The Lada Granta passenger car, which is considered one of the most affordable in the world, is equipped with a “stove” (or simply a heater) that is standard for VAZ cars. Typically this unit works very well, but problems can still occur. Therefore, if the Lada Granta stove does not heat well, then there must be reasons for this that simply need to be discovered.

We carry out diagnostics

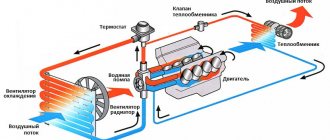

If it is cold outside and the interior cannot warm up properly, then you need to check the operation of the cooling system, which has a direct effect on heating the interior.

Coolant level

To do this, you need to open the hood and, with the engine not warmed up, check where the coolant is located.

If its level in the tank is between the minimum and maximum marks, then everything is in order. But, when this level decreases, problems with the tightness of the cooling system are possible, and this leads to a decrease in pressure inside the system. If the problem is not corrected, the stove will not be able to warm the air in the cabin effectively enough.

Thermostat

This is a native Luzar thermostat

We are talking about the possible sticking of the thermostat valves in a position where the coolant circulates only in a larger circle. So, during the cold period, the coolant will not warm up to normal temperature, and therefore the interior will not become warmer.

Thermostat location under the hood

You can verify the presence of this particular breakdown by the fact that the car, while stuck in traffic jams, begins to overheat very quickly. In addition, when moving along the highway at a stable speed, the engine loses its temperature too quickly, if we talk about the cold season. However, even if these “symptoms” are not observed in your car, this does not mean that the thermostat is working properly. It is quite possible that its defect lies only in tangible problems with the interior heater.

For even more complex cases, you can check the pipes that connect to the heater radiator. Normally, one should be hot and the other just slightly warm. If the second of the pipes is very cold, this will indicate that the stove radiator in your car is clogged. It won't be easy to clean it. Most likely, you will have to completely remove the entire stove.

And for the most extreme situations, when none of the above helps, and there is very severe frost outside, you can simply block the radiator’s air supply with any dense object, such as cardboard or plastic.

If the thermostat is faulty during the cold period, the coolant will not warm up to normal temperature, and therefore the interior will not become warmer.

Air temperature regulator damper

If the cooling system of the Lada Granta is working properly, then the reason for the poor operation of the stove may lie in the functioning of the air temperature regulator damper.

The fact is that the position of this damper directly determines which air flow will follow through the heater radiator, and which flow will enter the car interior without reaching the radiator itself.

Blown-out air temperature regulator (either the slider or the cable with the mechanism to which the regulator transmits tension may be faulty)

The malfunction may relate to the heater control panel or poor operation of the gearbox through which the damper moves. Depending on its position before the breakdown, cool air can enter the cabin in the cold season or hot air in the summer.

Heater fan and fuse

The fuse box is indicated by an arrow

Also check whether the heater fan turns on. If it remains motionless, then you need to check the condition of the 30A fuse. It can be recognized by its green color and F4 index (in the picture above). It is located in the additional concentration of power fuses. It is located under the hood, near the expansion tank of the cooling system.

Cooling system Lada Granta - 8 and 16 valves, with and without air conditioning

| Name | Peculiarity |

| The engine cooling system (hereinafter referred to as SOD) of the Lada Granta family is completely identical to the Lada Kalina | Heater radiator, single-pass, low resistance, aluminum, brazed, high efficiency |

| The radiator is built into a small circuit, unlike previous generations | |

| The thermostat has one valve, not two, as was previously the case | |

| The thermostat controls the flow of antifreeze through the radiator | |

| The interior heating system has been improved by removing more heat from the heater radiator | Increased flow of antifreeze through the radiator at a small circle of rotation |

| One-way passage pattern instead of two-way | |

| Aluminum pipes are flat instead of cylindrical | |

| Soldering is used at all stages of articulation | |

| No chance of airing | Changing the angle of inclination of the antifreeze supply/return lines |

| Improved aerodynamic performance | |

| Fine tuning of engine operating temperature | |

| Increased operational efficiency due to | Changes in ignition timing |

| Economical fuel consumption mode |

Additional Tips

However, it also happens that the problem with heating the interior consists only of some small mistakes. Therefore, before you start disturbing the service center workers, check whether all the dampers on the stove are set in the required position. It wouldn’t hurt to tug the hot air damper a little.

There is a possibility that it is simply stuck. And, with a significant push, it will be moved from its place.

According to reviews of many car owners, the Lada Kalina car is recognized as one of the warmest cars of domestic production. It is very warm in the car in winter, the interior is evenly heated and the rear passengers in the car are comfortable, since the hot air from the stove is supplied to the feet of the rear passengers in full and is not “lost” in the air tunnels of the ventilation system as in cars 2109 and 2110.

If one day it became cool inside the Lada Kalina car, and instead of the usual hot air, cold air began to blow from the stove, then there was a problem in the car’s engine cooling system. Malfunction of the cooling system can cause the engine to overheat to critical temperatures and lead to serious engine damage. An air lock can cause many problems in the cooling system of a Lada Kalina car. Before removing the plug, it is first recommended to check the entire car engine cooling system (SOD), since the cause of ineffective operation of the SOD and a cold stove can be not only an air lock in the system, but also a breakdown or deformation of the pump impeller, kinks in the pipes, or incomplete opening of the thermostat . Only after checking the entire cooling system should you begin to remove the air lock.

Signs of an air lock in the engine cooling system

An air lock creates an obstacle in the cooling system, due to which antifreeze or antifreeze cannot circulate and evenly cool a running engine.

Reasons for the appearance of an air lock in the engine cooling system:

— Air may enter the system when replacing or adding coolant.

— In the engine cooling system, there is a leak in external air due to weak compression of plastic fittings, loose clamps, a leaking radiator, a leak in the pump and a faulty expansion tank cap valve. One of the signs of a plug in the ODS is the gurgling of coolant under the instrument panel when the engine warms up.

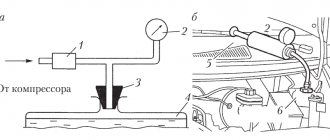

To remove the plug, you need to loosen the clamp and remove tube 3 or 22 from the heating of the throttle assembly

— The cylinder head gasket (cylinder head) was blown. As a result of the breakdown, a coolant leak is visible from under the cylinder head. Exhaust gases escape from under the cylinder head, you can see the bubbling of antifreeze, the formation of an emulsion in the expansion tank, and white steam in the car exhaust.

An air lock in the SOD can form in both the small and large circulation circles. The disadvantage of Kalina's SOD is the location of the expansion tank in a large circle. As a result, until the thermostat opens completely, it is difficult to remove the airlock. Therefore, in the cold season, “gasification” helps, as a result of which the car warms up faster, and when the engine reaches a temperature of 101-105 degrees. The thermostat opens a large circulation circle and the air exits into the expansion tank.

Causes of air locks

Air is characterized by relatively low thermal conductivity, and by itself it is rarely used as a cooling agent (the exception is radiator blowing, but the reasons here are prosaic - the complete absence of energy costs). But its danger when mixed with technical fluids lies not so much in the reduction of heat capacity, but in the formation of air pockets, which, accumulating at the highest points of the line, prevent the free flow of coolant.

When does air leak into a sealed engine cooling system? There may be several reasons:

- depressurization of the system is a violation of the integrity of the connections of pipes, tubes, hoses at the point of their attachment to the fittings, which leads to such a phenomenon as suction of outside air. This can happen as a result of overheating, accidental mechanical impact, inept driver actions, or due to natural wear and tear. Separately, it is worth mentioning cases where loss of tightness occurs due to prolonged exposure to low pressure in the system, observed at the surface of the pipeline walls during coolant movement;

- Many drivers don’t even realize that when replacing or adding antifreeze, if done quickly, a large funnel is formed that does not allow air to escape. As a result, a noticeable amount of air enters the system, which threatens the formation of traffic jams with all the ensuing consequences. Therefore, the recommendation to pour antifreeze in a thin stream, regardless of time, remains relevant for a significant part of car owners;

- problems with the functioning of the air valve. A pump is used to circulate coolant in the system, but the pressure created is not static: due to the heating of the liquid, the pressure increases in certain sections of the line, and decreases in the area of the radiator. This is, in principle, normal. But in some cases, the area of high pressure reaches the expansion tank, the air in which is compressed, and the valve in the tank lid bleeds it out. At reduced pressure, the reverse process occurs - air is sucked in. But if the valve is stuck, then it only works in one direction. This is fraught with the accumulation of air mass, which is simply forced to move on through the pipelines, mixing with the coolant;

- air can penetrate into the CO through a leaky pump seal, as well as through the fiber if it has end-to-end mechanical defects;

- antifreeze leaks through the connections of hoses, pipes and both radiators may not lead to air entering the system through them, but in such cases the volume of coolant decreases, which automatically leads to an increase in air volume (through the expansion tank). If the radiator is clogged, the engine begins to overheat, and collectively this leads to the formation of traffic jams;

- Violation of the integrity of the cylinder head gasket is another common cause of antifreeze leakage penetrating into the cylinders, as a result of which the volume of coolant decreases, and you already know the consequences of this phenomenon.

By the way, when antifreeze gets from the cylinders into the crankcase and accumulates there, checking the oil level with a dipstick may show its increase. If coolant enters the exhaust system, this can be detected by a change in the color of the exhaust from transparent to white.

This problem should not be treated as a minor issue. Troubles if airiness and the causes of its occurrence are not eliminated may be too serious. A change in the normal circulation of antifreeze along the main line is only the first sign, but this is where problems with heat removal from the power unit begin.

Since coolant does not enter the radiator due to air locks, it does not cool and flows into the engine while still hot. The latter begins to overheat, worsening its dynamic performance.

A secondary manifestation of CO airiness is deterioration in the performance of the cabin heater, since antifreeze does not reach it, and the operation of the fan does not improve the situation - cold air continues to flow into the cabin

Most often, drivers pay attention to traffic jams not because the engine is overheating, but because they are cold

In the warm season, this reason also becomes unobvious. Meanwhile, the abnormal temperature conditions of the engine will sooner or later result in thermal shock - the worst thing that can happen to it at all. And then you cannot avoid spending a lot of money on restoring the engine, and you will have to do without a vehicle for quite a long time - such malfunctions cannot be repaired in a day or two.

The main signs of the presence of an air lock

The most reliable factor indicating that air has entered the cooling circuit is a deterioration in the efficiency of the heating system in the cabin. Therefore, many people are concerned about the question: how to remove air from the system? If the air lock is large enough, Lada Kalina owners may notice a characteristic “murmur” coming from under the panel. Thus, the stove betrays itself, through the lines of which antifreeze circulates in “steam” with air.

It is also not uncommon for a plug to form directly inside the thermostat housing. A sign here is a very long warm-up of the engine. The temperature indicator needle remains at the beginning of the scale for a long time. An air lock in the cooling system prevents the valve inside the thermostat from closing, forcing fluid to circulate in a large cooling circle. And it is important to know how to remove air from the system.

Causes of air locks

Thermogram as one of the ways to detect air pockets

A formed air lock in a heating battery can occur for a number of reasons. The main one is coolant leakage. Even a slight decrease in the volume of water in the system entails the formation of air spaces in pipes and radiators.

In addition, we must not forget that water is characterized by the degree of oxygen saturation. During heating, not only expansion occurs, but also steam is released. It can concentrate at the highest points of the highway. Most often, an air lock in a heating radiator is formed precisely because of this. After the coolant cools, its volume decreases, and the resulting space is occupied by air. During operation of the system, in order to avoid the occurrence of these phenomena, you must adhere to the following recommendations:

- Compliance with the level of pipes and heating devices. Even a slight misalignment of the battery will pose the question to the owner - how to remove the air lock from the heating system;

- The use of system elements, the material of which does not allow oxygen molecules to pass through. The most common mistake is installing cross-linked polyethylene pipes without a protective sheath;

- Compliance with heating operating modes. This applies to both the operating temperature curve and the pressure. To do this, pressure gauges and thermometers should be installed in critical sections of the pipeline;

- For closed systems, it is recommended to install automatic coolant make-up. If even a small amount of water decreases due to leakage or evaporation, this mechanism will automatically add the required volume of coolant.

But how to break through a blockage in the heating if it has already formed? First you need to find it. A clear sign of its occurrence will be a sharp decrease in temperature in a certain place of the pipeline or radiator. Characteristic sounds will also appear - gurgling and flowing of liquid. Light tapping will help you find the exact location of the defect. At this point, the metal will create slightly higher sounds than when completely filled with water.

If you need to avoid a situation in which removing the formed air plug from the heating pipes will be difficult, it is recommended to install a separator after the boiler. This device reduces the gas content in water.

In what cases is air able to enter the system?

An air lock can enter the cooling circuit in three main situations, namely:

- when the owner ineptly fills in antifreeze or replenishes the system to the required level;

- if a partial depressurization of the circuit occurs, implying the penetration of an air plug through loose connections of the lines with the elements of the system;

- when a malfunction occurs in the valve present in the expansion tank plug (the valve is necessary to relieve excess pressure from the specified container). And then you will need information on how to remove air from the system.

Remove the air lock from the Priora vehicle

Priora air from the fuel system

Here's how it's done:

- the VAZ 2107 tank is checked to make sure there is fuel in it;

- the air release fitting on the fuel filter opens;

- Fuel is pumped up with a hand pump until fuel flows through the fitting without air bubbles;

- without stopping the pumping, close the air release fitting;

- Continue pumping until resistance is felt.

Now we need to try to start the engine. If this does not work, it means that air has entered the vehicle and must be expelled from there. On Priora it is done like this:

- the union nuts on the injection nozzles are loosened;

- the starter spins until the fuel comes out;

- Now the nuts are tightened and the engine can be started, as the air will escape along with the fuel.

In this way, the system of the Priora car is de-aired.

About design defects of the system

Over time, the owners discovered three significant design flaws in the circulation system of the Lada Kalina engine cooler. They allow air to gradually accumulate inside the circuit, leading to the formation of the well-known plug. When air is present in a sufficiently small volume, the circulation process is only slightly disrupted, which is so far tolerated by the system painlessly. Here, a thermostat is connected as a control element, raising the temperature of the antifreeze (before opening the valve). If you do nothing in this situation, then as air accumulates under the pressure of the plugs, the stove will “give up,” reminding the owner of itself with the previously mentioned “murmuring” and lack of heat supply.

- The location of the expansion tank is below the upper level of antifreeze in the system.

- Frequent failure of the valve in the tank cap plug.

- Gradual loosening of the clamps holding the pipes at the joints with the circuit elements. Here, over time, there is a danger of not only the plug penetrating into the system while the engine is running, but also creating the risk of fluid leaking out.

Reasons for air getting into the system

There are enough reasons why air pockets form inside the cooling circuit of the Lada Kalina engine. Among them we will highlight the main ones.

- Loss of system tightness, which is manifested by an intensively decreasing level of refrigerant (can be observed by the marks of the expansion tank).

- A valve in the tank cap breaks down, causing the antifreeze to begin to boil at a lower pressure, which inevitably causes plugs to appear. Now the question remains: how to remove the air.

How to remove air from the engine cooling system.

The process of removing an air lock on cars is almost the same, be it Kalina, Priora, Granta, Hray, Vesta, VAZ 211(0-5), 2101-2107, Opel, Daewoo Matiz, Nexia, Nissan Almera, Gazelle Business, Audi 80-100 , BMW E39, Peugeot, Chevrolet Cruze, Skoda, Mazda, Mitsubishi Lancer, Suzuki Grand Vitara, Niva, UAZ, Volkswagen, Ford, Renault Duster, on Chinese Lifan and even on premium class cars.

There are several options for removing an air lock from the cooling system:

Option #1:

- Remove the plastic casing from the internal combustion engine. Why do you need to unscrew the filler cap to fill the oil? Remove the trim. After removing the casing, you need to close the neck to avoid the ingress of various kinds of objects.

- Find the pipes that provide heating for the throttle assembly.

- Remove any one pipe.

- Unscrew the cap of the expansion tank.

- Cover the neck with a clean piece of rag or tightly connect the hose and blow into it.

How to “drive out” a traffic jam?

There are several ways to eliminate a blockage in the cooling circuit of the Lada Kalina power plant. Next, let's look at their features and how to remove air.

Method one

The location of the throttle assembly appears as a design convenience for the LADA Kalina cooling circuit. It is located at the highest point of the system. The procedure for eliminating a traffic jam is as follows.

- We set the heater temperature switch (knob in the cabin) to maximum.

- Under the hood, remove the valve cover protective panel.

- Use a screwdriver (cross-shaped) to loosen the clamp and remove the rubber inlet pipe from the throttle body fitting (you can also resort to removing the outlet hose).

- Unscrew the cap on the expansion tank.

- Now we use our own mouth. With its help and through a sterile cloth, we pump the air accumulated in the lungs into the expansion tank. We do this until antifreeze appears from the specified fitting.

- If this is successful, then return the hose to its place, secure it and screw the cap onto the tank.

However, this is not the only method of removing air.

Method two

Its principle closely echoes the manipulations in the first method. There is no need to get your mouth dirty or even open the tank lid. All actions boil down to:

- warm up the engine to operating temperature and turn it off;

- carefully removes the same hose from the throttle assembly;

- We observe liquid flowing out of the fitting: if it appears, then return the hose and tighten the clamp;

- a one-time manipulation may not be successful, so we repeat the procedure again until the liquid appears.

Method three

Let's look at another option for pumping air. Let us immediately note that this method is not particularly effective. The actions do not involve disassembling the system.

- Here you will need to drive your front wheels onto an embankment so that the highest point of the contour is the air plug in the cooling system on the radiator housing.

- It must be removed, as well as the cap on the expansion tank.

- We start the engine and bring the temperature in the circuit to the operating parameter.

- We observe a decrease in the volume of antifreeze in the LADA Kalina tank and immediately replenish it to the required level. During the process, air bubbles will be released from the liquid.

- We carry out the action until the release of air stops, as evidenced by the absence of “foaming” of the liquid inside the tank.

- We return the previously removed plug and cover to their original places.

Troubleshooting methods

Coolant hoses

There are three possible options for removing an air lock from the cooling system:

- Through the expansion tank with removal of the pipe.

- Without disassembling, by tilting the car and adding fluid.

- Using heat.

Let's take a closer look.

First option

The first option on how to remove an air lock from the cooling system is suitable for most owners of domestically produced vehicles. In these cars, it is possible to disconnect the carburetor heating hose or throttle assembly. To remove the hose, you will need to remove all parts that interfere with this procedure. Then you need to get this hose and remove it from the fitting. After this, unscrew the cap on the expansion tank and start blowing into it. As soon as the coolant begins to flow out of the hose, you must quickly return it to its place and secure the pipe with a clamp. We return all the parts to their place and enjoy the working stove.

Second option

Filling with coolant

To implement the following method of self-bleeding, you will need to drive into the inspection hole and set the car to the handbrake. Using a jack or other suitable tool, raise the front of the vehicle at a slight angle. You can achieve the same effect without a jack by placing the car on a steep incline. How to break through an air lock in the cooling system using this method? It's simple. Unscrew the caps on the expansion tank and on the radiator (if equipped). We start the engine and bring it to the optimal operating temperature. We wait for the valve to open and the liquid to move in a large circle. The switches on the stove should be set to the maximum heating level.

While the engine is warming up, it is important to monitor the fluid level in the reservoir - it should drop. Gradually add the leaving antifreeze (antifreeze). To increase circulation and outflow of antifreeze, it may be necessary to increase engine speed

A sharp drop in the fluid level may occur, and here it is important to very quickly add it to the required level. The procedure must be continued until the air bubbles escape. After completion, you will need to lower the car and add antifreeze to the required level.

To increase circulation and outflow of antifreeze, it may be necessary to increase engine speed

A sharp drop in the fluid level may occur, and here it is important to very quickly add it to the required level. The procedure must be continued until the air bubbles are released.

After completion, you will need to lower the car and add antifreeze to the required level.

Third way

The third method will also tell you how to remove an air lock from the cooling system. For its successful implementation, you will need to start the engine and not turn it off until the optimal operating temperature is reached. After turning off the engine, remove the protective parts from it to get to the heating hose of the fitting assembly. The coolant is very hot, as are the hoses through which it flows, so protect your hands to avoid burns. You can wear two pairs of gloves - work gloves and rubber ones on top. We disconnect the hose and wait for liquid (antifreeze, antifreeze) to flow out of it. When this happens, we return everything to its place. It may happen that the antifreeze never began to flow out. In this case, return the hose to its place, unscrew the cap on the expansion tank and screw it back on. Then we try again with disconnecting the hose.

Having considered three possible options for eliminating an air lock from a vehicle’s cooling system, you only need to choose the appropriate one. One thing is for sure - it is better not to delay solving this breakdown, because the air in the system causes malfunction of the stove and serious problems with the engine, up to its complete failure.

Let's sum it up

As you can see, an air lock in the cooling system is a significant obstacle to the normal functioning of the cooling system in the LADA Kalina car. It can not only cause the stove to become ineffective, but also cause more significant damage to the engine. Eliminating this negative phenomenon is not difficult, especially since now you know how to pump air, but the best measure would be timely and periodic diagnosis of the engine cooling system. It consists of checking the refrigerant level, the tightness of the circuit (reliability of clamps) and the functionality of the thermostat (control of heating of the lower radiator pipe).

Signs of an air lock in the cooling system

You can determine the presence of air in the engine refrigeration system by conducting independent diagnostics and eliminating the causes. We carry out diagnostics based on the above criteria.

- Checking the system for leaks. Over time, clamps weaken, oxidize, or break completely. The hose also has shock absorption; over time, it bursts and cracks; either heat or cold gradually destroy the rubber.

- Problems with the thermostat. If the engine heats up very quickly after starting, that is, the cooling fan has already turned on, and the temperature sensor shows that it is about to push the needle into the red scale, then this indicates a non-working thermostat or the presence of air in the pump discharge pipe. In this case, the thermostat valve will be in the closed position, the coolant will move in a small circle. The opposite may also happen. The engine takes a very long time to warm up after starting. This means that the thermostat valve is fully open or there is an air lock in the thermostat. In all cases, you will have to remove air from the engine cooling system.

It’s easy to check the thermostat yourself; you need to do the following:

- start the engine;

- after a couple of minutes, touch the radiator pipes (the top one should be warm first, then cold, the bottom one should be cold);

- when the engine temperature reaches operating temperature, 80-90 degrees, the thermostat should open and the lower pipe should heat up.

It's also easy to check functionality. It is determined by the noise level (it is not worth using a noise sensor and determining the level in decibels (dB)), by the sound you can already feel how the pump is working. The vibration of the pump is also checked. The pump bearing may have fallen off.

The main clue is that air has appeared in the engine cooling system in the heater. If the engine is hot and the heater is blowing cold air, then there is an air lock.