yes, I’m trying now, I write messages during smoke breaks) So far there is no result, the 4th speed has become difficult to engage. the rest doesn't turn on!

Added after 18 minutes 20 seconds:

We adjusted that 3,4,5 turns on quite hard. 1,2 are not included. The disk was installed correctly 99%. What else could it be?

Well, then it could be: 1. The clutch was assembled crookedly and made of “shit”. 2. The transmission gear selection is crooked and not adjusted in any way. 3. Broken clutch fork. 4. The clutch drive is not CORRECTLY adjusted (that is, the cable). 5. Heavenly punishment.

Here's the question: did you do it yourself, or at the station? It’s just that if they are at the station, then there is a reason to spoil their brains. If you do it yourself. then why did you go there?

I would vote for adjusting the gear selector rod. How to adjust: you disconnect it at the bottom, stick it on the rear box with pliers from below, snap the lever in the cabin onto the rear one, and combine it under the car.

What sounds are there from under the gearbox and clutch? Or is it just stupid not to stick the gear in? And all the same, where is such confidence that the driven disk was not turned over then? Clutch pedal position in studio. How does the clutch fork move on the box, and does it move at all? There are no miracles, we changed 3 parts and the machine stopped working. Maybe the basket was bent into a hollow, or maybe it was not from the same car that was installed.

I almost forgot: 6. The input shaft didn’t hit the flywheel

In order: In general, they didn’t climb into the box at all, they changed the disk, basket and release lever, they did this when they overhauled the engine, that is, they removed the engine, installed the disk correctly, in the flywheel papoli, there was a device for this. We did it ourselves. We worked on the engine, as I wrote above, and replaced the clutch in one go; it was a little burnt. There are no sounds. It has become a little better to turn on, now all speeds are turned on, but the rear one wheezes when you stick it in, the first and second ones are a little hard to stick in. All this time the car is running at idle during the run-in. 3 hours with breaks to cool down. The clutch pedal is in line with the brake. You can’t raise it higher, it’s resting, the adjustment is turned all the way down. The fork in the box moves. There are also suggestions that the link was bent when they jacked up the box to remove the engine.

I changed the clutch: the gears do not engage after replacement

Owners of cars with a manual transmission often encounter the problem of shifting gears, namely, after starting the internal combustion engine, one or more gears may not engage or engage, but with great effort. Also, when turning on the speeds, extraneous noise, vibrations, etc. may appear.

The problem may appear suddenly or progress gradually. Difficulties when switching gears can occur both on a “cold” and on a “warm” gearbox. In this case, the speed with the engine turned off will be switched on without much effort.

Next, we will look at why such malfunctions and failures occur, for what reason the gears do not engage when the engine is running, after replacing the clutch, first gear does not engage well, etc.

The owner installed a new clutch: the gears do not engage

So, the problem of gear shifting can arise due to serious malfunctions, such as: failure of synchronizers, wear or breakage of gears, jamming of gearbox components and mechanisms when selecting a gear. In this case, to identify breakdowns, it is necessary to dismantle the box with subsequent “defection” or replacement of damaged components.

It often happens that the cause of difficult or incomplete gear shifting is a faulty clutch or insufficient amount of lubricating fluid in the gearbox. The problem with the lubricating fluid can be solved by adding oil to the gearbox or by completely replacing it.

If the breakdown is associated with a malfunction of the clutch, the failed elements are replaced, or the clutch is replaced with a new one. However, even after replacement, problems may occur.

The problem of shifting gears after replacing the clutch in full and incomplete sets

Drivers often encounter this problem: when a car owner has installed a new clutch, the gears do not engage. There may be several reasons for this. Let's look at each in more detail.

- First of all, the release bearing. The clutch disc has been replaced, but the gears still do not engage or are not engaged completely. One of the reasons may be a failed clutch pressure (release) bearing.

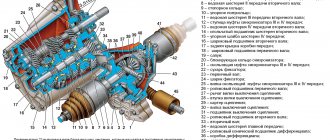

This element is located on the axis of rotation. Thanks to the clutch fork, the bearing moves together with the release clutch. The bearing disengages the clutch disc from engaging the basket (the clutch engages and disengages). There are two types of bearings:

- roller bearing (works due to a rigid connection between the rods);

- hydraulic bearing (creates force using a hydraulic system);

Symptoms of malfunction:

When you press the clutch pedal on a car with the engine running, a characteristic knocking or noise appears. If the bearing is severely worn, it may jam and it will no longer perform its functions as a transmission device between the drive and the clutch.

In this case, the clutch will stop engaging, as a result, destruction of other clutch elements and incorrect operation of the gearbox occurs. The breakdown is eliminated by replacing the release bearing, having first checked it for play (the new bearing should rotate very easily, avoiding jamming).

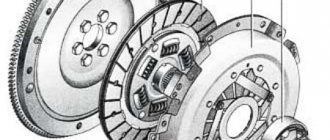

- Clutch basket. The basket through which the flywheel and disc are connected and disconnected is one of the main components in the clutch design.

The basket consists of: a pressure plate, a diaphragm spring and a casing. The clutch basket does not wear out as quickly as the clutch disc. If, after changing the clutch disc, the problem with gear shifting remains, you need to pay attention to the basket.

Often, basket malfunction is associated with wear of the petals (deformation, overheating, etc.). The basket ceases to perform its functions as it heats up, and as a result, the pressure disk is not completely retracted. The problem is solved by replacing the basket. If the problem is not corrected in time, then over time the release bearing and clutch disc may become damaged.

Also, the problem of shifting gears may appear after replacing the complete clutch. If after replacing the complete clutch (clutch disc, basket, bearing, etc.) the problem with gear shifting remains, it is recommended to pay attention to certain points.

- After replacement, the clutch disc turned out to be a little thicker or there is a defect in the clutch basket (some petals may be slightly lower than the others).

- Adjusting the backstage. The link can be adjusted either at a service station or independently. There are two adjustment methods: adjustment in reverse gear, adjustment in first gear (there is no possibility of engaging reverse gear).

- Wear of the flywheel (the flywheel is connected to the clutch and is its support). The flywheel sphere, in contact with the clutch disc, is subjected to heavy loads. As a result, there is difficulty switching gears, slipping, etc.

If the rear plane of the flywheel is damaged, it is reground on a machine in compliance with all standards. In cases where the flywheel crown is worn out, then it is replaced.

What's the result?

As you can see, if such a problem arose when the owner replaced the clutch and the gears do not engage, it is necessary to determine the cause. First of all, you shouldn’t immediately rush to change the clutch again.

We also recommend reading the article on how to replace the clutch on a DSG box. From this article you will learn about the subtleties and nuances when replacing the DSG clutch, as well as what to pay attention to during this procedure.

The fact is that there are many reasons why the gears do not turn on or are not turned on completely. In any case, to identify faults, it is first necessary to conduct a complete diagnosis of the gearbox. As part of the checks, it is necessary to separately take into account which clutch elements were changed, whether adjustments were made, adjustments to the rocker, etc.

What's the result?

As you can see, if such a problem arose when the owner replaced the clutch and the gears do not engage, it is necessary to determine the cause. First of all, you shouldn’t immediately rush to change the clutch again.

We also recommend reading the article on how to replace the clutch on a DSG box. From this article you will learn about the subtleties and nuances when replacing the DSG clutch, as well as what to pay attention to during this procedure.

The fact is that there are many reasons why the gears do not turn on or are not turned on completely. In any case, to identify faults, it is first necessary to conduct a complete diagnosis of the gearbox. As part of the checks, it is necessary to separately take into account which clutch elements were changed, whether adjustments were made, adjustments to the rocker, etc.

Clutch does not engage after replacing driven disc

Ford Focus II 2005 - 2011

After replacing the driven disc, the clutch stopped disengaging. Everything worked before replacing the disk. Checking all components indicates their serviceability.

7 answers

I placed the disk on the wrong side.

It doesn’t turn off, which means there is no squeezing of the release bearing; on FF2, the bearing and the clutch worker are one unit, which means the clutch is not pumped or is not sealed.

Due to overheating, they may not be able to wring out completely.

Change the cart... You'll have to fork out the cash (There is no way out, since the controls work.

Maybe there's just wear on the flywheel? And the ferido itself does not fit tightly into the seat, because of this, when the clutch is depressed, the disc does not completely move away from the flywheel, but clings with the edges of the disc to the unworn parts of the flywheel. It is necessary to remove the edges on the disk with sandpaper so that it fits tightly to the flywheel. Because of this, the petals on the basket sink deeper, and there is not enough movement to fully spin the basket. You need to remove it carefully, and only the edges that interfere with the flywheel side.

It's not about the company... It's about the flange configuration. The spline should be the same in it so that it can move freely when placed on the shaft spline... The diameter is similar and the thickness of the package/firado...

“If you hear a cracking sound when you engage the gears, and disengagement is difficult, it means that the clutch is not disengaging completely. We bleed the clutch release hydraulic drive. If there is no air in the actuator, the malfunction may be caused by a faulty clutch master cylinder or clutch slave cylinder, or a worn or weakened clutch diaphragm spring.”

Subscribe to our channel in Yandex.Zen

Even more useful tips in a convenient format

Subscribe

Breakdowns due to clutch replacement

The clutch is designed to transmit the torque of the internal combustion engine to the transmission. This mechanism also opens the transmission and engine to change speed. If switching speed when the engine is running becomes impossible, then most likely the problem lies in incorrect replacement of this unit.

Brake fluid leak

In many car models, brake fluid acts as a working fluid for the clutch. Very often, after replacing the clutch, first gear does not engage well, and the problem may lie in the insufficient amount of fluid poured into the hydraulic drive system. In such cases, the transmission is not only difficult to engage, it may not work at all. Therefore, first of all, it is worth looking at how much brake fluid is filled. If it is not enough, then you need to check the tank for leaks and remove all faults. After this, the clutch must be bled. The pumping technique is quite simple. You need to connect the hose and fitting, and then press the pedal and drain the liquid so that all the air comes out.

Release bearing problems

The reason why the gear is difficult to engage is most often due to damage to the clutch basket. Sometimes the reason lies in the release bearing. If the bearing moves on the input shaft with difficulty, this part must be replaced.

It is also worth adding that a marker of a faulty release bearing is rustling and humming noises when the car is running. The noise occurs when the pedal is pressed to the floor. This sound appears both in a warm car and in a cold one. After the driver releases the pedal, the noise should disappear.

I'm asking for advice about the clutch (the gears won't engage) - GAZ Volga Community on DRIVE2

Good time everyone. It turned out that yesterday I had to drive about 10 seconds in first gear before the cutoff (I think that this is the root of the problem). The following happened: getting ready to go to work in the morning, I got into the car, took it out of gear, started it, and began to reverse. The rear one didn’t want to stick into anything. Same problem with first and second gear. Third, fourth and fifth gears shift perfectly, as always. By some miracle, I was able to get to work, forcibly sticking the gears into gear, at lunch I was able to go to the store, but after work the gears finally stopped turning on. I noticed that with the engine off they turn on, as they always did, no force needed to be applied. I tried to put it in gear and start it by squeezing the clutch, but when ignited, the car immediately began to move off, after which it stalled. I tried to press the clutch + gear + brake = the car immediately stalled, and the clock on the radio was reset. Bottom line: I was driving home by bus :(I tried double squeezing and re-engaging! Previously, I had a problem with gears that were hard to engage, mainly 1 and 2, double squeezing helped. Then this problem disappeared by itself, except perhaps if I didn’t push it in all the way 3rd and 4th gears, then it was knocked out. Everything was fine until this moment. I don’t understand anything about gearboxes, so I’m asking for advice on what to change. After quickly studying the search in forums and books, I concluded that there may be a problem with the clutch disc. Really Is it possible to change it according to the instructions, if I have never changed it and have not climbed into it? Will I definitely have to drive the car onto a lift and pull out the box?

Sorry for the long text)

How to use a manual transmission

Operating a car with such a gearbox requires certain skills and abilities, so many, especially women, find it difficult to change gears on a manual transmission.

How to change gears

Gear shift

The first thing you need to remember is the position of the gearshift lever for each gear. Secondly, learn to choose the speed mode and operating range of each gear.

Speed modes:

- In 1st gear 15-20 km/h;

- In 2nd gear 30-40 km/h;

- In 3rd gear 50-60 km/h;

- At 4th up to 80 km/h;

- 5th for speeds over 80 km/h.

But it’s best to focus on the tachometer when changing gear. You can switch to higher speed by spinning the engine speed to 1500 - 2000 rpm for a diesel engine, or if it is a gasoline engine, then up to 2000 - 2500 thousand.

Before starting to drive, always make sure that the shift lever is in the neutral position. Then depress the clutch with your left foot and move the gearshift knobs to the position corresponding to first gear. In order to start moving without jerking and roaring of the engine, you need to smoothly release the clutch and also lightly press the accelerator (gas) pedal. Next, upon reaching the speed threshold, we switch to second gear, again squeezing the clutch and releasing the gas pedal, then smoothly repeat everything.

When switching on speeds, they cannot be skipped, only switched one by one.

When slowing down by pressing the “brake” pedal or when braking the engine, the gears are lowered in the same way, only engage not the next one down in order, but select the most appropriate one according to the speed limit.

3 tips for proper manual transmission operation

Despite the fact that a manual transmission is a reliable unit, if it is not used correctly, the transmission can very quickly fail. Therefore, it is recommended to follow these tips:

Shift gears smoothly and carefully; more than half of manual transmission failures are associated with failure of gears and synchronizers due to careless gear shifting.

Monitor the oil level in the box. The quantity and replacement lines are regulated in the repair manual

Protect the gearbox housing. The sump is very fragile and can be accidentally damaged by getting caught on some obstacle, therefore, as a rule, I protect the engine crankcase and gearbox from mechanical damage with an additional screen.

Related terms

- Cardan shaft (cardan)

- Axle shaft (drive shaft)

- Backstage

- Rear axle

- Speed sensor

- Automatic transmission (automatic transmission)

Why don't the gears turn on when the engine is running?

As for problematic switching when the internal combustion engine is running, then the list of the most common faults includes:

- lack of gear oil in the gearbox;

- problems with the clutch mechanism;

Engine speed and service life.

Disadvantages of driving at low and high speeds. At what engine speed is it best to drive? Tips and tricks. A complete lack of lubrication in the gearbox will not allow you to change gears, since without oil the synchronizers will not be able to work properly, and the gears in the gearbox will not engage.

It is imperative to fill only with lubricant recommended for viscosity and other characteristics.

In this case, the gears will engage slowly or not engage at all.

If the level is low, it is necessary to check for leaks, eliminate defects and bleed the clutch.

After removing the box, it is necessary to inspect the basket for deformation, signs of overheating and other defects. If found, the element must be replaced.

Engine speed and service life.

Disadvantages of driving at low and high speeds.

At what engine speed is it best to drive? Tips and tricks. The engine temperature does not rise, the internal combustion engine temperature needle drops while driving. Why does the temperature drop after turning on the stove?

Diagnostics and repair, advice.

What to do if the car accelerates worse, does not pick up speed, or has failures during acceleration.

Why the engine does not pull, how to find the reason for the decrease in power. Violation of the combustion process of the fuel-air mixture in the engine. Why does detonation occur: the main causes of this malfunction and the consequences for the internal combustion engine.

How to quickly start the engine with a discharged battery. Features and advantages of using an autonomous battery charger.

Tips for choosing a booster. How to remove the engine start lock.

Checking for random activation of the immobilizer and how to disable it. Diagnosis of possible alarm malfunctions.

Clutch slipping after replacing all its parts

After replacing all elements, adjustment is required, but many car owners ignore this point. The cause is slipping, the car accelerates slowly, the engine speed does not correspond to the speed of the car. The engine just roars, and the car is driving quite slowly, as they say, slipping.

In cars with a mechanical clutch cable, adjustment is made by the cable itself. In hydraulically driven machines, this process is carried out using a clutch rod. In modern cars, you often come across rods that do not have adjustments. But this does not mean at all that it cannot be produced. In such cases, adjustment of the clutch pedal itself is provided, but not everyone knows about this possibility. » alt=»»>