift;

- prepare a syringe - fill it with lithol;

- we find the upper grease fitting and use a syringe to finish lubricating it;

- then fill the lower grease nipple with lubricant; first, the grease nipples should be cleaned from dirt with an iron brush;

Such grease nipples are located on each side of the front axle of the car. But there is one nuance here - even new grease nipples sometimes do not break through with lithol. It is safer to inject using a flexible hose. We proceed as follows:

- unscrew the oil nipple from the plug and screw in a flexible hose instead;

- install the other end of the hose on the syringe;

- Use a syringe to pump lithol into the kingpin.

It is necessary to pump in grease until it begins to protrude from the connections. Dirt will come out first, but you need to wait until clean lithol begins to appear from the connections. Having coated the king pin, unscrew the hose and replace the grease fitting. So we lubricate all four points on the suspension.

Hoses for the syringe are sold in car dealerships; they are standard and must fit the thread.

Car owners have different opinions about lubrication; some Gazelle owners believe that such pivot joints must be lubricated with thick transmission oil, for example, TAD-17. Still, it is more reliable to inject Gazelle with lithol or other grease - the “transmission” is too liquid, it quickly flows out of the pins. But on the Volga they mainly inject with nigrol (TAD-17), for this you can use even not too dirty mining.

Repair and replacement of kingpins on a Gazelle car

The Gazelle car from the AvtoGAZ plant belongs to a class of cars that are used, as a rule, with maximum intensity. Its technical characteristics, in particular the pivot suspension, provide the Gazelle with a wide range of applications, both for production needs and for personal purposes.

This is what Gazelle looks like

The kingpin, as elements of the chassis, initially have a limited resource, and when used under load, it naturally decreases. Replacing the kingpins on a gazelle with your own hands will significantly reduce the cost of repairs, and will also allow the owner to restore the functionality of his car in the shortest possible time.

Functional purpose of kingpins in a car

The rod that provides the turning properties of the wheel in a car is usually called a kingpin, and a suspension using axle rods is called a kingpin.

This is what the kingpin looks like when disassembled

The prototype for car suspension using pins was the device of a conventional wheeled cart, which was used back in the 19th century and used an axial hinge mechanism.

The principle of a king pin suspension is also based on the properties of a spherical joint, which allows the wheel to freely move and the hub to be secured, thereby allowing the vehicle to turn within the steering constraints.

Gazelle front suspension components

The main indicator of machine stability during maneuvers is the established transverse and longitudinal angles of inclination of each kingpin, which ensure comfortable movement.

The material for making the pins is durable hardened steel, and all cavities that come into contact with it are filled with lubricant.

Watch the video: replacing king pins on a Gazelle.

The scope of application of kingpins in suspension extends mainly to trucks and medium-duty vehicles, such as the Gazelle, as well as to off-road vehicles designed for off-road driving. This is due to the combination of simplicity, reliability and maintainability in this design.

Proper operation and timely maintenance will guarantee long and reliable operation of the kingpins in the car.

Let's start replacing - sequence of actions

After everything necessary for work has been prepared, you can proceed directly to replacing the unit, carrying out the work in this order:

Afterword

That's all, the pins have been replaced. As you can see, there is nothing complicated in this operation and absolutely everyone can do it. Don't be afraid to try and you will succeed.

After studying the roads, you need to replace the kingpins on gazelles with your own hands. Car enthusiasts carry out all this work without outside help, in their own garage. Thanks to this, you will have confidence that nothing will go missing. Of course, you can contact a specialized service and have the technicians perform the replacement for money. But not every motorist trusts such workers, even professionals. There are times when after repairs new problems arise, you have to spend even more money and nerves.

Replacing the kingpins on a gazelle with your own hands is not a very complicated process; every driver can do it in his own garage. The main thing is to have a tool and free space. It is worth noting that many car enthusiasts have studied their vehicle inside and out and know all the features and what to look for. The first symptom of trouble is a characteristic shaking while moving. To make sure of all this, you need to hang the problem wheel, grab the base and swing it in different directions. If you observe play, you will have to change the king pins and wheel bearings.

If you do nothing, then in a short period of time the wheels will fail, and you may get into a traffic accident. It is also necessary to turn the wheel and inspect the steering knuckle while continuing to swing. Experts note that the service life of kingpins is affected not only by the quality of the road surface, but also by driving style. If the driver accelerates and brakes sharply, the parts will quickly fail.

Operating procedure

As for the replacement itself, there is nothing complicated here. The main thing is to have a special tool and free space in the garage. To simplify the work, you can call your friend to help with the work:

Subtleties

Be careful before purchasing a repair kit. The fact is that there are kingpins with a smaller cross-section. Because of this, they simply do not fit into the base of the pendant. Also pay attention to the bearings. They must have special lubrication and turn without any problems. Replacing the kingpins on a gazelle with your own hands is not a very difficult task. The main thing is to have free space in the garage, time and tools.

The Gazelle car from the AvtoGAZ plant belongs to a class of cars that are used, as a rule, with maximum intensity. Its technical characteristics, in particular the pivot suspension, provide the Gazelle with a wide range of applications, both for production needs and for personal purposes.

This is what Gazelle looks like

The kingpin, as elements of the chassis, initially have a limited resource, and when used under load, it naturally decreases. Replacing the kingpins on a gazelle with your own hands will significantly reduce the cost of repairs, and will also allow the owner to restore the functionality of his car in the shortest possible time.

The rod that provides the turning properties of the wheel in a car is usually called a kingpin, and a suspension using axle rods is called a kingpin.

This is what the kingpin looks like when disassembled

The prototype for car suspension using pins was the device of a conventional wheeled cart, which was used back in the 19th century and used an axial hinge mechanism.

The principle of a king pin suspension is also based on the properties of a spherical joint, which allows the wheel to freely move and the hub to be secured, thereby allowing the vehicle to turn within the steering constraints.

Gazelle front suspension components

The main indicator of machine stability during maneuvers is the established transverse and longitudinal angles of inclination of each kingpin, which ensure comfortable movement.

The material for making the pins is durable hardened steel, and all cavities that come into contact with it are filled with lubricant.

Watch the video: replacing king pins on a Gazelle.

The scope of application of kingpins in suspension extends mainly to trucks and medium-duty vehicles, such as the Gazelle, as well as to off-road vehicles designed for off-road driving. This is due to the combination of simplicity, reliability and maintainability in this design.

Signs of wear on the pivot suspension on the Gazelle

Before you begin repairing the suspension, you need to make sure that replacing the kingpins on the Gazelle is really necessary.

The first signs of a faulty king pin may include the following symptoms:

- The appearance of a metallic sound when hitting the wheel.

- Vibration in the steering wheel at speed.

- Difficulty turning the steering wheel.

- Pronounced wear on the outer or inner part of the tire.

We recommend watching: how to check for faulty pins on a Gazelle.

However, the presence of these manifestations can also be caused by other malfunctions of the chassis, so it is necessary to carry out further diagnostics to localize and clarify the degree of wear of suspension parts.

To be completely sure that the kingpin in the Gazelle requires replacement, you need to:

- lift the car with a jack, ensuring the wheel is suspended;

- fix the hub mechanism with the brake pedal;

- swing the wheel in a vertical plane.

This is what a worn king pin looks like

The presence of play in the wheel when swinging indicates a malfunction of the kingpin, which must be replaced.

Checking the wear of the kingpin and bushings

We carry out the check with the front wheel hub bearings adjusted.

1. Raise the front wheel with a jack. Rock the wheel in a vertical plane.

If play is felt (the upper outer edge of the brake caliper moves more than 0.5 mm - this distance can be measured, for example, using an indicator), then the kingpin and bushings are worn out and need to be replaced.

2. Place the car on the wheels and use a feeler gauge to measure the gap between the upper ear of the steering knuckle and the boss of the front suspension beam.

The maximum permissible gap is 0.15 mm. Eliminate the gap from 0.15 to 1 mm by selecting an appropriate set of adjusting washers installed between the upper ear of the steering knuckle and the boss of the front suspension beam.

If the gap is more than 1 mm, replace the thrust bearing.

Technology for replacing kingpins on Gazelle

To repair the pivot suspension on a Gazelle, you need to prepare the following parts and tools:

- Repair kit containing all necessary parts, including new king pins.

- Reamer for Gazelle 25 mm, as well as a holder.

- Set of sockets and keys.

- Wheel bearing puller.

- CV joint lubricant, carburetor cleaner and VD-40 fluid.

- Kingpin lubricant and thread locker.

Watch the video: replacing the pivot on a Gazelle.

It is recommended to replace both kingpins on the axle as part of one repair to ensure identical operation of the steering mechanism when driving.

The front part of the car must be suspended using a jack and supports that are placed under the beam, and the wheels must be removed, thereby ensuring the possibility of carrying out repair work.

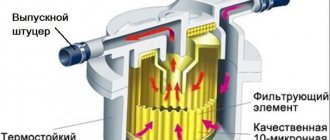

External view of the pivot suspension

The replacement technology is as follows.

- Initially, it is necessary to remove the oil from the bridge.

- Remove the brake caliper and disc.

- Having unscrewed the brake shield, the entire drive must be removed as an assembly together with the bearing in the housing.

- Next, the steering tip and the oiler located below are dismantled.

- After which the pivot cap, lubrication valve and plug are removed.

Removing the pivot suspension

When disassembling the assembly, it is advisable to process the parts with VD-40, as well as use the appropriate tool. It is recommended to heat parts that are difficult to remove with a torch or soak them in kerosene. The kingpin itself is usually knocked out with a hammer from the bottom up. The second part on the other wheel is dismantled in a similar way.

- The dismantled parts must be cleaned of dust and dirt by pre-treating them with cleaning liquids, and a visual inspection of their condition must be carried out. All parts with cracks or significant wear must be replaced.

- The installation process is performed in reverse order using new components.

Disassembled parts of the pivot suspension

In this case, you need to take into account some features:

- The steering knuckle bushings are pressed in using a mandrel; the installed parts are lubricated with CV joint grease;

- when developing new bushings, the technological tolerance ranges from 0.02 to 0.053 mm, and alignment must be strictly observed;

- it is recommended to perform the reaming through the old bushing, which is not dismantled, but remains in the steering knuckle;

- When installing a support bearing with a boot, it is important to observe the assembly directions, and it is installed so that the boot is on top;

Watch the video: how to replace the kingpin and install bushings in the axles.

Upon assembly, it is necessary to completely lubricate and check the assembly. After this, all parts are installed on the car in the reverse order, oil is poured into the axle and the wheels are installed.

If you follow the rules and use this technology, repair work can be done on your own.

Thus, replacing the kingpins on a Gazelle is a periodic procedure that ensures the car’s controllability and maneuverability on the road. The presence of a special tool and knowledge of technology will allow each owner to repair their car independently.

king pins

How to repair a Gazelle gearbox

1 year ago

UAZ Patriot, Hunter adjustment and lubrication of kingpins.

Subtleties of adjustment and lubrication of pins.

1 year ago

Do-it-yourself repair of pins on a Gazelle + what devices are needed

Punches (DIMENSIONS AND HOW TO USE HERE) https://www.youtube.com/watch?v=JCb5a2M-krc&t=99s Repair of gazelle kingpins. adapted...

10 months ago

Broaching the king pins

With a mileage of more than 60,000 km, the standard kingpin bearings still required restoration of the preload. How...

3 years ago

Tightly seated kingpin, the correct way to press out

The Auto-Craft company specializes in the restoration of automotive parts, combines, excavators...

3 years ago

Replacing kingpins on Gazelle

We roll out the beam completely and change the king pin! We knock them out in 10 minutes and install new ones! Thank you for watching…

3 years ago

How to syringe a kingpin

This video describes how to inject a king pin on a gazelle. Video tutorial for beginners. DETECTING ALL TYPES…

6 months ago

Replacing the king pin on Kamaz Euro!

RepairKamaz Donat Kingpin: https://www.donationalerts.com/r/gmeka https://www.instagram.com/zheka_saltovskiy/

3 years ago

Checking the king pins

We check the kingpins at home for play. Most often the kingpin in the steering knuckle breaks...

2 years ago

replacing old-style UAZ king pins

replacement of old-style UAZ kingpins.

4 years ago

#12 - Replacing kingpins on a truck

Uncle Roma changes the king pins on a Japanese truck. Very labor-intensive, a lot of sledgehammer work...

4 years ago

Replacing kingpins on MAZ and MAN

2 years ago

Pressing out the steering knuckle pin

Kingpin puller mod. VSh75-125 with a manual hydraulic drive is used for pressing out (pressing in)…

1 year ago

Kamaz kingpin repair. Installing a thrust bearing instead of washers!

A short guide on how to deal with jammed or rotated bushings on a kingpin in a KamAZ, call for...

5 months ago

Adjustment, centering of kingpins and steering knuckle, military axle

4 years ago

how to remove the backlash of the king pins on a UAZ

broaching kingpins for UAZ cars.

2 years ago

ZIL Diesel No. 3 (Replacement of pins, axles, bushings)

I'm on VKontakte - https://vk.com/id290812754 I'm on D2 - https://www.drive2.ru/users/krivosheevov/#blog.

2 months ago

Long-distance travel across the USA! Replacing the pins!

2 months ago

We got our hands on the kingpins! Roller bearing, in place of the Kamaz sliding washer.

6 months ago

Replacement of Gazelle pins, broaching of bushings. How to do it yourself.

How to replace kingpins and seal bushings on a Gazelle. DIY repairs. What tool is needed for this...

9 months ago

Let's disassemble the Kingpin on the UAZ Patriot. Repairs that you can do yourself.

We disassemble the pivot unit for the UAZ Patriot 2021. and change the liners. All work is performed in the Max...

1 year ago

How to tighten the kingpin of a UAZ Patriot, Hunter, LOAF

DO NOT JUDGE STRICTLY AND YOU WILL NOT BE JUDGED https://vk.com/id55935184 I'm in contact.

6 years ago

KPP 230 King pin extractor for commercial vehicles

8 months ago

Correct replacement of kingpin bushings, review of the kingpin for the Gazelle.

Hello everyone, I bought a kingpin presser for a gazelle for 3750. How to replace the kingpin yourself so that...

1 year ago

An effective way to lubricate the pins on a Gazelle

Brothers who asked for the sizes of bushings and drifts here https://www.youtube.com/watch?v=JCb5a2M-krc Repair of kingpins https://www.youtube.com/wa...

2 years ago

Replacing kingpins on Isuzu

Repair of the front suspension of a truck: replacement of kingpins, oil seals, bearings, grooving of landing...

1 year ago

UAZ - replacement of kingpins and restoration of parts

https://avtoznahar.org.ua Bridge repair. https://www.youtube.com/watch?v=5f3bsqLP_Og&list=PLm6qNJEyYV77o5JRnkbUqUF5S-gwJs2I2.

1 year ago

Replacing UAZ king pins (WITHOUT DISASSEMBLY the steering knuckle)

Replacing old-style kingpins on bronze bushings WITHOUT completely disassembling the steering knuckle, with a kingpin...

more (3547+ videos)

King pin function

The detail was known back in the days when carts and carriages drove along the roads. The axle for the front wheels was attached to their front part using a special bolt or rod. It was called the shkvornya.

The main purpose of the element is to connect the ball joints to the wishbones. It follows from this that the king pin on the Gazelle is a steel rod that secures the swivel joint located on the steered wheel.

There are two types of pivots:

- rotary - installed on Gazelle;

- trailed - most often used in the design of trucks.

The fastening of the pins directly depends on their appearance (shape) and location. Usually it is a cylinder or a cone.

We replace the kingpin

First we remove the wheel. Disconnect the caliper and unscrew the kingpin cover. We remove the nut and carefully knock out the locking wedge from the beam. Let's knock on the bolt and the king pin will move.

Dismantling the wheel

When we pull out the king pin, the steering knuckle will immediately come off. Sometimes a part gets stuck and does not come out. This means we have to roll out the front beam. Let's take a reliable sledgehammer.

To complete the repair, we'll call a partner. We place the beam on a metal stand (the bottom of the fist), and knock out the stuck pin. To advance the matter, we will use a drift.

If this method does not help, soak the kingpin in kerosene. You can use a gas torch to warm up your finger clamped in the beam.

Today, most drivers prefer to carry out repair work themselves. However, this requires knowledge of the structure and operating principle of automotive components. So, if it is necessary to replace the king pins on a UAZ, it is logical that the driver should know the location and purpose of this unit. Accordingly, replacing kingpins with . The success of the repair performed largely depends on the technical competence of the performer. Fortunately, today it is not difficult to get recommendations on how to change the king pin on a Gazelle.

In general, king pins are the hinge rods on the rotating joint of automobile parts. In fact, this unit is the turning axis of a steered car wheel. This axis has the form of a rod made of hardened metal. This axis is used to attach the steering knuckle to the suspension. The knuckle, in turn, is the supporting element for the hub and wheel. To ensure normal driving parameters of the car, it is important to know not only how to change the kingpin, but also how to subsequently set the angle of inclination of the kingpin.

When is it necessary to change king pins?

Replacing these elements is necessary in several cases:

- If you hit the wheel, a metallic sound will appear.

- At high speeds you can feel a vibration in the steering wheel.

- Turning the steering wheel is difficult.

- Signs of wear are clearly visible on the inside or outside of the tire.

The listed conditions of the car do not prove the need to replace the kingpins on the Gazelle. They can also be caused by other breakdowns. Therefore, it is necessary to carry out a number of clarifying procedures:

- Using a jack, raise the car so that its wheels are in a suspended position.

- Secure the hub mechanism using the brake pedal.

- Rock the wheel slightly vertically.

Detection of play when swinging is a signal that these parts still need to be replaced.

When does it become necessary to change the king pin?

There are several cases where replacement is necessary:

- If a metallic sound occurs as a result of hitting the wheel,

- As the speed increases, you feel a blow to the steering wheel,

- Difficulty turning the steering wheel.

- On the tire, both internal and external, signs of wear are increasingly visible.

All three points do not mean that it is necessary to change the kingpins, no. Many other breakdowns could be the cause.

Therefore, next you need to carry out several clarifying procedures:

- Using a jack, you need to raise the car to such a height that the car's wheels are free to move.

- Using the brake pedal, secure the step mechanism.

- Slightly tilt the wheel vertically.

If play is detected when swinging, this means that they need to be changed.

What tools and spare parts will you need?

During work you may need:

- special holder plus reamer;

- pins and bushings for them;

- O-rings;

- oil seal to axle shafts;

- gaskets;

- adjustment washer;

- bearing;

- wedge;

- cotter pins;

- corner oiler;

- devices that will help replace bearings and silent blocks;

- tools;

- open fire heater;

- board for rolling under a car;

- lubricants, including CV joints, sealant;

- anti-corrosion aerosol VD-40;

- carburetor cleaner.

Required tools and materials

During the work process you may need:

- reamer and special holder;

- bushings for the kingpins and the kingpins themselves;

- sealing rings;

- gaskets;

- seal for axle shafts;

- bearing and wedge;

- adjusting washer;

- corner oiler;

- cotter pins;

- devices that help replace silent blocks and bearings;

- locksmith tools;

- gas stove;

- rolling board;

- several heads;

- lubricant;

- sealant;

- CV joint lubrication;

- VD-40 (corrosion protection);

- carburetor cleaner.

After the preparatory work, you can begin replacing the kingpins on the Gazelle with your own hands.

Replacing kingpins - what is required for work

To carry out repair work on a gazelle, you should ensure in advance that you have the following tools and accessories:

- Set of reamers and holder for them;

- Angle type grease fitting;

- Set of keys of different types;

- Gas stove;

- Device for changing bearings and silent blocks.

In addition, you will need the following spare parts:

- Kingpins;

- Seals and gaskets;

- Washers and sealing rings;

- Cotter pins;

- Bushings;

- Lubricants and sealants;

- Carburetor cleaner.

Work order

Replacing kingpins on a Gazelle is carried out in several stages:

- First, you need to thoroughly drain all the oil, otherwise you will then have to wash the objects around and wash your clothes.

- Raise the bridge, install metal or wooden stops and remove the chassis.

- Remove the brake disc and caliper. Remove the brake shield and bearing.

- Remove the tip, unscrew the oiler located below, remove the steering tip and open the part. You also need to remove the valve.

- The kingpins have a plug at the bottom. It should be unscrewed.

- Using a bolt or metal rod and a hammer, knock out the part. If it does not give in, heat the mounting area with a torch.

- First soak all removed elements and then thoroughly clean them of dirt and oil. It is also necessary to check whether they are damaged or deformed.

- Lubricate the bushings and install them so that they are flush with the body. Once the pressing is completed, it is necessary to check whether the hole in the lubrication channel is visible. If not, clean it. Apply oil to the bushings.

- Now the actual replacement of the king pins begins. If everything is done correctly, it will be installed without difficulty. It is important that the backlash disappears. Experts do not recommend installing the part using great force. This will speed up its wear. In addition, the system will have to be developed over a long period of time.

- Check the condition of the seals. If necessary, replace severely worn ones.

- Reassemble the structure in reverse order: plug, valve, tie rod ends, oiler, brake disc and caliper, chassis.

All elements must be thoroughly lubricated. If necessary, replace parts on the other side.

Nuances when carrying out replacement

The work process has several nuances:

- When purchasing new parts, you need to pay special attention to their cross-section. Often it is much less than needed. This is why it is recommended to take a micrometer with you.

- Don't forget about bearings. They should turn without effort or extraneous sounds. It is important that they have a sufficient amount of lubricant.

In order for the kingpins to last as long as possible, it is necessary to lubricate the bushings (inside and outside) more often.

So, replacing the kingpins is not that difficult. It is enough to prepare all the necessary tools and materials in advance. And in order to avoid replacement and repair, it is necessary to regularly carry out preventive technical inspection of the car.

How to Change the Kingpin on a Gazelle All-Wheel Drive VESKO-TRANS.RU

Instructions for replacing a joint on a Gazelle car

The unsatisfactory condition of internal roads is often the reason that there is a knock in the front suspension of the car, which takes up most of the load. It doesn't go away and usually indicates that it's time to keep an eye out for replacement thieves. The specifics of this operation will be discussed in this material.

When should you seriously think about renovation?

As practice shows, replacement of pins is required with a significant gap that appears when the fist turns. Identifying the problem is quite simple. pull out the front wheel and, grabbing it at 6 and 12 o'clock, we make sharp jerks up and down. If there is a gap, then the rod has reached its end and needs to be replaced. Clear confirmation of the problem can be obtained by turning the wheel and stunning it. unnecessary fist movement in relation to the front beam is not very problematic.

There are a number of factors behind this problem, but most often the root cause is the following:

- Aggressively overcome problem roads;

- Malfunctions of wheels and guides;

- Lack of timely maintenance, including the syringe;

- Incorrect bearing torque on the front wheels.

Replacing pins. what is required for work

To repair gazelles, you must ensure in advance that you have the following tools and devices:

- A set of scanners and a holder for them;

- Carbon type sealing nipple;

- A set of keys of different types;

- Gas stove;

- Device for changing bearings and silent blocks.

All-wheel drive gazelle king pins on roller bearings after 2.5 years of active use

. forum about car tuning, come in, there's a lot of interesting stuff there! Anything with swear words will be deleted.

Pin remover GAZ-el from DTM.Garage

And again the everyday life of the garage: we press out soured kingpins on a GAZ spruce with a homemade puller

Carefully. V

In addition, the following spare parts will be necessary:

- Shtvorni;

- Seals and gaskets;

- Washers and O-rings;

- Split contacts;

- bushings;

- Lubricants and sealants;

- Carburetor cleaner.

We are starting to replace. sequencing

Once everything necessary for the job has been prepared, you can proceed directly to replacing the device by completing the work in this order:

- We drain the oil from the axle, after which we hang it up, install locks and disassemble the wheels;

- Unscrew the fasteners from the brake disc and support;

- Remove the fasteners from the brake panel and remove the bearing housing at the same time as the drive;

- Remove the tip of the steering wheel and pull out the lower oil filter;

- We remove the lube valve and the taper pin;

- From the lower rod we obtain a plug, after which we absorb the disassembled device and proceed to the analysis of the second side, performing similar actions in the same sequence;

- We carry out a visual inspection of the removed elements, and if there are defects or damage, we replace them with new parts;

- We lubricate the bushes with the weld and press again, placing the upper element flush with the body. Here we check the visibility of the lubrication outlet;

- We install the bushings strictly vertically, for greater convenience, filling them with oil;

- Clear scan. To install the trunnions, it should be enough to press with your finger;

- We check the axle shaft oil seals and lubricate their edges with oil;

- We assemble the mechanism and check the quality of existing threaded connections. All elements should move easily, without any effort;

- Lubricate the contact points of the individual parts with oil, then install the oiler in place;

- We reassemble the dismantled blocks in reverse order.

Afterword

That's all, the pins have been replaced. As you can see, there is nothing complicated about this operation and it is absolutely capable for everyone. Don't be afraid to try and you will succeed.