Toyota Motor Corporation (Japan) first showed 3uz fe engines in 2000. Before this, starting in 1989, the concern produced similar power units of the UZ family - 1UZ-FE and 2UZ-FE.

All engines of this family, including the 3uz fe engine, were installed in prestigious and/or sports cars of the Toyota and Lexus brands. And although mass production of UZ series power units was discontinued in 2006, the 3uz fe engine was produced in Japan for more than three years specifically for Toyota Crown Majesta 4WD cars.

Specifications

Download .xls file

xls

Download picture

Send by email

| OPTIONS | MEANING |

| Cylinder displacement, cubic meters cm | 4292 |

| Power, l. With. (at 5600 rpm) | 290 |

| Maximum torque, Nm (at 3400 rpm) | 441 |

| Compression ratio | 10.5 |

| Cylinder arrangement | V-shaped |

| Number of cylinders | 8 |

| Number of valves per cylinder, pcs. | 4 |

| Total number of valves, pcs. | 32 |

| Cylinder diameter, mm | 91 |

| Piston stroke, mm | 82.5 |

| Supply system | SPFI Electronic Injection |

| Gas distribution mechanism | DOHC+VVT-i |

| Fuel | Unleaded gasoline AI-95 |

| Fuel consumption, l/100 km (city/highway/mixed) | 10,3/6,2/7,7 |

| Lubrication system | Combined (spraying + under pressure) |

| Engine oil type | 0W-30, 5W-30, 5W-40,10W-30, 10W-40 |

| Engine oil quantity, l | 5.1 |

| Cooling system | Liquid, closed type, forced circulation |

| Motor resource, thousand hours. | 500 |

The engine was installed on production cars: Lexus LS 430, Lexus GS 430, Lexus SC 430, Toyota Crown Majesta, Toyota Celsior, Toyota Aristo, Toyota Soarer.

Cars with 3uz fe engine that took part in the Super GT championship: Toyota Supra GT500 Race Car, Lexus SC 430 GT500 Race Car.

Description

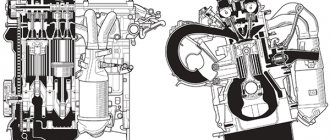

The engine is an 8-cylinder 4.3 liter power unit with a V-shaped cylinder arrangement. The 90-degree cylinder block is made of aluminum. The two cylinder heads (cylinder heads) are also aluminum. Each of them is equipped with a DOHC type twin-shaft gas distribution mechanism (GRM) with 4 valves per cylinder and a VVT-i system.

There are no hydraulic valve clearance compensators, so the engine requires periodic adjustment. The timing belt is driven by a timing belt, which needs to be replaced regularly.

Fuel injection is carried out under the control of an electronic SPFI system. A variable geometry intake manifold (ACIS) is also installed.

Electronic control systems for engine components:

- SPFI fuel injection system

The SPFI (Single Point Fuel Ijection) system provides direct fuel injection through one injector (single point injector) simultaneously into all channels of the intake manifold. The injector is installed in the throttle body.

- Gas distribution mechanism VVT-i

The gas distribution mechanism was developed by Toyota (1996). Its design is distinguished by the fact that the control element is a special VVT-i (Variable Valve Timing with Intellegence) clutch, adjusted in such a way as to provide good traction at low speeds.

As the speed increases, the oil pressure increases, under the influence of which the VVT-i clutch opens, thereby turning the camshaft at a given angle relative to the pulley. As a result, the timing of the opening of the intake and closing of the exhaust valves changes in such a way that the power and torque of the power unit increase. When the crankshaft speed decreases, the process occurs in the reverse order.

- Variable geometry intake manifold (ACIS)

ACIS - this system was also developed by Toyota. It allows you to increase engine power and torque by reducing or increasing the working length of the intake manifold. A damper is installed inside the collector, which divides the collector into two parts. Turning at the command of the electronic control unit of the power unit, it closes or opens parts of the manifold.

UZ series engines. Phenomenal reliability and one defect

V-shaped "eights", unless, of course, you take into account purebred "Americans", are usually not the kind of engines they talk about - simple, unpretentious, capable of withstanding any abuse. Another thing is that the Toyota company of the last century simply could not afford to create bad engines. I worked like a student, “for the record”, focusing on reliability. And therefore, almost everything that its engineers took on turned out to be unpretentious in maintenance, hardy and resourceful. Be it “fours”, “sixes” or V8 of the UZ series, which will be discussed.

"Eights" for the elite

The Japanese, who gave the world serial variable valve timing systems, massive and therefore inexpensive turbocharging and CVTs whose circulation numbers in the millions, in some cases cannot be called revolutionaries. At some fundamental points they will balk and slap the classic product. Following traditions is in their blood. Let them be imported from abroad when it comes to cars. Particularly on the other side of the Pacific Ocean. This happened with the V-shaped “eights” of the V series, which appeared in 1963. Camshaft in the block camber, two valves per cylinder, driven by rods and hemispherical combustion chambers. We won’t talk about the casting of the block and the cylinder-piston group, but according to these decisions, it is the spitting image of an “American”. It’s not for nothing that people call the installations of this line Toyota HEMI - by analogy with Chrysler HEMI (hemispherical - hemispherical). At first, the 2.6-liter 115-horsepower V8 emphasized the status of the second-generation Crown (the sedan was called the Crown Eight).

And when the “imperial” Century appeared in 1967, the “eight” V became the exclusive prerogative of this model.

As the years passed, the working volume increased - 3.0; 3.4; 4.0 l (3V, 4V, 5V). But structurally, these were all the same “lower shafts” with a compression ratio of only one version of the 60–70s, raised above 9.0:1. At the end of production in 1997, the small actual and liter power was even reduced, getting only 165 power from four liters. Traction without dips throughout the entire rev range was more important. So the only credit to Toyota and Yamaha, which helped develop these G8s, is that they became the first all-aluminum engines of the Japanese auto industry giant.

The 80s are a different time! It has been described more than once, and therefore we will limit ourselves to only a brief historical excursion. The economy is on the rise, the population's well-being is growing, and a trade boom is in full swing. In such a prosperous time, even relatively small companies such as Mazda, Subaru, Honda, allowed themselves to throw themselves into all troubles - to begin to develop and offer richer and more expensive models. What can we say about Toyota, which could easily aim at “premium” for export and separately for the domestic market. The history of the LS and the Lexus brand in general is also well known. As for the domestic market, its twin Celsior appeared on it. But two months before it and on the eve of the Crown Majesta, whose release was just getting ready, there was a Crown in the 130th body. Expanded and elongated, the so-called wide body. The company did not want to wait another two years before releasing Majesta. And the market supported such dense packaging of the top segment.

Lexus LS and Toyota Crown UZS131So for all these sedans, the V series unit would be like a steam engine for a modern vehicle. A new V8 was required that would fully correspond to the ideology of the coming era. Powerful, with all the technologies due to it and without the remnants of the past. It was introduced in the form of a 4.0-liter 1UZ-FE in 1989, and the first car to try it on was the Crown wide body - UZS131.

From classic to modern

1UZ-FE had a 90-degree block camber, just like its predecessor. However, everything else is from modern times. Four rather than two valves per cylinder. Four camshafts located in the heads and driven by a belt rather than a chain. The control unit, using an additional electronic damper, made it possible to implement traction control. Thanks to all these measures, power was increased to 260 hp. Only the distributor looked like an echo of a bygone era.

Six years later, the engine was modernized. So insignificant that it had virtually no effect on the performance (plus five “horses” and 12 Nm). It is reported that the pistons and connecting rods were lightened (this did not lead to any loss of CPG reliability) and the compression ratio increased from 10.0:1 to 10.4:1.

The “aggregate restyling” of 1997 gave much greater results. Phase shifters appeared on the intake camshafts, the compression ratio was increased a little more, the ignition system was switched to individual coils, the throttle valve unit became electronically controlled, and the bus began to transmit and distribute signals.

In the Japanese specification, 1UZ developed 280 hp, on Lexus LS, GS, SC - 300 hp.

It must be said that the appearance of the U.S. Zetas could not have come at a better time. Not only for sedans designed to compete with the “Germans” and “Americans”. Toyota SUVs, and Lexus jeeps like them, found themselves without a powerful modern engine by the late 90s and early 2000s. Can the in-line “six” 1FZ be considered as such, which consumed dozens of liters of gasoline, but provided dynamics not at the level of US “trucks”. In addition, the company dreamed of further expansion in America - in the direction of pickup trucks and SUVs. And without the G8, these plans were not destined to come true.

So the 4.7-liter 2UZ-FE, which appeared in 1998, became one of the foundations for the next stage of conquering the US market. It also had a 90 degree camber, four shafts and 32 valves. However, to obtain an extra 700 “cubes”, both the cylinder diameter and the piston stroke were increased. Another difference from the 1UZ should be considered fundamental - the cylinder block is made of cast iron. Until 2004, 2UZ developed in different markets within the range of 228–240 forces. After which it was given an “upgrade” similar to the first-born of the family - phase shifters were added on the intake camshafts and an electronic throttle valve.

Thanks to this, power rose to 263–275 hp. True, in the domestic market (and in ours, too, by the way), the power supply of the Land Cruiser was limited to the same 235 forces. In addition to the TLC, 2UZ was installed on the right-hand drive analogue of the Lexus Cygnus, on the Tundra, Sequoia and, of course, on the LX. Hilux Surf and Land Cruiser Prado did not rely on this engine. But their counterparts in the North American market - the 4Runner and Lexus GX - received it.

Meanwhile, by the beginning of the new century, as Toyota believed, the concern’s passenger models no longer had enough of the 4.0-liter 1UZ. And since they didn’t want to solve the issues of increasing power, torque and, most importantly, improving elasticity and efficiency on such large engines using supercharging, they increased the cubic capacity and changed the settings.

3UZ-FE is essentially the first “UZ”, which, while leaving the piston stroke the same, only slightly increased the cylinder diameter, thus obtaining an additional 300 “cubes” of volume. Power has changed slightly. On different models, having VVT-i from the very beginning (however, also only on the intake), this 4.3 V8 developed from 276 to 305 hp.

It was first installed on the LS/Celsior generation, which debuted in 2000, and then on the restyled GS.

A year later, they began to install it on Lexus SC and Toyota Soarer, and since 2004 - on Crown Majesta. Then it existed on the third generation GS. But the 3UZ did not survive the update of this Lexus sedan, as well as the new generation LS. The coupe-convertible under the mother and premium brands lasted on the assembly line until 2005 and 2010, respectively. In order, at least for the moment, to leave the lineup of both brands.

And only on the fifth generation Crown Majesta as part of the all-wheel drive modification did the 3UZ survive until 2013. Apparently, in order to separate the Toyota flagship and the “re-export” LS460, which combined 4WD and the V8 of the new UR series, in the local market.

The cast iron 2UZ also captured a number of subsequent generations of SUVs and pickups. For example, it was not installed on the TLC 200 for the USA, but until 2009 and 2012 it was present on cars for Japan and Russia (on the “200” it already developed 288 horsepower). Before the first restyling, it was an “average” engine for Tundra/Sequoia. And even on LX, although for Hong Kong, he lived until 2012.

"Inappropriate" use

As for use by non-Japanese people, in sports and not in cars at all, the “Yu Z” line has also gained some popularity. Despite, by the way, the volume, which did not seem to correspond to the mass use. Thus, a Chinese copy of 3UZ was installed on a Crown Majesta Hongqi HQ3 clone in the late 2000s.

In the mid-90s, 1UZ-FE was used in a unique project by SARD, a manufacturer of tuning components and a racing team under Toyota. To participate in GT group circuit racing, the Japanese installed a figure eight behind the cockpit of a prototype called MC8-R and a body styled after the MR2.

The V8, equipped with twin turbo, developed 600 horsepower. Unfortunately, this did not help the team achieve any noticeable success. In the 24 Hours of Le Mans and in the marathon at the Suzuka circuit, the car either retired or finished in the third ten. But the road version of the MC8, made in a single copy, immediately became a collector's item.

3UZ gained more sporting fame. In the Japanese GT500, a car based on the SC430 became the winner three times - in 2006, 2009 and 2013.

Toyota even tried to attach 1UZ to aviation. On its basis, in 1997, the FV2400-2TC unit was developed, again equipped with a twin turbo and developing 360 hp. It was supposed to be installed in a four-seater airplane, for the production of which the concern was going to create a subsidiary company and even received permission from the American Federal Aviation Administration. In the States, this topic was on the rise at that time. The engine was embodied in metal. The very idea of the release remained on paper.

1UZ finally made it to the water. In the late 90s and early 2000s, the 300-horsepower “vivity” “eight”, designated VT300i, was installed on a line of boats under the common Toyota Epic brand.

And in our country, the first “UZ” was, at least for one time, actively installed on airboats. Volume, torque, sufficiently powerful and light, it was perfect for such a vehicle.

To a large extent, of course, also because, despite the high cost of the models on which it was installed, it quickly became synonymous with reliability.

Are there any weak points?

When we talk about modern engines, perhaps in 90% of cases, their strong design solutions have to be looked for literally under a magnifying glass - among the innately weak ones. With almost all Toyota engines developed in the 80s and 90s, the situation is the opposite. And representatives of the UZ line are no exception. We talked to many mechanics and heard only the following.

At risk are the timing belt idler roller bearings, which suffer from water, dirt, and reagents falling on them from below. The generator is located low and also constantly receives its share of road chemicals. The cooling system pump is located in the camber of the block, driven by a toothed belt and constantly subject to a bending moment. Over time, the pump bends and it begins to “snot” with antifreeze. It is difficult to discern the beginning of this process. The consequences can be dire. Crystallizing under the influence of temperature, the coolant can get under the belt and break it. Meanwhile, the valves are guaranteed not to bend only on the first versions 1UZ and 2UZ.

Another reported problem is related to the system for changing the geometry of the intake tract. The screws that secure the dampers to the axle can come loose and get into either the valve mechanism or the cylinders. The same can happen with the dampers themselves. It’s probably not worth describing the consequences.

This does not mean at all that the owner of any of the UZs will necessarily be overtaken by one of these misfortunes. Other repairmen cannot remember that they have ever encountered something similar. Moreover, the judgments are categorical:

“It’s not some design flaws that are destroying them—it’s the owners’ belief that UZ will endure any abuse.” I have seen enough of these engines with burnt out parts due to the use of gas as fuel. With “chocolate” inside and without compression due to the fact that they were not replaced or low-quality air filters were installed.

Another opinion:

Alexander Denisov

Engaged in tuning, serviced and repaired U Zetas

— The impact of dirt and reagents on bearings and the generator is typical for many cars. As is the location of the pump in the camber of the block - for V-types. But I would like to ask those who complain about pump leaks - did you change it, say, 200 thousand? Or do you hope that its resource is comparable to that of the motor?

Or supposedly unscrewing flaps of the intake manifold modification system. Do you seriously think that in Japan, and specifically in Toyota, the screws might not have been tightened back then? This is not AvtoVAZ! This, of course, happens, but only if someone has already climbed into it. VVT-i valves fail - solely due to low-quality oil or untimely replacement.

These "eights" certainly have some features. For example, an inconveniently located starter, injectors in the camber of the block, which are not easy to reach. In the absence of hydraulic compensators, it is advisable to check valve clearances every 80,000 km. But otherwise they are easy to maintain, have no weak points and run a lot. In my memory there was no case when UZ “stood up”.

Let me give you another example. Once I was in Nikolaevsk-on-Amur. There are 800 km of broken road to Khabarovsk, along which Toyota Hiaces run as minibuses. There are 50 cars. All have welded frames, mud tires, and a pair of shock absorbers per wheel. The “cases” boiled over a long time ago and were thrown out, and 1UZ were installed in their place. I won’t tell you the exact mileage, but they work non stop - from flight straight to flight. And the owners are not overjoyed with them - they just serve them.

And yet we found one piece of incriminating evidence.

Vadim Chirkov

Engaged in tuning and setting up control systems

— On UZ there are weak oil pumps. The problem is similar to the same on Nissan “sixes” of the RB series. The pump drive is organized through a crankshaft journal with two chamfers. When these “eights” are boosted (by supercharging: a turbine or a mechanical supercharger), the load on this connection increases. A stronger shock load occurs, and the backlash gradually increases. Finally, the pump rotor on the neck cannot stand it and bursts. The problem is not predicted and may occur today or in a year. It is modified according to the “Erbash” type - by installing a bushing and a rotor with splines.

I know that on a 2UZ, pump failure can occur without any tuning - due to natural wear and tear, at high mileage. Another typical problem - this time on old 1UZs - is blown head gaskets. They are still paronite there. Besides this, of course, a reliable engine. On the same 1UZ, the Japanese lightened the pistons and connecting rods. However, this did not lead to any negative consequences.

"UZ" is our everything!

Like the Jay Zetas, our hero about ten years ago acquired the status of one of the most popular in swaps in Russia. Typically, not for sport, but for civilian use. “Eights” were installed in projects based on the 21st and 24th “Volga”, on fresher “barges”.

They “stuck” them into UAZs and GAZelles.

In Great Wall Hover and Kia Bongo.

We talked in detail about the installation of 1UZ in Hiace. By the way, a similar combination existed in the H100 body with a V8, produced from 1992 to 1998. The modification was called HiMedic and, as is clear, was an ambulance.

Owners of “geldings”, “beh”s, and “Rovers” turn to the swap shop, tired of adding oil to their original units and wide-eyed at the cost of their repairs. And then I paid 300,000–400,000 and forgot how the hood rose. We won’t say that this service is massive. However, in the west of the country there are services that specialize in just this.

Photo swapyoucar.ru and from open sourcesThere are even such examples.

What can we say about transplanting “Toyota to Toyota”! In Surf, TLC70, Mark II, Altezza, etc.

Elementary operation! Previously limited by the fact that since 1997, “Yu Zetas” began to be driven by bus. And the electricians were unable to combine different types of braids. The first 1UZ was chosen for installation - the one that is “non VVT-i”. Then they learned how to do this, and now “swapers” have a fairly wide choice of three “Yu Zetas” and a 4-, 5- or 6-speed “automatic”. With 3UZ and 6-automatic transmission, you get a unit with a good combination of power/efficiency. Fuel consumption can be kept within 12–13 l/100 km, although the 4.7-liter V8 with a four-speed transmission can consume up to 25 liters. We have one limitation - amendments to the Technical Regulations, which are hostile to engine replacement. Therefore, of course, they are swapping, but not in such volumes as before.

Overseas, especially in Australia and New Zealand, UZ is popular in sports. They are often installed in models that seem to be not intended for this purpose at all - in the old 200SX and younger Silvia. In AE86 and Civic. Supercharged with twin turbo and chargers. The latter, as we know, was also made by TRD, the racing division of Toyota (there was an official “whale” with a supercharger). And problems with the oil pump did not stop him!

In the USA, aluminum UZs are used in rock crawling. But we also have examples when these V8s were chosen to build off-road prototypes.

Maintenance

The 3uz fe engine is distinguished by very high reliability and is rightfully one of the power units that are popularly called “millionaires”. But its trouble-free operation largely depends on high-quality and regular maintenance.

The list of work that must be carried out during scheduled routine maintenance includes:

- changing engine oil every 7...10 thousand kilometers;

- replacing the timing belt after a mileage of no more than 100 thousand kilometers;

- monitoring the thermal clearances of the timing valves and, if necessary, adjusting them.

In addition, it is necessary to regularly check the engine oil level in the crankcase of the power unit; coolant in the expansion tank located in the engine compartment. If necessary, technical fluids must be added. It is also recommended to identify and eliminate the reasons that caused the decrease in their number.

Design Features

Initially, the 3UZ FE V-engine has a more complex design compared to in-line modifications and a larger number of parts. There are two cylinder heads and four camshafts, the timing drive is complicated, and the volume of oil and coolant is increased. The main feature is the low safety of the valves, which bend when they meet the pistons if the timing belt breaks.

Adaptation for automatic transmission

The engine package includes:

- gas distribution system DOHC;

- adjustment of injection volumes using the VVTi phase system;

- adjustable intake manifold length according to ACIS scheme;

- SPFI point injection.

The engine has two cylinder heads

VVTi module design

Intake manifold

SPFI point injection circuit

The camshafts of the gas distribution system are driven by a belt. The crankshaft and connecting rods are used from previous versions; management developed only pistons with a diameter of 91 mm specifically for this engine.

Despite the duralumin block, it is possible to overhaul the engine, mechanically modernize the intake/exhaust tract with your own hands, and boost it by installing a turbine. Cast iron liners with several repair sizes are used, so even with high sulfur content and the general low quality of Russian gasoline, Japanese 3UZ FE engines run the stated 350 - 400 thousand km without problems. Unlike German BMWs, for example, the M52 series with the same alloy block and a service life of 50 - 100 thousand km.

Malfunctions

According to experts, all power units included in the UZ family in general, and 3uz fe motors in particular, do not have design flaws and do not change their technical characteristics for a long time.

They do not have any typical faults. All the breakdowns that the service station workers had to deal with are related to:

- with long engine life;

- complete absence or irregular maintenance;

- aggressive driving style typical of some drivers.

As a rule, the malfunctions encountered by repairmen had complex cause-and-effect relationships, for example: “leakage in the radiator - violation of the engine temperature regime - dilution of the engine oil - jamming of the ignition timing mechanism - breakage of the timing belt - bent valves.”

Among the malfunctions that car service workers had to eliminate were:

| FAULT | CAUSE |

| Constant decrease in the coolant level in the expansion tank. | 1. Radiator leak. |

| 2. Leaking cooling system pump. | |

| 3. Cracks in old pipes. | |

| Noise in the cylinder head area. | 1. The thermal clearances of the timing valves are broken. |

| 2. The timing belt has stretched. | |

| Unstable motor operation. The engine “troits”, the speed “floats”, etc. | Poor quality fuel. Spark plugs may fail |

Tuning

The 3uz fe engine provides great opportunities for car owners to increase power. It is relatively easy to tune. There are several ways in which you can increase the power of the power unit:

- The most popular type of engine tuning is installing an Eaton m90 compressor. The easiest way is to purchase a kit based on this compressor. It also has a matching intake manifold. It is also necessary to install a fuel regulator; straight-through exhaust; exhaust manifold 4-2-1. Having completed all the necessary work and correctly configured the electronic engine control unit, you can increase the power to 330 hp. With.

- By installing forged pistons with a compression ratio of 8.5, instead of a compressor, you can assemble a turbo unit based on a kit with a Garrett GT40 turbine. However, this will require the purchase of a fairly large number of different parts and a major modification of the motor. By installing a turbine, you can get a power increase of up to 450 hp. With.

Maintenance schedule for Toyota 3UZ FE 4.3 l/290 l. With.

Initially, the 3UZ FE engine has a multiple reserve of reliability, so maintenance occurs as usual:

- lubrication system - change the oil along with the oil filter every 10,000 km, the manufacturer recommends modifications SL-3 or GF-3 according to API classification;

- timing drive - the belt lasts about 100,000 km in the absence of oil leaks, its integrity must be monitored every 10 thousand mileage;

- mounted - the thermostat and pump last 30 - 40 thousand km, they are usually changed along with antifreeze;

- electrics - spark plug life is about 60,000 km, it is better to use iridium modifications.

Motor maintenance

From the factory, the engine is equipped with metal timing gaskets, which should be changed after 100 thousand km. It is necessary to install a new intake manifold gasket, camshaft and crankshaft seals, belt tensioner and rollers. The throttle valve must be cleaned for the injection system to function properly.