However, according to traffic rules in the Russian Federation, the light must be turned on constantly, regardless of whether it is dark or light outside. The principle of this sensor is based on measuring illumination using photocells. If the automatic headlight switching mode needs to be turned off, the fuse is removed and the headlight and parking light control returns to normal mode. The connections can be soldered, but for full-fledged work, an ordinary insulated twist will suffice. Of these five wires, two wires go to the rear of the car, this is the license plate light.

Pro Tips

Of course, drivers who have at least basic training in electrical engineering and experience in doing this kind of work with their own hands can do the job efficiently with their own hands.

Professionals also advise that before starting work, you should really assess your capabilities. In some cases, in order to avoid problems, it is better to fork out some money and entrust the work to a professional auto electrician.

If the work will be done independently, then it is recommended to arrange all tie-in points inside the cabin. At the very least, they will be protected from the negative effects of precipitation.

It is more rational to make the connection points themselves by twisting the wires - this method is in no way inferior to soldering, and in conditions of increased vibration it turns out to be more resistant to loads.

The installation should not be carried out in such a way that, with the maximum permissible trajectory of movement of the wiring branches, their tension does not arise; all bending points of the wiring located near the metal fragments of the body must be protected using a polyvinyl chloride tube.

It is not advisable to follow the recommendations of amateurs who claim that to obtain the desired result, you can install a jumper in a certain place on the car's mounting block, without installing an additional relay. Failure to comply with basic electrical engineering rules is a real cause of serious problems, for example, headlights may turn on bypassing the fuse.

Carrying out installation work with your own hands will require maximum care and accuracy from the car owner. During operation, the possibility of moisture and mechanical deforming loads on system fragments should be excluded. It is not recommended to use gas-discharge lamps in automobile electrical systems.

If you are afraid to use homemade versions of Eurolight connection devices, you can install devices made in the factory, for example AvtoSvet AS, PHARAON, Skybrake M5, Meguna T 7.2, etc.

Benefits of installing the system

First, we will look at the main advantages that using automatic light switching options gives us:

| Convenience | Now you will not forget to turn on the lights, and you will not be fined by the traffic police. As practice shows, the majority of such offenses are committed precisely because drivers forget to turn on the lights when starting to drive. In addition, you will not have to be distracted, you will know that the system works automatically at a certain point in time |

| Battery preservation | As practice shows, very often after finishing driving, drivers forget to turn off the lights, as a result of which the battery runs out; if such cases are repeated periodically, the battery will fail very quickly. The presence of such a system allows you to eliminate such troubles, because the shutdown will also be carried out automatically |

| Ease of work | You can easily implement any of the options described below with your own hands; the installation instructions are simple and clear, so you can do it without outside help, especially since the delivery set includes all the elements necessary for installation. The main thing is to be careful and use only high-quality connection methods; twisting and electrical tape are unacceptable |

| Low costs | The price of the required elements is low, so you will not incur large expenses. The most important thing is to choose a high-quality option that will ensure good system operation |

The automatic low beam headlight switch in some models requires moving the regulator to a special mode, sometimes it is marked with the letter “A”

Workflow Description

If a relay for switching low and high beam headlights is already installed on the car, then you do not need to upgrade the system; if problems arise, you need to use the diagram to figure out where the required element is located to check its functionality.

Everything here is simple and clear, but if there are no relays, then we recommend installing them, as this will increase the reliability of the system and improve its operation.

Preparatory activities

When doing the work yourself, make sure that all the required elements are at hand, after which you can begin the process:

- To begin with, place the car so that you can work comfortably and nothing will disturb you. Of course, the ideal option is a garage, but if you don’t have one, then you can do everything you need right on the street;

- First of all, you need to open the hood, then turn on the low beam in the car and use a tester to find the power supply. The work is simple: you measure the voltage at each contact where it is - that’s where the power supply is supplied;

- Next, you need to turn off the ignition and remove the terminal from the battery to eliminate any troubles in the working process;

- Then you disconnect the connector from the low-beam headlight and try to get the power wire out of it, if it works - great, if not - cut the wire, strip it and crimp it with a terminal; it is best to close all open areas with a cambric;

The power wire is carefully removed from the connector

- You also need to connect a long wire to the positive terminal of the battery, how to do this depends on the characteristics of your car, decide for yourself how to do this most reliably and efficiently. This wire is carefully routed from the battery to the headlight. It is best to lay it in a standard corrugation or attach it to the car’s wiring harness from the outside, the main thing is that it does not dangle haphazardly;

The wire should be laid along existing harnesses and secured with plastic clamps - A fuse is embedded anywhere in the supply wire; you must decide for yourself where it will be best protected from adverse influences; it is important that, if necessary, you can easily reach it.

Connection

The instructions for connecting the relay are quite simple and clear; first, read the diagram to understand the design.

Connecting low beam headlights via a relay is such a simple operation that even someone who knows nothing about car electrical equipment can handle it

- First of all, take a short-length wire to ground; the easiest way is to connect it to ground on the lamp connection chip; this is the simplest and fastest option (most often it is a double brown wire);

- Now you need to connect all the wires to the relay, let's look at the work using the example of a relay from a VAZ: the wire from the steering column switch is connected to the 86th terminal, the line coming from the lamp connector is connected to the 87th, the ground is placed on the 85th, and the supply wire from the battery is located on terminal No. 30. All connections are made using chips - no twists or tape;

High-quality connections are the key to design reliability

- Decide in advance where the relay will be located; you cannot place it near the engine, since if this unit is constantly heated, its service life is significantly reduced.

Advice! You can place the relay next to the battery, it all depends on what is more convenient in your case.

Automatic switching on of headlights via a pressure sensor.

In the third connection method, automatic turning on of headlights, Kulibins suggest using an emergency engine oil pressure sensor. The connection diagram is identical to that described earlier, only the relay coil is connected not to the generator, but to the emergency oil pressure sensor. In this case, the headlights will light up immediately after pressure appears in the lubrication system. The disadvantage is that the headlights turn on regardless of the serviceability of the generator. When the oil pressure is low at idle, if the engine condition is not the best, the headlights will begin to flash when the sensor is triggered.

Only the simplest and possibly primitive ways of implementing automatic headlight switching are discussed here. On the Internet you can find many more schemes, both simple and quite complex. Also in stores they can offer you ready-made blocks to implement this function.

admin06/06/2013

comments 2

Subscribe to comments

- Danik — January 22nd, 2015 at 9:29 am

Hello! On my Nissan Maxima there are two wires from the headlights, left and right, to the switch! Both via relay and power plus! What about the connection?!

admin — January 23rd, 2015 at 20:00

There are several headlight connection diagrams on the Nissan Maxima. Depends on the year of manufacture and configuration. But I didn’t come across any relays in the headlight switching circuit. A special feature of the circuit is the installation of a switch in the headlight circuit, between the fuse and the headlight lamp and having constant power, regardless of the ignition being turned on. Execution of the scheme depends on what you want to achieve. The simplest solution is to install a relay in the headlight circuit, the coil of which receives power when the ignition is turned on. In this case, you will have to install two of them on the fuse side. You can get by with one, but it will have to be placed on the minus side, which must be combined for both headlights. Answer

A comment

Name *

Website

This site uses Akismet to reduce spam. Find out how your comment data is processed.

« Popping noise when turning on the ignition of a VAZ

Battery Operation »

Tags

VAZ, VAZ malfunctions Sensors Ignition Injector Devices Starter Circuits Electric cars Power supply VAZ 2110 gazelle gazelle business recorders car repair

Recent Entries

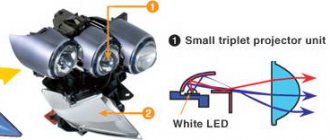

- Laser headlights.

- Advantages and disadvantages of halogen lamps

- Design and principle of operation of parking sensors

- Multifunctional device Roadgid X7 Hybrid GT

- Malfunction of the GAS ignition system

Archives

Archives Select month September 2021 August 2021 July 2019 December 2021 August 2021 July 2021 June 2021 May 2021 April 2017 March 2021 December 2021 November 2021 October 2021 September 2016 August 2021 July 202 1 June 2021 May 2021 April 2021 March 2016 February 2021 November 2015 October 2015 August 2015 July 2015 June 2015 May 2015 April 2015 March 2015 February 2015 January 2015 December 2014 November 2014 October 2014 September 2014 August 2014 July 2014 June 2014 May 2014 April 201 4 February 2014 January 2014 December 2013 November 2013 October 2013 August 2013 June 2013 May 2013 March 2013 February 2013 January 2013 November 2012 October 2012 September 2012 August 2012 July 2012 June 2012 May 2012 April 2012 March 2012 February 2012 January 2012 December 2011 November 2011 October November 2011 September 2011 August 2011 July 2011 June 2011 May 2011 April 2011

- Accumulator battery

- Video

- Generator

- Sensors

- Diagnostics

- Ignition

- News

- Equipment

- Devices

- Repair

- Spark plug

- Starter

- Scheme

- Devices

- Electric cars

- Electricity supply

Automatic switching on of headlights upon ignition

In order to organize such operation of the lighting elements, it is necessary to connect them to the ignition power source, and as many know, some devices can be connected at any position of the ignition switch, while others begin to function only when the ignition is already on. Based on this, the most convenient place to connect the headlights is the heater switch button (the rightmost switch block).

For this scheme you will need:

- any standard five-pin relay;

- diode;

- wires.

This is interesting: Photo spies saw the successor to the Toyota Supra

We recommend: What types of carburetor cleaners are there and which one is better?

Next, we need:

- Remove the size switch (switch block on the leftmost side).

- Disconnect the positive wire from the key block responsible for the low beam operation (usually this is a green double wire) and connect it to the relay.

- You need to insert an additional wire into the positive wire that goes to the heater switch and also connect it to the relay.

- Connect the wire that powers the headlights to the relay.

- Throw the wiring to minus (to the body).

The connections can be soldered, but for full-fledged work, an ordinary insulated twist will suffice. As a result, automatic low beam headlights will work as soon as you turn on the ignition.

However, this method is considered not the most economical, since the headlights start working immediately, which is not very important in winter, when the engine needs to be warmed up or when repairing a car.

To avoid such inconveniences, you can complicate the circuit a little so that the low beam turns off while parked, regardless of whether the ignition is working or not.

Automatic headlight switching: diagram, available options, advantages

It is quite logical that the automatic switching on of the low beam is the very option that allows you not to be afraid of the situation when the driver forgot to turn on the lights before the trip. At the same time, many imported cars have an automatic switching device, but it is activated only taking into account certain conditions (change in lighting, signal from the rain sensor, etc.)

However, according to traffic rules in the Russian Federation, the light must be turned on constantly, regardless of whether it is dark or light outside. Some owners, in order to remember to turn on the lights, are forced to leave the car in the parking lot with the headlights on during daylight hours, thereby draining the battery.

As you can see, the problem is very relevant. To solve the problem, the most rational way out of this situation is a system for automatically turning on low beams, which will work regardless of the degree of illumination and other conditions, and also operate without driver intervention.

In other words, the headlights must turn on parallel to the start of the internal combustion engine. It is also possible to turn off the lights after the engine is turned off. By the way, for cars that do not even have a standard light sensor (domestic cars, old or budget new foreign cars), which is triggered in case of changes in illumination, constantly switched on low beam will improve safety when driving through tunnels, under bridges, etc.

So, the demand for such systems has led to the fact that various enterprises that specialize in the production of electrical equipment began to produce ready-made solutions for cars (for example, Skybrake M5, AvtoSvet AS, Pharaoh, etc.) You can also note a large number of circuits and devices that enthusiasts and experienced car enthusiasts create on their own.

If there is no desire to install homemade devices on your car, then factory solutions will be the best option. However, functionality may be somewhat limited. The main thing is that in both the first and second cases, such solutions make it possible to automatically turn on the headlights; the light turns on synchronously at the moment the ignition is turned on or the engine is started.

At the same time, we note once again that different schemes differ in functionality. For example, you can make sure that only the headlights are on during the day, and at night the lights are turned on, etc.

Schemes for automatically turning on headlights when the engine starts

Let's look at a few of the most popular solutions. The main task for automatically turning on the headlights is to supply power to it. This power can be taken from the ignition. However, it should be remembered that there are often other devices in the car that are powered by the ignition switch. This may be difficult.

For example, if the radio turns on after the first turn of the key in the lock, the headlights may also turn on at that very moment. Such aspects need to be taken into account separately. It turns out that the engine is turned off, and the low beam is already on.

To avoid such nuances, the optimal scheme is considered to be one in which the supply occurs through a button (relay) at the moment the contact group in the ignition switch is closed when starting the internal combustion engine. The headlights will turn off, respectively, when the circuit opens and the engine stops.

Note that many drivers believe that such a scheme leads to increased loads on the electrical circuit. In practice, a properly executed connection minimizes or eliminates such loads.

To implement automatic switching on of lighting fixtures using the simplest do-it-yourself scheme, you need to purchase:

- standard relay (five-pin),

- wiring and diodes;

A more complex and at the same time more convenient scheme is when, in simple words, the headlights are powered by the parking brake or oil pressure sensor. To successfully implement such a solution, you will need to have 2 transistors, wiring, a relay and a K561TP1 type chip or similar.

Let's start with the first diagram. When installing, the best option is to turn off the stove, which is located on the switch block. All work boils down to removing the headlight switch, then disconnecting the “+” wire and the key block through which the low beam headlights are turned on.

The connection itself is made using a double wire that connects to the relay. Another wire is inserted into the “+” wire that goes to the heater switch, which is also connected to the relay. Next, a wire is pulled to the relay, through which power is supplied to the headlights themselves. Another ground wire is thrown onto the body. This completes the connection.

We also recommend reading the article on how to install a keyless engine start button with your own hands. From this article you will learn about the features of installing a start-stop button in a car, as well as what advantages and disadvantages keyless engine starting has.

All that remains is to either resolder all the connections, or carefully insulate all the “twists”. The result is a system for turning on the low beam when the ignition is turned on.

The disadvantages include the fact that in winter the load on the battery at the time of start-up will be higher, the car will warm up with the headlights on and will consume additional fuel, etc.

- To get rid of the shortcomings, you can use the following scheme. Improvements will make it possible to turn off the light after stopping the vehicle, regardless of turning on the ignition itself. To do this, the connection is made to the parking brake or to the oil pressure sensor. As mentioned above, it is based on a microcircuit, and the connection is made through a “handbrake” or an oil pressure sensor.

In the case of a sensor, after turning off the internal combustion engine, the pressure in the oil system drops. This leads to the fact that the contacts of the oil pressure sensor open, power is supplied to the capacitor, voltage goes through the transistors to the relay and the headlights turn off.

Also, after stopping the internal combustion engine, power from the sensor is supplied to a diode lamp, which is installed on the instrument panel. Also, the capacitor in the headlight control circuit will begin to discharge and power will not be supplied to the relay.

Although this scheme allows you to “bypass” the ignition switch, it is also not without some disadvantages. If the pressure in the lubrication system “floats” or decreases, the sensor may trigger when driving in neutral or idling. In this case, the headlights will blink.

Let’s also add that turning on the headlights can be done either automatically or manually. This feature is realized by creating a parallel connection and selecting the desired resistance on the microcircuit itself. By the way, the solution to connect to an oil pressure sensor is not a popular one, since the circuit is complex, additional wiring is needed, and the requirements for the quality of connections increase.

- It is easier to connect to the parking brake. To do this, you need to add an additional relay to the general list of parts, which is powered by the parking brake button.

This method allows you to achieve the following:

- as soon as the driver starts to raise the handbrake, the headlights turn off;

- if you start lowering the handbrake, the headlights immediately turn on;

Generator autostart circuit

All electrical appliances and equipment that require backup power are separately highlighted in the autostart diagram. The remaining consumers remain connected to the city network according to the standard scheme. The phase connection is carried out through an automatic fuse. The backup power consumers themselves are connected via a 32-amp outlet, which allows the full power of the generator to be removed.

The circuit must necessarily include a grounding loop to ensure protection and safe operation of the installation. Please note that the socket and autostart unit are not designed for high loads. The power of consumers connected to backup power cannot be higher than the rated power of the generator. In case of overload, there is a high probability of burning the winding and failure of the entire installation.

In some cases, the autostart circuit involves connecting voltage stabilizers. They are used for those consumers who are extremely demanding on the quality of electricity in domestic conditions and in production. The stabilizers are connected to the network in test mode. In case of stable operation of all consumers and absence of extraneous noise, the device is installed in front of the generator and connected to the city network. If the current supplied by the generator is of poor quality, then the stabilizer is installed after it and all consumers will receive an already stabilized current.

Turning on the headlights using the light sensor

Many foreign-made cars are equipped with special devices that turn the lights on and off without human intervention. Most often, such gadgets are combined with a solar light sensor in a car. If the controller realizes that it is dark outside, it turns on the headlights, and when it arrives at a lighter section of the road, it turns them off.

This is a very useful function for residents of some countries... But not for Russians. Traffic rules in Russia force drivers to turn on low beams (or daytime running lights) when driving at any time of the day and in any visibility.

How to connect daytime running lights?

Many motorists have wondered how to connect the DRLs so that they turn on when the engine is started. Garage craftsmen have found 10 ways to turn daytime lights on and off, as an example:

- From the handbrake;

- Battery;

- Instead of fog lights, etc.

And each of the methods requires money, as well as good knowledge of wiring diagrams.

Let's watch a video on how to install and connect daytime running lights via the control unit:

One of the main schemes is to connect the DRL via a 4-5 contact relay; some craftsmen connect the wires to the pressure sensor. Since when the engine starts, the pressure sensor on the dashboard automatically lights up, which means that when the DRLs are connected to it, the lights themselves light up.

We connect the DRL via a 5-pin relay

To work we will need:

- The relay itself, for example, from an alarm system;

- Several wires with a cross section of 4 mm;

- 3 male-female terminals;

- Daytime Running Lights;

- Heat shrink.

The first way to connect DRLs is as follows:

- Take the DRL and attach it where it is most convenient for you. We solder the negative wire to the body and secure it well. The positive wire is supplied with a “mother”, insulated with heat shrink and left for a while.

- In the car wiring you need to find the wire that goes to the low beam of any headlight. We connect to it, output it, solder the “mother” in the same way and forget about it for now. The same must be done with the positive ignition wire.

- Let's move on to the relay. It has 5 contacts, we will use all but 87. You can remove it or leave it, decide for yourself. Number 86 will need to be connected to the negative on the body, 85 will be connected to the headlight, 87a will be connected to the positive from the ignition. Contact number 30 is connected to the free DRL terminal. Assess the reliability of the insulation of the terminals on the relay so that there are no short circuits and the contact is good.

Another video, installing DRLs using a five-contact relay on a VAZ 2111, be sure to watch:

That's all, check your installation to see if it works. Turn on the engine and see how the daytime lights function. Then turn on the low beam, the lights should turn off. After turning off the lights, the DRLs should light up again, and after stopping the engine, they should go out. In order for the decay to occur smoothly, it is worth placing a good capacitor in the circuit in parallel.

Connecting DRL without relay

If you don't have a relay on hand, you can do without it. DRLs are very simple in electrical terms. At the output we have only two wires, red and black. By all rules, red is a “plus”, and black is a “minus”. Open the hood and look for a “+” on any of the car systems that starts when you turn the ignition key. As an example, these could be the wires going to the fuel sensor or any others. Connect the red DRL wire to the positive terminal of your chosen vehicle system. And connect the negative wire to another contact of the same charge.

The result of such a connection scheme will be that when the ignition is turned on, the DRLs light up, and when they are turned off, they go out. Be careful, after installing the lights, check the functionality of all electrical appliances. And do not drive on the road if there are any malfunctions in the car.

On the Internet you can find many other solutions on how to connect the DRLs so that they turn on when the engine starts. This article described only two of the most popular and less expensive methods. Other connection schemes require deeper intervention in the car’s electronics and the purchase of various materials and accessories. And, as you know, not everyone can understand intricate schemes.

New articles

- What is car clearance and how does it affect the car's performance?

- Fur car seat covers are a useful addition to your interior

Previous articles

- How to make wheel chains for a car with your own hands?

- What is engine chipping? Pros and cons of chip tuning

The following algorithm for connecting daytime running lights can be distinguished.

- When starting the engine, the tachometer pulsates. When this signal occurs, the side lights turn on. At this moment, the engine may warm up at idle speed. The next stage will begin only when the movement begins.

- When a signal from the speed sensor appears, the low beam mode is switched on

- After turning off the speed, a timer is activated, which breaks the low beam/running lights circuit

- While driving, power to the DRL circuit is restored

- After the engine is turned off, the low beam and DRLs are turned off.

- If the car stops and the parking brake is raised, a special controller turns on, which turns off the low beam and activates the timer. If the handbrake has been raised for less than 2.5 minutes, then the low beam turns on immediately, if more time has passed, then only after the start of movement.

- While driving, the controller operates on the speed sensor, which powers the low beam lamps regardless of the position of the parking brake

- To connect the kit, it is better to use an additional set of wires so that the system works in parallel. Also on the instrument panel it is necessary to additionally place keys for turning on the dimensions.

Also, if necessary, you can make a diagram that will provide for movement with the lights and other light sources turned off. This may be necessary for various types of cases, for example when moving, hunting or fishing, when the presence of headlights would be undesirable. In this mode, with the engine running, it is enough to raise and lower the parking brake three times. After this, the headlights and low beam are switched off forcibly. After this, you can continue moving without attracting unnecessary attention. The no-light mode turns off automatically after the engine is turned off. If you need to continue driving after this, you need to raise the handbrake at the moment the engine starts and the headlights will not light up.

You can implement this DRL operation by connecting the wires according to the diagram:

https://youtube.com/watch?v=xReAnqlazDE

International NIVA Club

Forums

| Photo gallery | NIVA-SHOP | Files | Video |

- List of forumsAuto - EquipmentTechnical section Lada 4x4 NivaElectrical equipment

- Search

Links

- Unanswered topics

- Active topics

- Search

Why use the function of automatically turning on the headlights and parking lights in your car?

The ANV high beam control system is becoming increasingly popular among car owners. Recently, it has become mandatory for installation for vehicles with a permissible maximum weight of up to 3.5 tons. Its main function is to switch headlights from high beam to low beam and back in automatic mode.

It was created primarily for safer driving at night. And, I must say, it copes with its task excellently. Visibility is significantly improved, and the light of your car does not blind oncoming people. In addition, the driver is freed from the need to be distracted from the road, constantly changing the operating modes of the headlights.

In addition, in accordance with Russian legislation, driving during daylight hours with low beam or fog lights on is mandatory. Violation may result in a fine, so you must constantly ensure that your headlights are on correctly.

At the same time, light assist is not free from shortcomings. And first of all, it does not work correctly in the off-season, in particular in the fall. And it has arrived not only on the calendar. Fog, frost, rain – road users constantly encounter these atmospheric conditions that are uncomfortable for driving.

And it is precisely in such weather that the ANV system does not function correctly, or rather, it is not activated and does not work. This is due to a fundamental flaw in its design. As already mentioned, it works without problems in low light, in the dark.

Here's how it's implemented, say, in Toyota cars: (video)

This happens because the car has a light sensor. It is also called a twilight or light sensor. It consists of a photocell, a control unit and a relay. When a car enters a low-light area, say a tunnel, the system automatically turns on the high beams without distracting the driver.

However, the aforementioned signs, which are so characteristic of the Russian off-season, such as fog, snow or rain, do not affect the level of illumination. But the automatic lighting system does not define them as a change between light and dark or day and night. And as a result, despite the dangerously poor visibility, we are still driving with daytime running lights.

This shortcoming of the high beam control system has been known for a long time. However, drivers have already become accustomed to its convenience and sometimes forget about possible tricks on its part in certain weather conditions.

But such forgetfulness can be costly. And not only for you. What does it mean - the road is poorly lit, visibility has deteriorated, the lights don’t light up? Answer: you are not just invisible on the road. You simply do not exist for other road users. And when your presence is finally discovered, the consequences of such a “find” can be unpredictable. It's good if it's just a fine. What if there is an accident?

Therefore, we strongly recommend that car owners whose cars are equipped with light assist do not rely on the tricks of technology, but use common sense: visibility has become worse, air transparency has decreased - turn on the low beam.

And we turn it on ourselves, by hand. And it’s a good idea to add fog lights to it.

Advantage of DRL

LED DRLs are more than just a fashionable gadget. They shine even brighter than xenon ones, making your car more visible. Another advantage of daytime lights is that their use does not require the inclusion of additional light sources. Moreover, DRLs consume significantly less energy when compared to low beams.

Many manufacturers claim that using such lighting in a car reduces fuel consumption. There is some truth to this, since DRLs have a power of around 12 W, while the full standard car lighting, namely:

- Front halogen side lights,

- Tail lights;

- Instrument lighting.

The total power of these light sources is usually about 140 W. And the current in a car is generated by a generator from the engine, which burns fuel. In practice, and not during laboratory tests, the reduction in fuel consumption will be almost unnoticeable. However, there are other arguments in favor of installing DRLs in a car. By turning on the DRL instead of the low beam, you reduce the wear and tear on your car's headlights.

In new models, after 3-4 years of intensive use of the car, plastic curtains and reflectors can seriously wear out. The same applies to gas discharge lamps (xenon), which can last longer than conventional halogen lamps, but they do not last forever. Such lamps do not tolerate frequent switching on and off, and replacing them costs a pretty penny. In such a situation, spending 4000-8000 rubles to buy a decent set of DRLs can be a very good investment.

It is worth warning car owners who, as a way to save money, want to connect an LED strip purchased at the nearest hardware store. LED strips attached with clamps or adhesive tape to the car's bumper will not be daytime running lights, although at a distance they may look similar. With such DRLs, you risk getting a fine for changing the design of the car. Only vehicles equipped with homologated lighting are allowed on public roads.

In addition, we advise you not to buy the cheapest unbranded, even homologated DRL kits. They are often unreliable, their housings often leak, and their drivers can drain the battery.

The price of installing DRLs at a service center will cost about 1500-3000 rubles. An experienced craftsman who understands connection diagrams can also successfully handle this on his own.

Tips and tricks

As you can see, self-made solutions can have more advantages than standard ones. The functionality is also expanding, and the cost is often more attractive. In other words, it is quite possible to assemble an inexpensive circuit for automatically turning on low beam headlights.

It is important to understand that to assemble a circuit with your own hands, you need certain experience and skills. If you are not confident in your abilities, it is better to seek help from a professional auto electrician.

If the work is carried out independently, it is optimal to place the insertion points in the interior space, and not under the hood. This approach will avoid oxidation of contacts, reduce the risks of moisture and short circuits, etc.

If we talk about what is better, soldering or twisting wires, correctly done twisting in some cases will be better than soldering in relation to a car. The fact is that the vehicle is subject to various vibrations, and soldering is less resistant to vibration loads.

As for relays, wires, fuses, etc., the relay must be securely fastened, the wiring must be laid so that the wires do not lie in tension. In places where wires are bent and at points where the wire touches metal parts of the body, additional insulating heat shrinkage must be present. Otherwise, the wire may fray and begin to short out.

It is also strongly not recommended to use regular jumpers instead of relays, connect bypassing fuses, etc. Ignoring these recommendations can not only cause equipment malfunctions, but also short circuits or fires.

- DIY engine start button

How does the engine start button work? Available options and solutions for installing the starter button yourself. How to install the engine start button yourself. Read more

- The radio turns off when starting the engine: reasons...

Why does the car's head unit (radio) turn off when the engine starts? The main reasons for turning off the car radio, possible malfunctions. Read more

- Engine demining: why is it?

What is the purpose of demining the power unit and why? The main advantages of this solution are installing additional mass yourself. Read more

- Do-it-yourself soundproofing of the engine compartment

How to properly make noise insulation of the engine and engine shield of a car yourself. Materials for processing, elimination of noise and vibration. Tips, recommendations. Read more

- On-board computer for carburetor engines: what...

On-board computer for a carburetor engine. The main functions and capabilities of the device, features of controlling the BC for carburetor cars, pros, cons. Read more

- Remote Engine Start Module

Remote engine start unit: basic functions. Safety of using the internal combustion engine autostart module, interaction with car alarms and immo. Read more

Lada 2107 › Logbook › Automatic switching on of low beam headlights after starting the engine.

After the last car (Subaru Forester SF5), in which the headlights turned on and off when the engine was started, I had to get used to pressing the button every time before driving. In just over a month of owning the 7, there have already been times when I turned on the headlights several times I forgot, fortunately I didn’t get a fine. It was decided to make small modifications to the car in order to automate the inclusion of low beam headlights. There are quite a lot of different options on the Internet for obtaining this effect, both homemade and factory goodies. Since it’s more interesting to do everything yourself, I decided to assemble a simple circuit using relays. For myself, I decided that my light should turn on only after the engine starts, not to disrupt the operation of the standard circuit, and so that when I turn on the light through the standard button, my “circuit” should be disassembled. To implement this task, the following were purchased: 1) 4-pin relay - 1 piece 2) 5-pin relay - 2 pieces 3) 4-pin relay block. — 1 piece4) relay block 5 pins. — 2 pcs. 5) holder for fork fuse 6) wires, corrugation, electrical tape Most likely there will be those who will say that it could have been done simpler, that three relays are a lot and could have been connected differently, but for me the circuit I came up with is simpler and more convenient. Naturally, I do not claim that this is exactly how this modification should be carried out)

The principle of operation and the role of each relay.1) The first relay is connected by contact 30 through a fuse to the battery. One contact of the coil is to the ground, the other is to the 15th contact of the ignition switch, the 87th contact is connected to the 30th contact of the second relay. 2) The second relay with the 30th contact, as already written above for the first relay, one contact of the coil is to the 15th contact of the ignition switch, the second end of the coil to oil pressure sensor. Contact 87A is connected to the 30th contact of the third relay. 87 The contact of the second relay is not connected to anything. 3) The third relay with its 30th contact is to contact 87A of the second relay, one contact of the coil is to ground, the second is to 12V from the size. Contact 87A is connected to the standard relay for turning on the low beam headlights, namely to contact 85 (if I'm not mistaken).

As a result, after turning the key to the “ignition” position, the first relay transmits voltage from the battery to the second relay. The second relay, until the engine is started and there is ground on the oil pressure sensor, opens contacts 30 and 87A, thereby not passing 12V to the 30th contact of the third relay. After starting the engine and increasing the oil pressure, the ground on the oil pressure sensor disappears and contacts 30 and 87A of the second relay close again. The third relay transmits voltage to the standard low beam headlight relay until the low beam headlights are turned on with the standard button, which is in the first position 12V is supplied to the dimensions, as a result of which the third relay opens contacts 30 and 87A.

When connecting to a standard relay, I decided to put a diode in the gap of the standard wire, which I took from an old PC power supply. Maybe it was unnecessary, but it makes me feel better =D

Connection points. 1) 15th contact of the ignition switch, on which 12V appears when the key is turned to the “ignition” position. Blue wire (double thicker and thinner). 2) Oil pressure sensor. The connection to it was made in the engine compartment. 3) Connection to 12V dimensions. For the left headlight, this is a yellow wire going to the headlight unit in the engine compartment, directly next to the headlight unit itself. 4) Connection to the standard low beam headlight relay. Gray wire with a red stripe Block Ш1 (black) going to the fuse and relay block under the hood. You can access this wire only from the interior by disassembling the control panel.

Automatic low beam switch off

Post by Anton773 » 02 Sep 2012, 23:08

Post by SteelRat » 02 Sep 2012, 23:31

Post by Anton773 » 02 Sep 2012, 23:51

Post by Portada » 03 Sep 2012, 03:24

Post by doc Brown » 03 Sep 2012, 04:40

It can be from the ignition, or from the signaling. Here are a couple of wiring diagrams for a 4-pin relay. A similar diagram is drawn on the relay body. It is placed in the break of the wire from the central light switch to the steering column light switch (if you are interested in turning off the headlights, you will need to turn off the side lights with a key) or on the general “+” of the central light switch - but at the same time you can be left without side lights when you have to leave the car in the dark place with the engine turned off. It is not difficult to adapt these circuits to a specific case, both with and without the use of a car circuit, simply by calling the necessary wires from the ignition switch and the DSP.

On my old car I turned off the lights using the alarm. But at the same time, I installed parking lights on the rear pillars, the same as they used to be on Moskvich and Volga vehicles - red at the back, white at the front, with separate buttons for the right and left sides. It's a polar night, you can't stay without dimensions at all. Now, on the Niva, there are DRLs controlled by an oil pressure sensor. The problems with turning off the light resolved themselves.

Do-it-yourself automatic low-beam headlight switching

As you know, low beams must be turned on when driving a vehicle, not only in the evening and at night, but also during the day. In a situation where the running lights do not work, the traffic police officer has the right to issue a fine to the driver. Of course, this is a small amount, but it creates a headache. In this regard, most motorists have encountered a number of inconveniences due to the fact that many simply forget to turn on the low beams when getting into the car, or do not turn off the lights when leaving the car, which is why they find the battery completely discharged in the morning.

In order to get rid of such problems, many decide to modify the process of turning on and off the headlights. Thanks to the simplest circuits, the headlights can turn on simultaneously with the ignition or when the engine starts. In this case, during the daytime the low beam headlights will light up, but not the headlights, and at night everything will work as usual. Let's consider both options.

Universal circuit for switching on auto lights

Your car spends the night in the garage, you care little about cold start problems, and even less so

longer lamp life, then it makes sense to consider a simpler, universal connection model based on an inexpensive four-pin relay:

85 control contact of the relay - to positive after the lock

86 relay control contact - to ground

30 power contact - to constant plus (to ground, depending on whether + or - is supplied to the headlight lamps when turned on)

87 – power contact – to the power wire to the dimensions or low beam

Automatic switching on of headlights upon ignition

In order to organize such operation of the lighting elements, it is necessary to connect them to the ignition power source, and as many know, some devices can be connected at any position of the ignition switch, while others begin to function only when the ignition is already on. Based on this, the most convenient place to connect the headlights is the heater switch button (the rightmost switch block).

For this scheme you will need:

- any standard five-pin relay;

- diode;

- wires.

Next, we need:

- Remove the size switch (switch block on the leftmost side).

- Disconnect the positive wire from the key block responsible for the low beam operation (usually this is a green double wire) and connect it to the relay.

- You need to insert an additional wire into the positive wire that goes to the heater switch and also connect it to the relay.

- Connect the wire that powers the headlights to the relay.

- Throw the wiring to minus (to the body).

Post navigation

I have a VAZ, injection. Method 1: Connecting to the oil pressure sensor To make this connection you will need: a relay; wires; KTP1 microcircuit. The higher this parameter is, the longer it will take the headlights to turn on and off. From pin 86 K1 we make a connection to the pink-black wire coming from the HF handbrake. You will need to cut an additional wire into the positive wire going to the heater switch and also connect it to the relay. Tuning Automatically turning on and off the low beam on a VAZ classic I think many people have encountered a problem - they arrived, left the car, forgetting to turn off the low beam, returned, inserted the key, turned it, but the car did not react at all, except that the instrument needles sadly lay down. The headlights will turn off, respectively, when the circuit opens and the engine stops. Which is better, electric power steering or hydraulic power steering April 25 Automotive Currently, all cars, for ease of driving, are equipped with either hydraulic power steering or electric power steering.

This is especially useful in cold weather - when starting the engine, unnecessary consumers are not turned on. This feature is realized by creating a parallel connection and selecting the desired resistance on the microcircuit itself. When the engine stalls, or the ignition is turned off and turned on again, the sensor contact closes and the lamp lights up. As a seat for the fuse, you can use a regular car connector - “female”, although the electrician supplied me with a special block for 1 flag fuse. At the very least, they will be protected from the negative effects of precipitation. In practice, a properly executed connection minimizes or eliminates such loads.

Lighting switching diagram

I remembered that in recent years many Schottky diodes have appeared, which are distinguished, in particular, by a smaller voltage drop and very high permissible forward currents. Scheme two The above-mentioned problems can be prevented by slightly complicating the schemes.

The value 10 must be written to byte 22, then the daytime running lights function is activated. Therefore, I decided to automatically turn on the low beam in my Niva in accordance with the logic used in imported cars. Connect the wire from the ignition switch to pins 85 and 30. But now the headlights work as expected.

As a result, a simple device was developed that connects to the standard wiring of the car with only 4 wires. Connect pin 86 to the generator terminal to which the wire from the charge control lamp is connected. VAZ 2106 headlight switching circuit

Light sensor failure

As a rule, such devices rarely break down on their own. Provided that you have chosen a quality product from a well-known brand. When it comes to safety while driving, there is no need to skimp. Breakdowns are usually caused by factory defects, improper installation or improper use. It often happens that it takes many hours to find a fault, but the repair itself takes only a few minutes.

Many manufacturers indicate some restrictions for their products, so you should carefully read the instructions

As a rule, these are standard precautions: make sure that no moisture gets inside the device elements, protect them from mechanical and other influences. There are also sometimes recommendations not to use gas-discharge lamps on cars.