An external sign of wear on the oil seals (valve seals) is the short-term appearance of blue smoke from the exhaust pipe when starting the engine after a long period of parking or when braking the engine after a long period of driving under load. Moreover, constant smoking is usually not observed.

Also, indirect signs are increased oil consumption, oily spark plug electrodes, and oil leaks on the valves.

Similar signs are observed when the caps jump off the seats of the valve guides.

The caps can be replaced without removing the cylinder head. It is more expedient to carry out this operation in conjunction with the replacement of timing parts or during a planned adjustment of the thermal clearances of the valves.

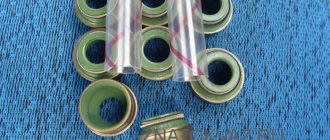

For this we need: - A set of valve stem seals Ø8 mm - A pair of crackers (optional) - An installation sleeve (if available) or a heat shrink tube Ø8-10 mm - A rod of tin solder Ø7-8 mm or other soft metal - A piece of cord or wire - Torque wrench - Wrenches and socket wrenches for 7,8,10,13,17 - Valve depressurizer - Collet puller-mandrel (preferably) or narrow-nose pliers for removing caps - Mandrel for pressing in caps - 0.15 mm feeler gauge or rack for adjusting the thermal gap valves - Tweezers or magnetic screwdriver - Screwdriver, hammer

So, turn off the engine and let it cool. Remove the cylinder head cover and align the timing marks at the top dead center (TDC) of the 4th cylinder.

In this position, the pistons of the 1st and 4th cylinders will be installed in the TDC position, which will prevent the valve from falling into the cylinder during “drying” and will make it easier to fix it with a tin rod.

Loosen the chain tensioner, unscrew the fastening nut and remove the camshaft sprocket along with the chain. Without allowing the chains to jump, we tie them together and secure them from falling into the engine crankcase so that the valve timing does not go astray.

We remove the bed with the camshaft.

We unscrew the spark plugs and use a flashlight to make sure that the piston of the 1st cylinder is in the upper position. Having overcome the force of the spring, remove the rocker (lever) of the valve, and then the spring itself.

Using a suitable socket, we apply a light blow with a hammer to the upper plate of the valve tension springs to facilitate the process of “de-drying” in the future.

We insert a tin rod into the candle hole under the valve, put on the desiccant and, pressing the plate, remove the released crackers with tweezers or a magnetic screwdriver. Then remove the desiccant, the upper plate with springs, and the support washer of the small spring.

Using a collet inertial puller, with light blows of the striker, remove the cap from the valve guide. If this device is not available, as a last resort, you can use narrow-nose pliers.

However, you should work very carefully, since they can easily damage the guide bushing made of fragile metal-ceramic, which threatens unscheduled repair of the head.

We wipe the seat, put an installation sleeve on the valve stem (usually included with the caps) or a heat-shrinkable one of suitable diameter, so as not to damage the working edge of the cap on the groove for the crackers.

If there is significant play and wear on the working surfaces of the guide bushings and valve stem, it is desirable and necessary to thoroughly degrease the seats to prevent the caps from slipping off the guides.

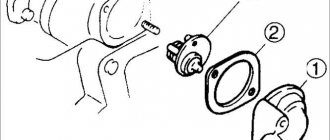

We put the cap on and move it to the guide, having previously lubricated its working edge with engine oil. We remove the installation sleeve, remove the spring from the cap, put on the mandrel and lightly press the cap until it stops, put the spring back on.

We install the springs, plates and “dry” the valve back, remove the desiccant.

After this, while the piston is still at TDC, remove the rod and apply several gentle blows with a hammer to the valve stem to make sure that the crackers are securely in place.

We install the spring and rocker in place.

Similarly, we change the caps on the second valve and on the valves of the 4th cylinder. Then, holding the sprocket with the chain, rotate the crankshaft 180°, and the camshaft, respectively, 90° and replace the caps of the 2nd and 3rd cylinders. To do this, it is very convenient to use the rear wheel in 4th gear.

We set the crankshaft again to the TDC position of the 4th cylinder and install the camshaft with sprocket in place. We tighten it with a torque wrench with a force of 2.2 kgf m according to the tightening diagram.

After installing the camshaft and tensioning the chain, be sure to adjust the thermal clearances in the valves.

Process video:

Good luck on the roads!

WHY ARE SEALS NEEDED AND HOW THEY ARE STRUCTURED

Engine cylinders need protection from foreign substances entering the combustion chamber. It is the oil seals (or valve stem seals) that play the role of a kind of protector. Their task is to prevent oil from penetrating while the valve stems are operating. If the caps have lost their function, they must be replaced. Otherwise, carbon deposits will begin to appear on the walls of the engine, which will lead to increased oil consumption.

A running engine causes all elements of the gas distribution mechanism to constantly move. They rub against each other, which inevitably leads to wear. To reduce the wear rate, oil gets onto the surface of each element. In this case, you need to ensure that the oil does not end up in the working area of the valves. Otherwise, the motor will begin to malfunction. To ensure that not a drop of oil penetrates into the combustion chamber, oil seals are installed.

Valve seals have a very simple structure. They consist of only three elements:

- Base. This is the oil seal frame, which is made in the form of a steel bushing. This element ensures the strength of the spare part.

- Spring. It ensures the tightness of the mechanism by pressing the rubber tightly against the valve stem.

- Cap. This is the main element of the device, made of rubber. With its help, excess oil on the rod is eliminated.

Assembly order

Pressing in valve stem seals using a bushing

- The valve stem, oil seal and cap are lubricated with engine oil; the valve cap corresponding to the valve is placed on the stem with the oil seal facing up. It descends down the stem, where it is pressed tightly against the hole with the valve guide.

- The end of the mandrel is pressed against the rim of the cap, by lightly tapping the top of the mandrel with a hammer, the cap is pushed into the hole until it stops. The cost of a mistake in case of strong impacts, damage to the oil seal or cap, will have to be replaced. The springs are installed in the reverse order of disassembly.

Attention! After installing the springs and removing the device for compressing the springs, you need to remove the plate from the spark plug hole and tap the end of the rod with a hammer so that the crackers sit in their place. This must be done carefully; if the crackers are positioned incorrectly, the springs may pop out.

Procedure for tightening the camshaft cover nuts

The camshaft cover, as required by the instructions, is pressed with a torque wrench with a force of 8 kg/m. tightening the nuts in the required sequence.

SIGNS OF BREAKAGE

To prevent serious problems in engine operation, it is necessary to promptly diagnose and correct oil seal failure.

You can judge the wear of valve stem seals on a VAZ 2107 by the following signs:

- There is an increased release of white or blue exhaust gases.

- Engine oil consumption increases significantly.

- The candles become covered with black soot.

If you find these signs of failure, you need to make sure that the entire gas distribution mechanism is working properly, and not just the caps. Pay special attention to valve diagnostics. If necessary, replace the valve stem seals on the VAZ.

If the problem is not diagnosed and corrected in time, the following consequences may occur:

- the motor will lose dynamics;

- it will begin to work unstably and will often stall at idle;

- the pressure in the cylinders will decrease;

- carbon deposits form not only on the valves, but also on the walls of the cylinders and pistons;

- the tightness of the system will be compromised.

When carbon deposits appear on the engine walls, its service life decreases sharply. If the problem is not corrected in time, the situation will lead to an expensive overhaul of the engine. But these difficulties can be avoided by simply replacing the oil seals on the VAZ 2107.

WHEN IS IT TIME TO REPLACE

Over time, the sealing material of the valve stem seals becomes hard. As a result, it loses its elasticity, which leads to oil leakage into the cylinder. The same problem occurs when the piston rings are faulty.

The caps are changed in cases where oil leaks occur without visible places. Watch how the exhaust behaves while driving. Brake the car sharply with the engine, and then also sharply press the gas pedal. If this leads to the appearance of thick smoke from the muffler, then it is time to replace the seals.

Thick, bluish-colored smoke may appear on the car even after a long period of parking.

It's easy to explain. If the caps are worn out, this leads to oil entering the engine cylinder. If the piston rings are worn out or coked, the engine behaves a little differently. Smoke will remain behind the car only when driving uphill or during rapid acceleration.

If, in addition to smoke, you observe an increase in fuel consumption, a decrease in engine dynamics and problems during startup, this may all be evidence of wear and tear on the mechanisms.

HOW TO REPLACE CAPS ON A VAZ 2107

- Drain approximately two liters of coolant.

- Remove the air filter housing and throttle linkage if you have a carburetor.

- Remove the valve cover.

- Place the first cylinder in top dead center mode.

- Loosen the chain tension nut.

- Remove the camshaft gear mounting bolt.

- Remove the sprocket and chain and secure them with wire to prevent a possible fall.

- Remove the bearing housing and rockers.

- Remove the candles. To prevent the valve from falling into the cylinder, be sure to plug the spark plug hole with a tin rod.

- Using a valve remover, remove the "crackers".

- Using a screwdriver, carefully pry and remove the oil seal.

- Before installing the new one, do not forget to lubricate the surface of the rod with oil.

- Replace the springs and other parts.

- Repeat all the described operations with each cylinder, installing them at TDC.

After completing all the work, return the crankshaft to its original state, install the bearing housing, camshaft gear and chain. The remaining elements are installed in reverse order.

Tools for repair

To carry out the repair you will need the following tools:

- a set of keys;

- valve puller;

- tweezers (to pull out crackers);

- oil seal remover;

- a mandrel (or something similar for pressing, for example a piece of tube slightly smaller than the diameter of the oil seal);

- hammer;

- tin solder rod 8 mm.

How to replace valve stem seals on a VAZ-2107

Fortunately, a process such as replacing valve stem seals on a VAZ-2107 is far from the most difficult thing you may encounter when repairing your car. The main thing in this matter is to be as careful as possible, and then replacing the valve stem seals will be quick and successful. The entire procedure is no different depending on what is under your hood, an injector or a carburetor, except that the carburetor will need to be removed before starting work. It is important to make the replacement without removing the head - this is an easy and simple method that most car enthusiasts can handle.

When is it time to change caps?

Experienced car drivers can easily understand when a replacement is necessary. Moreover, this is easy to do with your own hands, without resorting to the help of specialists from the workshop. If you see the following signs, it means it's time to change the caps.

- Black carbon deposits appeared on the spark plugs. It is important to understand that we are not talking about soot, but about soot. Soot may indicate other problems.

- Presence of blue smoke. The reason for this is a strong oil coating.

- Very high oil consumption. It is difficult to bring an engine to this state and is considered a serious problem. When the oil seal in the engine is too worn out, it will “drink” oil with such thirst that it will simply fly out through the exhaust. Therefore, you should not be surprised when, after driving just a couple of hundred kilometers, you find that you have no oil left at all, even though it was recently filled in.

Why do rubber seals wear out?

The following signs may indicate that the oil seal has worn out:

- The candle thread becomes coated with oil.

- Smoke appears from the neck where the oil is poured.

- The car's exhaust pipe itself smokes heavily.

- Soot appears on the spark plug electrodes.

- Fuel consumption increases noticeably.

- The recently filled oil is contaminated.

If such manifestations occur, it is necessary to replace the valve stem seals of the VAZ 2110.

However, there are exceptions:

- the price of “original” caps is much higher than those offered to the buyer in the nearest specialized store;

- If the cap is damaged, there is simply no time to search for and purchase exactly the same part. This forces you to use some other options.

Replacing caps

Before you start working on the carburetor, it must be removed. Before that, you need to disconnect the negative terminal of the battery.

Don't forget to also remove the air filter, then follow the following diagram:

- Remove the valve covers and carefully place all the nuts and washers in a separate container.

- Then you need to start cranking the crankshaft. It is very important to obtain a position where the pistons of the fourth and first cylinders are both at top dead center. Only in this case are both valves completely free.

- Then remove the chain tensioner by unscrewing the nuts that secure it.

- Now you can begin to unscrew the housing mounting nuts. After the nuts have been unscrewed, it must be removed directly from the camshaft.

- It is important to insert a tin rod into the spark plug hole, and then use it to support the bottom of the valve.

- Then you need to take the desiccation tool and secure it to a pin. We will dry out the first and fourth valves, and the main thing is to do it sharply.

- At the next stage you should be extremely careful, because it’s time to get out the plates, crackers and springs.

- Once we got all this out, it is important to put on the puller and remove the caps. Then insert a new cap.

- Then we return the plates, crackers and springs.

- After the operation with the first and fourth cylinders is completed, rotate the crankshaft 180 degrees and do the same with the remaining cylinders.

- Then we put everything back together in reverse order.

At this stage, we have successfully replaced the valve stem seals. Now you don't have to worry about your car losing oil faster than it gets it. Always monitor the condition of your engine and oil level, because this will have a positive effect on the life of the car.

Adjustment of valves

First of all, on a carburetor car we remove the carburetor and air filter, and on an injection car only the pipes, which will prevent you from removing the valve cover.

Then we unscrew all the nuts around the perimeter by 10 using a socket wrench, be sure to collect the washers in containers so as not to lose them, since they are quite specific. Of course, you can later purchase them in the store, but this can significantly delay the work process.

Now we take a crooked starter or key, then rotate the crankshaft clockwise until the mark on the pulley coincides with the last ebb on the front cover along the way. With this action we set the pistons of the first and fourth cylinders to top dead center. It is at this very moment that the valves in these cylinders should be completely closed; accordingly, it is in this position that the adjustment is carried out.

The VAZ 2106 engine works according to the 1-3-4-2 scheme. That is, when the pistons of the first and fourth cylinders are at top dead centers, the pistons of the third and second are at the bottom.

So, after we have aligned the pistons as needed, we proceed to adjusting the valves. We can determine the ones we need by simply shaking the rocker arms - a light tapping sound will be heard. We need valves 8 and 6, counting from the front of the car.

To adjust, insert a feeler gauge between the camshaft cam and the rocker arm. If the probe enters with tension and comes out the same way, then nothing needs to be adjusted. If it passes easily, then you need to unscrew the locknut and unscrew the adjusting bolt. At this time, while we are unscrewing, we fidget with the feeler gauge to find the optimal position.

Once it is determined, tighten the locknut

It is very important to ensure that the adjusting screw does not turn even a degree. In any case, you need to check

To do this, we fidget with the probe again. If this is not possible, or vice versa, the probe moves without effort, repeat the procedure.

At this moment, if you look at the camshaft gear, the mark on it coincides with the cast on the camshaft housing. So, this is the best guide, because the crankshaft will need to be turned exactly 180 degrees, while the camshaft will turn 90 degrees. We adjust valves 4 and 7. Next, we turn the crankshaft again and adjust the valves in accordance with the table.

There is no point in discussing the assembly

The only thing worth paying attention to is the flatness of the valve cover plate. Over time, it is pressed through by washers, so it requires editing

If indentations are visible in the tightening areas, then it must be corrected on an anvil.