The approximate concept of a crankcase is known to everyone who has at least a little studied the design of an internal combustion engine (ICE). But many believe that there is only one part hidden under it, which is actually called the oil pan. The more general concept is rather theoretical; it is not a specific part or assembly, but means the entire space of the engine located below the cylinders.

What is a car crankcase?

A car engine crankcase is part of the engine body. It is installed under the cylinder block. A crankshaft is installed between these housing elements. In addition to the engine, this element also has gearboxes, gearboxes, rear axle and other parts of the car that need constant lubrication.

It is generally accepted that the crankcase is a reservoir that contains oil. As for the motor, this is most often the case. As for transmission housings, this is not only the oil pan, but the entire mechanism housing with all the necessary drain, filler and mounting holes. Depending on the purpose of the container, a special lubricant suitable for a specific unit is poured into it.

What is this?

Let's look at what an engine crankcase is. This is one of the largest hollow parts, fixedly mounted on the cylinder block. The element is secured using a bolted connection through a silicone or rubber gasket. The body is made of metal, although many modern cars already have plastic products. Plastic is used to lighten the weight of the car.

The crankcase in the engine performs an important task - it stores the engine oil poured into the engine. A variety of parts can be installed inside - for example, the lower part of the oil pump. It's not just the engine that has a crankcase. Such parts can be found on gearboxes, on bridges and in any mechanisms where oil is poured. That's what a crankcase is in general. However, it should be understood that this part may differ slightly from other types of pallets. Differences may be in the shape, as well as in the material from which the part is made.

History of appearance

The idea that this part embodied first appeared in 1889. Engineer H. Carter came up with a small reservoir that contained liquid lubricant for a bicycle chain.

Additionally, the part prevented foreign objects from getting between the sprocket teeth and chain links. Gradually, this idea migrated to the automotive world.

Story

Humanity should thank the American engineer Harrison Carter for the invention of the crankcase. He created this part back in 1889. This development was originally intended for a two-wheeled bicycle. An engineer needed a tank to store lubricants for a bicycle chain. In addition, this container was supposed to protect the oil from moisture and dirt.

Purpose and functions of the crankcase

The main task of the crankcases is to secure moving mechanisms that require abundant lubrication. The engine crankcase contains a crankshaft, an oil pump, balancing shafts (read about which engines use such mechanisms and why they are needed in a separate article) and other important elements of the power unit.

The transmission housings contain all the shafts and gears that transmit torque from the engine flywheel to the drive wheels. These parts are constantly under stress, so they also need plenty of lubrication.

In addition to lubrication, the crankcase performs several other important functions:

- Unit cooling. As a result of the operation of rotating parts, the contact surfaces become very hot. The temperature of the oil in the container also gradually increases. To prevent it from overheating and losing its properties, it needs to be cooled. This function is performed by a tank that is constantly in contact with cool air. As the vehicle moves, the flow increases and the mechanism cools better.

- Protects unit parts. The engine and gearbox crankcase is made of durable metal. Thanks to this, even if the motorist is inattentive to the situation on the road, this part is able to protect the oil pump and the rotating shaft from deformation during impacts. It is mainly made of iron, which deforms when impacted, but does not burst (it all depends on the force of the impact, so you should still be careful when driving over bumps).

- In the case of transmission housings, they allow you to install shafts and gears into one mechanism and fix it on the machine frame.

Engine crankcase protection

Whatever the vehicle's ground clearance, the obstacle may still prove insurmountable. To avoid evacuation and repair in each such case, they strive to protect the crankcase.

On passenger cars and crossovers, unlike SUVs, maximum protection is provided against splashes from under the wheels. Plastic shields will not help when hitting a rock. Therefore, metal rigid protection is installed as additional equipment.

You can break through it, but having stiffening ribs and being attached to a power subframe, such a structure will work like a ski, lifting the entire front of the car. The probability of survival for the motor increases significantly.

The protection sheet is made of stamped steel sheet, 2-3 millimeters thick, or approximately twice as thick aluminum. The latter option is easier, but noticeably more expensive.

Those willing to pay for high technology can use Kevlar. When servicing the engine, the protective sheet can be easily removed, and the slots and holes made in it provide the necessary heat exchange; it is very undesirable to overheat the oil.

Crankcase design

Since the crankcase is part of the engine housing (or gearbox), its design depends on the characteristics of the units in which it is used.

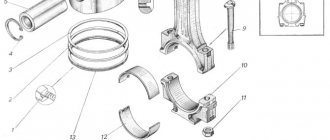

The bottom part of the element is called the pallet. It is mainly made of aluminum alloy or stamped steel. This allows it to withstand serious impacts. An oil drain plug is installed at the lowest point. This is a small bolt that is unscrewed when changing the oil and makes it possible to completely remove all lubricant from the engine. The box housing also has a similar device.

To ensure that the walls of the part can withstand increased loads during motor vibration, they are equipped with stiffening ribs inside. To prevent oil leakage from the lubrication system, sealing oil seals are installed on the shafts (the front oil seal is larger than the rear oil seal, and it fails more often).

They provide a high-quality seal, even if high pressure forms in the cavity. These parts also prevent foreign particles from entering the mechanism. The bearings are fixed to the housing using special caps and bolts (or studs).

Materials

In addition to the fact that pallets are divided according to the method of installation on the cylinder block, this part is also classified by design and materials. If we talk about the materials of the sump of a four-stroke internal combustion engine, and we already know what an engine crankcase is in a car, then these parts are most often made of aluminum alloys and stainless steels. It is very rare to find a cast iron pan. Previously, this was not uncommon, but now in the modern automotive industry they are abandoning cast iron due to its heavy weight.

In addition to traditional metal, plastic trays are also found in cars of the latest generations. In fact, the material has nothing in common with ordinary plastic. This is a special composition that can easily withstand high temperatures. The plastic crankcase is good because it has less weight.

Crankcase device

The crankcase design also includes oil-conducting channels, thanks to which the lubricant flows into the sump, where it is cooled and subsequently sucked in by the pump. During operation of the crank mechanism, small metal particles may enter the lubricant.

To prevent them from damaging the pump and getting on the contact surfaces of the mechanism, magnets are installed on the wall of the pan of some cars. Some engine modifications additionally have a metal drainage mesh that filters out large particles and prevents them from settling at the bottom of the pan.

Additionally, the engine crankcase is ventilated. Oil vapor accumulates inside the housing, and some of the exhaust gases from the upper part of the engine also enter it. The mixture of these gases has a negative impact on the quality of the oil, causing it to lose its lubricating properties. To remove crankcase gases, there is a thin tube in the cylinder head cover that is connected to the carburetor or goes to the air filter.

Each manufacturer uses its own developments to remove crankcase gases from the engine. Some cars have special separators in the lubrication system that clean crankcase gases from oil aerosol. This prevents contamination of the air ducts through which harmful gases are discharged.

Transmission housings

However, the engine housing, if the main one, is, as a rule, not the only crankcase included in the car. Modern cars usually have several such products, and most of them relate to the transmission. In particular, to the following elements:

- checkpoint;

- clutch;

- drive axle;

- transfer case.

Each of the crankcases in this group has its own purpose and design features. However, if we do not take into account the clutch system housing, we can identify elements common to all these products:

- the filler part through which the lubricant is introduced;

- device for draining unnecessary lubricant;

- a breather that brings the pressure in the crankcase into line with atmospheric pressure, thereby preventing oil leakage at the joints if this value is too high, caused by the high temperature of the housing.

- holes for shafts and seals.

Types of crankcase

Today there are two types of crankcases:

- Classic wet sump. It contains oil in a pan. After lubrication, they flow down through the drain, and from there they are sucked in by the oil pump.

- "Dry" sump. This modification is used mainly in sports cars and full-fledged SUVs. In such lubrication systems there is an additional reservoir of oil, which is replenished using pumps. To prevent the lubricant from overheating, the system is equipped with an oil cooler.

Most cars use a regular crankcase. However, two-stroke and four-stroke internal combustion engines have their own crankcases.

What is a crankcase used for in a car?

When driving a car on roads of varying quality, including country roads (fields, forests), there is a high probability of catching bumps on the bottom of the vehicle. As a result of hitting cobblestones, stumps and other obstacles without appropriate “armor”, the engine can be seriously damaged. The consequences of such an accident are very unpleasant and costly.

Purpose of the car crankcase

The power unit crankcase is mounted at the bottom of the cylinder block. It contains the engine oil and the pump oil receiver. The oil is used to lubricate and cool the crankshaft, as well as other parts of the cylinder-piston group by splashing. The gas distribution mechanism is lubricated under pressure. To drain the waste, there is a plug in the lower part of the crankcase.

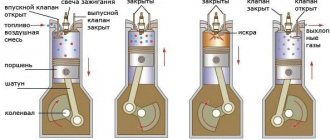

Features of a two-stroke engine crankcase

In a four-stroke engine, the crankcase is involved only in lubricating the engine. In such modifications, oil does not penetrate into the working chamber of the internal combustion engine, making the exhaust much cleaner than that of two-stroke engines. The exhaust system of such power units will be equipped with a catalytic converter.

The design of two-stroke engines differs from the previous modification. In them, the crankcase plays a direct role in preparing and supplying the fuel-air mixture. Such engines do not have a separate oil pan at all. In this case, lubricant is added directly to gasoline. As a result, many elements of two-stroke internal combustion engines often fail. For example, they need to change spark plugs more often.

What is a crankcase, why does the engine need it, and what materials is it made from?

Quite a lot of attention is paid to the repair and maintenance of various engine components. Moreover, very often when discussing all these issues, the concept of crankcase is heard.

But it turns out that not everyone knows the meaning of this element of engine design. Many motorists cannot answer what it is and why it is used in cars.

Although in fact, any vehicle equipped with an internal combustion engine is equipped with a crankcase. It is considered one of the main components of the power plant, despite the fact that it is a stationary element.

The difference between two-stroke and four-stroke engines

To understand how the crankcases in two-stroke and four-stroke engines differ, you need to remember the differences between the units themselves.

In a two-stroke internal combustion engine, part of the body plays the role of an element of the fuel system. Inside it, air is mixed with fuel and supplied to the cylinders. In such a unit there is no separate crankcase that would have an oil pan. Engine oil is added to the fuel to provide lubrication.

A four-stroke engine has more parts that need lubrication. Moreover, most of them do not come into contact with fuel. For this reason, lubricant must be supplied in larger quantities.

Types of construction and material

As I wrote above, it is made of metal - often an alloy of aluminum or steel, less often cast iron models (used on old engines). However, I have seen ones made from high temperature plastic. On European car models. Often black, made in the form of a small tray (if you look under the engine of your car, it will be exactly like this). Less commonly used with fins. Ribs are needed as additional elements of structural rigidity when it carries an additional load - for example, it is part of the hull.

A short video of a VAZ for general understanding.

I hope you now understand what this part is and what it serves, I tried to answer your question in simple words.

Similar news

- What is a crash test?

- Ventilated brake discs

- What is PTS

Add a comment Cancel reply

What is a dry sump

A separate article can be devoted to dry sumps. But, in short, a feature of their device is the presence of an additional oil reservoir. Depending on the car model, it is installed in different parts of the engine compartment. Most often it is located close to the motor or directly on it, only in a separate container.

This modification also has a sump, only the oil is not stored in it, but is immediately pumped out by a pump into the reservoir. This system is needed because in high-speed engines the oil often foams (the crank mechanism in this case plays the role of a mixer).

SUVs often conquer long passes. At a large angle, the oil in the sump moves to the side and exposes the suction pipe of the pump, which is why the motor may experience oil starvation.

To prevent this problem, the dry sump system supplies lubricant from a reservoir located on top of the internal combustion engine.

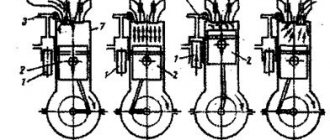

Design

Typically, the crankcase consists of the lower part of the cylinder block casting and a pan connected to it through a gasket.

But there are also more complex designs, where an intermediate plate is screwed to the bottom of the block, covering the crankshaft beds with main liners. Thus, with a decrease in the mass of the block, additional rigidity is provided, which is important for the long-term operation of the piston group.

This is interesting: How does the brake master cylinder work?

This is especially important for engines made entirely of light alloys; even imperceptible deformations of the block lead to uneven wear of the cylinders and scuffing.

The oil pump is installed at the front end of the crankshaft or under it, in which case it is driven by a separate chain from the shaft sprocket. Balancers can be placed in shaft beds or combined into a monoblock with a lower oil pump, forming a functionally complete module.

The rigidity of the structure is ensured by cast fins and additional baffles, in which holes can be made to reduce pumping losses from the bottom of the pistons.

Heat is removed through oil circulation, for which sometimes the pan is also made of cast light alloy with developed cooling fins. But more often the pallet is stamped from thin steel, which is cheaper and more reliable in case of possible impacts from hitting obstacles.

Maintenance, repair and replacement of crankcases

Crankcase failure is extremely rare. Most often, its pallet suffers. When a car goes over serious bumps, it can hit the bottom of a sharp rock hard. In the case of a sump, this will certainly lead to oil leakage.

If the driver does not pay attention to the consequences of the impact, then due to oil starvation the engine will experience increased stress and, ultimately, break down. If a crack has formed in the pan, you can try to weld it. Steel ones can be repaired with conventional electric or gas welding, and aluminum ones can only be repaired with argon welding. You can often find special sealants for pallets in stores, but they are effective until the next blow.

Replacing a pallet is not such a difficult task. To do this, you need to drain the old oil (if it hasn’t all escaped through the hole), unscrew the fastening bolts and install a new pan. Along with the new part, the gasket should also be replaced.

To minimize the chances of puncturing the oil pan, it is worth using steel plate protection. It is attached to the side members under the car. Before you buy such protection, you should pay attention to the slots in it. Some modifications have corresponding holes that allow you to change the oil in the engine or gearbox without removing the protection.

A little history

We owe the appearance of such an irreplaceable structural element of the engine to an American engineer. It was in his honor that the part was named, since the specialist’s name was Harrison Carter.

The engineer realized his idea a long time ago. This happened back in 1889.

Harrison Carter

But the most interesting thing here is that initially Harrison’s idea had absolutely nothing to do with car engines. Then he created a container that was filled with lubricant, especially for use on ordinary bicycles.

Due to the reservoir in which lubricant could be stored, the bicycle chain was constantly in the lubricating fluid. This increased the efficiency and performance of the mechanism.

And since the container was closed, the reservoir, eventually called the crankcase, protected the bicycle chain from the penetration of various contaminants, debris and moisture into it.

After some time, Carter's idea was borrowed by automotive engineers. This is how cars with a closed protective tank began to appear. Gradually the design was improved and finalized. But the idea and basis itself was taken from a bicycle chain guard.

Little Peggy Carter.

Even in early childhood, Carter had a huge thirst for adventure. Her mother did not approve of this and advised her to behave like a lady.

One day, Peggy's school principal reprimanded her for breaking into his house and trying to steal his wife's underwear and his most expensive bottle of brandy. This incident made Carter a hero among her classmates

The Second World War

Decoder.

Carter works at Bletchley Park

In 1939, Peggy was a member of the British Royal Army, doing the most basic office work expected of a woman of that time.

In 1940 she worked as a codebreaker at Bletchley Park. At the same time, she becomes engaged to Fred Wells, who works in her department. Her priorities are called into question when Mr. Edwards informs her that she has been recommended for a job with the Special Operations Executive. Believing that women shouldn't fight, Carter declines the offer.

Joining the Strategic Scientific Reserve.

Peggy Carter served under Colonel Chester Phillips in a service called the Strategic Scientific Reserve. She was sent there by the British government and collected information about Hitler's top-secret scientific division, HYDRA.

After some time, Phillips was sent to Europe so that he would be closer to HYDRA, and it would be easier for him to thwart the plans of his enemies. Agent Carter and Howard Stark went with him. They took Captain America to the HYDRA base. By that time, Peggy had already fallen in love with Rogers, although she claimed that she simply believed in him. They also agreed on a date, which Captain America could not get to, which he was very worried about.

Ant-Man

Howard Stark needed the Ant-Man suit created by Henry Pym to provide it to an undercover agent for a special mission in Berlin. The scientist refused, but Peggy, who entered the S.H.I.E.L.D. laboratory, convinced Pym to agree.

Resignation

In 1953, Peggy got married. Her husband was a soldier whose life was once saved by Captain Rogers. Peggy later had children. In 2010, having reached old age, Peggy was kept in a private hospital because she was sick with Alzheimer's disease.

Captain America, who has not aged at all, was found in the ice of the Arctic. After the Battle of New York, he finally met Peggy.

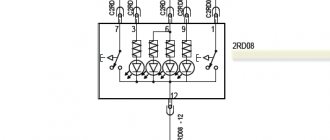

Gearbox and transfer case housing

This is the gearbox casing, and for all-wheel drive cars, also the transfer case. One of its main purposes is to provide these devices with a lubricant.

Currently, cast iron or aluminum products made as a single unit prevail among the shells of these devices. Such crankcases can be divided into 2 types, based on the location of the cover:

- top of the product;

- the end on the other side of the clutch.

Placing the lid on top is typical for old boxes, while modern ones typically have it on the side. Mechanical boxes with this design are now often installed on trucks. Moreover, some trucks are equipped with separate clutch, divider and gearbox housings. Well, the crankcase of an “automatic machine” is often combined with a similar part of the torque converter.

And on the gearbox housing there are areas for connecting a device that switches speeds, as well as various sensors, in particular, those connected to the speedometer.