Reasons to replace the crankshaft

The crankshaft is the most loaded part in a piston power unit. The main reason for its early damage is the lack of timely maintenance. In particular, if the car owner does not monitor the amount and freshness of engine oil and allows the unit to operate at high speeds for a long time, the crankshaft will fail much faster .

Read more about the main causes of part damage:

- low pressure in the lubrication system caused by insufficient oil level or other factors, refueling with low-quality auto parts and water hammer - because of this, cracks appear on the crankshaft;

- breakdown of the clutch mechanism, improper operation of the vehicle - causes wear of the end part of the crankshaft thrust rings;

- dilution of the lubricant caused by severe overheating of the engine or the ingress of flammable liquid into it - usually leads to the appearance of scuffs on the journals, the development of places for oil seals and other damage;

- clogging of the oil filter and operation of the power unit on dirty oil;

- improper tightening of bolts during repairs, consequences of an accident - key grooves, threaded fixing holes, seating areas for bushings, and pins are often destroyed.

Wear of this unit negatively affects the operation of the motor. The latter is not able to develop the same power. Oil pressure drops sharply even at low speeds. Complete disassembly of the internal combustion engine is inevitable, since failure can lead to severe destruction of the cylinder block. In such cases, in order to protect the engine, the engine crankshaft is repaired or replaced.

How to replace the crankshaft oil seal?

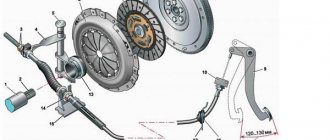

On most internal combustion engines, if oil oozes from under the crankshaft, this indicates worn out seals. Their purpose is to seal as much as possible the hole in which the crankshaft is installed. They prevent lubricant from leaking out of the internal cavity. There are front and rear oil seals. One is located on the pulley side, the other on the flywheel. It is easier to replace the front crankshaft oil seal.

On some vehicles, the location of the cuffs may differ. For example, on rear-wheel drive classic Zhigulis, the oil seal is placed in the crankshaft shield behind the support bearing. But on VAZ 2109, 2110, Lada Granta, Priora and Kalina, the oil seal is most often located in the cylinder block.

The rapid abrasion of the cuff is not surprising. Its resource is limited, since it is constantly in contact with the moving crankshaft. In addition, the seal is exposed to high temperatures. Therefore, even the highest quality products last no more than 200 thousand km of car mileage. Engine overheating, as well as the use of dirty or low-grade engine oil, further reduces its service life.

To bore the crankshaft or not

Now you need to determine whether the crankshaft should be bored or not, pay attention to the crankshaft journals, marks and wavy grooves are visible on the journals, run your finger along the journal, if marks and grooves are visible on the journal and by running your finger you will feel the slightest waviness, don’t even think about it, take it to boring crankshaft. But don’t buy liners for the crankshaft right away; after boring, the driller will tell you which liners to buy, as it happens that due to excessive wear on the crankshaft journals, they bore two sizes larger.

Photo. Heavily worn-out crankshaft journal of the Volga

It rarely happens that the crankshaft journals look good, pay attention to the main liners and if you see shiny abrasions on the liners, this indicates that the crankshaft is loose and has a large gap, and dangling in the liners gets shiny stripes.

Photo. Liners with signs of heavy crankshaft wear

But don’t get confused, shiny stripes on the liners may also appear when installing the crankshaft when tightening the cushion with the liner, when the crankshaft becomes clamped and barely turns or jams. In this case, firstly, the grinder made a mistake when grinding the crankshaft, secondly, debris got under the liner, so when installing the liners, carefully wipe the beds (the place where the liner is installed is called the bed).

If you simply replace the liners without grinding the worn crankshaft, then it’s like throwing money away, the effect will be zero. Also, if the engine had very low oil pressure before the repair (at idle the pressure light is on), this already indicates that it is necessary bore the crankshaft for repair liners.

It’s better not to be lazy and take the crankshaft for boring, and pay a little extra money, than to simply replace the bearings.

You can't fool iron!

Using these tips, you can easily determine without a micrometer whether you need to grind the crankshaft or not.

Symptoms of a problem

If you repair the crankshaft yourself, you can save a lot on car service costs. Therefore, it is worth understanding its diagnosis, repair and installation. If repairs are not carried out in a timely manner, the engine may seize, and this can lead to more serious repairs. The following are signs that serve to identify malfunctions:

- when the engine is running, the oil level control light does not go out, which indicates a decrease in oil pressure in the system;

- at medium and high speeds a metallic knock is heard in the engine, which increases with increasing speed;

- engine jams.

The cause of the first two malfunctions is the wear of the main and connecting rod journals. In this case, the distance between the neck and the liner increases, which leads to a decrease in oil pressure. If the distance is too large, the shaft may run out, causing metallic sounds in the engine. If the engine jams, it is better to replace the crankshaft. To diagnose the serviceability of the crankshaft, it should be dismantled and cleaned. It is better to remove the part together with the engine.

We remove the part from the VAZ 2106 for inspection

After removal, you need to perform a visual inspection of the necks and cheeks, according to which a decision is made on the need for grinding or replacement. No special instruments are needed for inspection; you can tell by touch. If scratches and burrs are found on the journals, the part is sent for boring. Boring can be done 4 times. Each boring increases the dimensions of the liners by 0.25 mm. After dismantling the crankshaft, you need to evaluate the size of the liners and whether they will allow boring. If grinding has never been performed, then the liners have an icon without any numbers.

Main bearings for VAZ 2106

If cracks are found, the crankshaft must be replaced. You can send it for welding, but usually restored parts last no more than 50 thousand kilometers. After boring, you need to polish the journals. Then the journals and crankshaft need to be washed with gasoline. The oil passages should also be thoroughly cleaned to prevent contamination from entering the bearings. After washing with gasoline, you need to blow out the oil channels using compressed air.

Purpose of crankshaft bearings

These parts are sliding bearings that ensure acceptable operation of the connecting rods when they rotate the crankshaft. At this very point, during the operation of the power unit, colossal loads arise on the parts. Imagine, the piston, after igniting the fuel-air mixture, gains a simply monstrous speed and at the same time, at the lowest point of its stroke, it encounters an obstacle in the form of a shaft elbow, which provides it with a reciprocating maneuver. It is this “return” that puts the greatest load on the connecting rod bearings.

Of course, no one has yet canceled the laws of physics, therefore, due to friction, sooner or later the liners will fail, that is, they will no longer provide the contacting parts with minimal friction. As they wear out, the oil pressure will decrease and the so-called oil film will no longer provide the proper degree of protection.

It is also worth knowing that liners are divided into two groups: connecting rod and main. To see the difference between them, look at the image below to see which ones are located and where:

Types, design and characteristics of crankshafts

Currently, two types of crankshafts are used in engines and other piston machines:

- Solid (non-separable);

- Composite (collapsible).

Parts of the first type are made from one metal blank; all parts are formed on the shaft during certain machining operations. Composite shafts are made from several parts that can be removed and replaced if necessary.

Any shaft, regardless of type, purpose and features, has a fundamentally identical design. In general, the shaft is divided into several parts:

- Main journals are parts of the shaft that make up its longitudinal axis; the main journals rest the shaft on the engine block. The shaft is mounted into the block through liners (sliding bearings) located on the main journals;

- Crankpins are parts that act as supports for installing connecting rods. The connecting rods are mounted on the shaft through liners located on the connecting rod journals;

- Cheeks are transverse parts connecting the main journals with the connecting rods. The length of the cheeks determines the stroke of the piston in the cylinder and, accordingly, the torque developed by the engine;

- Counterweights (not in all shafts) are a continuation of the cheeks on their reverse side. These are loads that balance the inertial forces that arise during the movement of the connecting rod journals and connecting rods. Counterweights reduce shaft imbalance, eliminating runout and unloading the crankshaft parts;

- Toe (front output part of the shaft) - a part extending beyond the engine block on the side of the first cylinder, intended for mounting a timing gear or gear wheel, as well as a gear or pulley for driving engine attachments;

- The shank (rear output part of the shaft) is a part that extends beyond the power unit block from the side of the last cylinder (more precisely, from the side of transmission of torque to transmission units), usually it is made in the form of a flange for mounting the flywheel, and the drive gear can also be located here Timing belt

How to install crankshaft cushions correctly

Remember this, the crankshaft cushions cannot be swapped, from which place the cushion was removed, it must be placed there, and the lock on the liner must be placed with the lock of another liner. It’s better to do this: before spinning the crankshaft, fill the pads with core points, the first pad is one dot, the second pad is two dots, etc. I use a set of numbers, but you may not have a set of numbers, then use a core. Also, when you put marks on the pillows, fill them so that you can understand where the front and the back of the pillow are, hit the marks closer to the edge of the front of the pillow, then when assembling, if you are distracted, then by looking at the placed pillow you will understand by the marks that you were not mistaken. VAZ engine mounts have factory marks on the mounts; you don’t have to mark them, but you can mark them and it won’t be any worse.

Photo. The number 2 I stuffed on the second pillow, the top of the number faces in front

I had a case, they asked me to look at the engine, they simply replaced the liners on it and did not bore the crankshaft. So the crankshaft turned out to be clamped, it immediately surprised me, how can the crankshaft be clamped when they simply replaced the old liners with new ones.

Everything turned out to be very simple, this master was told by another master that the pillows should not be screwed lock to lock on the inserts, but vice versa. I twisted the pillows as expected, lock to lock, and the crankshaft started spinning. But looking at this crankshaft I immediately realized that all their work was in vain, even at a glance it was full of grooves, I told him that the work would be of no use. But he decided that everything would be fine.

He didn’t drive for a long time; the oil pressure in the engine never appeared, even though he installed new liners.

How to remove the crankshaft without removing the engine

Question: is it possible to take off socks without taking off felt boots?

Answer: of course you can, but it’s better to throw away the felt boots after that.

Yes, there is nothing masochistic there, everything is done with hands and head on.

I apologize for my categorical judgment, but... There are no words.