Types of belts

Previously, cars were equipped with only one belt; it drove only the generator. In the process of improving engines, the number of power units that need to be driven, for example, the steering wheel and the compressor, increased. Collectively this is called attachments

. In the 21st century, it will no longer surprise anyone that the attachment consists of at least 3 units!

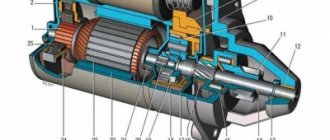

To transfer mechanical energy from the engine to the generator, cars use V-belts and poly-V-belts, the latter being more popular. Let's look at each type and look at their appearance.

V-belt

A belt having a trapezoidal cross-section and resembling a wedge shape, pointed on one side and widening on the other side. This type ensures more efficient operation of the mechanisms and makes the transmission more compact.

V-ribbed belt

The belt, which has longitudinal stripes on the inside resembling wedges, got its name from the Greek “poly” - which means many. This type is very flexible and has excellent traction capacity.

Belt drive and its features

Belting

- This is the transmission of mechanical energy using a drive belt.

This design has strengths

including a long service life, accessibility to maintenance and quiet operation. The belt is very strong and flexible, this allows it to be placed between many elements of attachments and set in motion.

However, there are also weaknesses!

The drive is demanding for the correct arrangement of elements, sensitivity to aggressive influences and the quality of the pulley surface.

As they wear out or become damaged, the moving parts experience additional difficulties during rotation, primarily affecting the transmitting torque. Whistling occurs

when the opposing force is too great.

Why does the whistle appear?

In 90% of cases, the cause is friction between the belt and the pulleys.

at the moment of slipping. When the belt cannot transfer mechanical energy to the generator pulley, it simply slips, making an unpleasant squeal.

Most motorists make a grave mistake! Remember, you need to look not for the reasons for the unpleasant sound, but for the reasons causing the belt to slip!

Let's list the 5 main causes of slippage in chronological order :

- penetration of moisture, dirt and technical fluids into the mechanism;

- severe wear of the drive belt;

- drive belt of poor quality;

- weak or excessive belt tension;

- pulley misalignment - parallel and angular misalignment are distinguished;

Whistling of drive belts. Causes and solutions

Key, ignition switch, starting the engine... But instead of the pleasant rumbling of the engine, there is an ear-piercing screech. Good morning, neighbors! If the trip begins with a shrill whistle, the culprit should be looked for under the hood. Let's figure out what can cause the morning "soprano" of the engine, and how to deal with it.

A whistle under the hood is a characteristic sign of problems with the drive belts of engine components (generator and other equipment). It is these flexible parts that are usually the source of unpleasant sound. To understand the possible reasons for their appearance, you need to understand the principle of operation of drive belts (which are also called accessory belts) and their varieties.

Common causes of unpleasant sound

Below we will look at the common reasons

occurrence of an unpleasant sound.

We will not consider specific reasons;

they are specific to specific car models.

Are common

- depend on external factors and faults.

Resource exhausted

Nothing lasts forever, including a belt reinforced with strong threads. Belt drive transmits enormous energy and handles variable loads. Over time, the belt stretches, its surface wears out, the rubber delaminates, and it is negatively affected by environmental factors. The average resource varies from 40,000 to 60,000 kilometers, but much depends on the conditions in which the car is operated.

Dirty surface

Drive surface cleanliness is one of the most important factors affecting belt service life. If the drive is corroded, dust or dirt gets into it, all this acts as a kind of abrasive that reduces adhesion properties and service life.

The most harmful effects are caused by technical, caustic liquids. Rubber is very sensitive to them. The process of aging and destruction accelerates, in addition to this, the friction force decreases, which is why the belt can slip and make an unpleasant sound.

Mounting location

A minimal deviation from the correct position of the pulleys relative to each other will have a detrimental effect on the belt contact patch. Deviations are: vertical-angular, horizontal-angular, parallel. In such a situation, the belt will slip and make a whistling sound.

Belt tension

If the belt is not tightened tightly enough, it will sag and slip. If it is overtightened, there will be a loss of adhesion, because the torque will prevail over the friction force.

Bearing condition

Bearings perform the following roles:

- prevention of axial displacements;

- alignment of moving parts;

- reduction of friction.

If the bearing is faulty the following will occur:

- distortions and protrusions of pulleys;

- wedging;

- make an unpleasant “squeal.”

Condition of pulleys and shafts

During operation, pulleys, shafts, and rotors wear out; this occurs less intensely compared to bearings. Traces of mining have the greatest impact on the adhesion properties of the surface.

The wear appears at the points of contact with the bearings, causing play that cannot always be eliminated even by completely replacing the supporting elements.

Huge pressure

If the belt has insufficient tension, the whistle may be caused by the simultaneous switching on of energy consumers such as headlights, heated or ventilated seats, radio, or air conditioning compressor. Together, they place a heavy load on the generator, which is operating at the limit of its capabilities.

In the cold

Belt whistling on a cold engine is caused by excessive belt tension or thickened low-quality lubricant. Both reasons create additional resistance to shaft rotation; as the engine warms up, the problem disappears.

Rain and slush

Moisture on the surfaces of the pulleys does not create any negative consequences for transmission, this is considered normal! However, if there is not enough adhesion properties to transfer mechanical energy, the water that gets into the mechanism acts as a lubricant, causing the drive belt to slip. If you hear a whistling sound, the work surface is most likely worn out!

Why does the belt whistle when cold?

The problem of whistling when cold can have several varieties. A squeak or whistle does not appear when the engine starts, but after a couple of minutes. This problem is easily diagnosed, since after the engine reaches operating temperature, the sound disappears.

The reason for the non-standard behavior of the belt is also hidden in its slippage. The torque transmitted from the crankshaft is not sufficient to spin the pulley. There are several reasons for this problem:

- Inaccurate selection of bearing lubricant for the generator. Due to the compaction of the lubricating fluid consistency at low temperatures outside, the generator pulley is not able to function as usual until the machine’s power unit warms up. At engine operating temperature, the lubricant will defrost and the unpleasant sound will disappear. The solution to the problem will be for the car owner to purchase a lubricant option that is more resistant to temperature changes outside the window.

- Weak tension. This situation is identical to the previous one. Until the engine reaches the required operating temperature, due to low tension, the belt is not able to perform its functions at the required speed and will slip.

This is interesting: Frequency of alternator belt replacement and breakage faults

The squeaking of the alternator belt when cold can be a sign of serious problems - a jammed pulley. This problem can easily be diagnosed on your own. The car owner should try to turn the specified part by hand. If the attempt does not lead to success, then you will have to either replace the generator or repair the broken part.

Ways to fix the problem

To eliminate unpleasant sound, first of all you need to do the following:

:

- checking the correct belt tension;

- cleaning the working surface from dirt;

- visual inspection and assessment of the condition of the belt;

- cleaning the pulley;

- visual inspection of the pulley for damage;

- checking the condition of the mounted bearings.

You can follow part of the recommendation yourself.

. To check bearings and pulley deflections, you can contact a service station. In most cases, these measures are quite sufficient to prevent whistling.

If no faults are found

, the belt continues to whistle, try to restore the elasticity of the product.

It is unacceptable to use petroleum-based fluids for lubrication! There are many spray products on the market, such as Liqui Moly Keilriemen-Spray, Hi-Gear Belt Dressing or Verylub. These products increase the elasticity of the belt, clean working surfaces and protect against moisture.

On a note! If the whistle disappears after using special tools, the belt is most likely to blame.

How does Alternator Belt Spray work?

Today, several manufacturers produce products for treating drive belts. One of the most popular and widespread is Keilriemen Spray from Liqui Moly. Products from other manufacturers have approximately the same composition and operating principle.

V-belt spray has several actions at once.

- Softens the hardened surface layer of rubber, which allows the wedge profile to contact the pulley grooves over a larger area. Belt sprays have the effect of rubber conditioner. And this increases the adhesion force.

- Creates a layer with a good friction coefficient on the surface of the belt and drive pulleys. Motorists mistakenly perceive this layer as a side effect of the product or rubber decomposition products. In fact, it is this black and sticky coating that allows the belt to sit securely on the pulley and not slip.

- Reduces wear rate. Friction when sliding wears out and heats the belt to a burning temperature. In addition to softening the belt, which prevents the formation of microcracks, the spray significantly reduces the likelihood of slipping.

Thus, these products eliminate belt slippage and extend their service life. But sprays can only be used for V-belts. Timing belts cannot be treated with the agents in question.

Consequences that may arise

An unpleasant sound cannot be ignored; it is a malfunction that can lead to even bigger problems.

- the intensity of belt wear increases;

- wear of mounted bearings increases;

- the belt can break at the most unexpected moment;

- The cooling system pump may fail.

If you ignore this problem, you will not be able to predict when the belt resource will reach critical, and this can lead to much bigger troubles.

Consequences associated with belt whistling

A problem related to the alternator belt that is not resolved in a timely manner can subsequently hit the car owner’s budget.

- The first thing that can happen is chronic undercharging of the battery. This will lead to a complete lack of charge and failure of the battery.

- A whistling sound may indicate complete wear of the belt and the possibility of its breakage. If this situation happens outside the countryside, you are unlikely to be able to drive a car.

When the whistle begins to appear, it is best not to tighten the situation and diagnose the tension and general condition of the belt.

Important! If the alternator belt breaks, the engine stops cooling. It is prohibited to drive such a car! Otherwise, the engine will overheat with very dire consequences.