Technical specifications 4A GE 1.6 l/115 – 240 l. With.

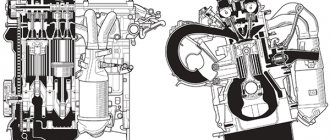

Initially, the GE engine of the 4A family had a combustion chamber volume of 1.6 liters and an angle of 50 degrees between the valves. This made it possible to increase power and ensure high performance. The ratio of cylinder diameter to piston stroke is constant for the entire series, 81/77 mm.

In the first generation 4A GE, the engine design was tailored for rear-wheel drive AE86 cars of the Corolla Levin and Sprinter Trueno variants from Toyota. The transverse installation of internal combustion engines for front-wheel drive sports models of Toyota began to be used later, with the advent of the MR2 sports car, and in 1991, Corolla in North America at factories in Canada and the USA of Toyota Corporation ceased to be equipped with 4A GE power units.

Engine 4A-GE Silver Top under the hood

To participate in the Atlantic Championship in the period 1990 - 2005, the manufacturer created a 4A-GE version for Formula Atlantic cars called Toyota Racing with a speed cut-off of around 12,000 min-1 and a power of 240 hp. With. Special attachments were installed here, and the service life was 1000 km maximum.

4A-GE

Technical characteristics of 4A GE correspond to the table values below:

| Manufacturer | GM DAT |

| Engine brand | 4A GE |

| Years of production | 1983 – 1998 |

| Volume | 1598 cm3 (1.6 l) |

| Power | 84.6 – 118 kW (124 – 160 hp) |

| Torque moment | 153 Nm (at 4200 rpm) |

| Weight | 112 – 130 kg |

| Compression ratio | 9,4 – 11 |

| Nutrition | injector |

| Motor type | in-line petrol |

| Ignition | distributor |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4/5 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin/4 throttles |

| An exhaust manifold | cast iron |

| Camshaft | original cam profile |

| Cylinder block material | cast iron |

| Cylinder diameter | 81 mm |

| Pistons | high skirt |

| Crankshaft | cast iron |

| Piston stroke | 77 mm |

| Fuel | AI-95 |

| Environmental standards | Euro-3 |

| Fuel consumption | highway – 4 – 5 l/100 km mixed cycle 5 – 7 l/100 km city – 8 – 10 l/100 km |

| Oil consumption | 0.2 – 0.6 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 5W40, 0W30, 0W40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Mannol, Toyota, Castrol |

| Oil for 4A GE by composition | synthetics, semi-synthetics |

| Engine oil volume | 3 – 3.7 l depending on the car |

| Operating temperature | 95° |

| ICE resource | declared 250,000 km actual 350,000 km |

| Adjustment of valves | hydraulic compensators |

| Cooling system | forced, antifreeze |

| Coolant volume | 6 l |

| water pump | Toyota 16110-19205, GMB GWT-83A, Aisin WPT-018 |

| Spark plugs for 4A GE | BKR6EP-11 from NGK |

| Spark plug gap | 1.1 mm |

| Timing belt | Gates 5124, Contitech CT527 |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Fram CA5466, Febi 27270, Champion U677/606, Bosch 1457433958, Blue Print ADT32239, Alco MD-9932, Toyota 17801-15070 |

| Oil filter | Mann W68/3, Jakoparts J1312010, Champion C138/606, Bosch 0986452028, Blue Print ADT32109, Alco SP-991, Vic C-110, Toyota 90915-10001 |

| Flywheel | 8 bolt holes, with clutch bore diameter 212 mm |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | manufacturer Goetze |

| Compression | from 13 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 750 – 800 min-1 |

| Tightening force of threaded connections | spark plug – 25 Nm flywheel – 102 Nm clutch bolt – 64 Nm bearing cap – 77 Nm (main) and 55 Nm (connecting rod) cylinder head – three stages 20 Nm, 64 Nm + 90° |

The user manual includes a description of the parameters of all 5 generations of the motor. To ensure that the hydraulic compensation and phase adjustment system remains operational, it is recommended to use high-quality oil.

4A-GE 16V

The first sign of the new generation of engines was the six-cylinder Toyota 1G-GEU of 1982. For the first time in the history of the brand, the engine received a two-shaft cylinder head with four valves per cylinder. The engine turned out to be very successful. Compared to its single-shaft brother, the 1G-GEU developed 30 hp. more and at the same time was quieter and more economical.

A year later in 1983, Toyota released the 4A-GE four-cylinder engine. It was built on the basis of the 1.6-liter 4A engine, but received a multi-valve cylinder head similar in design to the 1G-GEU. As a result, compared to the single-shaft 4A, the power of the 4A-GE increased by as much as 40 hp. and reached 120 hp. The new motor turned out to be extremely light and weighed only 123 kg, which is 29 kg less than its predecessor 2T-G.

Blue top

By design, the 4A-GE was a classic Japanese short-stroke engine with a cast-iron cylinder block. It had a volume of 1587 cm3, belt driven camshafts and electronic fuel injection. The highlight of the engine was its cylinder head with a tent-shaped combustion chamber and four valves per cylinder (2 inlet and 2 exhaust). In addition, the engine was equipped with a clever T-VIS (Toyota Variable Induction System) intake system. It worked as follows: at speeds less than 4200 rpm, four of the eight channels in the intake manifold were closed using throttles, thereby limiting the air supply. As a result, at low speeds the air flow rate increased, thereby achieving the best filling of the cylinders.

Due to the inscriptions on the cylinder head cover in blue, the engine of the first series received the informal designation “Blue top”. He first debuted on the legendary Toyota Corolla AE86 . It must be said that in the early 80s, 4A-GE made a lasting impression on the Japanese public. It had a bright high-revving character and quietly spun up to 7400 rpm. In addition, through simple modifications, the engine power easily increased to 140 hp. "Blue top" was produced until 1987 and left production along with the AE86.

Red & Black top

However, the story of 4A-GE was just beginning. In June 1987, under the hood of the Toyota Corolla AE92, a modernized 4A-GE was registered, which received the popular name “Red & Black top”. Since the new Levin and Trueno had front-wheel drive, this time the engine received a transverse arrangement. At the same time, the engine did not increase power, but the engineers strengthened the cylinder block and increased the diameter of the crankshaft journal, which had a beneficial effect on its reliability.

Red top

In May 1989, the third generation of engines known as “Red top” went into production. This time, Japanese engineers significantly modernized the engine. They abandoned the T-VIS system, simultaneously increased the compression ratio to 10.3 and increased the power to 140 hp. In addition, the mechanics strengthened the connecting rods, installed new pistons and oil nozzles under them. All these improvements had a positive impact on the reliability of the power unit. There are cases when even a seriously boosted 4A-GE “Red top” covered 250-300 thousand, not the easiest kilometers, without problems.

Design Features

Toyota designers, together with Yamaha cylinder head developers, incorporated the following basic architecture into the 4A GE engine:

- boring of cylinders and subsequent processing by honing their mirrors directly inside the cast iron block;

- the cylinder head is two-shaft according to the DOHC design, but initially for 16 valves (2 intake plus 2 exhaust), and then 20 valves (3 inlet and 2 exhaust);

- The location of the collectors is reversed, exhaust at the front, receiver at the rear;

- attachments are driven by a separate belt;

- the ignition system did not change, it remained a distributor system with one coil and spark distribution over a bundle of high-voltage wires;

Cylinder head with 20 valves

Next page""""""Regardless of the 4A GE generation, major overhauls are easily done in-house, and tuning is usually done by enthusiasts on this particular version of the 4A series.

- 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 54. 55. 56. 57. 58. 59.60. 61. 62. 63. 64. 65. 66. 67. 68. 69. 70. 71. 72. 73. 74. 75. 76. 77. 78. 79. 80. 81. 82. 83. 84. 85. 86. 87. 88. 89. 90. 91. 92. 93. 94. 95. 96. 97. 98. 99. 100. 101. 102. 103. 104. 105. 106. 107. 108. 109. 110. 111. 112. 113. 114. 115. 116. 117. 118. 119. 120.121. 122. 123.124.125.126.127.128.129.130.131. 132.133.134. 135.136.137.138.139.140.141.142.143.144.145.146.147.

29 Toyota Carina Toyota Carina 4A-GE removal and installation of the cylinder head Cylinder head Removing the cylinder head 1. Relieve the fuel pressure in the fuel manifold.

2. Remove the timing belt (see paragraph “Timing belt”). 3. Remove the coolant pump from the Toyota Carina 4A-GE. 4. Separate the accelerator cable. 5. (automatic transmission) Separate the throttle valve control cable. 6. Remove the air duct. 7. Separate the radiator supply line. 8. Separate the radiator outlet pipe. 9. Separate the heater pipes. 10. Separate the fuel inlet line. 11. Separate the fuel return line. 12. Separate the brake booster vacuum line. 13. Remove the air intake chamber. a) unscrew the five bolts and remove the air intake chamber cover. b) disconnect the pipes. c) disconnect the air lines and remove the air intake chamber. 14. Unscrew the nuts securing the wire harness guard, separate all terminals and dismantle the harness. 15. Remove the air intake chamber struts. 16. Remove the head cover of the Toyota Carina 4A-GE. 17. When the timing belt is removed, do not turn the camshafts and crankshafts to avoid collision of pistons and valves. Before dismantling the camshafts, you need to rotate the crankshaft 45° counterclockwise (see figure). 18. Fixing the camshafts by the hexagonal part, unscrew the bolts securing the toothed pulleys and remove the toothed pulleys of the exhaust camshafts and intake valves with the Wt device assembly. 19. Remove cover No. 4 of the timing belt. 20. Remove the right motor support. 21. Remove the intake camshaft and the support for the intake camshaft bearings of the Toyota Carina 4A-GE. 22. Separate the exhaust pipe. 23. Dismantle the cylinder head, a) Using a special tool, unscrew the cylinder head fixing bolts in the order prescribed in the figure (after loosening them in 2-3 passes).

b) Remove the cylinder head assembly and gasket. 24. Remove the exhaust camshaft. 25. Remove the supply and exhaust manifolds. Installation of the cylinder head of a Toyota Carina 4A-GE 1. Before installation, check the length of the cylinder head fixing bolts. (l) Maximum permitted length 116.5mm If the length of the bolt is longer than the maximum permitted, replace it. 2. Install the cylinder head. a) install a new gasket. b) install the cylinder head of the Toyota Carina 4A-GE. c) apply a thin layer of motor oil to the threads and under the bolt heads. d) pre-tighten the fixing bolts in the order prescribed in the figure, several passes (at least 3) to a torque of 30 Nm.

e) mark with paint the edge of the bolt facing the front section of the engine (towards the crankshaft pulley), as shown in the figure.

f) tighten all bolts in the sequence prescribed above, turning them 90°. g) tighten all the bolts again in the order prescribed above by another 90°. h) make sure that all bolt marks are oriented 180° from the initial position and turned towards the rear section of the motor (towards the power take-off). 3. Install the supply and exhaust manifolds. 4. Install the exhaust camshaft. 5. Connect the exhaust pipe. 6. Install the camshaft bearing support and the intake camshaft. 7. Place the right motor support. 8. Install cover No. 4 of the timing belt. 9. Install the exhaust and intake camshaft timing gear pulleys with the Wt device assembly. When fixing the camshafts by the hexagonal part, tighten the toothed pulley fixing bolts. Tightening torque 60 N m 10. Install the cylinder head cover. 11. Install the air intake chamber supports. 12. Place the wiring harness, connect all the terminals and tighten the cable harness guard fixing nuts. 13. Install the air intake chamber. a) install the air intake chamber and connect the air pipelines. b) install the pipes. c) install the air intake chamber cover and tighten the five bolts. 14. Connect the vacuum lines. 15. Connect the fuel return line. 16. Connect the inlet fuel pipeline to the cylinder head manifold of the Toyota Carina 4A-GE (4a-ge). 1 — accelerator cable, 2 — throttle valve control cable (automatic transmission), 3 — air duct, 4 — air intake chamber cover, 5 — pipes, 6, 11, 43 — gaskets, 7 — air intake chamber, 8 — vacuum hoses, 9 — sealing washer, 10 — cylinder head cover, 12 — intake camshaft bearing covers, 13 — intake camshaft, 14 — lower intake camshaft bearing pad, 15 — fuel return line, 16, 24, 26, 35 — ring seal, 17 — inlet fuel hose, 18 — heater pipes, 19 — radiator supply pipe, 20 — radiator exhaust pipe, 21 — cylinder head gasket, 22 — gaskets, 23 — exhaust pipe, 25 — coolant pump , 27 — oil dipstick guide, 28 — ground cable, 29 — oil dipstick, 30 — generator bracket, 31 — generator, 32 — timing belt cover No. 4, 33 — exhaust camshaft timing belt pulley, 34 — transport hook (eye ), 36 — toothed pulley of the intake camshaft with Wt device assembly, 37 — cylinder head with intake and exhaust manifolds assemblies, 38 — oil seal, 39 — front bearing cover of the intake camshaft, 40 — engine electrical wiring harness, 41 — rack No. 2, 42 — rack No. 1, 44 — cylinder head fixing bolt. 17. Connect the heater pipes. 18. Connect the radiator outlet pipe. 19. Connect the radiator supply pipe.

21. (automatic transmission) Connect the throttle valve control cable. 22. Connect the accelerator cable. 23. Install the coolant pump. 24. Install the timing belt.

Next page""""""

- 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 54. 55. 56. 57. 58. 59.60. 61. 62. 63. 64. 65. 66. 67. 68. 69. 70. 71. 72. 73. 74. 75. 76. 77. 78. 79. 80. 81. 82. 83. 84. 85. 86. 87. 88. 89. 90. 91. 92. 93. 94. 95. 96. 97. 98. 99. 100. 101. 102. 103. 104. 105. 106. 107. 108. 109. 110. 111. 112. 113. 114. 115. 116. 117. 118. 119. 120.121. 122. 123.124.125.126.127.128.129.130.131. 132.133.134. 135.136.137.138.139.140.141.142.143.144.145.146.147.

coming

List of internal combustion engine modifications

In total, the management of the Toyota concern, together with the manufacturer Yamaha, released 5 generations of the 4A-GE engine:

- Gen-1 – 1983 – 1987, modernization of the Big Port intake tract, variable T-VIS manifold geometry, power 112 hp. With. for Europe, 124 l. With. for the domestic market, compression ratio 9.4;

- Gen-2 – 1987 – 1989, power 125 hp. pp., compression ratio 10;

- Gen-3 – 1989 – 1992, reduced Small Port suction volumes, new type ShPG, red Red Top valve cover, power 128 hp. pp., compression ratio 10.3;

- Gen-4 – 1991 – 1995, 20 valves, a separate short throttle for each cylinder, Silver Top valve cover, VVTi timing adjustment system, power 160 hp. pp., compression ratio 10.5;

- Gen-5 – 1995 – 1998, upgraded intake/exhaust ports, lightweight flywheel and pistons, Black Top, 165 hp. pp., compression ratio 11.

Motor 4A GE V20

In parallel with the naturally aspirated version, a 4A GZE turbo engine with a 0.6 bar compressor was produced, which went through two generations to improve parameters.

Third generation

Production lasted three years from 1989 to 1991. Changes are observed on the surface of the valve cover, the color of which has changed to silver. The letter designation of the motor was painted in red. This engine received the nickname “Red Top”, which translated into Russian means Red Top. The compression ratio increased to 10.3:1. Thanks to the experience gained from designing previous engines, Toyota designers decided to reduce the geometry of the intake duct. This led to the engine receiving a new nickname "smallport", which means "Little Channel" in Russian. The T-VIS system was not used in this generation.

To increase the service life of the motor, the following modifications were made:

- Installation of additional oil sprayers located under the lower surface of the pistons.

- The thickness of the connecting rods has been increased.

- The production of fingers was carried out according to the thickness of the fingers, which was 20 mm.

- The installation of a sensor that controls air flow was carried out in two types MAF and MAP, which depended on the market for which the engine was produced.

In the power plant supplied to the Japanese market, the power parameter was 125 hp. and the torque is 149 Nm, and in American market engines these figures were 128 hp. and 105 Nm respectively.

The 4A-GE engine was first introduced in 1983. The Toyota Sprinter Trueno AE86 and Toyota Corolla Levin AE86 were the first cars to install this power plant. 4A-GE was installed on the AE86 body according to the scheme of a rear-wheel drive car. Its transverse installation began with the Toyota MR2. 1991 was the last year in America that the 4A-GE engine was installed in the Toyota Carolla. The Geo Prizm GSi car was equipped with this power unit from 1990 to 1992. All, without exception, modifications of the 4A-GE were equipped with forged pistons, unlike Toyota units, in which they were cheaper, cast.

From 1990 to 2005, Toyota was a sponsor of the Atlantic Championship. At this time, the completed modification 4A-GE from Toyota Racing was installed on Formula Atlantic cars. The cylinder head of this “charged” engine has been modified. Thanks to this change, the power parameter was 240 hp. at a rotation speed of 8400 rpm. The maximum rotation speed was 12 thousand rpm, but this contributed to a reduction in engine life.

Advantages and disadvantages

Initially, the internal combustion engine design is specially simplified - there are no introduced cooling jackets and cylinder liners. The resource of the power drive is considered high, in practice it reaches 350 - 450 thousand km.

Cylinder head 4A-GE

Boosting and overhauls are done with your own hands with minimal skill and the availability of special tools. The weak point of the 4A-GE is the engine temperature sensor, absolute pressure and CO, and the rear crankshaft oil seal.

List of car models in which it was installed

The naturally aspirated 4A GE in-line transverse engine, boosted by the manufacturer, was used in Toyota cars:

- Sprinter – fastback and sedan;

- Sprinter Trueno – three-door coupe;

- Sprinter Marino – five-door hardtop;

- Sprinter Carib – a station wagon with an original body exterior;

- Corolla Spacio – five-door compact MPV;

- Corolla Levin – two-door coupe;

- Corolla Ceres – hardtop sedan;

- MR2 – two-seater sports car;

- AE86 – hatchback and coupe;

- Caldina – C class station wagon;

- Avensis – liftback, sedan and station wagon;

- Carina – sporty design sedan;

- Carina E – hardtop station wagon;

- Corona is a family sedan.

Toyota MR2

The engine's performance characteristics were also suitable for three cars from third-party automakers - the American Geo Prizm sedan, a luxury convertible, a Chevrolet Nova coupe and a two-seat Elfin Type 3 Clubman roadster.

Maintenance schedule 4A GE 1.6 l/124 – 165 l. With.

In all versions, the 4A GE engine requires replacement of working fluids and consumables within the following periods:

- after 50,000 km – timing belt and attachments;

- after passing 30 thousand mileage, it is recommended to adjust the thermal clearances of the valves;

- every 2 years – the manufacturer stipulates cleaning/purging of the crankcase ventilation;

- after 7500 km – the manufacturer recommends replacing the engine oil and oil filter;

- after 40 thousand mileage - the fuel filter should be replaced;

- the air filter must be replaced annually, according to the manufacturer;

- after 40,000 km - after packing the coolant from the factory, the additives inside the antifreeze lose their effectiveness;

- after 20,000 mileage - spark plugs in the DIS-2 engine system;

- after 60,000 km, burnout begins in the intake manifold.

Replacing the timing belt

Periodically, the IAC wears out, the catalytic converter is destroyed, the rings fall in and the valve stem seals wear off.

Review of faults and methods for repairing them

Compared to the FE version, the 4A GE motor is considered forced.

Typical failures of 4A GE remain:

| Unreasonable increase in gasoline consumption | 1) failure of the oxygen sensor (usually the first one) 2) failure of the DBP | 1) replacing the lambda probe 2) replacing the absolute pressure sensor |

| Increased vibrations | clogged injectors | flushing or replacement |

| Increase and freezing of speed | 1) wear of TPS 2) failure of the XX valve 3) clogging of the remote control | 1) replacing the throttle position sensor 2) replacing the idle air valve 3) blowing and cleaning the damper |

Repair 4A GE

The factory allows lubricant consumption per 1000 km to be within 1 liter, so the rings/caps should be changed at a level of 1.2 liters or more.

Malfunctions and repairs

Like any 4A motor, Black Top has a number of the most common faults. Let's look at the problems and how to fix them:

Tuning the 4A “Black Top” engine.

- Increased fuel consumption. The problem is hidden in a failed lambda probe that needs to be replaced.

- Vibration. Often the cause is clogged injectors. Cleaning will help solve the problem.

- High speed, unstable. It is recommended to check the IAC and throttle valve.

- The revolutions are floating. The cause is a malfunction of the temperature sensor.

- The revolutions are floating. We clean the throttle valve block, the exhaust valve, check the spark plugs, injectors, and crankcase ventilation valve.

- Engine knock. Usually, the piston pins knock, if the mileage is high and the valves have not been adjusted, then adjust the valve clearances; this procedure is carried out once every 100,000 km.

Engine tuning options

You can boost the 4A GE engine in stages and quite inexpensively, using mechanical atmospheric tuning:

- in the first versions of the A4 GE, camshafts with high cam lift and phases of 264 degrees and a direct-flow exhaust should be installed to obtain about 140 hp. With.;

- then you need to dismantle the T-VIS variable geometry intake manifold, use other pushers and springs, camshafts with 280 phase, polish the cylinder head channels, increase the diameters of the seats and valves, buy a 4:2:1 spider, apply firmware version January 7.2 to provide 170 hp. With.

Tuning 4A GE

Further tuning to obtain power from 240 hp. With. requires an increase in the budget. A dry sump, 320 phase shaft and a special oil pump are required. It is prohibited to operate independently boosted engines without strengthening the suspension and modifying the braking system.

Thus, the 4A GE motor has factory boost by default. The engine architecture has changed over 5 generations, power from 124 hp. With. increased to 165 liters. With. It is intended for installation in Toyota C, E and D class models.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them