07/18/2021 7,855 VAZ 2115

Author: Ivan Baranov

Russian-made cars today are equipped with a variety of electronic devices that make it possible to ensure the normal operation of many components and assemblies. In this article we will talk about the controllers and regulators that are installed on the VAZ. Where are the sensors located on the VAZ 2115, what is their purpose, what malfunctions can occur in the operation of the devices - read below.

[Hide]

Sensor layout

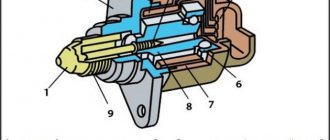

The sensors under the hood of the VAZ 2115 are located as follows.

1. Phase sensor; 2. Coolant temperature sensor; 3. Knock sensor; 4. Oil pressure sensor; 5. Oxygen sensor; 6. Crankshaft position sensor; 7. Speed sensor; 8. Idle speed sensor; 9. Mass air flow sensor; 10-11. Gasoline level sensor; 12. Antifreeze level sensor; 13. Throttle position sensor

Electronic engine control unit

The engine control unit is a kind of head control center for the entire car. This device processes all the readings provided by the vehicle’s sensors, regulates the engine control process, determines the required fuel and air ratios, generates a spark supply to the desired cylinder, and much more. The ECU is located inside the car, under the dashboard.

Location of all sensors on the injection VAZ 2114

It cannot be said that the VAZ 2114 is a very modern car filled with electronics. However, the list of sensors used that are connected to the electronic control unit is quite impressive on the fourteenth.

Each of these devices is responsible for certain functions and collects data transmitted to the main computer of the car. This way, the ECU controls the entire process and makes appropriate changes, so that the driver does not have to look for the reasons for the failure or insufficiently efficient operation of a particular unit.

Mass air flow sensor

Mass air flow sensor is one of the most expensive sensors in a car. It is responsible for counting the air passing through it. These readings are necessary for proper mixing of air and fuel. The flow meter can fail if the air filter is not replaced for a long time, as well as with strong ventilation of crankcase gases due to the high content of oil combustion products in the internal combustion engine. It is located on the air filter housing and is attached to it with two bolts.

Signs of malfunction:

- Uneven idle speed;

- Increased fuel consumption;

- Long start of the internal combustion engine;

Hall sensor replacement

Replacing the Hall sensor will not be particularly difficult. Even a novice car enthusiast can handle this work with his own hands.

The video below shows in some detail the process of replacing the sensor in the distributor of a UAZ car.

Typically, replacing a Hall sensor consists of several steps:

- First of all, the distributor is removed from the car.

- Next, remove the distributor cover and align the timing mechanism mark with the crankshaft mark.

- Having remembered the position of the distributor, you need to unscrew the fasteners with a wrench.

- If there are latches and stoppers, they should also be removed.

- The shaft is pulled out of the distributor.

- All that remains is to disconnect the terminals of the Hall sensor and unscrew it.

- By pulling back the regulator, the faulty part is carefully removed through the gap formed.

- The new Hall sensor is installed in the reverse order.

Checking the functionality of the Hall sensor not only allows you to accurately determine the cause of engine failure. Thanks to simple techniques, the motorist will save his time on repairs and also eliminate unnecessary waste of money.

Phase sensor

It is responsible for adjusting fuel injection only into the cylinder that is in the compression stroke, that is, fuel is supplied only through one injector to one cylinder. It is oriented along the camshaft, which is why it is called the camshaft position sensor. It works according to the Hall principle, producing an electrical impulse when a magnetic field is excited. If the VAZ 2115 phase sensor fails, fuel is supplied according to the principle of carburetor engines - into two cylinders at once. The result is a set of faults.

Symptoms of malfunction

The DPRV is located in the same place as the camshaft gear, on the cylinder head. The main symptom of the malfunction is high fuel consumption and loss of power. In addition, the computer displays error 0340 (sensor error) or 0343 (pulse level too high).

Examination

The malfunction of the DPRV can be judged by the error code and the burning CE lamp, but you can verify its functionality by checking the voltage at the power terminal A (12 V). The remaining terminals must not be live.

Crankshaft position sensor

You can often hear drivers with many years of experience calling this mechanism nothing other than a synchronization sensor. This name comes from the principle of operation of the device. The tasks of the DPKV are to synchronize the operation of the electronic unit and the gas distribution mechanism.

The VAZ-2114 is equipped with an inductive type DPKV. The cost of such a sensor is relatively small. If a vital controller for a car fails, most drivers prefer to immediately replace the device with a new one.

If the DPKV breaks down, further operation of the vehicle will become impossible. Without this mechanism, the fuel supply system will stop working, because the ECU will not receive information about when it is necessary to give a command to inject fuel into the cylinders. The location of the DPKV is in close proximity to the camshaft.

Crankshaft Positions

The VAZ crankshaft sensor is an element that allows you to transmit signals to the on-board computer about the position of the crankshaft. The performance of the combustible mixture supply systems, as well as the ignition system, depends on how this element works. And if we are talking about an injector, then the DPKV determines the functionality of the injectors.

This element is often called a synchronization regulator, since the control unit, having received data from it, detects the required moment of gasoline injection into the engine cylinders. If the device breaks down, the on-board computer will begin to transmit incorrect data, which will subsequently lead to malfunctions of the gasoline supply system. Accordingly, normal operation of the injectors will be impossible. The regulator itself is located next to the camshaft and the generator belt.

Crankshaft sensor for VAZ 2115

VAZ 2115 (Lada Samara) belongs to small class passenger cars, produced by the Volzhsky plant until 2012. The model had a single body type - a sedan and was equipped with a line of productive 8-valve engines with an injector fuel supply system. The crankshaft sensor of the VAZ 2115 is not a frequent consumable of the model, but given that the last “Fifteen” rolled off the production line 8 years ago, drivers are increasingly noticing signs of an internal combustion engine malfunction, which are typical for a breakdown of the DPKV.

DPKV

This sensor tells the ECU the current position of the crankshaft. It is inductive, that is, when the above node rotates, it produces certain impulses, the frequency of which allows the computer to make the necessary calculation. If the signal is lost, the power unit stops. That is, its malfunction will not even allow you to get to a car service center. Otherwise, it breaks very rarely.

In this situation, the ECU will show an error code - 0335. However, this does not always mean that it is the DPKV that has become unusable. Sometimes the same combination appears if the mass air flow sensor is not working properly.

Fuel level sensor

Indicates the remaining amount of fuel in the tank. Installed directly in the tank on the fuel pump glass. It fails when the graphite contacts on the electrical board are rubbed. When replacing, you should pay attention to its type number, which is indicated on the board, since all types of FLS have different resistance. If an unsuitable sensor is installed, large errors in readings may occur.

Signs of malfunction:

- Incorrect readings about the presence of fuel in the tank;

VAZ 2115 sensors, their purposes and malfunctions. List and tips »

VAZ 2115 sensors, their purposes and malfunctions. List and tips

The second one serenely ignores the signals - they say the engine is running, and the winking light is just a wedge in the electronic control unit. Both are wrong. If the system detects a failure in some sensor, this does not mean that the motor will fail right now.

Perhaps the contact has simply oxidized, and the problem can be fixed on the spot. But the signal can also indicate serious troubles that require an early visit to a car service center. To decide on further actions, you need to understand the instrument readings.

VAZ 2115 sensors, their purposes and malfunctions

It's pretty easy to remember. It is also easy to determine the probable causes of the breakdown and decide what needs to be done.

One of the most important in the series. Its readings determine many engine operating parameters:

- the calculation of the duration of permissible fuel injection is based on them;

TPS data is the basis;

On VAZs, the TPD is made in the form of a polymer film, onto which graphite tracks are sprayed, and a slider runs along them. The tracks have a clearly calculated resistance, and the stability of the sensor depends on the coherence of the system. However, the designers did something wrong - either in the material or in the technology. As a result, TPS is the sensor that most often fails. Most often, the path gets worn out, and when the slider hits a “bald” area, trouble begins;

When the gas pedal is held steadily, the car jerks;

The operating power drops noticeably;

There are dips and sharp jerks during acceleration;

- There is virtually no engine braking.

Knock sensor

Responsible for capturing noise from the engine and transmitting readings to the ECU. The principle of operation of a piezo element is reminiscent. When detonation occurs in the internal combustion engine, it generates a small voltage and transmits readings to the head engine control unit, thereby adjusting the fuel mixture. Installed on the cylinder block between the two middle cylinders.

Signs of malfunction:

- Clattering of fingers under load;

- Increased consumption;

Sensors VAZ 2114 injector 8 valves, DTOZH, speed and others

In addition to the above mechanisms, other very important devices can be found in various corners of the engine compartment. The location of the VAZ-2114 injector sensors is quite chaotic, some are located directly on the power unit, others in other places - the gearbox, on electrical circuits.

Some equally important mechanisms include:

- The knock sensor is sensitive to various engine vibrations. Based on the received pulses, the ECU determines the qualitative composition of the mixture. Located on the cylinder block.

- Engine temperature sensor - the only and simple, but extremely important task assigned to this device is to monitor the coolant temperature.

- Speed sensor – from the name itself it is clear that this controller is necessary to measure the speed of a car. The DS transmits impulses to the ECU, which processes them and determines the speed of the car; the resulting result is displayed on the instrument panel by the speedometer.

- Idling speed – not only reads information, but also corrects engine operation. DXH, using a special needle, controls the pipe - closes and opens. Due to this, the amount of oxygen supplied to the throttle assembly changes.

- Mass air flow sensor - reads the data and transmits it to the control unit, which, based on the information received, determines the optimal ratio of the various components of the fuel-air mixture. A breakdown of the air flow sensor leads to the fact that the car significantly loses power, and the driver begins to feel a significant increase in the amount of gasoline consumed by the car.

- DC - oxygen sensor, lambda probe. This controller is called differently among car enthusiasts, but the principle of its operation does not change. The DC informs the control unit about the amount of oxygen in the exhaust gases. The mechanism can be found in the receiving manifold.

These are the main and most significant sensors in the “fourteenth” system. It is also worth mentioning the FLS, which plays an important role - it determines the level of gasoline in the vehicle tank. Domestic drivers often experience difficulties with this device. Sometimes it works incorrectly and misinforms. But, as a rule, the FLS breaks down in old cars. You can repair the mechanism yourself, but it all depends on the severity of the breakdown.

Coolant temperature sensor

It is installed in the thermostat housing and is responsible for automatically turning the cooling fan on and off. The sensor is also responsible for adjusting the fuel mixture during a cold start; this can be noticed when starting the car in cold weather, with increased idle speed.

Signs of malfunction:

- The fan does not work;

- There are no warm-up speeds;

Oil pressure sensor

Oil pressure is an important indicator in engine operation; if it is absent, the internal combustion engine will not be lubricated, which will lead to engine failure. This sensor informs the driver about the presence or absence of pressure in the internal combustion engine lubrication system. The sensor is installed on the cylinder head housing and is mechanical.

Signs of malfunction:

- No oil pressure;

- The oil pressure indicator does not light up;

VAZ 2115 sensors: their features and purpose

Russian-made cars today are equipped with a variety of electronic devices that make it possible to ensure the normal operation of many components and assemblies. In this article we will talk about the controllers and regulators that are installed on the VAZ. Where are the sensors located on the VAZ 2115, what is their purpose, what malfunctions can occur in the operation of the devices - read below.