One of the relatively simple types of repairs on any car can be considered replacing the driveshaft crosspiece. This procedure is performed not only when absolutely necessary, but also as part of scheduled maintenance. If desired, each driver can make a similar replacement in his garage. Next, we will talk about how to determine the need for repairs, what tools you will need, and also in what order to proceed in the process of replacing the universal joint or steering shaft.

We also recommend reading the article on how to replace the fuel pump yourself. From this article you will learn about the main nuances when removing and reinstalling an electric fuel pump, as well as how to correctly connect electrical connectors and fuel lines.

Purpose of the cardan cross and history of creation

The need to use movable joints arose because the axes of the vehicle shafts are not always located on the same straight line.

While the car is moving, they change their position in space. At the same time, their interaxial distance in different horizontal and vertical planes also changes. The transmission of torque from the gearbox to the drive axles is carried out by a cardan joint. The principle of such a design was first described by the Italian engineer G. Cardano. His work served as the basis for the construction of a cardan transmission used in car transmissions.

The driveshaft crosspiece is a flexible connection between the vehicle engine and the drive axle.

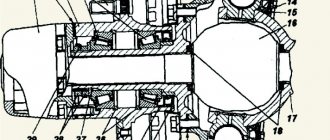

It consists of cardan shafts and hinges, intermediate supports and connecting devices. The crosspiece has a special role in this system. It is this that ensures the transmission of torque from the gearbox to the axle at constantly changing angles while the vehicle is moving.

Troubleshooting

Before carrying out repairs, you need to find the cause of the problem. To do this, you will need to drive the car onto a pit or a lift. We put the transmission in neutral and climb under the car. We inspect the cardan, special attention should be paid to the condition of the crosspiece seals. Next, holding the crosspiece, we rotate the cardan itself. If the crosspiece requires replacement, the play can be noticed immediately. If there is no play, but various noises and squeaks are heard during rotation, then the crosspiece may not need to be changed. You just need to replace the lubricant. There are two crosspieces in the cardan and both need to be diagnosed. The rear universal joint crosspiece fails most quickly, since it bears heavy loads. When moving, dirt and moisture also fall more onto the rear crosspiece.

This is interesting: Rear driveshaft device

The design and principle of operation of the cardan cross

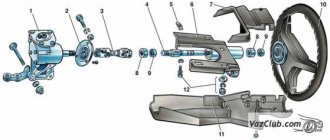

The driveshaft cross is, as the name implies, a cross-shaped joint that ensures the alignment of all rotating elements. It connects the two yokes that make up the universal joint. The ends of the forks are attached to the four ends, or tenons, of the cross. The propeller shaft pipe and one fork are rigidly attached to each other.

Cardan shaft.

The movement of the hinge is carried out using needle bearings mounted on the spikes of the cross. These bearings are installed in holes located on the forks and are secured with retaining rings to prevent them from moving. The thickness of the retaining rings depends on the size of the permissible axial clearance.

Thus, the cardan shaft crosspiece is a flexible connection between the car engine and the drive axle. Structurally, it consists of mutually perpendicular axes that rest on needle bearings installed in the driveshaft forks.

The functional purpose of the crosspiece is to provide a movable connection, dampen the dynamic deformation of the universal joint and transmit torque to the wheels.

The body of the cross is made of alloy steel and undergoes heat treatment, which ensures high surface hardness of the studs

Crosses vary in size. The size may depend on various factors: the make of the car, its dimensions, engine power and, as a consequence, the amount of torque.

The body of this important part is made of alloy steel and undergoes heat treatment, which ensures high surface hardness of the studs. To produce the outer races of bearings and the needles themselves, special bearing steel and appropriate heat treatment are used.

High transmission efficiency and durability of the hinges are ensured by the use of sealed needle bearings on the housing studs. To ensure the reliability of such sealing of the cardan cross joints, gasoline and oil-resistant rubber is used in the manufacture of bearing seals.

How to replace a crosspiece

It is most convenient to change this with the driveshaft removed. Although, if the vehicle’s ground clearance allows it and there is no way to drive it onto a pit or overpass, then you can do it this way, especially in the case of trucks. You can also remove the shaft without a hole. Although it will take much more time, effort and nerves to repair. In the first case, the procedure will be as follows:

- Following safety precautions, you need to block the wheels of the car. After this, you need to engage any gear (so that the driveshaft does not rotate).

- Mark the location of all parts that will be removed relative to each other.

- Unscrew the cardan bolts (secure the shaft to the axle flange). There are four of them.

- Unscrew the suspension bearing mount (two nuts).

- Pull the driveshaft out of the gearbox (there is a splined connection).

Once the shaft is removed, the universal joint spider can be removed. To do this, you will need pliers, a powerful flat-head screwdriver, a hammer and a round attachment (rod, tube). Its diameter should be slightly smaller than the diameter of the eyes in which the ends of the cross are secured. It will be much more convenient to work if you clamp the shaft in a vice.

Next you will need to do the following:

- it is necessary to remove the fixing rings that hold the ends of the cross in the eyes. For this operation you need pliers. If the rings are too tight, then you should tap them with a hammer through the adapter so that the cups at the ends of the cross sag a little;

- After removing the rings, you need to knock the cups out of the eyes. This is done using the same attachment and hammer. It is important to remember that striking the cardan itself is not recommended. In the process of removing the cross in this way, the cup that is being struck will move inward, and on the other side of the fork, the cup will come out to a certain limit. In some cases, the cups may fall out on their own, but often they need to be pulled out using various suitable tools: pliers, a gas wrench, and so on. All four cups are removed in the same way;

- When the cross is removed, it is advisable to clean the lugs and the fork itself from dirt using a wire brush. It is recommended to go over the internal surfaces with sandpaper, clean the grooves of the retaining rings and wipe everything well from dust.

It should be separately added that there are special pullers for crosspieces. However, in practice they are used extremely rarely, even in repair conditions at large service stations. Let us add that no special tools are required when replacing the crosspiece, since installing a new part is also not difficult.

- The two opposite cups can be easily removed by hand. You must act carefully so that the needle bearing does not crumble. It is important to pay attention to the presence of lubricant under the cup.

- The crosspiece is placed between the eyes on the shaft fork, after which the cups are put on. At this stage, they are easily recessed with your fingers as much as possible, and then, using a hammer and adapter, they are lowered so that the grooves of the retaining rings open.

- Retaining rings are installed.

- The same operation is performed with the other ends of the cross.

- Replacement of the cardan cross is completed. Now you can install it back.

As already mentioned, it is not always necessary to carry out this type of car repair. Sometimes lubrication is enough. This can be done without removal if a crosspiece with an oiler is installed - a special hole for introducing lubricant. There is nothing special about how to lubricate the cardan crosspieces. For this procedure you only need a special tool - a syringe. You can fill it with either a special lubricant for crosspieces, or use regular lithol.

Advantages and disadvantages of the universal joint

The driveshaft crosspiece itself is a simple, reliable and durable element of the car.

The main conditions necessary for the normal operation of this unit are the quality of the materials used in its manufacture and the presence of lubricant in places of contact with other elements. The theoretical service life of the cardan cross is 500,000 km.

When the shafts are misaligned, a universal joint is practically the only effective way to transmit rotation. Its main disadvantage is that when a large angle occurs between the connected shafts, their rotation becomes uneven. As a result, during transmission there is a large loss of power and increased wear on the connection nodes. The uneven rotation of the shafts becomes especially noticeable when the angle between them exceeds 10 degrees.

Preparing the lugs and forks and installing a new spider

The repair will be carried out poorly if the eyes and fork are not cleaned of dirt and rust. This is done with a metal brush or sandpaper. All internal surfaces also need to be cleaned and lubricated before installing a new cross. Do not forget about the grooves of the retaining rings; they need to be cleaned with an awl or a thin screwdriver. Next, the cups are removed from the new cross, and the cross itself is inserted between the eyes. When removing the cups, you need to make sure that the bearing needles do not fall apart. If there is no lubricant under the new cups, the part should be changed, or lubricated yourself. The cups are placed on the crosspiece, then they need to be pressed in with a hammer until the locking grooves open. The repair of the cross is completed by replacing the retaining rings.

This is interesting: Preparing for repairs

Other types of movable joints and their combinations

One of the alternative types of movable connection for transmitting torque is the angular velocity joint, or CV joint. This connection helps to avoid uneven rotation of the connected shafts when the angle between the mating parts is more than 20 degrees - from 30 to 70.

The transmission of torque in situations of large misalignment is carried out by the intermediate shaft. It consists of an elastic coupling, a flange and a constant velocity joint. The mobility of the connection of misaligned elements in this design is ensured by an elastic coupling. It is a structure of steel liners and rubber bridges connected together. Jerks of the car transmission are damped due to the elasticity of the coupling. Cardan joints are also used in the shaft design, since there is a large misalignment between the shafts that are connected by the shaft.

The intermediate shaft is used, for example, in the design of the transmission of all-wheel drive VAZ vehicles (21213, 21214, 2131) of the Niva - Lada 4x4 families. At the same time, in cars of the current VAZ 21214 model, the universal joints of the industrial shaft are replaced with CV joints - less noisy and do not require alignment adjustment.

How to check your work

You can check your work immediately after replacing the crosspiece and installing the cardan on the car. The verification process includes the same manipulations as when searching for cross play. The cardan should also be inspected for oil or grease leaks. Pay special attention to the seals. The second stage of testing is testing in motion. During a test drive, you can immediately hear vibration, noise or beating of the cardan.

The job of replacing the universal joint is complete, and you did it yourself, spending money only on spare parts. In addition, you have completely removed and installed the cardan, now if any unit of the cardan fails, it will not be difficult for you to replace it.

How to replace the driveshaft crosspieces with your own hands Video

The first step is to install the car on the inspection hole and put wheel chocks under the wheels. Unhook the handbrake cable fastening in advance. This is done so that it does not interfere with the work. After this, using a chisel and hammer, make special marks that should be at the junction of the gearbox flange and the driveshaft. Then, use a large screwdriver to secure the driveshaft from possible twisting, and use a wrench to unscrew the nuts by 13.

- Now, with a chisel, you need to mark the location of the cardan and the flange of the special rubber coupling. After this, bend the antennae of the locking device on the sealing ring located near the rubber coupling. Once the stopper is removed, move the seal towards the driveshaft.

- After this, you need to unscrew the nuts to “13” that secure the safety bar and remove it. To do this, use the head. Once the bar is out, hold the driveshaft with one hand and with the other unscrew the nuts that secure the outboard bearing plate.

- Now carefully pull out the cardan and remove it from the inspection hole. It's time to find out how to change the crosspiece.

- Make a note of the relative positions of the cardan forks. This is necessary in order not to disrupt the already complex balancing of the part, otherwise you can get powerful vibrations in the area of the bottom of the car and accelerated wear of the transmission. After this, clamp the part in the disks so that it is possible to press the bearings out of the articulated forks. Press them out using mandrels and remove the bearing using pliers.

Next, disconnect the shaft joints. To do this, it is necessary to shift the crosspiece, which is carried out towards the removed bearing. Gradually turning, the cross is removed from the landing site. Press out the remaining bearings in the same way as for the articulated bearing. If there is a need to replace the second cross, then you need to do the same list of actions for it as for the first.

The parts are assembled in the reverse order of disassembly. The most important thing is the correct pressing and alignment of all marks. This is where the replacement of the Zhiguli crosspiece ends. As you can see, this is not a complicated procedure at all, which any car enthusiast who has a certain understanding of car repair and maintenance can handle.

Removing and disassembling the unit

To make work easier, it is recommended to engage first or second gear, which will lock the cardan. Before you begin removing the driveshaft, you should definitely mark the position of the forks relative to the shaft and gearbox flange. This will allow you to correctly install the cardan during assembly, thereby avoiding imbalance and runout.

First you need to loosen the bolts securing the rear fork to the gearbox flange. This can be done using open-end wrenches (usually 12-13 mm in size). Then we dismantle the intermediate support of the outboard bearing. It will be more convenient to use a socket wrench or a 13mm socket. Now you just have to carefully pull the driveshaft out of the splines on the gearbox side.

After removing the shaft, it must be cleaned of dirt. Using a special puller or available tools (flat-head screwdrivers and an awl), remove the retaining rings from the shaft eyes and the universal joint fork. Be extremely careful and protect your eyes. Retaining rings are made of spring steel, so when they are removed using improvised means, they tend to fly out of the grooves in an unknown direction.

Next, you need to select a cylindrical spacer with a diameter slightly smaller than the eye on the shaft. The old crosspiece has already exhausted its service life and is of no value to us. Therefore, using a hammer to knock out the plug through the spacer, it is opposite to the direction of impact. Similarly, it is necessary to remove the remaining plugs and remove the cross.

After the cross is removed, thoroughly clean the eyes from any remaining dirt so that it does not get into the new bearings during assembly. You can use gasoline and a brush. After cleaning, you should carefully inspect the eyes. If necessary, use a round file to remove any burrs that have formed inside the lugs. The cork should fit in with a slight tension, but it should not bite.

Signs that replacement is needed

The reason for replacement is the play of the hinge joint. Its occurrence is signaled by the appearance of various extraneous sounds when the cardan rotates. This may include squeaks, knocks and metallic ringing. The car vibrates when starting from a stop and at high speeds.

When you hear such sounds, you will know that it is time to check the driveshaft. For such a check, you need access to the machine from below, that is, you need a lift, pit or overpass. We check this way:

- Roll the car onto a pit (lift, overpass)

- Move the gear lever to neutral position.

- Get under the car.

- Hold the cross with one hand, and with the other turn the cardan back and forth.

- You will feel the existing play immediately.

- There are 2 crosspieces in the cardan design, check both.

Troubleshooting Specific Troubleshooting Methods

If the threaded connections of the flanges and the gearbox coupling are loosened, it is necessary to tighten the threaded connections to the torque specified in the technical manual. In the case where the CV in the splined part has an excess of the permissible gap, it is necessary to remove the shaft, replace the damaged elements, or the shaft assembly. If there is excessive clearance in the bearings of the gearbox crosspiece, it is necessary to replace the KV crosspiece. When bending the HF, it is necessary to replace the bent elements or the shaft assembly. If the HF is installed incorrectly (when the installation marks are not followed during installation), reinstall the HF according to the marks made before disassembly. If the balance of the shaft is disturbed, check its balancing on a stand and, if necessary, restore it. If the centering sleeve of the intermediate coupling flange or the centering ring of the secondary gearbox shaft is damaged or worn, it is necessary to replace the damaged elements. If the intermediate coupling bushing is worn, the bushing and flange assembly must be replaced. If there is excessive clearance in the suspension bearing, you need to disassemble the shaft, change the bearing, and, if necessary, replace the intermediate support assembly. If the HF suspension support is damaged, replace it. If the threaded connection of the transverse support is loosened, secure it to the car body. If there is excessive clearance in the needle bearings of the crosspiece, remove the shaft and replace the damaged crosspiece. If the connecting nut of the gearbox fork is loose, tighten it. Then, when there is no lubricant in the shaft splines, you need to add Fiol-2U lubricant to the spline joint

It is very important to spray all points after 10,000 km or six months of vehicle operation, whichever comes first; it is also necessary to lubricate the CV. It is also necessary to do this after operating the vehicle in particularly difficult conditions.

If the oil seal of the splined part of the shaft is damaged, the oil seal must be replaced. If the oil seal of the bearings of the gearbox crosspieces is damaged, replace the crosspieces.

If a crunching, grinding or even worse vibration appears from the driveshaft, place the car on an inspection platform in line order or give the car to specialists to inspect the driveshaft and eliminate the defect, this will save money and prevent more serious damage.

Related terms

- Manual transmission (manual transmission)

- Rear axle

- Automatic transmission (automatic transmission)