On Lada Kalina cars there is an insidious reason that leads to the inability to engage reverse gear. It is interesting that this reason is purely electrical and has nothing to do with mechanics.

Reverse gear on Kalina is engaged by moving the gearshift lever towards you and forward. In this case, you need to lift the plastic ring on the lever. This ring protects the driver from accidentally engaging reverse gear instead of first gear, as often happens on “tens”. This is done using an electric drive - a solenoid.

The solenoid is installed in the transmission and blocks reverse gear from being engaged until the ring on the gear shift lever is lifted. When raised, the reed switch (sealed magnetic switch) in the lever is activated, connects the solenoid power circuit to ground, the solenoid rod is recessed, and the stroke of the gear selection mechanism increases - you can engage the reverse gear.

We will not talk about the advantages and disadvantages of this system. There are two camps of “Kalinovodov”, who are both “for” and “against”. Here we will look at the reasons why problems with electrical locking may arise.

Lockout fuse blown

As always with electrical breakdowns, the first thing we look at is the fuse. Fuse F21, rated 10 A, is responsible for the operation of the reverse locking system in Kalina. It is installed in the main mounting block. If the fuse is intact, then move on to the gear lever. If the fuse jumper is broken, replace it with a new one and see what happens. We try to engage reverse gear. If the fuse blows again, it indicates that there is a short circuit in the solenoid power supply circuit. By

Oil

The gearbox, just like the engine, contains oil. Its viscosity is thicker than motor oil. On domestic cars, the manufacturer recommends changing the fluid at least once every 60 thousand kilometers. If the reverse gear on the Lada Kalina does not engage, check the lubricant level in the box. If the mileage of the car is more than 60 thousand, drain the old fluid and use new one.

Place of the switch in the light switching circuit

On cars with manual transmission, voltage to the lamps when reversing is supplied through a limit switch (the so-called frog), which is screwed directly into the gearbox housing. When reverse gear is engaged, the switch button is pressed inside the gearbox. The contacts inside the “frog” bridge, and current begins to flow to the lamps.

On the circuit diagram for turning on the reversing lights, we can see that on the VAZ 1118 Kalina, the current from the battery through the ignition switch (No. 2) is supplied to fuse F1. Passing through the fuse that protects the switching circuit, “+” goes to the limit switch (No. 10). The contacts are in a normally open state and close only when reverse gear is engaged. Thus, current begins to flow to the light bulbs. The second contact of the lamps is connected to the “–” battery through the common ground contact of the lamps.

On cars with automatic transmission, the role of the limit switch lies with the selector position sensor. Information about changing the location of the gearshift knob is transmitted to the engine ECU, the light control unit.

How to check the "frog"

- Remove the headlight switch chip.

- Turn on the ignition.

- Using a small piece of wire, connect the contacts of the reverse gear sensor connector to each other.

If the reverse lights are on, then the problem is in the “frog”. Some drivers disassemble the switches, clean the contacts, after which the device continues to work properly. It is up to you to judge the appropriateness of such measures. But keep in mind that on many cars (including VAZ models) the limit switch is located below the oil level in the gearbox. We recommend simply replacing the power sensor. To minimize oil loss, jack up the car on the side where the end switch is installed.

On some cars, the reversing lights do not light up due to incomplete activation of the limit switch. The problem can be solved by installing a thinner washer under the “frog”. To make sure that the switch is working, check with a multimeter in ohmmeter mode whether the contacts close when you press the button.

Checking the circuit

The essence of diagnosing the reason why the reverse lights do not work comes down to identifying the section of the circuit where the voltage is lost. To do this, you can use a regular control light. Continuity testing is done with an ohmmeter, so you need to know how to use a multimeter.

You can start checking directly from the limit switch connector. Turn on the ignition. Connect one contact of the control light to an unpainted metal part in contact with the body, and the second to the “+” connector.

- If power comes in, check the reverse sensor.

- If after installing the “jumper” in the connector the lights do not light up, then the problem is in the section of the wire circuit going from the connector to the lights. Ring the wire to the point where it divides into light bulbs on the left and right sides. Most likely, the reason is the break.

To find the pinout of connectors, light contacts, and wire colors, be sure to study the electrical diagram of your model and vehicle configuration.

The lamps are constantly on

If the lights on your car are constantly on or come on regardless of whether reverse gear is engaged, the cause will be among the following breakdowns:

- short-circuiting the “+” going to the reverse gear sensor and the light bulb wires from the switch;

- the wire going from the connector to the lights has a short to “+” (this happens if the wires in the harness fray);

- The sensor is stuck in a closed state.

How to change oil

To do this you will need an inspection hole or overpass. Warm up the car before surgery. Transmission oil is very viscous, and at low temperatures it will not completely leave the walls of the box. Locate the drain plug on the transmission. Using a wrench, unscrew it and place a container to drain the waste liquid. Within 20 minutes, all the oil will pour out of the box. Next, tighten the plug with a wrench and find the filler cap. It's on the side.

Backstage adjustment

Often after its repair, the Kalina does not engage reverse gear. The speed at which the pedal is pressed does not matter. Fifth gear will also disappear along with it. To eliminate the malfunction, it is necessary to adjust the position of the rocker. How to do it? You need to find the backstage clamp and loosen it.

Next, the lever is moved to the desired position (reverse or fifth speed). The clamp is tightened. You should check the effectiveness of the adjustment with the engine running. If after this you still cannot engage reverse gear on the Kalina, make the adjustment in first gear. Move the gearbox lever to the appropriate position, having first loosened the bolt. Turn the rocker drive counterclockwise until the lever rests against the reverse gear lock R. By adjusting the seating depth of the rocker on the gearbox driveshaft, you will restore the proper operation of the box.

Malfunction of the electrical wiring connecting the gearbox

Since the solenoid is directly connected to the vehicle ground, you also need to check the operation of the fuses. Reverse gear may not engage due to damage to one switch. Here it is advisable to use a multimeter and perform a “test” of the conditionally burnt element. If there is nothing at hand, then you can simply close the contacts. But you should be extremely careful, because if we are talking about a short circuit in the wiring, this can even lead to a fire.

Every car owner is required to have spare fuses with him in case of emergency. It is better to close the contacts with it, having first removed it from another power circuit. After this, the engine starts, reverse gear is engaged and an attempt is made to move. If the car moves forward, then the problem lies deeper.

Solenoids

This mechanism is available on both automatic and manual transmissions. The solenoid is fed through a switch ring (located on the transmission lever). When you pick it up, the element fires. The solenoid rod is pulled inward. Reverse gear is engaged.

At the same time, the limit switch on the gearbox is activated, and the reverse lights turn on. Why doesn't reverse gear engage on Kalina? The reasons may be a blown solenoid fuse. It is marked "F-21". Check the fuse box and replace the burnt element.

Why the Lada Kalina stopped turning on: reasons and solutions

Failure of the locking mechanism fuse

Since this device in the Lada Kalina is of electronic origin, it is first of all worth examining the electronic systems. To do this, you need to check the condition of the corresponding relay and fuse, which are located in the mounting block. Its cover is located under the handle for turning on the dimensions. Open it and evaluate the functionality of the fuse responsible for the operation of the transmission reverse lock circuit.

The documentary designation of the required element is F21. The current rating of this component is 10A. The location can be seen in the photo below.

F21 (10) - the fuse you need

To determine the true cause, remove the fuse from its socket and carefully analyze the condition of the jumpers. If the part is damaged, the integrity of the jumper will be compromised.

Option to solve the problem: replacing the fuse with a new one is the only way.

Important! If a newly installed mechanism quickly fails, then the cause must be sought in the solenoid.

Magnetic switch failure

As a rule, such breakdowns are not so common due to the fact that the magnet itself is a fairly durable spare part and has a sufficient working life. However, if the reverse gear fails, it would not be superfluous to check it too.

What to do if it is whole?

If reverse gear does not engage (Lada Kalina), the reasons may lie in another part. To diagnose, you need to disassemble the box cover. Below it there is a connector connected to the solenoid switch. We turn it off and connect the contacts directly. Check to see if reverse gear is engaged. If not, remove the solenoid connector and measure the voltage in it. When the voltmeter shows values less than 12 V, it means there is a short circuit. You can also check using a test lamp. Its power should be from 3 to 5 watts. If it does not light up, it means that the wires in the circuit have burned out. We are looking further. We close the contacts of the connector that goes down under the floor of the car. This can be done using a metal clip. Next, turn on reverse. If it turns on without problems, it means that the short circuit occurred here. If the element is in good condition, remove the connector from the solenoid. Using two pins and a tester, we measure the voltage. The ends of the tester are applied to the pins. In most cases, breakage occurs due to a fracture of the harness and oxidation of copper. Most often, the wire frays at the place where the clamp is installed on the mechanical box pallet. How to check it?

Reading the instruction manual

The instructions included with Kalina-2 hatchbacks and station wagons say the following:

Before engaging reverse gear, you should depress the clutch and wait 3-5 seconds, and only then can you shift.

According to reviews, 3 seconds will be enough. By the way, the blocking stops working not after 3 seconds, but earlier. But if you switch immediately, there is a risk of breaking the gear teeth. All this, of course, is true only for the break-in period.

As the owners themselves say, reverse gear is engaged perfectly even on a car with “zero” mileage. But the driver is required to show dexterity: having squeezed the clutch to the maximum, the pedal is then moved back a little. The handle moves to the desired position and the pedal is fully released.

Clutch pedal response zones

You can also turn it on “through neutral”. This method is the most reliable. Release the pedal when the handle is in neutral and you are guaranteed to be able to shift into any gear. Actually, the method is suitable for any car and any manual transmission. But regarding AvtoVAZ products, the advice sounds like this: take a 3-second pause.

Release bearing

This element is very reliable. But do not rule out its breakdown. How to determine that it is the release bearing that has failed? To do this, you need to squeeze the clutch with the engine running and listen to the operation of the box. If, when you release the pedal, the characteristic sound (rustling) intensifies and the reverse gear on the Kalina does not engage, the reasons are in the bearing. But not only this speed will turn on poorly. Often, due to the “squeeze”, subsequent gears do not work well. They have to be turned on with re-gas and double squeeze.

We study the design of the VAZ-2181 gearbox

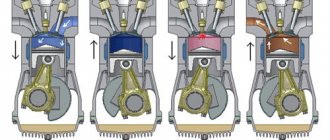

The force from the handle is transmitted to two gear selector levers (see figure). But these levers cannot move in any way - their trajectory is limited by the slots in the “3” grid. The pin "2" can be moved inside the slots, and the upper right part of the grille is closed with a latch "4".

Gear selection mechanism of LADA cable box

To open the latch, the following condition must be met: the car should not move forward even at low speed. Let's look at how blocking actually works:

- A stop is made;

- A certain amount of time passes;

- The lock is deactivated.

In order for the reverse gear to become fully unlocked, you need to wait less than a second after stopping the car. But it’s unlikely that you’ll be able to start moving on a slope while engaging reverse. But if the slope of the surface is directed backwards, the gear engages immediately.

2 Reed switch and bearing failures – such misfortunes also happen

Let's consider other common reasons that do not allow the use of reverse gear on regular and tuned LADA Kalina 1 and LADA Kalina 2. The reed switch may have flown. The functionality of this element is easy to check. We dismantle the decorative casing above the lever in the car interior and look for its connector. We remove the last one and close the contacts. This operation can be performed using a piece of wire, a paper clip, or any other suitable device at hand.

After mechanically closing the wiring, we try to turn on the reverse gear. If the problem is solved, leave everything as is. We're going about our business. And at the first opportunity we go to a car service and completely change the reed switch. It is impossible to operate a car with the wiring connected according to the specified diagram for a long time. Note that failure of the reed switch is most often caused by rotting of its contacts or the entry of small particles of dirt and debris into the mechanism.

It makes sense to check the reed switch when, when you try to engage reverse, you do not observe any reaction from the car. The gearshift switch simply does not go down, no matter how much pressure you put on it.

If the reverse gear is engaged, but the driver does not hear the characteristic sound with which the additional gear comes into operation, we can safely say that the release bearing is faulty. It usually breaks due to metal filings or waste oil that has penetrated the gearbox mechanism. These pollutants increase the friction force. This causes rapid wear of the bearing, and in some cases leads to combustion of the entire mechanism. The described problem can be solved in one way - you need to install a new bearing.

Analysis of the causes of the malfunction

So, as you know, on the Lada Kalina, reverse gear is engaged only when the lever is “retracted” and set to the first gear position. At the same time, the solenoid is activated, which correctly places the gears (including the “blind”) to transfer the force to the movement in the rear direction, that is, against its installed axis.

In fact, first gear is engaged, but the car moves backward due to an additional gear that is connected to the lever mechanism. If this is the reason, and not the wear of key components of the gearbox, then eliminating it is quite simple.

To do this you will need:

- turn the left front wheel completely to the side (all the way);

- open the hood;

- remove the solenoid housing (two wires come out of it: yellow and blue), releasing the tension washer;

- eliminate the wiring fault (as a rule, they completely rot from a mixture of oil and moisture);

- install the housing back;

- start the car, engage first gear and drive 10-20 m;

- try to engage reverse gear.

The whole procedure takes at most 20-40 minutes, you just need the “cherished” key for 36. Isn’t there something like this nearby? Alas, the repair will have to be postponed at least until the garage, since it will not be possible to unscrew the solenoid using improvised means.

If reverse gear on Kalina still does not engage, then the problem may lie in the faulty switch button itself. Here everything is even simpler: you just need to remove the lever (rubber gasket, right in the cabin) and look for damaged or rotten wires here.

You also need to pay attention to the presence of rust - it can simply stop the lever itself. If everything is in order there, but the reverse gear still does not engage, then you will have to disassemble the gearbox itself. Without experience, it is better not to perform such a procedure and trust the specialists.

3 Repairing the solenoid - all operations for independent work

We have already told you how to replace the wires leading to the solenoid. Now let's look at the rules for repairing the Kalina locking mechanism. Its malfunction makes it impossible to turn on the rear. To perform this type of repair, you need to look at the solenoid control circuit. It is given below.

Failure of the mechanism in most cases is caused by the failure of fuse F21 (it is rated at 10 A). Through it, as can be seen in the diagram, 12 V is supplied to L1 (solenoid). Then S1 (switch) closes the circuit to ground. As a result of this, the solenoid coil is activated. If the fuse is blown or the switch is faulty, reverse gear will be locked. Let's solve this problem. We take out the fuse (if you look at the left, it will be the eighth one), and check it with a multimeter. Instead of the faulty element, we install a new one (of strictly the same rating - 10 A). When F21 starts working, we work on the switch (see the first section of the article).

If replacing the switch and fuse does not produce results, remove the connector from the solenoid. We put regular pins in it (two pieces). We measure the voltage with a multimeter. With a normally operating mechanism, it is equal to 12 V. If the readings are different, we have a break in the electrical harness on the pallet - at the place where the clamp is mounted. We pull out the entire harness, expose the wires, and eliminate the break. We solder the twisting area and treat it with heat shrink for greater reliability.

In very rare cases, the solenoid itself breaks down. You can check if it is faulty with a multimeter. We connect the device to the solenoid and measure the resistance. If we see a value other than 2.2 Ohm, we will have to change the element. The work is not difficult, but quite dirty. You will need to drain the oil from the gearbox, then remove the old solenoid and install a new one. Before installing a working element, be sure to treat the threads with sealant. It is important. Without this procedure, oil will soon begin to seep through the threads.

Reverse signal indicator Meander entertaining electronics

Fuses and relays

The gearbox of front-wheel drive VAZ cars is designed in such a way that reverse gear and first gear are engaged with almost identical movements. At first, out of habit, you can start from an intersection in reverse..., with all the ensuing consequences. A simple alarm device, the diagram of which is given here, will allow you to avoid these unpleasant consequences. Basically, it's just an audible warning light that sounds when the car is in reverse.

In the simplest case, you can take a buzzer type NSM1212X and connect it parallel to the reversing light. You don't even need to draw a diagram here. But such simplicity also has a drawback - a quiet and monotonous sound that does not stop all the time while reverse is engaged. In general, this can be tolerated, but it can be done better.

Rice. 1

Figure 1 shows a diagram of a signaling device operating in the following algorithm:

- When reverse gear is engaged, the indicator emits a short beep to warn the driver that reverse gear is engaged.

- If the reverse gear remains engaged for a long time, the indicator periodically emits a short sound signal with a period of 4-5 seconds, reminding the driver that reverse gear is engaged. Using an adjusted resistor, you can set any ratio between the duration of the pause and the sound signal.

The circuit is based on one popular microcircuit CD4001 or its domestic analogue K561LE5 (K176LE5). The sound source is a capsule speaker from a faulty telephone.

The device is connected in parallel to the reversing lamp (“To the Z.H. lamp”), observing polarity. When reverse gear is engaged, voltage is supplied to the reversing light and to the device. Circuit C1-R1 creates a pulse that goes to pin 6 of D1.2. As a result, a logical zero appears at output D1.2 for the duration of the pulse, which leads to the launch of the multivibrator D1.3-D1.4, generating pulses with a frequency of about 1500 Hz. These pulses are sent through VT1 to the sound source B1. A tonal sound is heard, the duration of which depends on the values of C1 and R1 (by selecting them, you can set the desired duration).

If the reverse gear remains turned on, capacitor C1 is charged and a logical zero is set at pin 6 of D1.2. Multivibrator D1.1-D1.2 starts working, generating pulses with a period of about 4-5 seconds. On the decline of each pulse, the multivibrator D1.3-D1.4 is triggered and a sound is heard

The ratio of the duration of the pause and the sound can be set by trimming resistor R2, which regulates the duty cycle of the multivibrator pulses D1.1-D1.2

The CD4001 chip can be replaced with any other analogue of “...4001” in a 14-pin DIP package, or with a domestic analogue K561LE5 or K176LE5.

Transistor KT3102 - any transistor of npn structure, low-power, for general use.

1N4148 diodes can be replaced with any silicon diodes, for example, KD522, KD521.

Capacitors C2 and C1 are necessarily non-polar and non-electrolytic.

The sound source is a capsule speaker from any landline telephone. It can be replaced with almost any miniature speaker, for example, from a pocket receiver. But it is desirable that its resistance be in the range of 30-200 Ohms.

The installation is made on a printed circuit board made of foil fiberglass. Figure 2 shows a drawing of the printed tracks and installation. The printed track drawing is shown from the printing side.

Rice. 2

That is, if the board is made using photo exposure or a “laser iron”, the design will need to be printed in a mirror image. But, I think, it will be easier to make such a simple board in the “old-fashioned” way - draw it using carbon paper and draw paths with nitro enamel or bitumen varnish using a sharpened match as a writing pen.

Setting up. The sound tone can be set by selecting the resistance of resistor R4. The duration of the first sound when reverse gear is engaged is determined by selecting resistance R1. The ratio of pause and sound is determined by trimming resistor R2.

4 Why reverse gear does not engage - other reasons

If the described methods for restoring the normal functioning of the gearbox did not help, most likely we encountered problems in the mechanical part of the gearbox:

- the spring burst;

- the retaining bolt has been cut off;

- The device that secures the gearbox elements has broken.

These faults are truly complex. Such problems must be solved by car service specialists, since they will need to remove the gearbox, disassemble it, find the cause of the breakdown, and then fix the problem. All this takes more than one hour and requires the use of special tools. It is irrational to carry out such repairs at home.