A car drive belt is an element of a belt drive, a working part of vehicles and mechanisms, which serves to transmit engine torque.

The transmission of torque occurs due to frictional forces or engagement forces (timing belts, V-belts).

There is a misconception that the timing belt (the timing belt drive) does not belong to the drive belts. But actually it is not. The timing belt also falls into the category of drive belts.

Drive belts are divided into several types:

— Timing belt (timing belt drive)

— Drive belts for auxiliary components (engine attachments)

2. V-ribbed belt transmitting engine torque to engine attachments

3. V-belt transmitting engine torque to engine attachments

Belts No. 2 and No. 3 in our country also have additional names: flat belt (V-ribbed belt) or ripple belt (V-belt).

The belt drive is easy to install and replace; overloads are compensated by the elasticity of the drives. This type is indispensable when working at high speeds.

Drive belts differ in a number of characteristics, primarily:

Traditionally, the marking of such belts indicates the following data:

The sizes of drives can be very different and are produced for a specific model of car or equipment. Before replacing this part on your vehicle, be sure to compare the new part with the part you are replacing.

To choose the right drive belt, you need to take into account the make and model of the car, the type of engine, its volume, engine code and the purpose of the drive belt itself , be it, for example, a timing belt that drives the pump and camshaft of the engine's gas distribution mechanism, or a poly-V-ribbed one-way belt , driving the air conditioner.

Malfunctions of poly-V-belts of attachments and methods for their elimination

Operational wear is inherent in any structural element, and moving parts exposed to friction and under load are more susceptible to wear than others. Belt damage poses a high risk of an accident.

The main safety measures are monitoring the condition of the belt and timely restoration of its functionality (cleaning, tightening, etc.).

- An unpleasant sound (squeaking) while driving indicates a weakening of the belt tension. In this case, it is necessary to perform a tightening without delay.

- If dirt and traces of fuels and lubricants are found on the belt or pulleys, the system requires cleaning.

- When inspecting, pay attention to the appearance of the drive belt - the presence of mechanical damage (frayed belts, tears, worn edges, etc.).

To ensure trouble-free operation of the system and extend the service life of the poly V-belt, it is also important to monitor the auxiliary devices, primarily the idler and tension rollers. They directly affect the driving behavior, the degree of wear and the likelihood of damage to the belt, and therefore must be kept in good condition.

The rollers are constantly under pressure and wear out as a result. Roller wear affects the degree of belt tension and the quality of the system as a whole. The drive belt, pulleys and rollers are checked at least every 15 thousand km. mileage The rollers are replaced when significant wear is detected and when the suspension belt is replaced.

Checking the drive belt

Evidence of irregularities in the operation of the poly-V-belt is not only a whistle, but also other extraneous noises occurring in the engine compartment. These sounds clearly indicate that the likelihood of the belt breaking has increased significantly.

This gap, in turn, can lead to much more serious problems, the most minor of which is the lack of light.

Rules for replacing a poly V-belt

The drive belt must be replaced:

- in case of a break or significant damage is detected indicating a high probability of break,

- after 50 thousand km. mileage since the start of operation or since the previous replacement.

When replacing a belt, it is recommended to follow certain rules:

- Before installing a new belt, it is carefully inspected for defects.

- When replacing a belt, the roller system is also changed along with it.

- The belt tension should ensure a deflection of no more than 5 mm.

Accurate and correct installation of the belt that transmits torque from the engine ensures the correct operation of a number of systems, since the flexible design of the poly-V-belt allows you to assemble a vehicle generator and a whole range of auxiliary equipment into a single system.

We recommend: How to change the heater radiator on a Lada Kalina

The performance of each element of this system directly depends on the operating parameters of the drive belt:

- no sagging,

- no vibration,

- motion trajectory accuracy,

- uniformity of movement.

Checking the belt system, its rollers and associated pulleys is mandatory during any vehicle inspection.

If the drive belt is cracked (consequences)

If your car's drive belt(s) are worn out, they will have cracks and scuffs on the surface. As a result, a whistle will begin to appear as they move. In this case, the time has come for their planned replacement. Remember that if you do not change the drive belt on time, you risk being left without functional vehicle equipment. For example, if a belt has reached the end of its service life due to severe wear and tear, it will naturally break sooner or later.

Typically, when the drive belt breaks, you will hear a loud bang from under the hood. As a result, the equipment that received torque from it will cease to function. For example, if the drive belt powering the alternator breaks, it will stop charging the battery and powering all electrical equipment in the car. You will eventually see the battery icon illuminated on your dashboard.

Also, if the belt breaks, the power steering will stop working. As a result, your steering wheel will become very difficult to turn. But the most important problem when the drive belt breaks is the lack of rotation transmission to the water pump, which promotes the circulation of coolant through the engine cooling system. As a result, the engine can quickly overheat. In this case, you must immediately stop driving and turn off the engine.

Therefore, while driving, constantly monitor the engine temperature sensor, which should show the same temperature of 90 degrees after the engine warms up. If you see that the temperature needle has gone up and is approaching the dangerous red zone, then you need to stop and, turning off the engine, diagnose the cooling system.

Attention! Overheating of the engine can lead to its failure (damage to valve stem seals, failure of the head gasket, damage to the piston system). Therefore, do not allow the power unit to overheat under any circumstances by monitoring the engine temperature on the dashboard.

What determines the service life of drive belts?

Modern drive belts have a fairly long service life due to their construction from modern, reliable materials. On average, a quality belt can last up to 25,000 hours of operation. Please note that service life is shown in hours, not kilometers, as mileage does not directly affect the service life of drive belts. After all, these belts are in motion even when the car is standing still and the engine is idling.

But this is in theory, and according to information provided by belt manufacturers to consumers.

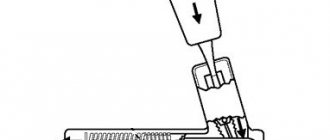

In practice, the service life of drive belts may differ significantly from that declared by the manufacturer. The fact is that the wear of drive belts is influenced by many factors. For example, the way it was installed on the car plays an important role in the long service life of the belts. For example, it is not uncommon for car mechanics in technical centers, due to their low classification or lack of experience in car repair, to try to fit a belt onto a pulley using a screwdriver. As a result, the new belt is damaged and will no longer be able to serve the period stated by the manufacturer. This method of installing the drive belt is also used to speed up the replacement process without removing the pulley.

In addition, the service life of the belts is affected by the storage conditions of the components in the warehouse and their transportation. For example, it is not uncommon for car dealerships to sell drive belts that have expired. Yes, drive belts have an expiration date. The fact is that the chemical composition of drive belt materials changes over time. And if the drive belt was manufactured 5 years ago and was stored incorrectly in the warehouse, then when installed on the car it will not last very long.

Weather can also affect the durability of car belts. For example, if you live in a hot climate, then you often use air conditioning. This means that the air conditioning compressor must receive more energy. As a result, the belt transmitting torque to the air conditioning compressor experiences increased load.

Drive belts can also wear out quickly if the machine is operated for a long time in cold weather. For example, in winter, the electrical equipment of the car requires more power than in warm weather.

As a result, the alternator requires more power to maintain the vehicle's electrical system. As a result, the alternator belt experiences increased load due to increased torque.

As a rule, drive belts in a new car last longer because they were installed at the factory and all necessary storage conditions were observed before installation. After replacing the factory drive belts, the life of the belts will be reduced.

We recommend: Manual gearbox, device, principle of operation

Each car manufacturer usually indicates in its technical documentation and service book during routine maintenance when it is necessary to routinely replace drive belts. Therefore, we advise you to carefully read the list of scheduled technical inspections and the schedule for replacing consumables. As a rule, the manufacturer indicates the maximum mileage at which technicians at the technical center must replace the drive belts. This way you will know approximately the service life of the drive belts. But this does not mean that you should not regularly inspect the condition of the belts.

How to tension, tighten or loosen a drive belt

If the cause of the whistle, squeal or squeak is a belt that has become loose, causing it to slip on the pulleys, then if the belt does not show signs of wear or damage, in order to remove the extraneous sound, it is necessary to tighten the belt.

Using the generator belt as an example, this is done using a special adjusting bolt (on modern cars) or using an adjusting bar (on older cars).

For example, to tighten the alternator belt on a modern car, you need to do the following:

— Loosen the generator mounting bolts slightly (upper and lower fastenings)

— Turn the adjusting bolt clockwise, moving the generator away from the engine block and immediately checking the belt tension level

— Then shade the nuts of the generator fastening elements

Please note that in some vehicle systems, the process of tensioning the drive belts is too labor-intensive and requires the use of special tools.

Attention . A new generation of poly-V-ribbed elastic belts are currently widespread on the market and in many cars. For example, one of the world's well-known manufacturers of such belts is the Elast company. Their products have proven themselves to be the best. This company is the official supplier of many car factories. Elastic poly V-belts do not require tensioning, tightening, etc. Thanks to their design and material, such belts do not stretch. Typically, such drive belts last about 120,000 kilometers.

But for its initial tension a special tool is required.

Many cars also use special belt tension rollers, which saves drivers from constantly tightening belts. The only drawback of this design is that, as a rule, when replacing drive belts, it is also necessary to change the tension roller, since its reuse together with a new belt is impossible.

How can I temporarily replace drive belts if my car breaks down on the highway?

Unfortunately, it is not possible to temporarily replace drive belts with something if they break on the highway in modern cars. In older cars, women's tights sometimes helped with a similar problem. But those times are gone. If the drive belts break, you will need technical assistance.

Description

Belt drives have become widespread due to a number of unique qualities, among them it is worth noting:

- smooth and quiet operation;

- balancing inaccurate installation of pulleys;

- compensation in case of occurrence (the drive belt will simply slip);

- reduction of vibrations (for example from internal combustion engines);

- no need for lubrication;

- cheapness of parts;

- ease of installation;

- Possibility of use as a clutch;

- reliability in operation at high speeds;

- in the event of a break, unlike the chain, other nodes are not damaged;

- transmission of rotation over any distance.

Belt drive operation diagram

Concept

A belt drive is a device that consists of a main pulley, which is mounted on the shaft of the power unit, and the drive belt is connected to the driven pulley. Rotational motion is transmitted due to friction or engagement forces.

Application

In addition to cars, traditional drive belts are actively used in machine tools, all kinds of installations and agricultural machines. The surfaces of these parts guarantee the necessary load distribution and smooth connection of the pulleys.

The drive belt of any size does not require lubrication and operates with low noise levels at any speed. It is distinguished by a slight extension and this is what makes the rotation transmission system quite simple.

Invented more than five hundred years ago and becoming mandatory in modern mechanisms, belt drives are now widely used in a wide variety of industries. It is worth noting that one drive belt can transmit rotation to several pulleys at once.

Transmission scheme for several pulleys

Generator belt: features and possible repairs

The generator belt ensures the transfer of mechanical energy from the shaft to the generator, which converts it into electricity for the on-board system of the machine. The generator belt is installed on pulleys, rotating on which it ensures interaction between the crankshaft and the generator.

The designs of this system have a wide variety, depending on the specific manufacturer, but the principles of operation are the same for all. Problems associated with the alternator belt are also similar in all systems.

Don't panic if you hear a whistle coming from under the hood. You should immediately check the alternator drive belt and pulleys. However, do not forget that in some cars the alternator drive belt also goes to the hydraulic booster. If the belt breaks, then a sudden failure of the power steering will give you several unpleasant seconds or even lead to an accident.

How it's done

If we talk about production, then it all starts with the preparation of components, in particular with rubber layers, which in a certain sequence enter a machine called a “builder”, where the construction of the belt takes place. The components of the future belt are wound onto the mold in the required sequence. After winding all the components, the mold is immersed in a vulcanization chamber, where, under the influence of a certain temperature and a certain pressure, the process of sintering the components into one whole occurs. Next comes cooling and removal of the resulting “sleeve” from the production drum, from which straps are cut into the required sizes.

Almost all Gates belts supplied to the European market, including the Russian one, are of European origin.

We recommend: Checking the oil pressure

Functions and design of the gas distribution mechanism

Gas distribution mechanism (GRM): 1 - camshaft gear; 2 - cams; 3 - camshaft; 4 - bearing; 5 - valves; 6 — springs; 7 — timing belt; 8 — crankshaft with flywheel; 9 — gas distribution gear;

Before talking about belts, which are components of many gas distribution mechanisms of internal combustion engines, it is necessary to find out what a timing belt is.

In fact, the timing (or gas distribution mechanism) is one of the most complex mechanisms found in internal combustion engines. Its functions are to ensure timely filling of the cylinders with the fuel mixture and timely removal of exhaust gases from them.

The gas distribution mechanism solves these problems by opening and closing at strictly defined points in time the intake and exhaust valves with which each of the engine cylinders is equipped. It is they, as well as the camshaft that directly controls their operation, that are the main elements of any modern timing belt.

In order for the camshaft to perform its functions, it must be provided with torque. It is transmitted from the crankshaft using a drive specially designed for this purpose, consisting of pulleys located on it and the crankshaft, as well as a belt connecting them. This is what is called the timing belt.

Checking for wear and its signs

Before you try to change the unit yourself, you need to make sure that it has actually exhausted its resource, does not perform the functions assigned to it and requires replacement.

The most important sign of wear is the appearance of a characteristic whistle during generator operation. This whistle can be heard by applying an appropriate load to the generating equipment. In practice it looks simple. You need to start the air conditioner or just turn on the high or low beam headlights. Next, the engine starts and the gas pedal is pressed. If at this moment a sweat appears from the engine compartment, the belt is loose.

Whistling and loosening of tension does not indicate complete wear. In some cases, it is only slightly damaged, but still suitable for further use.

A whistle does not signal a critical failure of the unit. But this is an obvious sign that the element will soon have to be changed.

When the device wears out and the tension decreases, the generator continues to function. Even if its efficiency decreases and the charge may be partially supplied, you can still get to a car service center or your own garage. But as soon as you find out what the price of work at a service station is for such a procedure, you will probably want to personally understand the nuances of replacing the alternator belt. There is nothing complicated here. But you will gain additional experience and save a significant part of your budget.

The constant noise from the generator is considered much worse than whistling. Moreover, it can appear under load and without any impact load from electrically dependent equipment.

Characteristics of drive belts

The belt drive is easy to install and replace; overloads are compensated by the elasticity of the drives. This type is indispensable when working at high speeds.

Drive belts differ in a number of characteristics, primarily:

- type geared or not;

- length;

- width;

- form;

- rigidity;

- material.

Types

Drive belts are divided into different types, starting with narrow-section V-belts. Drives of this type are specialized for high-speed transmissions operating under different conditions. They were developed on the basis of parts with a regular cross-section. This design increases elasticity, reduces bending stress and guarantees better performance.

V-belts with shaped teeth are used when there is a need for increased rotation speed. Such drives guarantee the transmission of any power, having many advantages when compared with conventional ones.

V-belts with shaped tooth

CVT types are characterized by increased strength and higher efficiency. They are used in industrial and agricultural machinery units when significant power transmission is required. The cord base of these parts ensures not only wear resistance in operation, but also the ability to maintain their own characteristics in all modes of engine operation. Flexible and durable fibers prevent the drive from stretching and contracting. The special shape of the teeth guarantees a smooth ride and stability at all speeds.

Variable drive type

Poly-wedge types combine the excellent elasticity of flat ones with the better power transmission of wedge-shaped ones. They have a flat surface with special ribs. To improve performance and wear resistance, drives of this type are reinforced with a special cord. They are distinguished by better data when installed in tortuous drives.

Gear types have found application in machine tools, industrial, home equipment and auto engines. The main characteristic feature of transmissions of this type is synchronism and the transmission of large loads at low tensions. This makes it possible to reduce the load on nodes and systems.

Gear drive pattern

Marking

Traditionally, the marking of such belts indicates the following data:

- manufacturer;

- cross section;

- size;

- Date of issue;

- GOST;

- drive class;

- appointment.

Dimensions

The sizes of drives can be very different and are produced for a specific model of car or equipment. Before replacing this part on your vehicle, be sure to compare the new part with the part you are replacing.

Conversion table

Length table - part 1

Length table - part 2

Where it all started

The first rubber V-belt was invented in 1917 by one of the Gates brothers. Until this time, the main material for drive belts was leather. About 25 years later, the second important event occurs - the invention by Uniroyal Power Transmission of a synchronous, or toothed, belt, which is used in timing drives to this day. The company, by the way, by the mid-80s of the 20th century will become part of Gates. In the same 80s, the development and introduction of poly-V-belts for drives of attachments took place.

Today, the latest milestone in the development of timing belts is timing belts running in a hot oil bath. Due to the use of this design, the friction force was significantly reduced, and the belt itself became narrower, almost like a chain. As a result, wear has been significantly reduced and the service life of such a drive has increased, which today is equal to the service life of the engine. However, a drawback also emerged: the problem was to come up with a roller tensioner that runs in oil.

When you need to replace the alternator belt: signs of wear, we do it ourselves

Good day to all! In our material today, I propose to discuss such a topic as replacing the alternator belt.

If there is severe wear and tear, the generator may simply stop working because its drive belt has failed. Do not forget that in some cases the fault lies not in the wear of the belt itself, but in the components of the entire assembly. For example, motorists are often faced with the need to replace the tensioner pulley bearing. But some cars provide for the use of alternator belts without a tensioner.

In practice, changing the node is not difficult. It is much more important to notice problems in a timely manner so that a breakdown does not take you by surprise, at the most inopportune moment.