A wheel bearing is vital to a car as it helps the wheels rotate. To “kill” him you have to try! In production, high-quality material is used, because the part is subjected to a high degree of load. As soon as the first signs of bearing failure appear, it should be replaced quickly, otherwise damage to the car may result in the form of suspension repairs. You can diagnose a malfunction yourself if you learn to “hear” your car, so we’ll talk about that.

Front wheel bearings

Causes of malfunction

A fairly strong part of the hub is the bearing. Often struts break, bushings and other attached parts wear out, and the wheel bearing can sometimes fail. Let's look at the 5 main causes of part failure:

- Great mileage. In this situation, every automotive component is subject to wear and tear. On average, after 80 - 120,000 km, you can hear the first crunches, which indicate that it is time to change the bearing.

- Gaps in tightness. The spare part contains lubricant, which is covered with plastic or rubber casings. When the protection is destroyed, the lubricant begins to come out, as a result, the wear of the part increases many times over. And after 2000 - 4000 km, you can notice that a characteristic hum has appeared.

- Careless driving. Constantly hitting holes at high speed can cause bearing failure. It is possible that other suspension parts will fail first, but it all depends on the case.

- Incorrect pressing. A secondary reason is when, during repairs, a new part was pressed in incorrectly, for example, diagonally. Due to the incorrect position, the bearing will wear out faster and after three thousand kilometers the part will need to be replaced again.

- Strong puff. This happens more often with Russian cars when the bearing is overtightened during repairs. Due to heating above normal, the resource is reduced and you can prepare for another breakdown. Such actions must be performed based on the manufacturer's instructions.

These were common causes of breakdowns, but the last 2 options were the “crooked hands” of service station workers. It is better to change spare parts in trusted services.

How to identify faulty wheel bearings

There are several ways to determine if your front or rear wheel bearings are faulty. Moreover, all of them do not require special skills or specialized tools.

First of all, pay attention to the following signs of possible front or rear bearing failure:

- a hum when driving, which depends on the speed of the car, and not on the gear engaged;

- light metallic knock when driving over bumps;

- increased play in the steering wheel, its shaking when driving at high speed on a road with defects in the road surface (one of the symptoms of a faulty front wheel bearing).

The main and most obvious sign of a wheel bearing failure is a hum. Its source is determined by a fairly simple method. On a flat, straight, and preferably empty stretch of road, accelerate to a speed at which the hum occurs. After this, slightly “throw” the steering wheel left and right. If the noise intensifies when you turn the steering wheel to the right, the bearing on the right is faulty; and vice versa.

After this, we hang out the side of the car on which the faulty bearing was identified. We rotate the front and rear wheels manually, rocking them in the horizontal and vertical plane. If a slight step-like rotation is felt on one wheel, the characteristic rustling of rolling balls or rollers is heard, or there is increased play - the wheel bearing is acting up on this particular axis.

Also, one of the signs of a wheel bearing malfunction is strong heating of the hub. If you suspect problems with the wheel bearing, after the ride, carefully touch all the wheels with your hand. The hub that is noticeably hotter than the others has problems with the bearing (or brake system).

Signs of breakdown

You can identify a node malfunction in one of the following ways:

- initial stage – humming, light tapping in the area of the bearing;

- a hum when turning a car (sometimes can be confused with tire noise), after some time the sound will be similar to the launch of a jet plane;

- the noise disappears when turning, but when driving into a straight lane, a humming noise appears;

- crunching noise at the wheel bearing when driving.

The bearing mechanism contains spherical elements, and it is they that reproduce such sounds. The above reasons indicate that the part holder is broken and the position is uneven.

There are other symptoms of a breakdown: vibration when driving is reflected in the steering wheel and body. This is a sure sign of a damaged clip. In this situation, the wheel can instantly jam, and it’s good if the car moves at low speed or slows down. The part must be changed immediately to prevent an emergency.

When the car pulls to the side, the mechanism may not be working properly and the bearing may be jammed.

Self-diagnosis

When turning left, the car body rolls to the right. The main load falls on the right side, and the left wheel is unloaded. At a speed of 15 km/h, turning the steering wheel sharply to the left, the extra sounds disappear, which means that the reason is not in the left wheel bearing. When the noise disappears when turning to the right, the problem is in the right bearing.

You can diagnose using a lift, overpass or jack. After starting the engine, accelerate the car to 80 km/h in 4th gear with the clutch depressed. Switch to neutral when leaving the car, listen and find the source of the noise. When the wheel is not driving, you can spin it yourself.

As soon as the wheels stop, you need to grab the bottom of the wheel with one hand and the top with the other. Then swing it slightly in a vertical plane. It is worth checking in the same way in a horizontal position, grasping the edges of the wheel with your hands. If you find a slight play, this indicates that the bearing is quite damaged.

In some cases, play is caused by failure of other parts of the suspension or steering system. Then you will need an assistant who will press the brake pedal, and at this moment you will swing the wheel in the vertical direction. If there is still play in the brakes, the reason is in the suspension. When play is eliminated, this is wheel bearing wear.

Another way to determine if a part is faulty is to move it in a “snake” motion. You need to accelerate the car to 60 km/h and swing the steering wheel to the left - driving through the snake. At this moment you need to listen and determine the presence of extraneous noise. When sounds are heard when turning left, the right front bearing is faulty, and if when turning right, the same is true for the left part.

Is it possible to drive with a humming noise from the wheel bearing?

It is not uncommon for motorists to drive over 100 km/h on the roads with faulty bearings. And since the part is responsible for turning the wheel, this is very dangerous. That is why, when the bearing is humming, you can drive your car at a speed of no more than 40 km/h. Otherwise, due to a wheel lock, the car may be thrown onto the side of the road or into the oncoming lane.

To summarize, we can add that good wheels cannot have play. Only timely diagnostics, whether at a service station or in your garage, will keep you safe on the road.

Rear hub bearings

It turns out that increasing the life of a wheel bearing is not difficult

If a hum appears while driving, especially when accelerating, then the wheel bearing needs to be replaced. Another sign of wear of this element is the strong heating of the brake disc, even during a short trip. In this case, the car’s braking system operates normally, without failures.

But replacing a wheel bearing is not a cheap pleasure. This is due to the fact that car manufacturers produce maintenance-free hubs, that is, when one element wears out, the unit is completely replaced. This concept is positioned as a faster repair without compromising safety, since when installing a new bearing it must be correctly aligned. Another factor is the use of high-strength materials that can withstand enormous loads.

See also: How to diagnose car suspension problems

But practice shows that nothing can save you from potholes, vibration, temperature, pollution and moisture. No vehicle is operated under the conditions created during testing.

It is worth noting that incorrect installation of the wheel bearing is a very common cause of premature wear. Here the human factor comes to the fore. That is, in order to ensure long-term, safe operation, the master must have practical experience, be armed with a special tool and perform the work conscientiously.

Experts note a high percentage of low-skilled craftsmen at Russian service stations. This significantly reduces the quality of work (even with a special tool) and increases the number of claims against the manufacturer from vehicle owners. Foreign brands monitor similar dynamics and make decisions aimed at reducing the number of complaints. But this is not done at a loss to the companies that produce components.

See also: Ten sounds that indicate a car breakdown

Services do not remain at a loss either. In addition to making repairs easier, they increase profits. This is simple arithmetic, since the average car owner pays 50% of its cost for installing a component. Obviously, a complete hub is more expensive than a single bearing. It turns out that the decision made by car manufacturers is beneficial to everyone except the car owners. Their vehicle maintenance costs increase. So how can you avoid this and prevent wheel bearing wear?

Design and operation: Wheel bearing

Car owners have more than once encountered a situation where the chassis of their vehicle required replacing the wheel bearing. It’s good if the car enthusiast “played ahead of the curve,” but it’s much worse when a howling bearing ultimately becomes the cause of a serious accident with all the ensuing consequences. We will devote today's article to wheel bearings - their purpose, types, and the reasons why they fail over time.

Main signs of wheel bearing wear

- Identifying dangerous wheel play requires urgent consideration of how to change the wheel bearing;

- The presence of a constant hum while the vehicle is moving along a given route;

- The appearance of noise and crackling when entering sharp turns;

- You can feel the steering wheel beating, the car disobeying when performing maneuvers;

- Heating of the hub and its components, as a result of unwanted friction and wear of the bearing, because for some reason the lubricants were used up. As a result, the temperature inside the hub increases, lubricant residues are washed out, and the hub body and its bearing are contaminated with road dust and gravel.

Determination of wear

So it turns out that the question of how to change the rear wheel bearing is considered relevant, and every driver faces this problem and changes small elements of the chassis system on his own or contacts service centers or service stations.

Brake discs of the correct diameter

Another reason for the accelerated destruction of bearings is that the car is equipped with discs of increased diameter, the maximum allowed by the car manufacturer. This does not take into account the shift of the center of gravity of the part to the outer edge. This leads to an imbalance of dynamic loads and uneven wear of component elements.

Also, do not forget that the wheel rim is designed to take on all the negative impacts from bad roads. Due to frequent impacts on bumps and potholes in the asphalt, the disc is subject to deformation and its center of gravity shifts to the side. This is called loss of center balance.

When driving at high speeds, the centrifugal force of an unbalanced disc will transfer increased load to the wheel bearing. This will undoubtedly lead to its accelerated destruction.

What types of wheel bearings are there?

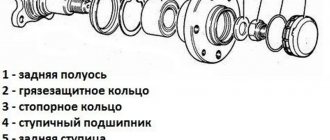

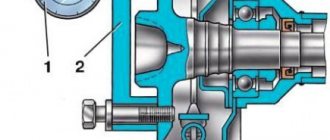

In the modern automotive industry, there is a significant difference between wheel bearings used in foreign cars and bearings intended for Russian models. Foreign parts have a much more complex design, ensuring the highest level of reliability. Foreign concerns mainly resort to the use of “HUB” wheel bearings of the 2nd and 3rd generations. These bearings have flanges for attachment to brake discs or to the wheel hub housing. Often the bearing is attached to both of these parts at the same time. In addition, the HUB-2 and HUB-3 bearings are equipped with a special electronic sensor. Such a device greatly simplifies the installation and alignment of bearings, allowing the degree of wear to be determined with high accuracy.

With domestic cars everything is noticeably worse. Front-wheel drive VAZ models still receive obsolete double-row sealed “HUB-1” bearings. On Nivas, engineers use single-row tapered wheel bearings. It's about the same story with other models, including commercial cargo vehicles. These bearings are quite difficult to install, have strict requirements for the accuracy of the tightening torque and require a constant supply of large amounts of lubricant. Unfortunately, apart from 1st generation “HUB” bearings and zero-class bearings, Russian manufacturers do not produce anything.