When is replacement needed?

Discs need to be changed after 40-100 thousand mileage, it all depends on the model of the car, the features of its operation and the quality of the installed spare parts. The period may be longer if the condition of the elements is good and wear does not exceed acceptable values. Pads are changed much more often, the average period on cars with an automatic transmission is from 25 to 30 thousand kilometers, on cars with a manual transmission - from 30 to 50 thousand. Main signs of wear:

- The braking distance has become noticeably longer.

- The brake fluid level has decreased and remains the same. If it constantly decreases, it means there is a leak and repairs must be done urgently.

- The brake pedal fails or its travel has become much longer.

- Disc squeaking when braking or any other extraneous sounds.

- A metallic grinding noise while driving occurs due to severe wear of the pads. This leads to disk damage.

- Vibration during hard braking. With severe deformation, it occurs constantly.

- The car pulls to the side when you press the pedal.

- Damage or deformation detected during inspection after removal of the wheel.

For your information!

Many models are equipped with pad wear sensors. When their thickness is less than the permissible value, a light comes on on the panel. There is a simpler option - a spring is placed inside the pad; after the lining wears out, it rubs against the disc and a characteristic squeak is heard.

Any malfunction of the brake system requires immediate attention. The easiest way is to go for diagnostics, but you can check it yourself by removing the wheels one by one and inspecting the discs and pads. Do not forget that the cause of the problems may be the brake master cylinder or other elements included in the design.

About the dismantling procedure

This work should be performed with gloves. The discs are replaced on both sides of the axle, and it is recommended to change the pads as well.

Sequencing:

- The bolts on the front wheels are loosened (the car is raised using a jack or lift);

- Remove the wheel;

- Disconnect the brake pad wear sensor cable;

- Unscrew the bolts securing the caliper, then remove it and fix it;

- Dismantle the pads, fasteners, disc screws and the disc itself.

Important nuances of replacing brakes that you need to know

If you carry out the work yourself, you should understand all aspects in order to avoid mistakes. You should not skimp on the reliability of spare parts; not only their service life, but also traffic safety depends on this; cheap ones work worse and can lead to damage to other parts of the system. Please note the following:

- Front pads and brake discs should be replaced much more often than rear ones. They bear the main burden. On average, the resource is 2 times less.

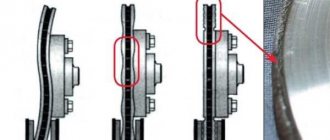

- All data on the disks is printed on the end part. From the markings you can determine what the permissible minimum thickness should be. If it is less, it is impossible to restore their normal performance.

- Change discs in pairs, even when one of them is in good condition. This is due to the fact that due to uneven thickness and wear, the brake system will not work as well as it should. When buying used parts, you should only take those that were on the same car.

- Grind only cast iron products if the thickness is greater than the minimum permissible value. This can be done on both solid and ventilated parts, but composite versions are not subject to such processing. It is not possible to restore rims made of metal ceramics and carbon fiber. This work can only be done on a machine; it cannot be done in a garage. Usually the thickness reserve is only enough for one groove.

- Bleed the brakes even when the system has not been opened. New parts have different parameters from old ones, so it’s better to play it safe and rule out any problems.

- Change the brake fluid every 60,000 miles or every 2 years if the car has driven less during this period. The composition loses its properties, becomes contaminated and becomes saturated with water, which is unacceptable.

- In addition to discs and pads, it is necessary to change other parts of the system from time to time - brake cylinders, springs, brackets and other parts of the caliper. This is done as it wears out. When the rubber boot on the cylinder is damaged or the steel surface is corroded, it should be replaced immediately.

- After work, make sure that there are no leaks at the connections. Inspect the components from the pit, this makes it much easier to detect problems.

- Check the condition of the brake hoses. If they are cracked or swollen, replace them immediately.

Advice! It is advisable to use discs and pads from the same manufacturer.

In order for the brakes to work longer, you should not brake sharply or hold the pedal without releasing it; overheating will cause the metal to deform. Very often the discs will slip if you drive into a puddle when they are very hot. Temperature changes can ruin them in one go, especially when the spare part is of poor quality.

Where to buy brake discs

In order for the brake system to last as long as possible, it is necessary to purchase only high-quality certified parts. The modern car market is replete with a huge number of spare parts, including many low-quality analogues. Their price is several times lower, which attracts car enthusiasts. Such a temptation will soon lead to even greater costs. Therefore, to make driving your favorite car comfortable and safe, you should purchase spare parts only from trusted manufacturers. Buying brake discs in the Dvizhkom online store means guaranteeing reliable and durable operation of the brakes. We work only with well-known domestic companies, so our products meet all quality and safety standards.

The best disc manufacturers

When replacing, it is important to choose a reliable option; you should not use products from other models or skimp on quality. All disks can be divided into three types: inexpensive, medium and premium segment. It is best to select based on the characteristics of the car; the more powerful its engine, the higher the requirements for the brakes.

Inexpensive options

A low price does not mean the same quality, it’s just that manufacturers are focused on the used car market or on cheap models that use the simplest, small-sized wheels. The following brands performed best:

- Avantech. A South Korean manufacturer that supplies products to the assembly lines of some automakers. An alloy of cast iron and carbon provides special strength, and a special coating protects against corrosion. This option is an order of magnitude cheaper than most analogues with comparable quality.

- Nipparts. The Dutch company produces brake discs for Asian cars and sells them throughout Europe. They are distinguished by good quality, high safety standards, and low prices. During production, they are tested for braking efficiency for the best performance.

- Bosch. The brand is German, but all factories are located in Asia, and the quality meets all standards; the products are supplied to many automobile conveyors. The discs are cheap, but this option is only suitable for those who use the car in standard mode; if you often have to brake urgently or drive in the mountains, it is better to choose another manufacturer; under high loads, the efficiency is greatly reduced.

- NIBK. The Japanese company began producing parts for brake systems only at the end of the last century, but its quality and reliability made it popular all over the world. A wide range allows you to find discs and pads for most models, prices are at an average level.

- Ferodo. British concern producing brake discs. They are manufactured using a special nonlinear processing technology, which ensures quality and long service life.

For your information! Some automakers recommend certain manufacturers of spare parts. It is better to follow their recommendations as all the brands offered are tested and ensure safety and reliability.

It is worth buying discs from trustworthy stores. There are a lot of fakes on sale, which are much cheaper, but the quality is so low that the service life is reduced significantly. Contact an official representative of the brand, if there is one.

Medium and expensive price segment

They are used as a replacement for original products, which most often cost much more. Middle-class products are of good quality; all the brands presented have been in business for a long time and their production process is streamlined. Best options:

- Blue Print. British company with factories in Asia. Made from steel, the surface is perforated in a special way to ensure better adhesion to the pads and minimal braking distance.

- Masuma. The Japanese brand, which has the lowest number of manufacturing defects of all the companies represented, products are purchased by some Asian car manufacturers. There are often fakes on sale.

- Schneider. A German company focused on vehicles used in extreme conditions and heavy loads. Produces ventilated, cross-drilled discs that provide very effective braking in difficult conditions. But the pads will wear out much faster.

- Lucas (TRW). German manufacturer of brake system parts. The products are painted black, which protects them from corrosion and makes them recognizable. The price is low, but some models have a short service life, especially with aggressive driving.

- Brembo. An Italian company that produces high-quality wheels using special technology, which provides a warranty period of up to 80,000 kilometers. The model range is constantly updated, there are many options, so you can choose them for almost any model.

This group is distinguished by good quality, it is suitable for everyday driving, and there are options for those who use the car under high loads. It is worth selecting based on engine power and the nature of operation; sometimes it makes sense to install larger discs to increase braking efficiency.

As for expensive options, the quality is always high, but each has its own characteristics:

- Fremax. Suitable for extreme driving, packaged without air access, so there is no need to degrease the surface.

- DBA. They have perforations, which ensures good braking even when water gets in, are resistant to overheating, and have a long service life.

- AND THOSE. It supplies products to many manufacturers, there is a line for extreme driving, it can withstand high temperatures without breaking the geometry.

- Otto Zimmermann. They produce wheels for the VAG concern and other European manufacturers. The quality is high, it has good wear resistance.

- EBC. Expensive products for sports cars and premium cars. Defect rates are minimal, performance characteristics are among the best.

You should not buy expensive options for a small car, since there will be almost no difference compared to cheap models due to low loads. When choosing, you can read reviews, since different brands have their own optimal price solutions.

About the features of brake systems

What kind of brakes a car has, drum or disc, depends on the make of the car and the year of its manufacture. Cars produced 20-30 years ago mostly had a mixed system, that is, the front axle was equipped with discs, and the rear axle was equipped with drums. This trend has continued to this day on models of the automobile plant in Tolyatti. Modern cars are equipped with powerful power units capable of developing greater power and high speed performance.

In such conditions, the requirements for car brakes increase several times, so leading automakers have switched completely to disc brake systems. This replacement had a positive effect on traffic safety; such systems are easier to equip with ABS, they are well ventilated, and have less weight compared to drum brakes.

How to carry out the work

When replacing disc brakes, the sequence of work must be followed. This must be done on a level surface, preferably in a garage, and prepare a set of tools for fastening in advance; different models use different options - from ordinary bolts to screws with an internal hexagon or star. Step-by-step instruction:

- Place chocks under those wheels that will not be removed to prevent the car from rolling.

- Remove the mounting bolts or nuts on the wheel rim. Raise the car with a jack and remove the wheel. It is dangerous to put a stop and leave the car on a jack.

- Unscrew the cap on the brake fluid reservoir. This will make it easier to press in the brake cylinder.

- When there are fixing brackets, carefully remove them with a screwdriver. Then unscrew the caliper mount. Take a flat-head screwdriver and carefully press in the piston on the brake cylinder.

- If you need to change the pads, the old ones are removed, the installation site is cleaned of dirt, and then new parts can be installed. Reassemble in reverse order.

- When removing the disc, move the caliper to the side and hang it so as not to damage the hose. The bolts must be removed carefully; to do this, first block the hub in a stationary position.

- Clean the installation site from debris and deposits. Replacing the brake disc is carried out in the reverse order. If there is a protective lubricant on it, remove it with a degreaser.

For your information! Carry out work no earlier than half an hour after the trip. All parts of the brake system must cool down.

When installing discs or replacing pads, inspect all elements and, if necessary, replace worn ones. Pay attention to the fasteners and brake hoses; if they are cracked, buy new ones. You can test the system ahead of time from the pit to ensure you have everything you need in advance.

About the design of disc brakes

When the wheel is removed, you can see that such brakes consist of only three main parts:

- Metal disks;

- Light alloy caliper body;

- Brake pads.

The discs are attached to the wheel hubs and rotate with them while driving. There, a caliper with a brake cylinder and two pads, which stand on both sides of the disc, are attached to the axle. Initially, two cylinders were installed, but later, after modernization, only one was left. This did not in any way impair the performance and efficiency of the mechanism. Where there is only one cylinder, it is mounted on the inside of the disks to improve their cooling.

How to bleed and break in brakes

After replacing parts, bleed the system, even when the calipers were not removed. The easiest way to do the job is with two people; prepare everything you need in advance: fresh brake fluid, a cut-off plastic bottle and a piece of hose that should fit tightly onto the bleeder fitting. Sequencing:

- Open the cap on the expansion tank and pour liquid to the very top. Start with the wheel furthest from the master cylinder.

- Pour some brake fluid into the container, put one end of the hose on the fitting, and lower the other into the bottle.

- The assistant must press the pedal vigorously several times and hold it in the lower position. Carefully unscrew the fitting by half a turn or a little more, watch how the liquid comes out into the container, and close it after a few seconds. Carry out the work until there are no air bubbles in the extruded composition.

- Also bleed the remaining wheels. Monitor the level in the tank, top up if it falls below the mark.

After finishing the work, put on the rubber plugs and put the wheels in place. Make sure that the system is working properly by accelerating and pressing the pedal sharply. If the car pulls to the side, it means the pumping was done incorrectly, you need to repeat it again.

After replacing the pads and discs, the system must be run in. At first, do not press the pedal too sharply, do it smoothly and intermittently. After a run of 300 kilometers, accelerate on the highway and brake sharply several times, finally grinding in the parts. After that, drive as usual.

Replacing discs and pads with your own hands is not difficult if you follow the instructions for carrying out the work. Select quality replacement parts to ensure your brakes work properly and are safe. After replacement, be sure to bleed the brake system and run it for at least 300 kilometers.

What is a block?

If anyone has not seen this detail with their own eyes, let us briefly talk about it. It is a plate of a certain shape made of steel. Materials with a high coefficient of friction are attached to it in a special way. The effectiveness of the pad completely depends on their properties and quality. They are subject to special requirements, since they have to work in special conditions.

When braking, the working area heats up to high temperatures, the pads have to deal with water, chemicals used to treat the road surface and other negative factors. At the same time, they should not be a source of premature wear of the discs. Their design must ensure unhindered removal of wear products and smoke from the working area.

To extend their service life and delay the time for their replacement, follow very simple rules for operating and driving a car:

- Avoid sporty or aggressive driving;

- Do not overload the vehicle;

- Monitor the technical condition of the suspension, steering and tires.

Pads and discs belong to the category that is subject to rapid wear. But you should not save on this, since road safety largely depends on this. The specificity of how the brakes work is that the front ones work earlier, so they are replaced approximately three times more often than the rear ones.