- home

- /

- Services

- /

- Car diagnostics

- /

- Diesel engine diagnostics

If you have problems with the operation of your diesel engine, contact the Auto-Maxima car service center in Moscow, Southern Administrative District, Annino metro station.

To identify a malfunction of a diesel internal combustion engine, diagnostic equipment alone is not enough; it also requires experience and high qualifications of a technician. The difficulty of diagnosing a diesel engine lies in the fact that a diesel engine has few system parameters, so it is not always possible to accurately identify a malfunction using diagnostic equipment alone. As a rule, to confirm the cause of a breakdown, a comparison of other indicators is required.

Diagnostics of a diesel engine and its individual systems is carried out in our car service by mechanics with experience of 12 years or more.

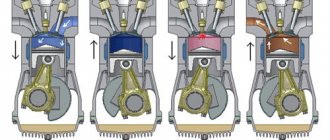

To identify the exact cause of the breakdown, it is necessary to use an integrated approach. Diesel diagnostics takes place in three stages:

- Visual inspection. A visual inspection of the engine is carried out. The condition of the unit is assessed without dismantling, we give an assessment of the condition of individual components based on indirect signs.

- Manual diagnostics. It is carried out manually, where the operation of the car engine is checked.

- Computer diagnostics. We connect computer equipment to read error codes. Decoding the received data allows you to identify the problem and identify the malfunction.

Diesel engine diagnostics shows the current condition of the diesel engine and the level of wear of individual parts. Diagnostics can also be carried out during vehicle maintenance, which allows you to keep the engine condition under control, as well as promptly identify and eliminate minor faults. Diagnostics are mandatory before starting repairs of the engine and its components.

The main signs of a diesel engine malfunction

A modern diesel engine with high build quality and reliability. Typically, a diesel engine begins to exhibit obvious operating abnormalities long before it stops completely. The most common problem is a malfunctioning fuel system, but other malfunctions may also occur.

Main symptoms of a malfunction:

- There is a drop in power while driving, and you feel a “lack of grip on the horses” when accelerating. May indicate a number of malfunctions, including a problem with the fuel system.

- Obvious malfunctions of the power unit:

- stalls

- extraneous sound that was not there before

- the smell of exhaust gases in the car interior

- Check indicator on the dashboard

Listed above are the most common symptoms of a diesel engine malfunction; if you notice them, do not wait for the engine to stop completely, contact a car service center as quickly as possible.

Diagnostics of fuel systems of diesel engines

As you can see, although timing valves, pistons or rings may well fail in a diesel engine, most diesel malfunctions are related to the power system.

For this reason, checking the components and elements of the fuel system is a primary task.

Owners of diesel internal combustion engines regularly encounter coking of the nozzle on the injectors or deterioration of needle mobility. Also, the check often reveals a decrease in injection pressure, which is usually associated with wear or damage to the plunger pairs.

The discharge valves may also be worn out, and another common situation is a violation of the correct adjustment of the fuel injection pump. As a rule, such problems are caused by severe operating conditions, violation or ignorance of basic engine maintenance recommendations, as well as the use of low-quality diesel fuel.

Among the main diagnostic methods, experts identify three:

- Visual inspection and analysis of noise during engine operation.

- Measurements of certain parameters (fuel pressure, etc.).

- Computer diagnostics of a diesel engine.

In the first case, you can quickly identify serious faults that lead to obvious malfunctions in the operation of the power plant. If the technician is experienced, then one visual inspection will be enough to assess the condition of the engine, critical components of the fuel supply equipment, etc.

The air filter, the sound of the diesel engine and fuel injection pump at idle and under load, the color of the exhaust gases, the appearance of the glow plugs and inspection of other elements allow you to draw conclusions about the condition of the internal combustion engine.

- In the second case, it is assumed that the technician has localized the problem, but a more accurate determination of the problem is necessary using measurements of a number of parameters that will indicate deviations in the operation of a particular system or the motor itself.

Currently reading:

How to maintain and charge a maintenance-free type of battery for...

ZIL 130 engine: a legend of the Soviet automobile industry

We also recommend reading the article about why a diesel engine stalls. From this article you will learn about the possible reasons for the unstable operation of a diesel engine and cylinder tripping.

Such diagnostics of the fuel system of diesel engines and other components is usually carried out on machines where electronic diagnostics using scanners is impossible (old diesel with a mechanical injection pump). In this case, you will need to remove the injectors to check them, measure compression, boost pressure, crankcase gas pressure, check filters, valve timing, install drive belts, diagnose glow plugs, etc.

For example, compression measurements in cylinders are often carried out if a diesel engine is running rough. Troubling may indicate both problems in the power system and malfunctions in the power unit. In a situation where compression is low, the fuel does not burn and the cylinder simply does not work. This means that it is not the fuel supply elements that need to be repaired, but the engine itself.

- The third method allows you to identify failures and breakdowns both in the electronic engine control system (ECM) and a number of “mechanical” problems. Computer diagnostics allows you to check the operation of sensors and control electronics, as well as, based on the analysis of readings from sensors, determine other malfunctions.

Nowadays, computer diagnostics of a diesel internal combustion engine allows for a multi-level check of the unit, diagnosing the fuel system, control system, and actuators.

As for the diagnostics of fuel equipment of diesel engines, at the initial stage the operation of the “electrical” part of the injectors is analyzed, computer scanning also determines temperature indicators, parameters are measured during operation of vacuum devices, etc.

Next, all collected readings are evaluated, after which the computer displays error data, which allows you to begin eliminating the detected defects. The main advantage of such diagnostics is the simplicity, speed of operation, and the absence of the need to disassemble the engine and carry out additional manipulations.

How much does engine diagnostics cost?

Diagnostics of a diesel engine should be carried out at a car service center. In this case, simultaneous testing of all components of the power unit is carried out. You can find out the exact cost of diagnosing your car by phone.

| Engine diagnostics | |

| Services list | Price |

| Computer diagnostics of cars. (PROMOTION !) | from 1500 0 rub. |

| Diagnostics of diesel engines | from 1000 |

| Computer diagnostics of electronics | from 1000 |

| Diagnostics of the transmission (suspension and chassis of the car). | from 700 |

| Computer diagnostics of manual transmission and automatic transmission. | from 1000 |

| Diagnostics of external and internal lighting of a vehicle. | from 500 |

| Diagnostics of vehicles when buying or selling | from 1000 |

| ICE diagnostics | from 1000 |

| Pneumatic system diagnostics | from 1500 |

| Diagnostics Wheel alignment | from 1000 |

The cost of diagnostics and repair of fuel equipment

| Name of service | Price, rub * |

| 1. Common Rail injection system components | |

| CRI/CRIN injector diagnostics | 500 |

| Diagnostics of the PIEZO CR Bosch injector | 1000 |

| Fuel pump CP1, CP2, CP3, CP4 without troubleshooting/with troubleshooting | 3500/5000 |

| Restoration of CRI/CRIN, PIEZO injector | 3000 |

| Repair of fuel pump CP1, CP2, CP3 | 9000 |

| 2. Components of individual injection systems: “Pump-injector”, “Individual pump (pump section)” | |

| PDE/UIS pump injector diagnostics | 1000-1500 |

| Diagnostics of individual PLD/UPS pumps | 1000 |

| Restoring the PDE/UIS unit injector | 4000 |

| Repair of individual PLD/UPS pumps | 4000 |

| 3. One- and two-way nozzles (mechanical nozzles) | |

| Diagnostics of one- and two-way injectors | 200 |

| Restoration of one- and two-way injectors | 800 |

| 4. High pressure fuel pumps (HFP) | |

| Diagnostics with adjustment: | |

| In-line injection pumps with mechanical regulator | 5000 |

| In-line injection pumps with electronic control | 6000 |

| Distribution injection pumps with mechanical regulator | 2200 |

| Distribution injection pumps with electronic control VE/VP | 3200/5000 |

| Recovery: | |

| In-line injection pumps with mechanical regulator | 9000 |

| In-line injection pumps with electronic control | 14000 |

| Distribution injection pumps with mechanical regulator | 7000 |

| Distribution injection pumps with electronic control VE/VP | 7000/9000-12000 |

| 5. Vehicle diagnostics | |

| System computer diagnostics of a car using a KTS tester | 1500 |

* The cost of work does not include the cost of spare parts, consumables and removal and installation of fuel cells. The cost of work may vary, depending on the complexity. The final cost is agreed upon directly by the acceptance specialist.

Since we restore 90% of used spare parts to new condition, from the table below you can compare the cost of a new and a unit restored by us. This table does not show the entire range, but only a part - to understand the price ratio of a new product and one restored by our specialists.

| Product no., application | Refurbished price, rub. | New price, rub |

| Bosch units | ||

| 0445120217 - CR MAN D20 E4-5 | 14 000 | 21 000 |

| 0445120044 - CR MAN D28 E3 | 13 000 | 29 500 |

| 0445120219 - CR MAN | 13 000 | 27 200 |

| 0445120218 – CR MAN D20 E3 | 13 500 | 25 500 |

| 0414755005 – PDE DAF PE83 | 10 000 | 35 300 |

| 0445120011 - CR IVECO F1AE0481A | 12 000 | 21 000 |

| 0445120012 - CR RENAULT PREM. DCI6AE | 12 000 | 27 200 |

| 0414701019 — UIS SCANIA DC11.08 | 12 500 | 24 900 |

| 0414701044 - UIS SCANIA DC12.17 | 13 500 | 26 800 |

| 0414701036 — UIS SCANIA DC9.3 | 13 500 | 21 800 |

| 0414703008 - UIS IVECO STRALIS F3A0681D | 12 800 | 29 000 |

| Delphi units | ||

| 1668325 – DAF SMART INJECTOR | 20 000 | 42 400 |

| 1846419 – DAF SMART PUMP | 20 000 | 59 000 |

| 20430583 – DELPHI VOLVO/REN UI | 19 500 | 36 000 |

| 21340611 – DELPHI VOLVO/REN UI | 23 500 | 59 000 |

Diagnostics of diesel engines at the Auto Maxima car service center

Diesel diagnostics includes a number of sequential measures, so you won’t be able to do it yourself if you don’t have specialized equipment and experience. The procedure for accepting and diagnosing a car with a diesel engine:

- A visual inspection of the unit is carried out without dismantling. We evaluate indirect signs and extraneous sounds;

- We carry out diagnostics by connecting computer equipment to read error codes;

- We decipher error codes and identify the breakdown;

- We carry out troubleshooting of spare parts, determine a list of parts for replacement.

- We prepare documents for repair of the unit.

During diagnostics, special attention is paid to the fuel system. We check everything down to the smallest detail - from compression to timing marks, assess the condition of the injectors and other components of the unit.

Diagnostics of individual components and assemblies of a diesel engine

- Volume and pressure. The regulation of the diesel fuel supply by the pump is checked.

- Nozzle operation. The condition and operation of the injectors is checked.

- Operation of fuel injection pump. The frequency of fuel injection into the fuel injection pump section is checked.

- Fuel pump operation. An assessment is made of the functional characteristics of the fuel pump, and the shaft rotation speed is checked in different phases of operation.

These are additional paid services for diagnosing individual components and assemblies of a diesel engine, which are produced and evaluated separately.

Many years of experience working with diesel engines allows us to quickly determine the condition of the engine and identify the cause of the malfunction as accurately as possible. Once it is identified, we will be able to eliminate the cause of the breakdown and restore the unit to working condition.

Causes of fuel injection pump breakdowns

There are several most important reasons why a high pressure pump fails. This is usually due to the breakdown of the following parts:

- Plunger. The most common cause is contamination of the plunger pair. There are two main factors here. The first is the nature of the design (for example, the gap is too small). The second is poor fuel quality (presence of undesirable impurities clogging the device). In addition, contamination can also come from the engine - soot, dirt, etc. The operation is also affected by the wear of the plunger pair, which leads to severe overheating of the bearings.

- Presence of water in fuel. Moisture can wash away the fuel layer that protects the surfaces of precision parts of the high-pressure pump, which leads to a decrease in its service life and even possible jamming.

- Fuel filter is dirty. This leads to possible dirt getting into the plunger pair, and the pump also wears out.

- Irregularities in fuel supply and distribution. Another common reason for this is a malfunction of the plunger pair, namely wear of the drivers, teeth on the rack, discharge valves and contamination of the nozzles.

- Defective parts. Quite rare, but still found on cheap pumps. This may include cracks and chips of the housing, damaged bearings, jamming of plunger bushings, and the like.

- Bearing wear. More often caused by aging or defective parts. This leads to malfunctions of the pump, and the bearing itself and nearby parts overheat, which reduces its service life.

- Jamming of pistons and bushings. Leads to failure of the rack, cam shaft, gear, governor and keys. More often caused by moisture entering the cavity between the piston and bushing.

- Wear of injection pump components. Occurs as a result of aging or after water penetrates inside, which leads to corrosion of pump parts.

- Corrosion of the plunger pair. Appears when there is a large amount of water in the fuel.

- Problems in the cooling system. In other words, with prolonged use or heavy loads, the pump simply overheats. Cooling malfunction can be caused by insufficient antifreeze, blockages, breakdown of individual parts, etc.

If you suspect a faulty operation of the injection pump rack or related elements, you must check the following components for serviceability:

- detaching the rack from the regulator parts;

- check the clamps of the plunger leads;

- jamming of the gear rim screws.

The most dangerous cause of failure is a malfunction in the mobility of the fuel supply rack. If it is wedged at maximum fuel supply so that the regulator cannot return it to the reverse position, then the crankshaft speed in the engine sharply increases. This leads to the engine starting to work at the limit, and this is fraught with consequences. If the rack wedge is in the off position, the engine will not start.

When operating a car in low temperature conditions, there are cases of freezing of fuel injection pump parts and components. To prevent such situations, you should use fuel and oil that correspond to the temperature conditions.

In battery injection systems (or Common Rail), there are cases of control valve failure. Most often it is immediately replaced with a new one. Sometimes it is rebuilt and some parts are replaced.

Diesel car repair in Moscow

A complete car diagnostic includes checking all the main components and allows you to assess the condition of the car as a whole. Auto-Maxima service station repairs diesel engines using specialized equipment, original spare parts and professional tools.

We provide a wide range of diesel repair services:

- Diagnostics of diesel engines

- Diagnostics and repair of the diesel engine fuel system. Injection pump repair (adjustment, adaptation)

- Diagnostics and repair of diesel injectors, including Common Rail injectors

- Replacing the glow plug

- Replacing the cylinder head gasket

- Replacing the timing chain of a diesel engine

- Repair and restoration of diesel engine turbines

- Overhaul of diesel engines

- Vehicle maintenance

Diagnostics, maintenance and repair of diesel engines is carried out at the Auto Maxima service center in the Southern Administrative District of Moscow. You can get quality services at a competitive price.

Determining faults in fuel injection pump

It is worth remembering that the most reliable data on the condition of the fuel pump can only be obtained after checking it at a special stand in a car repair shop. Naturally, such diagnostics at home is impossible without special equipment. But it is still possible to check some elements and the correctness of their operation.

Water in plungers

To do this, you will need to remove the belt from the timing mechanism and carefully rotate the pulley. When rotating with variable forces, there is no water. If you have to apply significant force when rotating or you can’t turn it at all, then there is moisture.

The presence of moisture in the fuel injection pump is extremely harmful both for it and for the entire engine. This leads to rapid wear of parts and a reduction in their service life, and can also cause corrosion and even a complete wedge of the unit.

Pressure in the plunger pair

You can check it using a special tester - KI-4802 or TAD-01A. If there is none, then a regular pressure gauge with a large measurement range will do.

The device is screwed in instead of the fuel pipe or fixed in the central hole of the injection pump head. The engine is then started and readings are taken. Under normal conditions the value should be close to 300 kg/cm2. This is a conditional value and depends on many factors, the main thing is that during testing the figure is as close as possible to the specified one. If the system pressure is significantly lower than 300 kg, the parts of the plunger pair are severely worn out and repair or replacement is necessary.

Checking control sensors

On diesel cars with a Common Rail injection system, the injection pump is controlled using an electronic control unit (ECU). The most common failures in them are failure of sensors or wiring. More often this is indicated by a special signal on the dashboard - Check Engine. In this case, the error scanner needs to read the code and decipher it. Then, based on the data obtained, decide on the repair.

More often, the sensor simply expired or its wires were accidentally damaged. This leads to the fact that an incorrect signal arrives at the ECU and it begins to malfunction.

Fuel leak

If fuel is leaking from the high-pressure pump, then the cause is most often worn o-rings. To determine this, you need to shake the axis of the pump lever with the engine running. Solar oil will leak from under a damaged seal.

There are cases of fuel leakage from the installation site of the plunger pair. Then it is necessary to carry out a diagnosis. For these purposes, the pump should be removed from the car.

The tightness of the injection pump valve is checked in the following sequence:

- unscrew the high pressure tube from the defective segment;

- move the pump rack to the off-feed position;

- Use a hand pump to create pressure in the fuel system.

If the valve is faulty, fuel will appear from the pressure fitting hole. If this does not happen, the valve is working.

Grasping the rack

Before checking the rack, the rods and levers of the regulator and stop brackets should be disconnected from it. Then use the pump control levers to move the rack to its extreme position. Based on the effort when moving, we can conclude whether she is “stuck” or not. It is important to make several revolutions of the cam shaft during the process. If there are no defects, the rack will move smoothly and without shocks.

To freeze

If there are signs of fuel pump failure during the cold season, you should check it for freezing. If this happens, it must be removed from the car and brought into a warm place. When it warms up and the mobility of the parts is restored, it must be disassembled, drained of oil and rinsed thoroughly with clean diesel fuel. After these procedures, fresh oil is poured into the crankcase and the pump is installed back on the car.

If the pump freezes in very severe frosts, it is recommended to also use a defrost.

Diagnostics and repair of diesel engines in Moscow

Why choose our car service:

- Diagnostics of diesel engines of different car brands. Common Rail diesel diagnostics

- The service center has modern diagnostic equipment and all the necessary tools.

- Experienced and competent specialists with at least 12 years of experience.

- We provide a wide range of services that we are well versed in

- Affordable pricing policy

Another advantage of our company is that we always provide a guarantee for all types of services.

You can ask a question or sign up for diesel engine diagnostics by phone or through the feedback form on the website.

Diagnostics of pld sections

Cost of installation and dismantling work

| Service | Price |

| Removal and installation of fuel injection pump | from 4500 rub. |

| Removal and installation of injectors, subject to their easy removal with milling of the injector ring | from 800 rub. |

| Removing/Installing/Washing the fuel tank | from 4000 rub. |

| Replacing the fuel filter | from 500 rub. |

| Replacing the air filter | from 200 rub. |

| Changing the oil and oil filter | from 700 to 1500 rub. |

| Compression measurement with easy removal of injectors | from 500 rub. |

Replacing the fuel filter

| Service | Price |

| Replacing the fuel filter | from 500 rub. |

| Replacing the fuel filter (submersible) | from 2400 rub. |

injection pump

| Service | Price |

| Removing/Installing Injection Pump | from 4500 rub. |

Why is TurboDieselService suitable for you when you need to restore the functionality of your equipment? First of all, the profile of our service center will matter. Since we specialize specifically in repairing fuel equipment for cars, our technicians perform this work with the highest quality. They are familiar with all the intricacies and possible breakdowns of this particular equipment, which is the best guarantor of excellent results of their work.

You can also pay attention to the fact that our price for repairing fuel equipment, indicated in the price list on the website, is quite low. This will allow you to save money and pay attention to other possible breakdowns of the devices at your disposal. They may need diagnostics, which can also be carried out by our experienced specialists. Thus, for the same money you can solve more issues than in any popular fuel equipment repair service, thanks to our loyal pricing policy.

How we are working?

Bench tests of fuel equipment produced by DELPHI are carried out on certified HARTRIDGE stands - CRI-PC and AVM2-PC with the assignment of an IMA code. Inspection and repair of fuel components produced by BOSCH is also carried out on certified BOSCH - EPS 708 and BOSCH - EPS 815 equipment using the BOSCHQualityScan quality control system. This equipment allows you to completely eliminate the human factor when repairing products. Refurbished products in our services are covered by a warranty from the manufacturer of fuel components BOSCH, DELPHI - 12 months of operation from the date of repair.

Individual conditions are provided for each corporate customer. We pay special attention to deadlines, quality of work performed and feedback from the customer.

(“Truck Agregat”) has been operating in this area for several years, during which time it has accumulated unique experience in the maintenance, repair and restoration of fuel equipment of varying degrees of complexity. By cooperating with our company, you save up to 50% of the cost of fuel components without loss of quality and maintain the manufacturer’s warranty. We offer you to compare prices on our most common new and refurbished products. We guarantee a comprehensive and professional solution to your problems - no need to waste your time and money on experiments, call us by phone number.