The service life of outer tie rod joints, also called tie rod ends, greatly depends on their original quality, driving style and smoothness of the road surface. In any case, these consumables have to be changed quite often, since the slightest play in the hinges is unacceptable. In addition to the sound, this has an extremely negative impact on the durability of the tires and the overall safety of driving.

The replacement procedure is quite simple and can be done independently, without the use of complex specialized equipment.

Checking the condition of parts

The presence of play in the connection must be checked during each maintenance of the machine. To do this, it is quite enough, with the suspension loaded with the weight of the car, to forcefully shake the steering rod with one hand and hold it on the tip with the other hand. If there is wear, you can clearly feel the play of the ball pin.

You can use a lever (mount), but there is a danger of mistaking the normal play of the spring-loaded pin for wear. Diagnostics by rocking the wheel has the same potential for errors; in this case, play will be selected in other parts and masking knocks will occur.

Working method

You need to do the following:

1. Hang up the car and remove the wheel, not forgetting to install a reliable safety stand.

2. Clean the parts with a wire brush and spray the joints with a penetrating fluid such as WD-40 or equivalent. These are mixtures of white spirit with anti-corrosion and lubricating additives.

3. Loosen the nut securing the pin and the locking connection of the toe adjustment unit. One turn is enough. It is better to go through the thread of the pin nut several times until it rotates freely.

4. Install the puller onto the ball joint. Pullers come in different designs; it is most convenient to use a device in the form of a wedge fork; a couple of strong blows to its end are enough. The screw puller does not always cope on its own; it needs help with a sharp blow of a hammer on the bipod of the steering knuckle.

5. In the absence of a puller, you can create tension in the connection using the same pry bar, and then apply sharp blows to the edge of the bipod. The finger will detach with a characteristic click. All that remains is to unscrew the threaded end of the rod and install a new one.

The disadvantage of such a simple replacement is the need to immediately carry out operations to adjust the wheel alignment angles, as they say, wheel alignment. We must remember that replacing the tip does not affect the camber in any way, only the toe-in of the wheels changes.

If you approach the work carefully, have a sufficiently large caliper or tape measure, and understand the principles of toe adjustment, then additional costs can be avoided.

To do this, you need to perform the following operations with the highest possible accuracy:

1. Before starting to loosen the nuts, make two marks. The first should be located exactly in the center of the circle of the back of the ball joint. There are usually ring stampings or rolling. Their center must be calculated, at least using a caliper. In the found center, it is advisable to make a small depression with a light blow of a sharp core. Carefully check to see if there is any slight shift of the mark from the center. Repeat the procedure on a new tip.

2. On the steering rod, from the inside of the threaded connection, apply an annular mark lying exactly in a plane perpendicular to the axis of the rod. Smooth and neat.

3. Using a caliper or tape measure, measure and record the distance between the applied marks.

After installing the new tip, rotate the adjusting connection to achieve the same result. Lock the threads.

Despite the possibility of preserving the previously existing toe angles in this way, it will still be safer and calmer to visit the stand. The toe-in angle is quite accessible for measuring in a garage yourself; you can find various techniques in numerous tips from home craftsmen for repairing their own cars.

Replacement and repair of main parts

When a malfunction is detected, you need to collect all the necessary parts and tools for the VAZ 2110. You will definitely need sets of screwdrivers and wrenches. It is also necessary to check the availability of socket heads, pliers, a metal brush and a special puller that is used to service the device. If it is not there, then a small crowbar or hammer will do as an alternative.

How to change tips and rods

Replacing tips and rods is as follows:

- The first step is to jack up the VAZ 2110 and remove the front wheel;

- The area where the rack tip attaches to the steering knuckle must be thoroughly cleaned, and then the nut must be treated with WD-40;

- Next, you need to remove the cotter pin securing the connection; for this you will need pliers;

Remove the wire fixing nut by pulling one end with pliers

- After this, you need to remove the finger using a special puller, after unscrewing the nut;

- Once the pin is removed, the tips can be unscrewed and removed. They must be checked for defects and replaced if necessary;

- Having removed the tips, you should bend the plate at the bolt to get to the rod;

- The next step is to unscrew the rod bolt;

- Done, now the rod and its ends can be dismantled. Replacement is carried out in reverse order. After installing new parts, you need to check the steering wheel without completely assembling the entire steering mechanism. If everything works, the steering wheel does not move tightly and does not wobble, then assembly can be carried out.

Removing the finger

Replacing the steering wheel

It will be easier to dismantle the steering wheel than the ends and rods. It is worth saying that the steering wheel is rarely changed; usually a more stylish and convenient option is installed instead. It is necessary to check before purchasing whether the new part fits the steering mechanism.

The replacement takes place as follows:

- The cover must be carefully pryed off with a screwdriver and removed;

What are the best steering tips for the VAZ 2114

Tie rod ends are steering control elements that are present on every modern car. The VAZ 2114 model was no exception.

The purpose of the tie rod ends is to provide a connection between the linkage and the steering knuckle of your car's wheel. When the tips move, the steering rack rods move, turning the wheel. In essence, steering tips provide the ability to make maneuvers, turns, and change the direction of movement of the car.

Element appearance

Replacement timing

Steering rods have a fairly long service life and require extremely rare replacement.

Much more often on the VAZ 2110 it is necessary to change the steering tips. If the driver is familiar with the design of the car, then he can do this completely independently. The approximate service life of the tip is a mileage of 40 thousand kilometers. Of course, deviations can be in any direction and this depends on the operating conditions of the car.

The steering system wears out under the influence of the following factors:

- Operating conditions of the vehicle.

- What quality do the elements initially have?

- The degree of wear can be determined by the quality of the road surface and the speed of the vehicle.

- This is even influenced by the driving style the driver prefers.

Signs of breakdown

Tie rods have two main enemies.

- Dirt. PH are hinged parts, therefore, when the boot is damaged, various solid particles of debris, dust, and dirt begin to enter the mechanism. Friction occurs, parts begin to wear out faster, and moving components are destroyed.

- Bad roads. How many bumps, holes, curbs do you have to overcome every day? All these impacts negatively affect the condition of the tips - the hinge begins to actively wear out, and play occurs in the vertical direction.

If a tip is found to be faulty, it must be replaced. It is better not to do with restoration and restoration of functionality.

Many people are interested in the question of how you can check the steering tips and make sure they are worn out or, on the contrary, intact. It is not necessary to go to a service station and pay money for this.

To check the condition of the LV, you need to turn the wheel all the way in one direction and remove all dirt from the boot. If there are breaks or cracks in the rubber, then the part has worn out and no longer performs its functions properly. Do subject to replacement. The second wheel is checked in a similar way.

There is one more important measure that is recommended to be carried out even if there are no signs of wear on the launch vehicle. To do this, a pry bar is inserted between the steering knuckle and the rod, after which the parts are moved relative to each other. If no vertical play occurs during these manipulations, everything is fine. If it is, you will definitely have to change the component.

Preparatory activities

Many experts advise taking certain steps to prepare for the replacement so that everything goes easier and faster. These actions include the following.

- Treat all nuts and fasteners with penetrating liquid. WD40 works great.

- If the tips last longer than one winter, to remove their fist you will need to use a 17 socket to unscrew the nuts.

- If the nuts stick, try heating them with a hair dryer. A gas burner is also suitable, but you need to be as careful as possible with it.

- Prepare tools for removing tips.

Today, two methods are used to dismantle steering tips - modern and traditional. The first involves the use of a special puller, and the second - a sledgehammer.

Jack and WD40 at the ready

The traditional dismantling method involves the following actions:

- The steering wheel is turned all the way;

- Several strong blows are applied to the steering knuckle;

- Vibration causes the tip to pop out.

But the method has two serious drawbacks.

- It will take special skill to deliver precise, but at the same time accurate and strong blows.

- This method can reduce the service life of steering racks.

Therefore, the best option is a puller. You can literally buy it for 200-300 rubles, but it will be useful in the future and will significantly preserve the integrity of the remaining parts when replacing the launch vehicle.

Dismantling works

Replacement

The replacement procedure is quite simple. Especially if you have prepared the connecting elements in advance and acquired a puller.

- Using a jack, lift one of the sides where you will begin to change the tips.

- Turn the steering wheel to such an extent that it is convenient for you to replace damaged elements.

- Treat the elements again with a penetrating liquid.

- Unscrew the fastening nut.

- Remove the tip from the steering knuckle hole. Here you just need a puller or the traditional old-fashioned method using a sledgehammer.

- Check the condition of the steering rods. Sometimes it is better to replace them in the first couple of wears. Besides, you still got into this knot.

- Replace damaged tips with new ones.

- Perform the reassembly procedure.

Assembly

- Do the same with the second wheel.

- We recommend that you think additionally about protecting threaded fasteners from moisture and dirt. To do this, the threads can be lubricated with lithol, graphite grease, a tube of a suitable diameter can be put on, or heat shrink can be used.

- After completing the replacement of the steering tips, visit a service station to adjust the wheel alignment.

- If you don’t want to go to a service station, then count in advance the number of revolutions when removing the old tip. The new one is twisted by the same number of revolutions.

- Drive onto a straight road and check whether the car does not skid to the sides when driving in a straight line.

One of the main conditions for a successful replacement is the choice of quality parts.

New part

What to choose

Finally, we will present several options for the most popular steering tips, which are used today when replacing a VAZ 2114. So you can decide for yourself what to choose and which ones are better.

They vary slightly in price, but are of good enough quality to serve your vehicle faithfully and reliably.

| Manufacturer | Price |

| AvtoVAZ | 620 rubles |

| TRACK | 620 rubles |

| VIS | 730 rubles |

| Lemfoerder | 830 rubles |

| Finwhale | 860 rubles |

The last two tips are foreign made. This makes their price higher. But the quality is somewhat higher than AvtoVAZ products.

Replacing a LV is not so difficult that you need to go to a service station and pay 500-1000 rubles for the work of the craftsmen. You can easily cope with this task yourself, relying on the video and instructions provided.

Algorithm for replacing steering rods on a VAZ 2106

An operation such as replacing VAZ 2106 steering rods is carried out on the basis of diagnosing the technical condition of the car’s front suspension. The unit is responsible from the point of view of the safety of the driver and passengers, so if it malfunctions or wears out, you should not hesitate - you need to install new parts.

Return

Operation of articulated rods

On most modern cars, the wheels are turned by a gear rack. But on cars of the classic Zhiguli family, instead of a rack, outdated technology is used using special rods, called “steering linkage”.

This mechanism is not very reliable. The maximum you can count on is 50,000 kilometers, although in reality the resource rarely exceeds 30 thousand km.

The structure of the mechanism is simple, and if you have experience in car repair and knowledge of the subject, you can carry out repair work or replace components yourself.

Return

What is a trapezoid for and how does it work?

The articulated rods serve as an intermediate link between the steering shaft and the wheel hub at the front; the force is transmitted through the steering knuckles. The main purpose is to turn the front wheels simultaneously in the direction in which the steering wheel turns.

This mechanism is attached to the front side members and structurally consists of the following parts:

- medium traction;

- right thrust;

- left pull.

The middle part is a tube with hinge mechanisms on both sides. The side parts consist of a short and a long tip. They are connected to each other with a special clamp and two bolts.

The principle of operation of a trapezoid is as follows.

- When you turn the steering wheel, the steering shaft and the gearbox shank begin to rotate. Thanks to the worm mechanism, more torque is transmitted to the bipod at a reduced number of revolutions.

- The bipod begins to rotate, and with it the middle rod on the left. At the same time, the middle rod transmits force to the right side of the trapezoid via a bracket.

- All three parts turn in one direction or another depending on which direction the steering wheel goes, and at the same time the front wheels begin to turn synchronously.

THIS IS INTERESTING: Citroen C4 will not start

A pendulum-type lever is attached to the second spar, which serves as an additional hinge. At the ends of all three rods there are conical pins, thanks to which the trapezoid is always in a strictly horizontal position, regardless of the travel of the car’s suspension.

Return

Design features of articulated rods

The middle element is the simplest in its structure. It is a non-separable rod, at the ends of which there are hinges. The conical fingers of the rods are installed in the holes of the bipod and secured with castle nuts, and a cotter pin is used for additional fastening.

The right and left rods consist of an outer tip with a pin and an inner tip with a hinge. They are connected to each other using a threaded clamp and two bolts. The design of the side rods consists of several parts and can be separated. This was done to be able to adjust the wheel alignment/camber. The length can be changed by twisting or unscrewing the threaded clamp, thus adjusting the position of the front wheels.

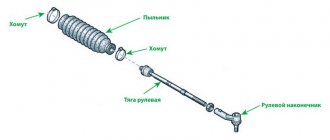

The hinged ends of all rods are identical in design and consist of the following parts:

- threaded pin and hole for a cotter pin;

- boot (protective cover made of rubber or silicone);

- durable metal body;

- cracker (support liner);

- spring;

- cover installed in the housing.

A ball joint (hinge) works on the same principle as a bearing, i.e. a metal ball rotates in a plastic housing. On more expensive and high-quality ball bearings, manufacturers cut a grease fitting into the cover on the body to allow lubrication using a syringe. External or external rods on both the right and left are the same, internal ones have differences. The right lever is bent so that it does not touch the gearbox housing when moving.

Return

Selection of new steering rod parts for VAZ 2106

Repairing the steering linkage allows you to replace only the failed part. Rarely does anyone change all the components at once. As a result, the articulated rods on many cars are assembled from different parts that differ in quality. At the moment, finding original spare parts for the VAZ 2106 is becoming increasingly difficult, since the car has long been out of production.

Due to the low resource, standard kits have long become a rarity. However, there are many other manufacturers that produce analogues of factory steering linkage parts:

- BelMag;

- Track;

- VIS;

- Delphi;

- Kedr et al.

These brands have proven themselves well among car enthusiasts; their products are of good quality. When choosing, it remains to recommend not to buy spare parts in dubious places, since the likelihood of purchasing a fake in this case increases sharply. You should not chase low prices; high-quality parts cannot be suspiciously cheap.

All steering rods of VAZ 01-07 models are identical, so when purchasing, do not worry about reading the numbers 2101 on the packaging. The only thing worth paying attention to is the mobility of the ball pin in the rod end. In the new product, it should be difficult to turn in the socket due to manual effort. After successfully replacing even just one tip, you cannot drive right away; you must definitely adjust the toe angles of the front wheels at the nearest service station.

Return