What is a CV joint in a car?

The constant velocity joint is called a CV joint. In common parlance, motorists are also called a grenade or a car grenade.

CV joints began to be installed in cars when the first cars with front-wheel drive appeared. Front-wheel drive cars have some advantages:

- improved maneuverability;

- improved handling dynamics;

- efficiency.

When creating driving front wheels, during the transmission of torque to the front wheels, power was lost and there were other disadvantages:

- The hinge mechanisms quickly broke down.

- The transmission of rotation was uneven.

- The transmission was accompanied by strong vibration.

- The gears and shafts of the gearbox were operating under excessive load.

After this, when automobile grenades (CV joints) were invented, these shortcomings were effectively solved. Thanks to CV joints, torque is transmitted without reducing power and does not create other disadvantages.

The constant velocity joint is also used on rear-wheel drive vehicles that have independent suspensions.

If you change CV joints on time and buy high-quality ones, then they are relatively reliable and do not break so often.

Debugg

The detection of even small defects in the boot indicates that the joint is filled with dirt and lack of lubrication. The CV joint cannot be operated in this condition, so it is necessary to remove the boot and fill the hinges with new lubricant.

Before applying fresh lubricant, the part is disassembled, thoroughly cleaned, and dirt is completely removed. Then the mechanism parts are washed with gasoline, dried and new lubricant is applied. For the internal hinge, 100–110 grams of lubricant are used; for the external hinge, 70–80 grams are sufficient. The CV joint is installed on the wheel and covered with a boot.

Experts recommend installing new, original boots after lubricating the hinge, since old parts lose elasticity and may crack after a short period of time. Non-original anthers do not fit perfectly at the mounting points, so a new portion of dust and water will quickly fill into the gaps.

You can fix the problem yourself

An important condition for the successful operation of CV joints is the choice of high-quality lubricant. Experts advise giving preference to compositions based on molybdenum disulfide, which minimize friction in the components and effectively protect them from corrosion, and also have a minimal destructive effect on the boot.

It is important! It is contraindicated to use graphite lubricant for CV joints. It cannot protect the part from increased loads, and therefore leads to accelerated wear.

What happens if you don't change the CV joint?

It is possible to operate a car with problems in the CV joint if a slight crunch is heard when turning: it is enough to replace the damaged boots and renew the lubrication of the part. When driving a car with a slightly damaged joint, you must reduce your speed when turning.

If vibration is observed when accelerating and a crunching sound is heard even when driving straight, the CV joint must be replaced urgently. A faulty CV joint can fail completely, causing the wheel to suddenly seize. If this happens at high speed, you can expect the most dire consequences.

It is important! On some vehicle models, significant wear or breakage of the tripod CV joint causes the bearing needles to be thrown into the gearbox housing, from where they are lifted along with the oil and ground by the gears. Repairing such an engine costs almost the same as buying a new car.

Video: what can happen if you don’t change the CV joint boot in time

The CV joint is one of the main chassis parts of a front- and all-wheel drive vehicle, and driving comfort and safety depend on its condition. If there are signs of a joint failure, do not delay diagnostics and repairs - otherwise it is unlikely that it will be possible to “cure” the drive.

(10 votes, average: 4.6 out of 5)

Types of automobile CV joints

There are 4 types of CV joints based on their design features:

- Crackers. Installed on trucks and buses.

- Tripoid. It is used in internal structures due to its axial movement.

- Paired. Rarely used type of hinges. Complex in design.

- Ball. This is the most common type. Installed in all front-wheel drive passenger cars.

Classification of CV joints:

- internal;

- external.

The inner CV joint is the connecting link between the gearbox and the axle shaft. The outer CV joint is the connecting element between the axle shaft and the wheel hub. They work in pairs and transmit all types of loads. If a tubeless tire punctures while driving, you can pump a special sealant for tubeless tires into it.

Did you know that it is forbidden to use xenon headlights, as they shine too brightly and blind oncoming drivers? But, you can install xenon fog lights.

Problems of CV joints

Often such CV joints themselves signal that not everything is in order. More often this happens with external ones, which, in addition to heavy loads, collide with stones and other objects on the road. When dust and dirt get into them, the mechanism wears out and begins to crunch or squeak when turning. This may indicate low or no lubrication.

In addition to poor lubrication, causes of CV joint damage can be:

- low quality of lubricants used;

- low-quality product that may be counterfeit or defective;

- damage to the boot with subsequent entry of sand and dirt into it;

- bad roads;

- overly active driving style.

The problematic hinge must be removed and inspected. The ball CV joint does not need to be changed, just remove the grease, wash it in kerosene and wipe it. If the balls and structural elements are intact, it is assembled, filled with fresh lubricant and installed back. It is more advisable to change tripoid CV joints using only the lubricant that is recommended when purchasing them.

Despite the same functions, outer CV joints fail more often due to greater load. Replacing them in a timely manner will help avoid troubles on the road and preserve the health and lives of people.

Constant velocity joint device

Since we are interested in the ball joint, we will consider its structure. Due to the fact that the elements are not in oil (unlike the rear axle), the device is called “dry”. The design of the ball joint is quite simple.

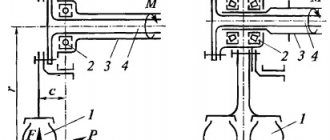

What does a CV joint consist of:

- Frame. It is a hemisphere, a bowl. The driven shaft is installed in it.

- Bottom part. This is a sphere-shaped cam with a drive shaft.

- Separator. This is a ring with holes into which metal balls are installed and held there.

- Metal balls. Movable elements. There are 6 of them.

How to protect the CV joint mechanism

Many constant velocity joints serve for a long time and trouble-free. However, sand and dirt getting into them may soon require the purchase of a new part. Therefore, before you start checking the CV joint, you should understand its protection. It is a cone-shaped rubber or silicone case with a corrugated surface that covers the hinge. The protection is also called anther. It simultaneously functions as a lubricant reservoir. The boot is tightly closed on both sides with metal clamps, preventing the ingress of water, dirt and sand, as well as to prevent lubricant leakage.

Experienced motorists believe that anthers should be inspected regularly to identify deformations and damage such as ruptures, cracks, loose clamps, etc. It is useful when inspecting the anthers to check the condition of their clamps and, if necessary, replace them with screw ones. Sometimes it is recommended to replace the anthers as they fail. If you have to remove the entire drive with two CV joints, it is reasonable to immediately install new covers on both. This way you can prevent device failure in a timely manner.

→ can select the required CV joint and find out its price in our store by contacting the contact numbers or using the VIN request.

CV joint - constant velocity joint. Designed for uniform transmission of torque from the shaft to the wheel. The design of the CV joint is designed in such a way as to transmit torque from the shaft to the wheel at rotation angles of up to 70 degrees. The CV joint has replaced the universal joint, which is capable of transmitting torque only at angles up to 35 degrees. The CV joint consists of an outer and an inner part. The outer part contains grooves along which the internal hinge, which has several degrees of freedom, moves. The grooves securely fix the hinge, allowing it to move along them, while simultaneously changing the angle of inclination, without loss of torque.

CV joint device (photo from Wikipedia)

As can be seen from the image, the internal CV joint assembly moves freely along the external one in three dimensions, ensuring high-quality transmission of torque with acceptable wear of the assembly. Considering the fixation of the wheel on the ball joint side and the shaft on the engine side, the CV joint does not separate while driving, fulfilling its purpose.

How much does a CV joint cost?

Prices for CV joints can vary in the range from 400 to 7,000 rubles , depending on the make and model of your car. Non-original CV joints can be chosen from a very wide list of manufacturers, with a CV joint price ranging from 400 to 1,500 rubles, original CV joints can cost from 1,600 rubles. In most cases, the CV joint kit includes the following components:

- Grenade - the outer part of the CV joint, which is a heavy cylinder with several grooves parallel to each other

- Clip - a hinge inserted into the grenade according to the grooves

- High temperature lubricant - a substance applied to the clip and grooves of the grenade

- Boot - rubber CV joint casing

- Oil seal - sealing rubber

- Mounting bracket

- Clamps - 2 pcs., for attaching the boot

Which CV joint to choose

Before buying a new CV joint, you should find out about the types (what they are), which ones are better according to driver reviews, and what the prices are. The main emphasis should not be placed on the price when purchasing this element of the car device.

There are the following companies that produce CV joints:

- Pilenga. According to reviews, it's a good option.

- Febest. According to reviews from drivers who bought spare parts from this company at an inexpensive price, they quickly break down.

- Metelli. Recommended.

- Loebro. Recommended.

- SKF. Recommended.

The characteristics of CV joints are different. There are 23 splines in the design, and there are 24. If you make a mistake, the wrong one (the difference is one tooth) will not fit on the shaft.

On the list, the last three brands have proven themselves well and have been tested. There are disadvantages with the anthers from the Metelli company, namely, the anther is poorly fixed. In Loebro, the anther is also a weak link. The third type of SCF created its high rating due to the high quality of the bearings they produce. SKF CV joint life = 100 thousand km. provided that the anthers are in good condition and the car is operated in a quiet mode. When using a car, squeaks often occur. It is usually the stabilizer bushing that creaks, the service life of which is usually 30 thousand km. I advise you to look at how to change stabilizer bushings.

A high-quality new spare part differs from a new one in appearance and feel. A defective CV joint has a thin boot, little lubrication, and a weak clamp securing it.

CV joint device

The CV joint works almost the same way as the universal joint known to all drivers. Nevertheless, the second drive is more advanced and complex. What are the differences? In the case of a cardan: the transmission transmits torque asynchronously (that is, one shaft rotates evenly, while the other does not), and the crossing angle is quite difficult. The CV joint is different in that it does all this work, but is 90% simpler: it has a longer service life, since its rotation angles are no more than 70 degrees relative to the axis.

Important! CV joints originated more than a hundred years ago. However, today they have evolved greatly and are one of the main components of absolutely all vehicles that are found on the road (regardless of their “age” or high cost).

The grenade is a power spare part that is often subjected to stress. Therefore, it needs protection from the environment, which lubricants can help with (and thus extend its service life). The design of the part is covered with a boot made of plastic or rubber (which is filled with lubricant and held on the shafts using clamps). Note that the life of the grenade also depends on the quality of the boot. If this component fails and you do not take any action, you will soon have to check the CV joint for serviceability (since it cannot work in an unprotected environment and fails quite quickly due to direct exposure to the environment: hit dirt, road precipitation, etc.).

CV boot

The CV joint boot looks like a cover made of thermoplastic or rubber, protecting the joint from external adverse factors, and also protects the loss of auto-lubricant, which is located inside the CV joint. The number of such covers in a car is up to 20 pieces. Externally, the boot looks like part of a corrugated tube. Damage to the protection housing can lead to loss of the lubricant coating and, as a result, increased shock absorption occurs. The boot is the only effective protection against damaging segments and a guarantee of long-term proper operation. Diagnostics of the cover should be carried out on a regular basis (monthly), and if there is the slightest crack, it should be replaced. You need to choose an anther not based on the composition of the product, but on the quality and reputation of the manufacturer. The material of the boot that is too hard is not suitable for installation; first you need to rotate one of the folds around its axis and there should be no creases or cracks on the resulting bend.

The internal boot is subjected to heavy loads from high-temperature engine operation. Often worn out by foreign objects falling from the roadway under the hood. Damage to the boot is characterized by the release of lubricant in large quantities, external cracks and microcracks. The outer CV joint directly transmits the movement of the shaft to the wheel hub and is smaller in size than the inner one. It also experiences more wear due to friction of parts, interaction with the road and from constant compression and stretching, since the CV joint is installed directly on the wheel. To examine the damage to the outer boot, you need to turn the steering wheel all the way, one side of the element will stretch, which gives a good opportunity to determine the integrity.