Suspension is one of the most important vehicle systems, directly affecting the level of comfort and safety. Technologies are developing, and automakers are constantly improving designs using new solutions. Today, the automotive industry uses many types of suspensions, based on the main types - dependent, independent and semi-dependent. All of them are presented in various versions and connections; they may differ in design, number and location of levers, type of damping and elastic element, but the purpose of the suspension system remains unchanged. The suspension is designed to reduce vibration and shock caused by uneven road surfaces, which reduces the load on the body shell and increases the level of comfort for all occupants of the car. Thanks to the system, wheels or continuous axles are connected to the body or frame, traction is transmitted from the engine, the position of the car is stabilized when driving, and possible body roll is reduced. Also, by maintaining the required geometry of the position and movement of the wheels by the suspension, which is the connecting link, maneuvering accuracy is ensured.

Features of the functioning of a multi-link suspension, its advantages and disadvantages.

Today, the most widespread assembly of cars is where MacPherson struts are mounted on the front and a semi-independent torsion beam on the rear axle, while the popularity of multi-link suspensions, which were born back in the mid-twentieth century and have significantly evolved since then, is growing. Today, complex systems with multiple levers are widely used as mountings on the rear axle of passenger cars (mainly rear- and all-wheel drive). Previously, multi-link suspensions were an attribute only of premium cars (Mercedes, Audi, BMW), but the variety of options and lower production costs have expanded the field of activity. The use of this type of chassis provides the car with a smooth ride and excellent handling, reduces noise, but, as in the situation with other variations, there are both advantages and disadvantages.

Multi-link suspension - what is it?

The first production car to feature the new type of suspension was the 1961 Jaguar E-type. Over time, it began to be successfully used on the front axle of cars, as, for example, on some Audi models. The use of a multi-link suspension gives the car amazing smoothness, excellent handling and helps reduce noise.

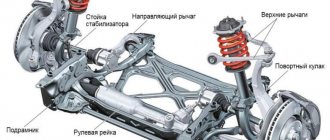

In this design, the wheel hubs are fastened using four levers, which allows adjustment in the longitudinal and transverse planes. The multi-link suspension design consists of the following components and parts:

- trailing arms;

- wishbones;

- stretcher;

- hub support;

- shock absorbers;

- springs.

The main load-bearing element of the suspension is the subframe; transverse arms connected to the hub support are fixed to it, which in turn ensures its transverse position. The multi-link rear suspension found on modern cars consists of three or five wishbones.

This is interesting: Do-it-yourself dismantling and replacement of the stove fan on Renault Megane 2 (3)

Which is better, Torsion beam, MacPherson beam or Multi-link

There is no absolute scale of values for different types of suspensions; each has its own limited use in certain classes and categories of cars. And the mood of producers often changes over time.

A torsion beam or semi-independent suspension, where the wheels are connected through a torsional element of a certain rigidity, can use MacPherson-type struts in its composition, although it is not exactly one.

The suspension is simple, highly durable, inexpensive and ideal for the most inexpensive cars. At the same time, it will not provide precise handling, nor high comfort.

MacPherson strut is a purely independent suspension, so it is more comfortable and better adjustable. But the complex design of massive struts and increased friction in reinforced telescopic shock absorbers create problems in terms of weight and accuracy of operation.

In addition, it is very desirable to use a subframe, which the torsion beam does not need.

The multi-lever has the best consumer properties, but is complex and high in price. Good for expensive cars with high requirements for handling and comfort.

Recently, there has been a return to simpler suspensions, even in those models that previously used multi-links. Manufacturers consider it unnecessary to adapt to the wishes of sophisticated auto journalists, which are not always clear to ordinary car buyers.

Principle of operation

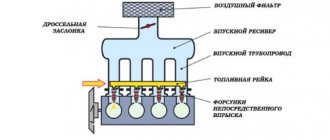

The functioning features of the suspension give the car such important characteristics as handling, stability and smoothness, which generally determine the level of safety. When performing various maneuvers, accelerating, braking, as well as overcoming uneven road surfaces, the system is activated. The ability of the hub to change its position in the horizontal plane, resulting in excellent performance when cornering and other conditions, is a distinctive feature of the design. The independent multi-link suspension is nothing more than the result of the evolution of the double-wishbone suspension. It is more difficult to design a chassis of this type, so it is designed using computer modeling. As a rule, the rear axle is equipped with a chassis with multiple levers, while there are also options where it is used for the front part, and the multi-link suspension scheme involves connecting one of the levers to the steering rack.

There are many chassis options based on the degree of rigidity. The most informative control is provided by a stiffer suspension, but the level of comfort is reduced. A soft suspension, on the contrary, while providing maximum comfort, is inferior in handling, which is why it is so important to implement these necessary qualities in one design. Independent suspension implies the implementation of autonomous operation of the wheels, so the upper and lower arms, independent of each other, are fixed on the body and on the hub, and each of the elements performs its own task, forming the character of the system, be it a change in lateral movement or camber.

The operating principle of a multi-link suspension remains the same as that of a double-wishbone suspension. The displacement of the wheel in the up and down directions relative to the body is ensured by transverse arms, while the trailing arm is responsible for preventing longitudinal movement. Under the influence of damping devices, the rigidity of the movement of the elastic elements is softened and the transmission of the impact force created by the wheel hitting a road unevenness to the body is minimized, which determines the smoothness of the ride. At the same time, the stabilizer performs a function that prevents swaying of the body and rolls. The system, like other components and assemblies of the machine, requires periodic maintenance, and the more complex the design, the more troublesome the maintenance. Suspensions operating in harsh operating conditions will have to be repaired more often.

Independent suspension - we put it in order with our own hands

The main suspension defects that appear after traveling 40,000-80,000 km are knocking and creaking , which are clearly audible even inside the car while driving on a bumpy road. What is this connected with? Knocking occurs for several reasons, they can be both serious and not so serious. In any case, the independent suspension must be urgently repaired; you can do it yourself if the repair involves replacing parts or tightening threaded connections; in other cases, you cannot do without visiting a service station.

The first step is to establish the cause and conduct a visual diagnosis of the suspension. To do this, the car should be driven into an inspection hole or use a jack, since in an unloaded state this part of the car will more readily show its defects. Yes, and it will be more convenient for you to crawl under it. Let's say in advance, if you are not a high-level locksmith, then arm yourself with a manual for your car, which is always included with the purchase.

Remember that a knock in the suspension area can be caused not only by a malfunction of this part, but also by a breakdown of other elements of your vehicle, for example, steering rods or CV joints.

So, you are located in a convenient area to examine the front suspension. Remove the shock absorbers and carefully inspect them for cracks. Next, check the integrity of the ball joints, lever, rod, silent blocks. Pay attention to all mounting bolts and rubber seals. There should be no cracks, tears, cuts or other damage anywhere. Carefully walk your gaze along the perimeter of the body: where the parts touch the body, there should be a intact and undamaged rubber gasket.

If any “illnesses” are clearly visible, evaluate your strength, whether you can unscrew the damaged part and insert a new one, whether the assembly sequence of the damaged unit is clear, whether the diagram is clearly depicted in the car’s operating book. If you can’t, or everything appears to be intact, then it’s time to visit the service station.

The main advantages of a multi-lever

Many car models offer either excellent handling or comfort, but the implementation of several levers in the design allows you not to choose between two important characteristics, excluding one of the concepts from the list of advantages of the car. Of course, there are no ideal solutions, just as there is no limit to perfection, so multi-link suspension has its pros and cons. The excellent combination of convenience and ease of control made Multilink a very popular system, despite its shortcomings. It is not for nothing that chassis of this type are used on premium cars. The main advantages of a car with multi-link suspension are as follows:

- The wheels of one bridge are not dependent on each other (for example, only the lever of the wheel that falls into the hole is activated). In the case of a beam, force is transmitted to the adjacent hub;

- Excellent handling, including at high speeds and in conditions of extreme, emergency driving;

- Softening of the hard suspension is achieved due to swinging springs, which absorb the impact of road imperfections, while no shocks are felt in the cabin;

- Stability, excellent grip on the road surface, which ensures a high level of safety;

- Keeping the wheel perpendicular to the road, which ensures an increase in the contact surface and improved traction on the road surface;

- Weight reduction due to the use of aluminum elements in the structure of the system;

- Transverse and longitudinal adjustment of the hub position;

- Protection from noise and vibrations;

- Chassis versatility, it can be used in cars with front-wheel drive, rear-wheel drive or all-wheel drive.

Advantages and disadvantages

Like any complicated mechanism, a multi-link suspension performs all the functions for which it was created:

- cars with Multilink have excellent handling, the contact patch with the road is always as large as possible, the influence of unwanted lateral forces is minimized, and positive forces arise on time and are well regulated when fine-tuning the suspension;

- the suspension provides the comfort inherent in any independent scheme, minimizing not only vertical accelerations of the body, but also lateral shocks when hitting bumps in corners; numerous elastic elements work well against small vibrations;

- the design has good maintainability, all levers and hinges are autonomous and can be independently dismantled for replacement;

- the suspension is usually combined with a subframe, which allows it to be further isolated from the body;

- the spatial separation of all levers and their arbitrary configuration (only the relative position of the end hinges is important) makes it easy to assemble rear-wheel drive units.

There is actually only one drawback - high complexity, and therefore price. Both in production and in repair, since a large number of wear-out hinges must be replaced.

It is unprofitable to include an increased safety margin in them; the addition of unsprung masses is multiplied by the number of levers.

How is all this secured?

The hub is attached to the wheel using four levers. This allows the car wheel to move freely in the transverse and longitudinal plane. The supporting element in the design of this suspension is the subframe.

The transverse arm is attached to it through special bushings with a metal base. To reduce vibrations, they use rubber. The transverse arms are connected to the hub support. This ensures the correct position of the wheels in the transverse plane. Often, a multi-link independent rear suspension includes three wishbones:

- Lower rear.

- Front.

- Upper.

The latter transmits forces and connects the subframe to the wheel support housing. The lower one is responsible for toe-in. The rear element absorbs the forces that are transmitted from the body when the car moves. The steering of the wheel in the longitudinal position is carried out thanks to the trailing arm. It is attached to the car body using a support. On the other side, the element is connected to the hub.

A passenger car has four trailing arms, one for each wheel. The hub support itself is the base for the wheel and bearing. The latter is secured with a bolt. By the way, if the tightening torque is not observed, the bearing can be damaged. When making repairs, you should leave a slight play in the hub. Otherwise, your bearing will fall apart. Also, the multi-link front suspension has a coil spring in its design. It rests on the lower rear wishbone and absorbs forces from it. The shock absorber is located separately from the spring. It is usually connected to the hub support.

Flaws

If the question arises about what is better - a beam or a multi-link suspension, it is worth considering the disadvantages of the latter. The biggest drawback is the complexity of the design. Hence the high cost of maintenance and the expensive price of the car itself.

The cost of a multi-link suspension is 2-3 times higher than a conventional semi-independent beam. The next thing is a resource. Since the design uses many hinges, levers and steel blocks, they all fail sooner or later. The service life of multi-link suspension parts is 100 thousand kilometers. As for the beam, it is almost eternal. The design is much more reliable and does not require expensive maintenance. The most that needs to be replaced is the shock absorbers. They “walk” on our roads for about 80 thousand kilometers. The multi-link suspension requires more attention when driving over uneven surfaces. If the car begins to make knocking noises in the front or rear, it is worth inspecting the condition of the levers and silent blocks. If there is play or free play, they should be replaced.

The cost of new levers for a Mercedes in the 124th body is $120 per wheel. Despite the age and low cost of the car, spare parts for it have not become cheaper. The same applies to other cars that use this type of suspension. When replacing silent blocks, you need a lift or inspection hole. Typically, such machines are repaired at service centers. And these are additional costs.

Diagnostics and repair of rear suspension

Now move on to the rear suspension. There are fewer details here, but this does not mean that you need to be less careful. Again, we start with the shock absorbers. Next, your attention should be given to the rods and seals. A special feature of the rear suspension is the proximity of the exhaust pipe, which can also produce a sound similar to a suspension failure if it is poorly secured, loose or leaning against some part, creating friction and knocking. The muffler is carefully examined, you can rock it in different directions, this will probably eliminate the strange knocking noise, and also inspect the fastening.

So, the inspection is completed, the components have been tightened, and a partial replacement has been made. Perhaps this is “first aid” for your car. Other repairs will require more complex technical equipment and qualifications. Don’t be too lazy to crawl under the belly of the car if you hear a suspicious knock. Naturally, the service station will fix any problem for you, but there is a chance that you will simply overpay for a minute replacement of a rubber gasket or for some other minor operation.

Home →

Maintenance and Repair →

Chassis →

This is interesting: Degreasing the body is a necessary step in painting a car

Can I identify the problem myself?

If you notice characteristic knocking noises when driving your car, your suspension may need to be repaired. To find out the exact cause, you need an inspection hole or overpass. If it is a front suspension, inspect the condition of the constant velocity joint. It has a duster on it. If it is cracked, an urgent replacement is needed. Otherwise, all the dirt will get inside and you will have to buy a new CV joint assembly.

Check the play in the tie rods. Inspect the shock absorbers. If there are streaks on them, most likely the sound is coming from them. This means that the valve inside the shock absorber is broken and the rod moves randomly. The silent blocks of the levers and anti-roll bar should also have no play. Inspection of the rear suspension should start with the shock absorbers. Next, we check the rubber seals and rods. Often elements are damaged in the area of contact with the exhaust pipe.

Pay special attention to this place. If the muffler hits the body, there are characteristic traces of impacts, it is worth replacing its cushion. In most cases the problem disappears. After examining the condition of the suspension, summarize which elements have failed and require replacement. If you have no experience, it is recommended to contact the service.

Stabilizer

The multi-link, unlike the semi-independent beam, has a stabilizer bar in its design. The name itself speaks for the purpose of the element. This part reduces roll when cornering at speed. This parameter is also affected by the stiffness of shock absorbers and springs. The presence of a stabilizer significantly reduces the risk of skidding when cornering, as it ensures continuous contact of the wheels with the road surface. The element is a kind of metal rod. It looks like the photo below.

It is installed on the subframe of the multi-link suspension and secured with rubber supports. Thanks to the rods, the rod is connected to the hub support. What are the pros and cons of multi-link suspension? Let's look at them below.

Advantages

Cars using this suspension are much more comfortable. The design uses several levers. All of them are mounted on subframes through silent blocks. Thanks to this, when passing through a hole, the suspension perfectly absorbs all the irregularities.

By the way, the lever of only the wheel that fell into the hole works. If it is a beam, all forces will be transferred to the adjacent hub. In a car that uses a multi-link suspension, there is no unnecessary noise or vibration when going over uneven roads. This car is also safer. This is explained by the use of a stabilizer bar. The weight of the levers is much lighter than the beam. This reduces the vehicle's curb weight.

Thus, a multi-link suspension is:

- Comfort.

- No strong impacts on the body.

- Increased wheel grip.

- Possibility of transverse and longitudinal adjustment.

History of appearance

The first car with Multilink suspension was the 1979 Porshe 928.

The first multi-link suspension design was used on the Porshe 928 sports coupe in 1979. In 1982, the modernized scheme was used on the Mercedes 190 model. The peculiarity of the multi-link suspension design provided the car with excellent cornering. This was achieved by creating the effect of steering the loaded rear wheel several degrees into the turn. Later, other automakers began to use multi-link suspension.