Electrolyte concept

Two electrodes are placed in a container with electrolyte (a mixture of distilled water and sulfuric acid). The cathode (negatively charged electrode) is made of lead. The anode (positively charged electrode) is primarily made of lead dioxide. Electric current flows weakly through the electrolyte, but ions move easily. Ions with a positive charge are directed to the positive electrode, and negatively charged particles are directed to the negative electrode. A potential difference is created at the electrodes. This process is called electrolytic dissociation. After connecting the load, current flows between the electrodes through the conductors.

At the same time, the transformation of tetravalent lead into divalent lead occurs at the anode with the release of two electrons.

During the work process the following processes occur:

- sulfur trioxide is consumed;

- reduction of lead oxide at the cathode (to metal);

- during the reaction, the acid is replaced by water and the density of the electrolyte decreases;

- The metal is oxidized to form lead oxide at the anode.

During charging, on the contrary, lead is reduced at the anode. After complete reduction, electrolysis occurs (decomposition of water in the electrolyte) into hydrogen and oxygen. They accumulate in the form of bubbles on the electrodes and begin to be released into the atmosphere. In a small, unventilated room, if an open flame or just a spark appears, an explosion is possible. Another unpleasant side effect of electrolysis is an increase in the concentration of acid in the electrolyte. The level of working fluid in the bank decreases and, accordingly, the battery capacity (the ability to accumulate and release energy in the form of electric current) decreases.

The battery capacity decreases over time due to the formation of sulfate, which covers the surface of the electrodes with an insoluble layer and reduces their working area.

What kind of acid is poured into a car battery?

Some types of car batteries may use alkali as an electrolyte. For example, a nickel-cadmium type battery. In addition, there is a group of gel batteries where the liquid is in a bound state. But, in fact, it is a solution of sulfuric acid, converted into a gel state or fiberglass impregnated with it.

Sulfuric acid is widely used in the production of lead-acid batteries for vehicles. Its concentration in the electrolyte is about 30-35%, the rest is distilled water. It is prohibited to use ordinary tap water, since it contains salts of many metals and their entry into the battery will shorten its service life.

As a rule, in the domestic sphere, 30% sulfuric acid is quite sufficient, but in the industrial sphere, acid with a higher concentration is often used. Concentrated sulfuric acid can be obtained in two stages. The first is when the concentration is brought to 65-70%, the second is when it is increased to 98%. This composition is most suitable for long-term storage. It is possible to obtain a high concentration of 99%, but later due to significant loss of SO3 it will drop to 98.3%.

Application of sulfuric acid and its grades

There are several types of sulfuric acid, these include:

- Nitrous or tower. The concentration is 75%, and the density of this variety is within 1.67 g/cm3. It received this name due to the production method using the nitrose method in lined towers. The roasting gas is treated with nitrose and the reaction produces acid and nitrogen oxides.

- Contact. The concentration reaches 92.5-98%, density – 1.837 g/cm3. This grade is also obtained from roasting gas containing SO2 dioxide. During the chemical reaction, it is oxidized upon contact with a vanadium catalyst.

- Rechargeable. Concentration 92-94%, density – 1.835 g/cm3.

- Variety Oleum. The concentration is quite high - 104.5%, density - 1.897 g/cm 3, it is a concentrated solution of acid and SO3.

- High percentage oleum. The concentration is quite high – 114.6%, density – 2.002 g/cm3.

Processes occurring in the battery with the participation of electrolyte

The functioning of a lead-acid battery is based on chemical processes that occur with the help of an electrolyte. A car battery made of plates: positive and negative, immersed in an acid solution. The plates have current-carrying grids made of lead with additives (depending on the type of battery), and grayish lead powder is applied to the negative electrode grids, and reddish-brown lead dioxide is applied to the positive electrodes.

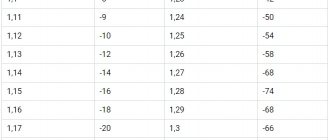

The density of the electrolyte on a charged battery is in the range of 1.128─1.300 g/cm3. When a battery is discharged as a result of a chemical reaction, acid is rapidly consumed from the electrolyte and the density drops significantly.

A fully charged vehicle battery cell produces a voltage in the range of 2.5-2.7 V with no load on the terminals. Under load, this voltage drops slightly to 2.1 V in just a few minutes. During this short period, a dense layer of PbSO4 manages to form on the surface of the negative electrodes. Accordingly, the cell voltage on the battery connected to the car is 2.15 V.

If you discharge a vehicle battery with a small current (approximately 10% of the rated capacity), then after 1-2 hours of discharge the cell voltage will drop to 2 V. This is due to the fact that at this moment a large amount of PbSO4 is formed, which, in turn, heavily clogs active mass pores. In addition, the internal resistance of the battery cells increases and the liquid concentration decreases significantly.

Electrolyte monitoring

Electrolyte monitoring is an important procedure that should be carried out regularly. The vehicle owner is required to monitor both the electrolyte level in the battery and its density. To check the electrolyte level, it is recommended to use a glass tube, but if you don’t have one, you can use a transparent pen housing. To measure, you need to open the caps of all jars and immerse the plastic/glass tube up to the plates. Then press it tightly with your finger from the upper end and lift it up.

The optimal electrolyte level in the tube should be 10-12 mm. If there is a shortage of electrolyte, water is added to the required level. Water should not be filled above the required level.

Electrolyte life

It is worth knowing that an acid electrolyte is a solution that does not have an expiration date. The service life for such a fluid is determined solely on the basis of how it is able to perform its functions.

Indicators that affect the battery life include:

- Electrolyte density.

- Temperature operating conditions of the battery.

- Battery charge level.

If these indicators correspond to the norm, the service life of the electrolyte is quite long.

How to increase electrolyte density

An increase in the density of a liquid occurs due to an increase in temperature and as a result of a process called hydrolysis. In order for this indicator to be at the required level, regular addition of distillate is required. If the acid concentration sensor in the electrolyte shows a value lower than 1.275 g/cm3, it should be raised.

The acidity of the electrolyte can be increased in two ways: by completely replacing the old electrolyte with a new one or by adding diluted concentrated acid.

If the liquid is diluted, a number of actions should be taken for each jar:

- Try to pump out the maximum amount of electrolyte using a syringe or rubber bulb.

- Add 0.5 of its volume to the jar with a density of 1.26 to 1.28 g/cm3.

- To thoroughly mix the liquid, it is necessary to apply a load with minimal power to the terminals.

When measuring density, it is worth determining the required level. If no changes occur, then more electrolyte must be added to half the remaining volume.

With the help of such manipulations, the concentration of acid in the electrolyte can be brought to the optimal density.

If the indicator shows density values lower than 1.2 g/cm3, a complete replacement of the electrolyte is required, since it will not be possible to raise it by refilling. However, if the battery is less than a year old, then it's worth a try.

Important! Sulfuric acid is an aggressive environment for human skin and clothing. Therefore, when working with an open battery, it is recommended to take protective measures: be sure to wear rubber gloves and safety glasses. A rubberized apron will also come in handy.

Battery fluid

The performance of an acid battery depends on the quality and percentage of its components.

The electrolyte contains:

- Distilled water – obtained using a distiller (a device for purifying water from impurities).

- Sulfuric acid.

A prerequisite is that the water should not have impurities. The presence of impurities greatly reduces the battery life.

During the manufacturing process, the sulfuric acid in the battery is 35% and 65% distilled water.

Concentration and density

The main indicator of acid concentration in a battery is its density. In the normal state, the density of the electrolyte is 1.23 g/cm3. Depending on the time of year, the acid in the battery should have different densities. In summer it can be 1.07 g/cm3, in winter 1.3 g/cm3. In winter, an increase in density is required to ensure that the liquid does not freeze and the jars do not burst.

The operation of the battery also depends on the level of electrolyte in the banks. A glass tube is used to determine it.

The following operations are performed:

- the caps on all cans are unscrewed;

- the tube is lowered to the level of the plates;

- the hole in the tube is clamped with a finger;

- the tube is pulled out and the filling height is determined.

It is recommended to maintain a distance of 10 to 15 mm above the level of the plates.

At the same time, the density of the electrolyte is measured. In case of large deviations in the level and density of the electrolyte, adjustments are started.

Battery status monitoring

It is important to monitor the main indicators of a car battery at the time of its operation. This is due to the fact that with a slight change, it is possible to restore the structure. The amount of electrolyte in the battery is controlled as follows:

- Some car batteries have a printed scale that allows you to quickly determine the fluid level in the case.

- A simple way to determine capacity involves using a glass tube. To begin with, all the caps of the cans are unscrewed, after which the tube is immersed in the structure. The recommended level of active substance is 10−12 mm.

We recommend: Battery Tyumen Bear: description of a car battery

If the electrolyte drops slightly, the level can be replenished by adding distilled water. It is recommended to purchase it at a pharmacy, since ordinary stores often sell ordinary water under the guise of distilled water. It is not recommended to replenish the level above the required level, as this leads to an increase in pressure and destruction of the main structural elements.

Special attention should be paid to maintenance-free batteries. They have a reduced water consumption rate, the lid has an electrolyte recirculation system. However, the service life of the structure can be significantly extended by replenishing the liquid level by adding it.

Density is also an important indicator that is quite difficult to measure. To determine density, a hydrometer is used, which is a combination of a sealed glass tube with shot and mercury. The required parameter can be determined using a graduated scale.

Density measurements are carried out as follows:

- First you need to remove the top cover, after which you will gain access to the plugs. After this, all the plugs of each can are removed.

- The instrument used should be lowered into the jar and the electrolyte should be collected. Do not mix or shake the structure.

- After this, the instrument is removed and the density indicator can be determined using the applied scale.

- Some hydrometers are labeled "full charge", "half charge" or "discharged state".

It is recommended to test the power supply periodically or if problems arise with starting the engine or movement when a large number of consumers are turned on. If a low electrolyte level or a change in density is detected, the power source must be restored.

Electrolyte preparation

To prepare the electrolyte, it is necessary to prepare tools and protective equipment.

Means of protection:

- latex gloves;

- apron and sleeves resistant to aggressive chemicals;

- protective glasses;

- soda ash or other alkali for neutralization.

Tools and materials:

- glass or other acid-resistant container;

- glass thermometer for measuring the temperature of the solution;

- hydrometer or densimeter for measuring the density of liquids;

- stick for stirring liquid;

- distilled water;

- sulfuric acid.

Sulfuric acid in the battery is produced in accordance with GOST 2184-77 or GOST 14262-78. These standards specify the concentration, amount of impurities and other technical conditions. Often ready-to-use electrolyte is sold for batteries. Here you should pay attention to the conditions for which it is prepared.

For distilled water, GOST 6709-72 is used.

In addition to materials and protective equipment, the sequence of actions during preparation is important:

- the density of sulfuric acid is determined;

- the required amount of water is poured into the prepared container;

- carefully, in a thin stream, pour the acid into the water;

Important! When acid and water are mixed, a chemical reaction occurs and heat is released. Therefore, under no circumstances should you pour water into acid. The water will instantly boil with drops of acid splashing in different directions.

- Gently mix the resulting composition;

- let it cool and settle for several hours.

Which acid in the battery is sulfuric or hydrochloric?

Miscellaneous: What kind of battery acid?

Many car enthusiasts ask themselves the question of what kind of acid is in the car battery. Out of ignorance, various incorrect assumptions are made. Some say it contains hydrochloric acid. Some people think there is water there. It's time to clarify this issue. A car's lead-acid battery is filled with sulfuric acid. To be very precise, a solution of sulfuric acid in distilled water is poured. This solution is called an electrolyte.

articles

Application of sulfuric acid and its grade

In general, alkali can be used as an electrolyte in some types of car batteries. For example, nickel-cadmium or nickel-iron type batteries. There is also a group of gel batteries AGM and GEL, where the electrolyte is in a bound state. But this is the same solution of sulfuric acid.

It’s simply either put into a gel state using additives (GEL), or glass fiber is impregnated with it (AGM). The most common today are lead-acid car batteries with liquid electrolyte.

Therefore, we will talk specifically about an aqueous solution of sulfuric acid intended for pouring into the battery.

Electrolyte

Distilled water

Sulfuric acid is used in a variety of sectors of the national economy. For example, it is used to clean the metal surface before coating; it is used in the preparation of various synthetic dyes. In addition, sulfuric acid is in demand in the production of fertilizers, explosives, pharmaceutical industry, and oil refining.

Sulfuric acid is widely used in the production of lead-acid batteries for cars. The acid concentration in the electrolyte is 30-35 percent (wt.). The rest is distilled water. You cannot use regular tap water because it contains salts of various metals.

If they get into a car battery, it will significantly shorten its service life.

In the domestic sphere, a concentration of H2SO4 of 30 percent is sufficient, but in the industrial sphere, sulfuric acid of a higher concentration is often used. Concentrated sulfuric acid is produced in two stages. At the first stage, the concentration is brought to 70 percent, and then increased to 98 percent. Sulfuric acid of this concentration is most suitable for subsequent storage. It is possible to obtain a concentration of 99 percent, but later due to the loss of SO3 it decreases to 98.3 percent.

There are main grades of sulfuric acid, which are listed below:

- Tower or nitrous. Concentration 75 percent. The density of this variety is 1.67 g/cm3. This variety received its name due to the production method in lined towers using the nitrous method. The roasting gas with sulfur dioxide (SO2) is treated with nitrose (h3SO4 with added nitrogen oxides). The chemical reaction produces nitrogen oxides and acid. In this case, oxides constantly circulate in the production cycle;

- Contact. Concentration from 92.5 to 98 percent. The density of the variety is 1.837 g/cm3. This grade is also produced from roasting gas, which contains SO2 dioxide. During the reaction, it is oxidized to SO3 upon contact with a solid vanadium catalyst;

- Variety Oleum. Concentration 104.5 percent. The density is 1.897 g/cm3. The variety is a solution of SO3 in sulfuric acid (h3SO4). The ratio of SO3 is 20 percent, h3SO4 is 104.5 percent;

- High percentage oleum. The concentration is 114.6 percent, and the density is 2.002 g/cm3;

- Rechargeable. The concentration is from 92 to 94 percent, and the density is 1.835 g/cm3.

Electrolyte replacement procedure

More often, water is consumed in the battery and it is necessary to add it, checking the density, but sometimes it is necessary to prepare and fill the electrolyte of the required density to replace the “native” one.

This operation is performed:

- when the density of the working fluid in the cans has dropped to a value below the regulated value;

- when the battery does not hold a charge.

Knowing what kind of acid is in the battery (more precisely, its quality), the electrolyte is replaced completely or partially.

Partial replacement is carried out as follows:

- Using a syringe or medical bulb, gradually pump out the maximum possible amount of liquid.

- Add half the volume of the prepared solution to the jar.

- A small load is applied to the terminals to mix the components in the jar.

- Check the density and repeat the procedure if necessary.

- If the density is below 1.2 g/cm3, then a complete replacement is required.

Life time

Battery fluid does not have an expiration date. As long as the electrolyte copes with its functions, it is considered suitable for use. If you inspect the battery every three months, do preventative maintenance, and use the battery correctly, the acid will last a long time.

Currently, car owners are switching to modern analogues, in which the working fluid is in the form of a gel. Such devices do not require maintenance. It is necessary to monitor the charge level.

Remember! Sulfuric acid and spilled electrolyte are very dangerous for the environment. Knowing what acid is added to the battery, you cannot throw the battery into a landfill. It is easier and more profitable to hand them over to a collection point.