Installation and repair of the steering column on a VAZ 2107

One of the elements of the VAZ 2107 car, which received a number of improvements in this model compared to the previous ones, is the steering column.

How is its device different? In the VAZ 2107, the steering column shaft consists of two parts connected by a cross. Thanks to this design, driver safety is significantly increased, since in the event of a collision the shaft simply bends at the hinge joint and does not cause serious harm to the person. Also, the shaft in the VAZ 2107 has bearings, so turning the steering wheel requires much less effort. The steering column of the VAZ 2107 consists of a shaft with an articulated joint and a gearbox with a worm gear. Column repair is a very rare occurrence. If you ensure timely maintenance of this unit, it may never be needed. Steering column maintenance work includes lubricating the steering shaft joint, tightening the steering wheel nut, changing the oil and adjusting the gearbox. Let's look at possible problems associated with the steering column and methods for eliminating them.

- Creak in the column

- Steering wheel play

- Removing the gearbox

We will completely improve the steering!

Everyone prepares for the new year differently. I want to take part in a couple of competitions during the New Year holidays. If you are not afraid of cold garages and colds on your face, then my story is for you.

Whatever one may say, precise control on the track is a very important thing. And in my case, the play on the steering wheel is colossal. I got the car in pretty bad condition. Lately, all I've been doing is eliminating oil leaks from certain components. This time was no exception, and I took up the steering partly because the steering gear was flooding the snow-white asphalt with puddles of dirty oil every time I stopped.

If you do it, do it well. So I removed the steering gear completely from the car. Like all spare parts before this, after removal they look like a piece of oily shit. But in this pile of dirty pieces of iron, some will recognize the steering pendulum from left to right, connected through the middle link to the steering gearbox.

During the inspection, it turned out that I already had a pendulum arm installed on bearings, but it was smashed to pieces and it turns with great effort. And in the gearbox, oil presses from both seals in completely indecent volumes. Unfortunately, simply changing both seals was not at all easy for me. I finished off the gearbox myself and ended up having to buy the entire assembly new. On the left are old, but already washed pieces of iron, and on the right are new spare parts.

This seemed to me not enough and I wanted to install a steering gear bracket. Not many people know, but on domestic classics, the steering gear eventually begins to wrap the spar around itself))) It sounds crazy, but in the most advanced cases it even rips itself out of the spar. At the initial stages, there is a gap in control. This can easily be fixed with a steering gear bracket. In our country there are two large manufacturers of similar pieces of hardware, but neither of them works when purchased without modifications. Therefore, I put this revision aside for now.

neither this one fits

nor competitors' products

Now it's the turn of the wheels. Here we will switch to the newest type of bearings))) I mean that the obsolete cone bearing mechanism in the hub of a VAZ 2107 can be replaced through spacers with the hub (rear) of a VAZ 2108. This will no longer allow you to be smeared head over heels in grease and play on the wheels structurally will disappear. More details in the video, because... Otherwise I'll just overwhelm the whole story with a huge number of photos.

And for dessert my original Chinese RUDDER! This is a very necessary thing indeed. Many people think that such things are staged solely in order to stroke their pride and impress... I don’t know who. Well, for some people in general)) But a good steering wheel with reach and not a large radius is simply necessary on the race track. It is extremely inconvenient to intercept the huge steering wheel. If you take into account that this needs to be done quickly, then the civilian steering wheel simply disappears. I ordered mine from China and bought the spacer here and it is REALLY BAD. Because it is not injury-proof. Those. It doesn't fold when hit - it's a very dangerous thing. So I'll replace it as soon as possible. The steering wheel has a persistent smell of glue, but it performs its functions and I have not yet found any disadvantages, except for smelly hands.

In order not to be unfounded, I decided to test my improvements on the most winding track that can be found in Yekaterinburg. And I liked the result, although I again spent a lot of evenings in a cold garage. The race itself and a detailed story on video. And Andrey and I, who often remain behind the scenes, wish you a good holiday weekend! Maybe someone will even get out on the track during the holidays and give it a blast in their car (sober as glass). See you on the track.

Repair of VAZ 2107 steering gear

Rods, bipod, hinges - where is it all?

The main parts and steering components of the VAZ-2107 and other rear-wheel drive models are shown in the figure below. To understand what is faulty, let’s remember “who is who”. You also need to remember that breakdowns of steering parts and assemblies are very dangerous and, in most cases, lead to serious accidents! For example, if the steering rod breaks, the front wheels lose contact with the steering wheel and the car flies into a ditch or into oncoming traffic. To prevent this from happening, let's check the condition of the steering of our “classic”.

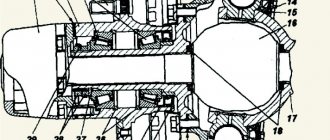

Steering VAZ-2107

1 – lateral thrust. 2 – bipod. 3 – medium traction. 4 – Pendulum lever. 5 – adjusting clutch. 6- lower ball joint of the front suspension. 7 - right steering knuckle. 8- upper ball joint of the front suspension. 9 - right steering knuckle lever. 10- bracket for the pendulum arm. 11- bearing of the upper steering shaft. 12, 19 - steering shaft mounting bracket. 13- pipe of the steering shaft mounting bracket. 14- Upper steering shaft. 15 - steering gear housing. 16- intermediate shaft. 17- facing casing. 18- steering wheel. 20- fixing plate of the front bracket. Pinch bolt for fastening the universal joint. 22- body spar.

Inspection and testing of the VAZ-2107 steering

You need to check your steering if your car has the following signs: -increased play (free play) of the steering wheel; -knocks in the area of the front wheels; - difficult (tight) rotation of the steering wheel. It is better and more convenient to perform all work in an inspection ditch or on a lift. Be sure to invite an assistant; you can’t handle the check alone. Before work, the car must be thoroughly washed from below. Set the steering wheel to the position for driving in a straight line. Turning the steering wheel left and right, we check one by one: - the play of the steering wheel along the rim is 18 – 20 mm; - there should be no knocking in the hinges and joints; - the fastenings of the steering gear housing and the pendulum lever are not loose; - there is no play in the ball joints of the rods and in the bracket of the pendulum arm, and the bipod does not move in the axial direction; - steering force does not exceed 20 kgf; - the adjusting couplings of the side rods are securely secured with clamps; -all protective caps and rubber covers have no cracks or tears.

Ball joints of steering rods are considered to be in good condition if the axial movement (along the axis of the fingers) is no more than 1.5 mm. When you press the mount on the hinge, you should feel the resistance of the spring.

Trouble-shooting

Loose threaded connections must be tightened, damaged and worn components and parts must be replaced. The most common parts to be replaced are tie rods with joints and a pendulum arm. A stiff steering wheel or knocking noise in the steering mechanism can be eliminated by adjusting the worm gearing . After replacing the rods, you need to adjust the camber and toe angles of the wheels.

Steering gear location

Since under the hood of a car there is the main “culprit” of vibrations – the engine, the steering gearbox is attached exclusively to the car body. Its location differs among different brands and modifications, but access to the fastener is always extremely difficult.

Gearbox location in Jeep WJ Limited

To adjust the steering gearbox, you will have to remove the protection from below, at a minimum. Driver injury safety in a frontal collision is ensured in the following way:

- the upper mounting bolts are welded to the gearbox housing;

- At the bottom there are tear-off bolts, the edges of the fixing plates of which pass into special slots in the bracket.

Breakaway bolts for driver safety

When impact occurs, the steering wheel folds forward upward, which is safer for the driver's chest than any other option.

Malfunctions of the steering column of VAZ 2107

Given the simple design of the column, there are few options for malfunction. It is important to monitor its condition and promptly eliminate problems when they arise. There are several main types of faults:

- Column creaking. The cause of the squeak may be wear of the column parts, deformation of the trim panels, or malfunction of the steering switch unit.

- Steering wheel play. There are probably two reasons for this. The first is that the steering wheel fastening nut has been loosened. Fixing this problem is easy. But if this is not done in time, the splines on the shaft will break and the steering wheel may turn, leaving the car uncontrollable. Another reason is wear of the steering gear worm gear. Then it is necessary to adjust the gearbox or repair it.

- Play in the plane of the steering wheel or column axis. This is a dangerous malfunction that appears when the elements of the mounting bracket or spline connections are worn (loose).

Loosening the nuts and bolts of the spline fasteners over time leads to the abrasion of the splines, causing the car to lose control. Therefore, the column play must be eliminated immediately.

PRICES — REPLACEMENT OF STEERING GEAR

A gearbox is a mechanism that transmits and converts torque, with one or more mechanical gears. The main characteristics of the gearbox are efficiency, gear ratio, transmitted power, maximum angular speeds of the shafts, number of drive and driven shafts, type and number of gears and stages. It must be said that there are a large number of types of gearboxes. Therefore, all of them can be combined into several groups, classified according to the following criteria: According to the type of gears, they can be gear, worm or gear-worm. According to the number of stages: single-stage, two-stage, and so on. By type of gears: cylindrical, bevel, bevel-cylindrical. Depending on the location of the shafts in space, gearboxes are divided into horizontal and vertical. Depending on the features of the kinematic scheme: they can be with a bifurcated stage, or they can be with a deployed coaxial scheme. It is worth noting that such a great variety of steering gearboxes is due to the fact that each of them has a different load capacity and, accordingly, a completely different efficiency.

The most common breakdown is a leaking steering gear. The presence of such a problem can be detected visually by the presence of oil under the car. The reason may be a leaking oil seal or corrosion of the input shaft. In this case, in the first case, during the repair it is necessary to install new oil seals, cuffs, and gaskets. And in the second case, the shaft should be polished, and then it is mandatory to carry out gas thermal spraying to normal dimensions. Feeling of a “tight” steering wheel. It appears due to an increase in the effort to turn the steering wheel. At the same time, in order to be sure whether there are reasons for repairing the steering gearbox, it is necessary to measure the level of steering wheel rotation gain with a special torque wrench. Then compare the obtained result with the data provided by the car manufacturer. If the indicators do not correspond to the established standards, it is necessary to carry out diagnostics on a specialized stand. This will help you find out the pressure, flow rate of the working fluid, as well as the presence of leaks in the gearbox. In this case, you should not try to repair the gearbox yourself.

↑ Disassembly and repair of the VAZ 2107 steering gear

- To repair individual parts and elements, you will have to completely disassemble the gearbox. To do this, clamp it in a vice and unscrew the bipod nut. Then the shaft thrust is tested.

- Removing oil. In order to pour out the lubricant, you need to unscrew the filler plug. After this, the adjustment nut is unscrewed and the lock washer is disconnected.

- Then you need to remove the bolts (there should be four of them) and remove the cover.

- The thrust shaft is carefully pulled out along with the roller.

- Next, you need to unscrew the fasteners of the worm cover and dismantle it.

- A series of blows with a hammer will knock out the shaft, which comes out along with the bearing.

- The oil seal and seal are removed with a screwdriver.

- Finally, you need to remove the outer race of the second bearing using a tool and a hammer.

↑ Cleaning all elements and troubleshooting them

After the gearbox has been removed and disassembled, you need to wash all the elements with diesel fuel (an alternative is kerosene). This will make defects more visible.

Replacing oil seals

If an oil leak is detected in the machine components, it is necessary to replace the VAZ 2107 gearbox seals.

Replacing the cuff of the drive gear of the rear axle gearbox of a VAZ 2107

Rear axle malfunctions due to oil leakage:

| Malfunction | Elimination method |

| Continuous increased noise when the rear axle is running | The oil level is restored and the seals are checked for leakage. If necessary, replace the rear gear oil seal on a VAZ 2107 |

| Noise occurs when accelerating the car | The oil level is restored and the seals are checked for leakage. If necessary, the rear gearbox seal of the VAZ 2107 is replaced. |

| Damage to sealing gaskets leading to oil leakage | On a VAZ 2107, replacing the rear gearbox oil seal in other components of the vehicle. |

To replace the VAZ 2107 gearbox seal on its drive gear you will need:

- Wrenches for “13” and “24”.

- Screwdrivers.

- Calipers.

- Torque wrench.

- Dynamometer.

- Mounting blade.

- Durable cord.

Instructions for removing the cuff

So:

- Replacing the oil seal in a VAZ 2107 gearbox begins with draining the oil from the crankcase mounted on the rear axle . After this, the plug on the oil drain hole is screwed back on.

- Both axle shafts are removed from the beam on the rear axle.

- The four nuts are unscrewed and the bolts connecting the universal joint flange and the drive gear flange are removed. To fix the cardan (see VAZ 2107 repairing the cardan on your own) from turning, it must be held with a mounting blade.

- The flanges are separated using a screwdriver.

- A strong cord is wound around the drive gear flange. To do this, you need to make several revolutions of the shaft. Then, while winding the cord using a dynamometer, check the moment of resistance when turning the drive gear. Its meaning is remembered. This is very important when replacing the rear axle gearbox seal on a VAZ 2107

- The nut holding the drive gear flange, which is secured with a special key, is unscrewed and the flat washer is removed.

Fixing the flange when unscrewing the nut

- The flange is removed.

- The drive gear oil seal is removed from the crankcase neck of the assembly, for which it is pryed off with a screwdriver.

Removing the oil seal from the crankcase neck of the unit

Installing a new oil seal

So:

- The seat is cleaned of traces of corrosion.

- Litol-24 lubricant is used to lubricate the working surfaces of the crankcase of the new cuff.

- The oil seal is put in place and pressed into the gear housing through a mandrel with light blows of a hammer. The oil seal must not be skewed. The pressing depth is 1.7 - 2 millimeters from the end of the crankcase.

Tip: If there is no mandrel, you can use a piece of pipe or a ring of a faulty bearing of a suitable diameter.

- After the oil seal on the VAZ 2107 gearbox has been replaced, the drive gear flange and washer are installed.

- The flange is held with a special wrench and the nut securing it is tightened. The tightening torque depends on the moment of resistance of the drive gear to turning, and is equal to 117 - 254 Nm. It is necessary to start tightening with a smaller torque, periodically checking the resistance moment of the nut being tightened.

Replacing the gearbox seal on a VAZ 2107

Tip: Exceeding the moment of resistance of the drive gear when turning indicates excessive deformation resulting from the spacer sleeve, which is installed between the bearings. In this case, the bushing needs to be replaced. Why do you need to disassemble the gearbox and adjust the engagement of the main gear gears? Repairs must be carried out using special tools and equipment. It is better to do it in specialized workshops.

Once the VAZ 2107 axle gearbox seal has been replaced, installation of the removed parts is done in the reverse order of removal.

Tip: The key that secures the flange when tightening the nut can be made with your own hands from a pipe onto which two bolts with nuts are attached, as shown in the photo.

Key for fixing the flange when installing the oil seal

In this way, the rear axle gearbox seal of the VAZ 2107 is replaced.

Video - Steering gear repair

In most cases, this unit is not repairable, since it is relatively inexpensive and consists of only two main parts. However, the manufacturer left the option for car technicians to purchase a repair kit.

Before repairing the steering gear, let's determine the malfunctions.

- Firstly, it can be repaired if the steering wheel rotates but the wheels do not. This means that there are defects on the threaded part of its shafts that prevent the two interacting parts from touching.

- The second type of fault is oil seals. If they have reached critical wear, then the oil from the gearbox will certainly leak, which already leads to its accelerated wear. If there are other mechanical damages, the gearbox must be replaced.

First, remove the faulty unit from the car. After this, press the bipod off its shaft using two hammers. Drain the oil from the gearbox through any technological hole. Now unscrew the four bolts that secure the cover and remove it. To access the worm shaft, you need to unscrew a similar cover on the other side of the mechanism. Pull out the remaining parts and replace the faulty ones. These may include oil seals and damaged shafts. After this, reassemble the gearbox in the reverse order. Don't forget to add oil!

General ideas about steering gears

Replacing the steering rack of Vito W639

It's probably no secret that mechanical engineering developed gradually. With each step in the development of this industry, cars were improved and acquired more and more new devices. Thus, many modern auto parts were added much later than the creation of the car. But there are units that initially appeared already at that stage in the history of the engineering industry at which the vehicle acquired its final shapes and outlines. One of them is the steering gear. It is a special steering mechanism that plays a significant role in driving a car. The main task of the steering gear is to increase the force applied to the steering wheel. It is this applied force that causes the wheels of the vehicle to turn in the desired direction.

Device, purpose.

The steering column, also known as the steering wheel shaft, has a specific purpose, which is to transmit rotational movement directly from the steering wheel (steering wheel) to the worm shaft of the steering mechanism.

The design of the VAZ 2107 steering column.

- bipod shaft adjusting screw plate

- bipod shaft adjusting screw

- adjusting screw nut

- oil filler plug

- mechanism crankcase cover

- worm

- steering gear housing

- bipod

- nut securing the bipod to the shaft

- spring washer bipod fastening nuts

- bipod shaft oil seal

- bronze bipod shaft bushing

- bipod shaft

- bipod shaft roller

- worm shaft

- upper ball bearing

- lower ball bearing

- shims

- worm bearing bottom cover

- roller axis

- needle bearing

- worm shaft seal

A – coincidence of marks

It is held on the body by a special bracket. And in its structure it has two universal joints, which, by the way, allow the steering column of the “seven” to fold, so that in the event of an accident it does not cause injury to the driver. This, by the way, significantly distinguishes it from the steering column of other representatives of the VAZ family, for example, the “Six”.

VESKO-TRANS.RU

Content

replacement gearbox for VAZ 2104, VAZ 2105, VAZ 2107

The control transmission is still popularly called the control column, thanks to which the wheels of the car rotate; it consists of an integral part of the body and the shaft coming out of it, by the way, depending on the length and thickness of this shaft and depending on the size of the parts themselves ( for example, from the worm itself inside the gearbox housing), which are inside the gearbox housing, the steering wheel can rotate quite easily if all the parts have huge shapes (the longer they are in length, the easier it will be to turn the steering wheel), everything is fine, since the gearbox makes it easier for the wheel to turn and transmits all the torque to the wheels of the car, but it doesn't matter that the other part wears out over time and starts leaking mostly after wear, especially if you don't add oil to the gearbox, then over time it becomes very difficult to turn steering wheel, especially when driving at very high speeds, this is especially noticeable. This is possible because the gearbox is in need of repair (if it can still be repaired) or because it can be quickly replaced.

gearbox manager You will need tools on your machine, namely a basic set of wrenches, as well as various other types of wrenches, in addition, it is recommended to use a ring socket and a screwdriver, since it is not always convenient to turn the nuts with a wrench without taking into account (this does not apply to tools), you will also need to take a helper with you, as you will have to do this operation together, as it is more convenient!

Where is the steering gear?

It is located in the engine compartment and at the bottom of the car, so it is not very convenient to remove from above, so for this job you will need a second person to pick up the transmission itself once you have removed all the mounting nuts.

If you want to see the gearbox itself, in other words, where it is located, then open the hood of the car and look where the body (not the engine) is located on the driver's side, you have a gearbox that was shown with a red arrow in the photo just below for clarity :

When should I change my steering?

Many people advise going to a car dealership, getting a new gearbox and replacing it with a new one, although it can be fixed like any other part (Vita doesn't have all the money to buy a new unit), but it works. It's up to you to decide here, but we will list the main ones malfunctions that occur when the steering gear , firstly, oil can seep into it (be it the rust and corrosion that left it, or the oil seal that it sent requiring its own replacement), not counting it, the steering wheel through a worn The transmission control system may also rotate a lot (There are many other components in the steering that are responsible for steering, because if your steering wheel starts to rotate a lot, do not throw all the obstacles at once to the steering gear , as this may be due to the pendulum arm , as well as other details).

Step-by-step adjustment of the worm gear.

In order to independently adjust the steering gear of a VAZ 2107 car, you need a flat screwdriver, a 19mm wrench, the help of another person and follow the step-by-step work:

Article: 2101-3401023, additional articles: 2101-3401023R

Order code: 003031

- Buy with this product

- show more

- Passenger cars / VAZ / VAZ-21011 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2101-3/reduktor_rulevogo_upravleniya-163/#part3582″>Bipshaft cuffSteering control / Steering gearbox

- Passenger cars / VAZ / VAZ-21031 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2103-106/reduktor_rulevogo_upravleniya-129/#part11642″>Bipshaft cuffSteering control / Steering gearbox

- Passenger cars / VAZ / VAZ-21051 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2105-6/reduktor_rulevogo_upravleniya-128/#part18009″>Bipshaft cuffSteering control / Steering gearbox

- Passenger cars / VAZ / VAZ-21071 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2107-8/reduktor_rulevogo_mehanizma-177/#part25471″>Bipshaft cuffSteering control / Steering gearbox

- Passenger cars / VAZ / VAZ-21311 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2131-73/reduktor_rulevogo_mehanizma-221/#part65161″>Bipshaft cuffSteering control / Steering gearbox

- Passenger cars / VAZ / VAZ-21213-214i1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213_214i-1240/reduktor_rulevogo_mehanizma-226/#part2990620″>Farm shaft cuffSteering / Steering gear reducer

- Passenger cars / VAZ / VAZ-21021 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2102-4/reduktor_rulevogo_upravleniya-163/#part8066″>Bipshaft cuffSteering control / Steering gearbox

- Passenger cars / VAZ / VAZ-21041 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2104-5/reduktor_rulevogo_upravleniya-128/#part14903″>Body shaft cuffSteering control / Steering gearbox

- Passenger cars / VAZ / VAZ-21061 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2106-7/reduktor_rulevogo_mehanizma-140/#part21278″>Bipshaft cuffSteering control / Steering gearbox

- Passenger cars / VAZ / VAZ-21211 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2121-13/reduktor_rulevogo_mehanizma-129/#part60128″>Bipshaft cuffSteering control / Steering gearbox

- Passenger cars / VAZ / VAZ-212131 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213-731/reduktor_rulevogo_mehanizma-170/#part2011140″>Bipshaft cuffSteering control / Steering gear reducer

- There are no reviews for this product yet.

Today, the next article in the series “Crystal VAZs or typical breakdowns of domestic cars” is dedicated to the “classics”: VAZ-2101, 2103, 2104, 2104, 2105, 2106 and 2107. These cars have been driving along our roads for decades and, despite Despite all the shortcomings that we will talk about, their popularity is still high.

Replacing the oil seal in the steering gear

If an oil leak occurs in the steering gear, it is most likely necessary to replace the oil seals of the VAZ 2107 steering gear.

Removing the cuffs

- Oil is drained from the gearbox housing. To do this, unscrew the adjusting nut and remove the lock washer.

- Unscrew the bolts holding the top cover of the gearbox using a key set to “13”.

- The head of the adjusting screw is removed from the groove on the bipod shaft and the cover is removed.

Tip: If the gap between the shaft groove and the screw head increases by more than 0.05 mm, it is necessary to install adjusting plates. Their installation pitch is 0.025 mm, the thickness of the elements is 1.95 - 2.2 mm.

- The bipod shaft with the roller installed on it is removed from the crankcase.

- Use a 13mm wrench to turn the bolts securing the worm shaft cover.

- Together with the gaskets for adjusting the ball bearings, the thickness of which is 0.1 - 0.15 mm, the cover is removed.

- The worm shaft and bearing are knocked out of the gearbox housing with light blows of a hammer made of soft metal. There are special tracks at the ends of the worm for the bearing balls.

- Carefully pry up and remove the worm shaft cuff using a screwdriver.

Removing the worm shaft seal

- The cuff of the bipod shaft is removed in a similar way.

- The outer ring on the second bearing is knocked out using a punch.

Removing the outer ring using a bit

- All parts are washed in diesel fuel or kerosene.

- The working surfaces of the worm and rollers are carefully checked for signs of wear, damage or scuffing. The gap between the bronze bushings and the bipod shaft should be no more than 0.1 mm. The surfaces of the cages, rings and balls must be free of any damage or signs of wear. Bearings must rotate freely without seizing. Any cracks on the crankcase are not allowed. Damaged or worn parts are replaced with new ones. Replacing gearbox seals on a VAZ 2107 is always done.

Steering assembly

- All internal parts are lubricated with transmission oil.

- The inner bearing ring is pressed into the crankcase using a piece of pipe of a suitable diameter or a special device, which is used when replacing rubber-metal hinges in the front suspension.

- A cage with balls is inserted into the bearing ring.

- The worm shaft is installed.

- The outer bearing cage is placed on the shaft.

- The outer ring is pressed in.

- The cover with gaskets is installed.

- The cuffs of the bipod and the worm shaft are pressed in, the working edges of which are first lubricated with Litol-24 lubricant.

- A worm is installed in the crankcase.

- Using a set of adjusting shims, the turning moment of the worm is set to 2 - 5 kgf/cm.

- The bipod shaft is installed and the engagement gap is adjusted. The shaft turning torque should be 7 - 9 kgf/cm when the worm shaft rotates left and right by 30 degrees. When turned all the way, it gradually decreases to 5 kgf/cm.

- Carry out an oil change. Transmission oil is poured into the crankcase up to the lower edge of the filling hole.

The VAZ 2107 gearbox seal has been replaced. In more detail, all the work to prevent leaks in oil seals can be viewed in the video. With timely diagnostics of the operation of the components of the VAZ 2107 car, the use of high-quality parts and lubricants, the car will be used for a long time without major repairs, the price of which is much higher than constant preventive maintenance.

Steering mechanism VAZ 2107

VAZ cars, which are classic models, are distinguished by pleasant reliability.

This also applies to the steering mechanism. It is quite complex, but its design allows you to maneuver and ensure reliable vehicle control even in the most difficult road conditions.

The modernization process led to the installation of a composite shaft and a safety column. Due to the size of the steering wheel, the driver makes the necessary maneuvers without any problems. From lock to lock, it takes 3.5 turns to turn the steering wheel completely. The force from the steering column is transmitted to the drive via a composite shaft.

The current steering mechanism on the VAZ 2107, a product of the Volga Automobile Company, is quite informative and does not allow the driver to get tired during long trips. There are certain difficulties when turning in a parking lot, but as soon as the car begins to move, the resistance weakens and turning the steering wheel becomes easier.

There is one more nuance - when the steering mechanism is working properly, there is a slight play. But its limit value complies with the traffic rules. This is due to the fact that there are steering rods on the VAZ 2107 and an impressive number of elements in the gearbox.

In general, the steering of the 7 can be considered reliable.

Mechanism design

To repair the steering column on a VAZ 2107, you first need to understand its structure, as well as the principle of operation.

The seven is in many ways similar to the “penny”. Therefore, the device and design received minor changes. The structure includes:

- A mechanism that transmits the driver’s force to the executive components;

- A steering drive that turns at an angle specified by the driver.

In turn, the steering mechanism consists of:

- Composite shaft with cardan transmission;

- Steering wheel (steering column together with a steering wheel with a diameter of 520 mm);

- Worm gearbox of the VAZ 2107 steering mechanism.

The control system has the following components:

- Bipod;

- Pendulum arm;

- Swivel arms;

- Steering rods for VAZ 2107 (one middle, two side).

The outer rods include two parts, which allows you to change their size by adjusting the toe angle.

Tie rod/end set for VAZ 2107

The operating principle of the steering mechanism looks like this:

- The driver begins to rotate the steering wheel, the wheel size of which ensures that this task can be performed quite simply;

- By means of a composite shaft, a worm gear is activated, which reduces the speed;

- The steering mechanism is lubricated with special oil (TAD 17) poured into the gearbox;

- The worm gears rotate, which causes the double ridge roller to move;

- This, in turn, causes the secondary shaft to rotate;

- The tray mounted on the secondary shaft makes a turn and pulls the rod system behind it;

- These components influence the levers that synchronously rotate the wheels to the required angle specified by the driver.

Parts of the steering gear housing

1 - housing; 2 - bipod; 3 — lower crankcase cover; 4 — adjusting shims; 5 — outer ring of the worm shaft bearing; 6 — separator with balls; 7 — bipod shaft; 8 - adjusting screw; 9 — adjusting plate; 10 — lock washer; 11 - worm shaft; 12 — upper crankcase cover; 13 - sealing gasket; 14 — bipod shaft sleeve; 15 — worm shaft seal; 16 — bipod shaft seal.

Details

1 — steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

Repair and maintenance

Over the years of operation it has been proven that the steering on VAZ 2107 vehicles has impressive reliability. However, this does not take away the fact that the machine requires periodic inspection and repair.

- When performing maintenance, it is important to check for increased play as well as increased wear on the ball joints. To do this, you need to turn the steering wheel from one side to the other. If the wheels do not respond when the steering wheel is turned 5 degrees from its original position, this indicates severe wear. Here you will need to repair the steering column on a VAZ 2107.

- To avoid the need for urgent and rather expensive repairs of the steering gear on a VAZ 2107, it is necessary to change the oil in the worm gear housing. This is done at intervals of 60 thousand kilometers. Leaks may occur through the seals, so they are carefully checked 2-3 times a year. This is one of the weak points of the system.

- The swing arm should be inspected by slowly rotating the steering wheel from side to side. If the parts move in a vertical plane, then surgical intervention is required.

To do this, the drive and steering mechanism are dismantled completely or partially. Everything depends directly on the nature of the breakdown.

Check which parts have defects and what has failed. Inspection is required for each component of the mechanism. If parts are worn out, there is no point in trying to repair them. There is only one way out - a complete replacement of worn-out components of the steering system on a car from a Volga company.

If problems arise with the steering, it is advisable to contact a professional service station.

Photo of the VAZ 2107 steering gearbox

You can replace the gearbox yourself, but the process is complicated and requires at least minimal experience and skills.

The VAZ "Seven" is a true classic of the domestic automotive industry. Unlike modern LADAs, they are more reliable and durable, which is proven by the huge presence of these cars on our roads.

Of course, the VAZ 2107 has long been outdated, it does not have a hydraulic booster, and you have to apply sufficient force to turn and maneuver. But for connoisseurs this is not a problem.