Fuel system VAZ 2107 injector (photo and video)

Low fuel pressure, what is the problem Injector!? VAZ The

VAZ 2107 injector power supply system has some differences from the classic carburetor. The main distinctive features are caused precisely by the fact that instead of a standard system for supplying the air-fuel mixture to the cylinders, the new VAZ 2107 models use an injector. Accordingly, other elements, such as a pump, filter, etc., differ. In addition to the indicated differences in the fuel system, the VAZ 2107 injection engine has fundamental differences in the ignition system. At the same time, the undeniable advantage of this type of engine is the presence of electronic control of all major systems. It is thanks to it that the efficiency and efficiency of the engine significantly increases.

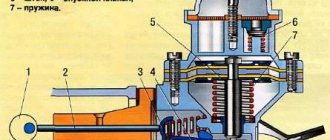

The schematic diagram of the fuel supply system for the VAZ 2107 injector is shown in the following figure.

Here the main elements are indicated by numbers from 1 to 12:

Air intake tube. Filter for air purification. Connecting air pipe. Damper with built-in idle speed control system. Fuel injection system (injector). Filter for mechanical fuel purification. Pump with electronic fuel volume sensor (installed in the tank). Bypass valve. Safety valve. Tank.

In addition, the power supply circuit contains a system for cleaning and subsequent saturation of air with gasoline vapors, consisting of a fuel purge valve 8 and an adsorber 12. VAZ 2107 adsorber (malfunctions, disassembly, removal)

As you can see, the power supply system of the VAZ 2107 injector has a number of significant differences, therefore, the procedure for its maintenance has its own characteristics. As for the air filter, everything is exactly the same as in the case of a carburetor. The filter element is replaced during each routine maintenance.

The pump does not require special maintenance, except for cleaning the fuel strainer installed on the suction pipe. This mesh traps mechanical impurities present in gasoline poured into the tank. If the fuel pump fails, it is replaced. To do this, it is necessary to disassemble the tank, remove the entire pump assembly from it, after which the failed element is replaced. The repaired pump is installed in its regular place in the tank.

mesh filter for rough cleaning from mechanical impurities; fuel supply pump; electronic sensor for monitoring the fuel level (filled in the tank); fuel supply pipe; fuel outlet pipe; electrical connector; float.

The fuel filter is replaced periodically, in accordance with the manufacturer's recommendations. The main element is a special paper insert assembled in a metal case, and it is installed in the supply pipeline between the fuel pump and the injection system. The direction of fuel movement is indicated by an arrow on the body. For example, according to the arrows in the following photo, the pump (fuel tank) should be connected on the right side, and the ramp on the left.

The fuel injection system or fuel rail of the VAZ 2107 engine injector is designed directly to supply the mixture to the engine cylinders.

fuel injectors; feed tube; outlet tube; ramp; spool fitting for pressure control; electronic pressure regulator.

One of the main working elements of the VAZ 2107 engine injection system is the injector. It is essentially an electromechanical valve that is controlled by the engine management system. When voltage is applied, the valve opens and the mixture is injected into the cylinder through the nozzle under the pressure created by the pump. During operation, the nozzles become clogged and therefore require periodic cleaning. As a rule, injectors are cleaned during maintenance, but if engine performance deteriorates, they need to be cleaned without waiting for routine maintenance. Injectors are replaced only when they fail.

Another element of the fuel supply system of the VAZ 2107 engine injector is the throttle valve. It is with its help that the engine speed is controlled, the damper regulates the volume of intake air to prepare the combustible mixture. To prevent freezing of the insides of the damper during the cold season, it is connected to the engine cooling system.

pipe for connecting the adsorber; frame; flap; damper drive; pipe for removing crankcase gases; pipes for connecting to the cooling system; electronic damper position sensor; idle speed control element.

Another new element of the VAZ 2107 engine is the adsorber. It is designed to collect gasoline vapors when the car is idle. After starting the engine, the vapors held by the activated carbon are mixed with air, and the resulting mixture is fed through the throttle valve into the cylinders. In this air exchange scheme, among other things, the tank is involved, which is the main supplier of air saturated with fuel vapor.

In general, the nutrition scheme described above is more effective than the classic one. This is also due to the presence of an electronic engine control system, which regulates injection depending on operating mode, temperature and other factors. And if you follow the manufacturer's recommendations regarding routine maintenance, there will never be any problems with your car.

VAZ 2107 power supply system (carburetor)

The purpose of the engine power system is to store and purify fuel, mix with air and supply the mixture to the engine. The power system includes:

- Gas tank.

- Fuel pump

- Level sensor.

- Fine fuel filter.

- Coarse fuel filter.

- Fuel lines.

- Fuel rail with injectors.

- Air filter

- Air supply sleeve.

- Throttle valve.

- Fuel vapor recovery system.

Power supply system for the injection engine of a VAZ 2107 car

The idle speed regulator for VAZ is

– 2107 shut-off valve driven by an electric stepper motor.

The regulator is installed on the throttle body under the throttle position sensor. Based on an electronic signal from the control unit (ECU), the idle speed controller changes the cross-section of the additional supply air channel, thereby adjusting the idle speed of the crankshaft. idle speed control VAZ 2107 The gas tank

of the VAZ 2107 car is steel, leaded from the inside, welded from stamped two parts.

The gas tank is located in the trunk of the VAZ 2107 car on the right side. The filler neck of the gas tank is closed with a plug and is brought into the niche of the filler neck on the right wing. VAZ gas tank Fuel

2107 from the gas tank is supplied by a gas pump combined with a fuel level sensor.

A mesh filter is installed on the inlet pipe of the fuel pump, which traps large contaminant particles that enter the gas tank along with gasoline. car on the VAZ 2107 fuel pump is turned on by the Serviceable command. The fuel pump ECU should develop a pressure of not 3 bar, less than 2 bar (320 kPa). electric fuel pump VAZ receiving

1 – 2107 mesh filter; 2 – fuel pump; 3 – fuel level sensor indicator; 4 – supply tube; 5 – drain tube; 6 – electrical connector block; 7 – fuel pump float From the sensor, fuel flows through the fuel pipe into the fuel filter for more thorough cleaning.

Fuel injection system VAZ 2107

The VAZ 2107 injector is a complex device that is much more expensive to repair than a carburetor power system. To accurately determine the cause of a power system malfunction, it is necessary to read error codes from the ECU (electronic control unit). You can do this by contacting a car service or yourself, having certain equipment and software.

- Device

- Gasoline pump

- Nozzle

- Idle speed control

- Canister valve

- Crankshaft position

- Air flow

- Throttle position

- Coolant temperature

- Speed sensor

- Oxygen concentration

- Engine diagnostics

General diagram of the electrical equipment of the VAZ 21074 injector

General diagram of the electrical equipment of the VAZ 21074 injector

1. Electrical connection diagram of the wiring harness of the instrument panel assembly LADA 21074

- – ignition switch unloading relay;

- – relay-interrupter of direction indicators;

- – windshield wiper relay;

- – brake signal switch;

- – switch for headlights and direction indicators;

- – windshield wiper and washer switch;

- – ignition switch;

- – hazard warning switch;

- – instrument cluster;

- – rear window heating switch;

- – rear fog light switch;

- – external lighting switch;

- – heater motor switch;

- – additional resistor for the heater electric motor;

- – heater electric motor;

- – indicator lamp for heated rear window;

- – brake fluid level warning lamp;

- – instrument lighting switch;

- – cigarette lighter;

- - watch;

- – reverse light switch;

- – hand brake sensor;

- – rear fog light relay;

- – block of the instrument panel harness to the ignition system harness;

- – glove box lighting;

- – mounting block.

Additional designations

The fuses of the VAZ 2107 car are located as follows:

- taillights and reversing lights;

- electric motor of the heater fan, headlight washer and glass wiper pumps;

- indicator for turning on the rear window heater VAZ 2107;

- direction indicators and hazard warning relays;

- fog lights;

- tachometer, voltmeter;

- control lamps for oil pressure, fluid, fuel level and reserve indicators on the instrument panel, instrument panel lighting;

- cigarette lighter and clock;

- VAZ sound signal;

- interior lighting (up to 2000 there was one lamp on the ceiling, for those manufactured after 2000 there were two lamps on the rear door pillars);

- high beam headlights;

- high beam warning lamp;

- engine compartment lighting and license plate lighting;

- glove compartment lighting;

- right headlight;

- left headlight.

A detailed wiring diagram of the VAZ 2107 will help you understand the intricacy of electrical wiring elements, find the air cover switch or the windshield and headlight wiper relay.

PROMOTION: SALE OF NEW CAR 2021 PRODUCTION

About the fuel pump on the VAZ2107 injector

If the car engine does not start, then various factors can be the reasons for such consequences. One of these factors may be a gas pump, the main purpose of which is to pump gasoline into the engine from the gas tank. The VAZ 2107 has an injector and a fuel pump that is much more reliable than on carburetor cars. Despite this, even on fuel-injected cars the fuel pump can fail.

What is the device in question?

The fuel pump on the VAZ 2107 injector is presented in the form of an electric motor with a pump, which pumps gasoline from the tank.

The pump design has an electric motor that is powered from a 12V vehicle network. The design of the electric motor consists of a rotor, brushes and a commutator, which are constantly in gasoline. Many will think that such an injector power system for the VAZ-2107 car is quite dangerous, but not everything is so simple.

Spark and gasoline are a dangerous compound that can lead not only to fire, but also to explosion. This would happen, because sparking occurs in the electric motor of the gasoline pump, if not for the fact that gasoline belongs to the category of liquids that do not conduct electric current. In addition, gasoline does not burn if there is no air, and the fuel circuit is exclusively closed. Thus, the design of an electric fuel pump on a VAZ 2107 car is presented.

Device

Injector VAZ 2107

The VAZ 2107 injector consists of the following elements:

- Computer;

- Sensors;

- Fuel pipes and hoses;

- Fuel and air filter;

- Actuators;

- Gas tank;

- Wiring.

The injector power system contains the main element - a computer or ECU. Its permanent memory contains a program (algorithm) in accordance with which the control of actuators is implemented, these include:

- Fuel pump;

- Injectors;

- Idle air control;

- Canister valve.

Each of the above elements performs its own function.

Gasoline pump

Turned on by the ECU output signal through a relay. Has a strainer and fuel level sensor. The gasoline from it passes through the fuel filter. The pump is located in the tank and to remove it, you need to remove the back seat, remove the hatch and unscrew the fastener.

Nozzle

It is a sprayer equipped with a solenoid valve. Triggered by an ECU impulse. Accordingly, the duration of valve opening (the amount of gasoline supplied) depends on the time the pulse is applied. It is installed on a ramp common to all injectors, a constant pressure in which is maintained by a valve. If it is exceeded, the valve opens and gasoline returns back to the tank. The injector enters the intake manifold. The air flow, passing through the intake manifold, carries away a portion of gasoline ejected by the nozzle.

The structure of the VAZ 2107 fuel system

Idle speed control

The fuel system maintains engine idle speed using a regulator. It is a stepper motor connected to a conical shaped control body. Its approach reduces the air flow entering the intake manifold; its removal, on the contrary, increases it.

Canister valve

It is needed to turn on the ventilation of the adsorber, which accumulates gasoline vapors and releases them into the intake manifold at the right moment.

The injector power system contains sensors for measuring, converting and transmitting the signal to the computer.

The following sensors are installed on the VAZ 2107:

- Crankshaft position;

- Mass air flow;

- Throttle position;

- Coolant temperature;

- Speed;

- Oxygen content in exhaust gases.

Crankshaft position

This parameter is needed by the ECU to open the injectors in a timely manner. If this sensor malfunctions, the VAZ 2107 will not drive.

Air flow

Allows you to supply fuel in the right quantity. The signal from this sensor is sometimes incorrect. The reason for this may be its malfunction caused by high humidity or low temperature. An air filter with condensation inside or dirty will adversely affect this sensor.

Throttle position

This signal is analog, i.e. continuous. It transmits precise data about the throttle position.

Coolant temperature

The parameter is needed so that the ECU understands whether the engine is warmed up. This is necessary for the correct operation of a cold motor. The mixture is enriched due to temperature correction.

Speed sensor

Measures and transmits a signal in the form of a sequence of pulses to the ECU.

Oxygen concentration

The oxygen content in the exhaust gases must be measured to adjust the composition of the fuel mixture. It doesn't work when it warms up. This is advisable because the mixture is enriched.