All about balancing cardan shafts with your own hands. Important points and recommendations

What is it - balancing cardan shafts with your own hands, and “what do you eat it with,” as they say?

Probably, few of the average car enthusiasts have seriously faced this issue for real. Although for owners of used cars with a driveshaft, one way or another, problems with vibration or an unpleasant hum in this area sometimes come to light. For those who do not yet attach the necessary importance to the transmission parts (well, it hums and vibrates - so what): an experienced mechanic will probably tell you what the dangers of such an imbalance of the cardan are. And this problem, which seems not so important to many, can lead to disastrous consequences: rapid wear of the transmission in particular, and the entire car as a whole.

Video of cardan balancing in the garage

The higher the angular velocity of the part, the greater the likelihood of its imbalance, and vibration can be eliminated only and exclusively on complex balancing machines. Moreover, the larger the part, the more complex the equipment should be. Balancing the driveshaft with your own hands, video attempts of which we presented below, as a rule, gives only psychological results, but by no means real ones.

The fact is that it is possible to eliminate the balance of the cardan transmission only if the location and weight of the imbalance are accurately verified, and the cardan must be balanced exclusively in the assembly with the crosspieces. In a garage and without balancing equipment, this is only possible with a cardan installed on the car. Technologically this is impossible to accomplish. Eliminating the imbalance itself is a matter of five minutes, but the main thing is to calculate the exact location, cause and eliminate it.

Content

Balancing driveshafts with your own hands can be comparable to balancing wheels. In practice, driving a car with unbalanced tires is possible (and many careless drivers take advantage of this). But the problems and material costs associated with this, believe me, are not worth it. It’s better to hang the weights on time. And most likely, do a complete wheel alignment of your chassis.

To prevent it from being pulled to the side when driving

, the wheels did not feel beating when accelerating. Of course, an important place is also occupied by the issue of a comfortable ride, from which you enjoy, and do not swear after each “difficult” kilometer. In addition, in the end, with such a long enough ride, worn out and beaten tires have to be changed. And this can cost a lot.

Results

It is quite possible to balance the cardan yourself at home. However, it is necessary to understand that it is impossible to independently select the ideal mass of the counterweight and its installation location. Therefore, self-repair is possible only in case of minor vibrations or as a temporary method of getting rid of them. Ideally, you need to go to a service station, where you will have the cardan balanced on a special machine.

Did not find an answer to your question? Ask in the comments. We will definitely answer!

The most unpleasant thing in technology is parasitic vibration. Vibration is not only unpleasant in itself, but can also destroy the most durable and complex assembly completely unnoticed. It’s not for nothing that so much attention is paid to balancing crankshafts, wheels, flywheels and clutch assemblies.

Vibration consumes a lot of useful energy. In this regard, the driveshaft is no exception.

The higher the angular velocity of the part, the greater the likelihood of its imbalance, and vibration can be eliminated only and exclusively on complex balancing machines. Moreover, the larger the part, the more complex the equipment should be. Balancing the driveshaft with your own hands, video attempts of which we presented below, as a rule, gives only psychological results, but by no means real ones.

The fact is that it is possible to eliminate the balance of the cardan transmission only if the location and weight of the imbalance are accurately verified, and the cardan must be balanced exclusively in the assembly with the crosspieces. In a garage and without balancing equipment, this is only possible with a cardan installed on the car. Technologically this is impossible to accomplish. Eliminating the imbalance itself is a matter of five minutes, but the main thing is to calculate the exact location, cause and eliminate it.

Causes and symptoms

Let's get back to our cardans! There can be many reasons for the malfunction and imbalance of these devices. The most basic: wear and tear during long-term use, manufacturing defects, mechanical deformations caused by impacts. Another reason is that the gaps between the elements of which it consists are too large.

If, for example, you repaired a cardan or installed a new one. There is also a need to perform balancing when installing a used shaft.

What are the signs that the driveshaft is out of balance? The main thing is to increase the level of vibration when the car is moving until it is clearly felt by the driver and passengers. Additionally, a clearly audible hum may appear, accompanying the vibration of the housing.

Folk method

As soon as you begin to feel vibrations that seem too strong and unnecessary, and getting to a service station is not possible - due to time or money - you can balance the cardan with your own hands. Fortunately, folk craftsmen have long developed a rather labor-intensive but effective method. To do this, we conditionally divide our cardan into 4 equal parts with an imaginary cut across (this operation should be performed in a garage on a pit or on an overpass). Next, we take a small weight (lead or alloy, like for balancing a wheel) 30 grams.

We attach it rigidly to the first part of the cardan

. The next stage will be testing. To do this, you need to drive out onto a smooth, level road and listen for vibrations: have they become more or less? We return back to the garage and attach the weight to the next part of the part. We are testing. Let's go back. This operation must be performed with each part of the cardan.

To be more confident, you can try breaking the part into more parts. So, you have already decided (by experience) on the cardan sector. Now all that remains is to decide on the weight of the weight.

If you have ordinary electrode welding, you can weld with it. Thus, we will get an approximately balanced shaft that will not vibrate excessively when driving, and will serve you for quite a long time. It is fair to note, however, that this labor-intensive process does not relieve us of the need, in the end, to contact the service for more thorough repairs. But, for a while, you will almost forget about vibration and keep the accompanying transmission parts intact.

How to balance a driveshaft yourself

Based on the information received, it is clear that without special equipment there can be no talk of any precise balancing. However, if a situation arises where it is necessary to carry out balancing, but there is no such workshop nearby, as a temporary measure you can do the following:

- the cardan is conventionally divided in the longitudinal plane into 6-8 parts;

- a weight (15-30 g) is attached to each of the sectors in turn; this can be a weight for balancing wheels;

- the car is taken out onto a flat road and a check is carried out to determine whether the vibration has been eliminated or has become even greater;

- After this, the cargo is moved to another sector.

It is clear that this method will only remove the main imbalance and in no way claims to be accurate, but it will allow you to get rid of vibrations for a while and get to the service station. Make sure the rotating parts are balanced and enjoy your travels!

Technological method

When the cardan shafts have been balanced with your own hands, which gives the driver some respite - collect some money, gather your thoughts, and after a certain time, go to the service station anyway. Here you will have your car checked on a balancing stand using sensors, the working elements of which touch the “control surfaces” of the cardan.

The scheme is simple:

the shaft rotates and the working element moves, showing us an imbalance in a specific section.

The data is processed and displayed on the monitor using a specially developed computer program. Moreover, checking in this way does not involve removing the cardan itself.

Subsequent compensation for the found imbalance is carried out in several ways:

installation of balance plates directly on the cardan itself, installation of gaskets, removal of metal (in extreme cases, in case of factory deformation, for example, of a part).

Balancing the driveshaft on cars

Balancing a driveshaft is a fairly simple process that requires the use of special tools, so this work can be done both at home and at a service station. But asking such a question to service station workers is more appropriate, because when you independently calculate the balancing mass, the calculations are less accurate. There are several ways you can do it yourself and measure it correctly; we’ll talk about this later.

- Signs of balancing

- Self-balancing

- Balancing by car dealership employees

Signs and causes of imbalance

If vibration occurs in the car body, you can understand that the cardan is unbalanced. Each time you pick up speed, the vibration will increase; strong vibrating processes can appear already at a speed of 60 km/h. This occurs as a result of a shift in the center of gravity of the shaft itself, after which the centrifugal force that arises as a result of this contributes to the tossing of the car while driving. Vibration is usually accompanied by a hum that arises from under the bottom of the car.

How to balance a cardan at home

We will describe the process of balancing the driveshaft with your own hands using the well-known “old-fashioned” method. It is simple, but it can take quite a lot of time . You will definitely need an inspection hole into which you must first drive the car. You will also need several weights of different weights used when balancing the wheels. Alternatively, instead of weights, you can use welding electrodes cut into pieces.

A primitive weight for balancing a cardan at home

We recommend: Causes of engine water hammer and how it can be avoided

The work algorithm will be like this:

- The length of the driveshaft is conventionally divided into 4 equal parts in the transverse plane (there may be more parts, it all depends on the amplitude of vibrations and the desire of the car owner to spend a lot of effort and time on it).

- The above-mentioned weight is attached securely, but with the possibility of further dismantling, to the surface of the first part of the propeller shaft. To do this, you can use a metal clamp, plastic tie, tape or other similar device. Instead of a weight, you can use electrodes, several of which can be placed under the clamp at once. As the mass decreases, their number is reduced (or vice versa, as the weight increases, they are added).

- Next is testing. To do this, drive the car onto a flat road and analyze whether the vibration has decreased.

- If nothing has changed, you need to return to the garage and transfer the load to the next section of the driveshaft. Then repeat testing.

Mounting the weight on the cardan

Items 2, 3 and 4 from the list above must be performed until you find an area on the driveshaft where the weight reduces vibration. Next, in a similar experimental way, it is necessary to determine the mass of the weight. Ideally, if it is selected correctly, vibration should disappear completely.

The final balancing of the “cardan” with your own hands consists of rigidly fixing the selected weight. For this it is advisable to use electric welding. If you don’t have one, then as a last resort you can use a popular tool called “cold welding”, or tighten it well with a metal clamp (for example, a plumber’s clamp).

Balancing the driveshaft at home

There is another, albeit less effective, diagnostic method. In accordance with it, it is necessary to remove the driveshaft from the car. After this, you need to find or select a flat surface (preferably perfectly horizontal). Two steel angles or channels (their size is unimportant) are placed on it at a distance slightly less than the length of the driveshaft.

After this, the “cardan” itself is placed on them. If it is bent or deformed, then its center of gravity is shifted. Accordingly, in this case it will scroll and become such that its heavier part is at the bottom. This will be a clear indication to the car owner in which plane to look for imbalance. Further actions are similar to the previous method. That is, weights are attached to the cardan shaft and their attachment points and mass are experimentally calculated. Naturally, the weights are attached on the opposite side from the one where the center of gravity of the shaft is shifted.

Another effective method is to use a frequency analyzer. You can do it yourself. However, you need a program that simulates an electronic oscilloscope on a PC, showing the level of frequency of oscillations that occur when the cardan rotates. You can tell it from the Internet in the public domain.

So, to measure sound vibrations you will need a sensitive microphone with mechanical protection (foam rubber). If you don’t have one, then you can make a device from a medium-diameter speaker and a metal rod that will transmit sound vibrations (waves) to it. To do this, a nut is welded into the center of the speaker, into which a metal rod is inserted. A wire with a plug is soldered to the speaker outputs, which is connected to the microphone input in the PC.

Next, the measurement procedure occurs according to the following algorithm:

- The drive axle of the car is suspended, allowing the wheels to rotate freely.

- The driver of the car “accelerates” it to the speed at which vibration usually occurs (usually 60...80 km/h), and gives a signal to the person who takes the measurements.

- If you are using a sensitive microphone, then bring it close enough to the place where the marks are being applied. If you have a speaker with a metal probe, then you must first secure it to a place as close as possible to the applied marks. The result is recorded.

- Four marks are applied to the driveshaft around the circumference, every 90 degrees, and numbered.

- A test weight (weighing 10...30 grams) is attached to one of the marks using tape or a clamp. You can also use the bolted connection of the clamp directly as a weight.

- Next, measurements are taken with a weight on each of the four places in sequence with numbering. That is, four measurements with the movement of the load. The results of the oscillation amplitude are recorded on paper or a computer.

Location of imbalance

The result of the experiments will be numerical voltage values on the oscilloscope that differ from each other in magnitude. Next, you need to build a diagram on a conditional scale that would correspond to the numerical values. A circle is drawn with four directions corresponding to the location of the load. From the center along these axes on a conventional scale, segments are plotted based on the data obtained. Then you should graphically divide segments 1-3 and 2-4 in half by segments perpendicular to them. A ray is drawn from the middle of the circle through the intersection point of the last segments until it intersects with the circle. This will be the location of the imbalance that needs to be compensated (see figure).

The desired location point for the compensation weight will be at the diametrically opposite end. As for the weight of the weight, it is calculated by the formula:

Where:

- imbalance mass - the desired value of the mass of the installed imbalance;

- vibration level without test weight - voltage value on an oscilloscope, measured before installing the test weight on the cardan;

- the average value of the vibration level is the arithmetic average between four voltage measurements using an oscilloscope when installing a test weight at four indicated points on the cardan;

- the value of the mass of the test load is the value of the mass of the installed experimental load, in grams;

- 1.1 is the correction factor.

We recommend: How to assemble an inner CV joint

Typically, the mass of the installed imbalance is 10...30 grams. If for some reason you were unable to accurately calculate the mass of the imbalance, you can establish it experimentally. The main thing is to know the installation location, and adjust the weight value while driving.

However, as practice shows, self-balancing the driveshaft using the method described above only partially eliminates the problem. The car can still be driven for a long time without significant vibrations. But you won’t be able to get rid of it completely. Therefore, other parts of the transmission and chassis will work with it. And this negatively affects their performance and resource. Therefore, even after carrying out self-balancing, you need to contact a service station with this problem.

Ways to balance a driveshaft professionally and with your own hands

The appearance of parasitic vibration in a car must be stopped as soon as possible. The resulting shock and high-frequency loads can cause metal fatigue, which leads to the accumulation of damage. Operating a car with an unbalanced driveshaft will lead to excessive wear on all elements of the power transmission. In the most advanced cases, imbalance can lead to metal ruptures and complete failure of expensive mechanisms.

Purpose and design of the VAZ 2107 driveshaft

The driveshaft is a mechanism that connects the gearbox to the rear axle gearbox and is designed to transmit torque. This type of transmission is most widespread on vehicles with rear-wheel drive and all-wheel drive.

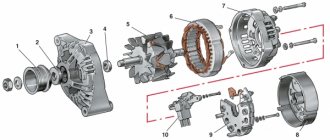

Cardan device

The VAZ 2107 driveshaft consists of the following elements:

- one or more sections of thin-walled hollow pipe;

- splined sliding connection;

- fork;

- crosspiece;

- suspension bearing;

- fastening elements;

- rear movable flange.

The driveshaft of the VAZ 2107 has a fairly simple device

The cardan transmission can be single-shaft or double-shaft. The second option involves the use of an intermediate mechanism, to the back of which a shank with splines is attached to the outside, and a sliding sleeve is fixed to the front through a hinge. In single-shaft structures there is no intermediate section.

The front part of the cardan is attached to the gearbox through a movable coupling with a spline joint. To do this, there is a hole with internal splines at the end of the shaft. The cardan design involves longitudinal movement of these splines at the moment of rotation. The design also includes a suspension bearing attached to the body using a bracket. It is an additional attachment point for the cardan and is designed to limit the amplitude of its movement.

The cardan is unified for all classic VAZ models.

Reasons that cause imbalance

Vibration emanating from the underbody of the car can occur both after repairs and as a result of daily use. Reasons that can cause this unpleasant phenomenon may be:

- High error of driveshaft parts. Since the cardan is not a monolithic mechanism, each of its elements is made with a certain tolerance. When manufacturing inaccuracies are superimposed on each other, an uneven distribution of masses around the axis occurs.

- Heterogeneity of the structure of the metal from which the cardan is made. Most often, this reason manifests itself during repairs accompanied by the replacement of elements. The presence of voids, cavities and other defects is strictly controlled in production, but defects still end up on the market.

- Incorrect alignment that occurs during garage repairs. It is impossible to strictly observe the alignment of the elements in the absence of special equipment.

- Excessive wear will also lead to vibration, even if the driveshaft has been recently balanced.

- Mechanical damage, bending caused by an accident, which also leads to shock loads during rotation.

Parasitic vibration takes up a lot of the energy produced by the engine. This leads to excessive fuel consumption and a decrease in dynamic performance. A car that requires balancing of the driveshaft is not able to please the owner with high speed and good handling.

Temporary elimination of imbalance

The vibration that arises along the way cannot be ignored, so at the first sign you should go to a stand for balancing driveshafts. Being outside the city, it is not always possible to get to a service station with the necessary equipment. In this case, you should perform balancing yourself. The following sequence should be followed:

- Place the car on an overpass or over a hole in the garage, as you will need access to the driveshaft.

- Divide the cardan in half lengthwise.

- Conditionally divide the cardan crosswise into 4 parts. If the car owner has a lot of time, the cardan can be divided into 8 or even 16 parts.

- Take a weight with a weight of up to 30 grams. A piece of lead or a wheel balancer is suitable for these purposes.

- Number the parts of the cardan and attach a weight to the first section.

- Drive onto a flat section of the road and listen to the vibrations.

- Consistently test the car, changing the position of the weight. In this case, it is necessary to find a position in which vibration is minimized.

- By changing the weight of the weight, you need to ensure that there is no vibration in the car interior. At the same time, visual elimination of interior rattling does not mean the complete elimination of parasitic loads on the cardan. At the first opportunity, you need to balance the cardan using special equipment; you need to visit a service station.

- Secure the weight using welding or glue.

By balancing the shaft, the car owner will protect the car from serious repairs. Traffic safety will also increase, since the vibration transmitted into the cabin significantly distracts and irritates the driver.

What is an imbalance and how to eliminate it

The main sources of vibration in a car are large parts with high angular velocity, namely: the driveshaft, automatic transmission torque converter, wheel, crankshaft and flywheel with clutch assembly. If the center of mass of a part does not coincide with the longitudinal axis along which the part rotates, an imbalance will inevitably occur. From a physics point of view, imbalance is the product of the weight of the part and the mass of the eccentricity.

Balancing the driveshaft is the only effective method for removing imbalance. To eliminate it, it is necessary to attach a load to the cardan that is equal in weight, but opposite in sign to the eccentricity. In this case, it is very important to maintain the coincidence of the axes and the location of the suspensions when balancing with the axes and suspension points in real working conditions. In cases with those parts whose length is significantly less than the axis of rotation (wheel, flywheel), it is enough to hang the part by only one point, which greatly simplifies the balancing work. It is also necessary to take into account that the rolling resistance at the suspension point should be minimal and the accuracy of determining the location and module of the imbalance often depends on this. The part simply rotates and stops at the place where the unbalance point is at the bottom. All that remains is to simply mark this point and install a correction weight, and then repeat the operation.

Professional cardan balancing

Since the length of the shaft significantly exceeds the thickness, moment imbalance may occur. It can only be calculated using the sensors equipped on the machine for balancing cardan shafts. The accuracy of the operations performed depends on the technical level of the equipment and the knowledge of the operating personnel. Therefore, balancing should be performed only by trusted service stations.

Balancing is performed as follows:

- The shaft rotates around its axis.

- The sensors touch the surface at control points.

- The working element is displaced.

- The computer displays information about the imbalance in a specific section.

- Special plates are applied in the calculated locations.

- In particularly advanced cases and due to manufacturing defects, metal cutting may be required.

How to balance a cardan on a car

In parallel with balancing the cardan, the master visually inspects all its components in order to determine the degree of wear of each part and the possibility of their further use. The most common malfunction that can be detected is wear (thinning) of the splines. Further use of such parts is fraught with very serious damage, so it is better to replace them to avoid big problems.

Numerous videos about balancing cardans show that during this operation, additional parts are “hung” onto the cardan installed on the stand. These are so-called balancing plates, with the help of which the driveshaft is subjected to pressure that simulates the operating conditions of the unit. The stand itself is in many ways reminiscent of a lathe: in the process of unwinding a part fixed on it, its imbalance (if any) is revealed, so the master can only get rid of it by grinding off a thin layer of metal from the surface of the shaft with a special cutter.

Do not forget that an insufficiently centered cardan will not only cause vibration in the chassis of the car while it is moving, but will also lead to accelerated wear of the entire transmission.

Balancing the driveshaft with your own hands: how to do it correctly

In every mechanism that performs rotational movements, due to mechanical stress or wear of components, an imbalance occurs, which manifests itself in the form of vibrations. If there are vibrations throughout the car body as it accelerates, it means there is a possibility that the driveshaft is unbalanced. This problem can lead not only to failure of the cardan, but also to the entire vehicle, which will require significant material costs to repair it. You can perform balancing yourself, or you can contact a service station.

If vibration is observed in the driveshaft, it is recommended that it be balanced immediately. Photo: cardan-garant.ru

Features of balancing the cardan drive

In the case of a cardan shaft, we are dealing with a part whose length significantly exceeds its diameter, and the imbalance may have the same module, but a different direction vector. This is called moment imbalance and can only be calculated using driveshaft balancing equipment. Such vibrations can only be treated with dynamic balancing, which requires calculating and eliminating several imbalances at once.

An imbalance of the cardan can occur not only due to its damage, but also in some other cases:

factory defects (different cardan pipe wall thicknesses, poor-quality and incorrect fixation of the lugs);

the occurrence of gaps in the cardan transmission elements;

curvature of the shaft itself;

In addition, in most cases, dynamic balancing of the new cardan is necessary, and after each repair, the cardan shaft must be balanced. The price of this operation in special centers depends on the car model, and the approximate cost of the work is given in the table.

Why balance the driveshaft?

Probably every car enthusiast has heard about cardan balancing, but not everyone understands the need for it. The main function performed by a car's driveshaft is to transmit torque.

You can find out how the Brilliance V5 appears in owner reviews in our material.

What to do if the alarm stops working - see here.

The main causes of imbalance

There are quite a few reasons for the imbalance. They differ in their nature and other features. Among the most frequently encountered are the following:

- The initial assembly of the cardan shaft was performed poorly;

- Failure to comply with technology when securing parts. If balance has been found, then incorrectly secured parts will soon become loose, after which balancing will be required;

- Poor quality of materials used, improper hardening of the metal from which the cardan is made. A cardan shaft that is made of metal with insufficient performance characteristics will not withstand all static and dynamic loads;

- Too much load. The imbalance appears even in cases where the car has not been used for some time;

- Mechanical damage to parts that may occur as a result of an accident.

What is a cardan shaft

The cardan shaft (universal shaft) consists of a pipe and two hinges that allow you to change the angle of rotation from 0 to 30 degrees. The basis of the hinge is a cross, a steel cross made of a round rod, on which caps of needle bearings are placed. The crosspiece with bearings is inserted into two forks located at an angle of 90 degrees relative to each other. The entire structure forms a hinge of unequal angular velocities. With the help of one cardan, it is possible to effectively compensate for misalignment at a hinge deflection angle of no more than 20 degrees. Deviation by a larger angle leads to increased power loss.

On most passenger cars, the driveshaft is made of two driveshafts, one of which is fixed by a support bearing. This is necessary to reduce power losses and reduce vibrations. The longer the cardan tube and the higher the speed of its rotation, the stronger the vibrations it produces. On trucks, the rotation speed of the cardan is noticeably lower, and the influence of vibrations due to the mass of the vehicle itself is felt weaker than on passenger cars. Therefore, the following driveshaft schemes are most widespread:

Cars:

- front axle drive – one shaft without support bearings;

- rear axle drive – two shafts, one of which has a support bearing.

Trucks:

- front and rear axles - one shaft without support bearing.

How to balance a driveshaft yourself

The resulting vibration, which is observed as the vehicle speed increases, cannot be ignored; at the first sign, action must be taken to eliminate it. To perform balancing you need to have some knowledge and experience.

In general, self-balancing is not a difficult process, although it can take quite a lot of time. Photo: static.imfast.com

To balance the shaft yourself, you need an inspection hole into which you must first drive the car. You also need to prepare several weights with different weights, which are used when balancing the wheels. Instead, electrodes or pieces of lead may be suitable. To carry out balancing, you must perform the following steps:

- Divide the cardan into 2 parts along the length;

- Conditionally divide it across into 4 equal parts. If you have a lot of free time, the gimbal can be divided into 8 or more parts;

- A weight weighing 30 grams must be attached to the surface of the first part. It must be attached securely, but with the possibility of subsequent dismantling;

- Test the vehicle's driveshaft. To do this, you need to drive onto a flat section of the road and listen to see if the vibrations have decreased;

- If the vibrations have not disappeared, you need to return to the garage and move the used weight to another section of the driveshaft. After this, re-test on the road.

The above steps must be carried out until you achieve the absence of vibrations in the car interior.

After you have found the optimal weight of the weight, you need to firmly fix it. This can be done using electric welding. If you don’t have electric welding, you can use another popular method - “cold welding”, or tighten the weight with a metal clamp.

Video instructions for adjustment can be found in this video:

What types of balancing exist?

There are several types of balancing:

1) Static - usually used to identify and eliminate the resulting imbalance of the rotor without taking into account the forces generated during the rotation process. This type is not suitable for a cardan, since it is performed in one correction plane.

2) Instant – here the main factor that caused the imbalance is identified and eliminated. Instant balancing is performed in two correction planes.

3) Dynamic - combines elements of static and instantaneous balancing. This type is most suitable for eliminating driveline imbalance.

Additionally, it should be noted that when operating a balancing stand, it is difficult to determine which method is being used. However, it is known that dynamic balancing is used for driveshafts.

If an imbalance occurs, it is recommended to immediately contact a car service, since high-quality balancing can only be done using special equipment.

So, the whole process can be divided into several stages:

Stage 1 - first, the driveshaft is removed from the machine;

Stage 2 - then it is installed on a special stand designed for dynamic balancing. This device consists of several sensors and control surfaces. If there is an imbalance, the shaft will touch these parts during rotation.

Stage 3 – analysis of all curvatures and geometry violations is carried out. The results obtained are displayed on a special screen.

Stage 4 – repair work is carried out.

There are several ways to correct driveline imbalance. The main ones include:

Method 1 - special parts, so-called balancer plates, are welded onto the surface of the cardan. The location of their installation, as well as the weight, are calculated using a computer.

Method 2 – balancing is done using a lathe. Typically, this method is used when there is significant deformation of the cardan. In this case, some part of the metal is removed from the surface of the shaft. This reduces its strength and also increases the load encountered during operation.

Procedure for temporary balancing

Undoubtedly, the best option for eliminating cardan drive imbalance is to turn to real professionals. However, sometimes due to certain circumstances, the driver does not have the opportunity to immediately come to the service center. In this case, you can use temporary balancing done by yourself.

So, eliminating cardan imbalance at home is carried out as follows:

1) First of all, the driveshaft should be visually divided into several parts (the greater the number, the better the balancing will be).

2) Next, you need to take a metal weight with a mass of 30-40 grams and secure it in one of the intended parts.

3) Then you should drive onto a flat road and determine whether the vibration has decreased or increased. This procedure will have to be done several times, hooking the load first to one part of the shaft, then to the other.

4) Once the optimal location of the load has been identified, you should begin to determine the appropriate weight of the load. To do this, it is necessary to alternately hang metal objects with different weights on the selected section of the cardan.

5) After choosing the exact weight and location of the load, you should select a metal plate with a similar weight and weld it to the cardan.

Thus, the process of eliminating cardan imbalance with your own hands is quite long and labor-intensive. In addition, it is impossible to absolutely accurately calculate the location and mass of the balancing weight without special equipment. In this regard, balancing the cardan at home will always be inferior in quality to a similar procedure performed within the walls of a car service center.

Today, in addition to an impressive list of repair work, specialists also provide high-quality balancing of driveline drives. We have the latest equipment for this, as well as competent and experienced craftsmen.