Cars admin26.02.2020

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Very often, when setting the heater air flow control lever to the “feet” or “chest” position, some of the air still goes “to the glass”. Eliminated by adjusting the dampers. In this case, it was enough to shorten the adjustable rod by three divisions and bite off its protruding tip with side cutters.

After such adjustment work, the heater damper of the VAZ 2110 was in the correct position and the heat from the stove began to flow much better in the right direction. The adjustment of the VAZ 2110 heater dampers was successful. This procedure requires a minimum of tools and time, but maximum benefit and heat.

This photo report will show you more details on how the heater 2110 dampers are adjusted.

- An old-style damper control unit with a vertical lever arrangement.

- Thrust of the damper “to the legs” - “to the chest”.

- The place where the damper rod is attached is “in the chest” - “on the glass”.

The end of the rod had to be bitten off with side cutters, because... it rested against the body when the lever was positioned “at the feet.”

This is what the control of the new type of dampers with a horizontal lever arrangement looks like.

It cannot be said that the build quality of AvtoVAZ cars is at an extremely sad and low level. But these cars cannot be called exemplary either. One way or another, if you properly care for your car, monitor it, and carry out periodic preventive maintenance, expensive repairs will be reduced to a minimum.

A car is a means of transportation that has a certain level of comfort. The stove is partially responsible for the comfort of the driver and his passengers in the VAZ 2110 . Various problems occur in its design, and the heater damper on the VAZ 2110 is no exception. The role of this unit is to maintain the temperature specified by the user.

Heater channel damper VAZ 2110

The automatic temperature maintenance system used on the VAZ-2110 is more convenient in terms of control, since the automatic control system does everything independently, but is less reliable than a mechanical cable drive.

Moreover, problems are caused by the electronic and electrical components of the stove - the controller, temperature sensor and micromotor gearbox, the central damper, which regulates the air supply to the cabin from the outside. Problems with the operation of the VAZ-2110 heater related to the damper:

- lack of temperature control (only hot or cold air comes from the stove) regardless of the position of the handle on the controller;

- insufficient air heating (even when setting the handle to the maximum temperature);

- squeaks, knocks and extraneous noises after setting the temperature.

The cause of such problems is the central damper of the VAZ-2110 stove, which is adjusted by the controller through a gearbox. The design of the stove includes another damper - air distribution into zones. It is controlled using a handle mounted on the central air supply deflector into the cabin, so malfunctions with this part are rare.

Depending on the design of the stove, the damper may cause a disruption in the efficient operation of the heater for the following reasons:

- deformation;

- wear of seals;

- deterioration or damage to control levers and rods;

- skew.

Deformation is a problem with old-style heaters. The first dampers of the VAZ-2110 stove were equipped with plastic elements that bent under the influence of temperature. Because of this, even when completely closed, cold air from outside leaks in and mixes with the heated air, and the efficiency of the stove decreases. Subsequently, the designers replaced the plastic flaps with aluminum ones and the problem with deformation disappeared.

To ensure tightness, the dampers have seals that reduce air leakage. Initially, foam rubber seals were used, which quickly wore out and became damaged. Later, foam rubber was replaced with rubber, but this only extended the service life of the seal; over time, the rubber ages, cracks and collapses.

On old-style stoves, rods and levers may break. On new heaters, there is another problem - wear on the edges of the square end of the gearbox, with which it is inserted into the groove made in the damper axis. As a result, the limit switch bypasses the groove, and the heater damper jams, although the gearmotor operates. The misalignment occurs due to the displacement of the damper axis in the mounting holes of the housing. Because of this, the damper warps and jams when opening.

Common faults

Most often, the VAZ 2110 suffers in terms of heating because the heater adjustment, as they say, does not work. Regardless of the selected position of the temperature control knob, only cold or, conversely, only hot air blows from the heater.

The reasons for this phenomenon may have different origins. Among them:

- Jamming of the MMR (micromotor-reducer) that controls the damper drive;

- The plastic damper (the first VAZ 2110 was equipped with these) has a destroyed seat, and due to jamming it is impossible to control it normally. If the gearbox is working, but the damper does not turn, you can most often hear peculiar clicks - this is the square shaft turning in the socket. For such a malfunction, there is only one treatment - replacing the old plastic damper with foam insulation with a new one. Better, more modern, metal, with a rubber seal. This one does not warp or warp like its plastic sister;

- To finally decide who to blame - the damper or the MMR, you still need to pay attention to its control unit. He is also among the “suspects”.

Repair of the VAZ-2110 heater damper

Repair of the damper is carried out only in a situation where it is skewed or jammed in a certain position. It is very difficult to call this a repair; it is most often a forced measure to extend its operation for a short period of time. If there are problems with the valve or its drive, then soon you will still have to disassemble the stove and replace the failed parts.

The repair consists of installing the valve in its standard seat. To do this, you do not need to completely disassemble the heater. With the ignition on, it is enough to try using manual adjustment to try to seat the valve in its seat. You can also remove the deflector and try to activate the damper by hand. If it starts to move, then you have a temporary fix. However, as previously stated, this is a conditional fix for the problem. If a part jams, it will soon have to be replaced, since the stove will not function correctly.

Location of the heater damper of the VAZ-2110 car

If, after restoring the performance of the damper with the ignition on, it is only possible to manually control the damper, then the source of the breakdown is the micro-gearbox.

Step-by-step cleaning instructions

If the damper does get dirty, it doesn’t matter; with the help of several cleaning steps, the car’s operation will be restored. Before cleaning, you must remove the throttle assembly according to the following instructions:

- remove the corrugation;

- turn off the power supply to the sensors;

- push out the “weight” that secures the pedal cable;

- disconnect the coolant pipe;

- remove the ventilation hose; unscrew the assembly fastening;

- Unscrew the idle speed control.

To clean mechanisms, special products are required, in most cases aerosol cans. The best solution for this task is a carburetor or brake cleaner.

Causes of malfunctions

Depending on the design of the stove, the damper may cause a disruption in the efficient operation of the heater for the following reasons:

- deformation;

- wear of seals;

- deterioration or damage to control levers and rods;

- skew.

Deformation is a problem with old-style heaters. The first dampers of the VAZ-2110 stove were equipped with plastic elements that bent under the influence of temperature. Because of this, even when completely closed, cold air from outside leaks in and mixes with the heated air, and the efficiency of the stove decreases. Subsequently, the designers replaced the plastic flaps with aluminum ones and the problem with deformation disappeared.

Popular problems

Diagram

The reasons for valve failure are different

| Causes of failure | Characteristic |

| Micromotor gearbox jammed | This element is responsible for controlling the damper drive |

| Problem in the control unit | It should be checked in order to understand whether the micromotor gearbox, the damper, or the control unit is at fault |

| The plastic dampers have moved from their seat and are jammed, making it impossible to control the stove. | This is typical for the old-style VAZ 2110 heater damper, when plastic was still used for this component. |

When the gearbox is functioning, but the damper still does not turn, you can hear characteristic sounds - clicks . This indicates that a square shaft rotates inside the socket.

Assembly

Position of the damper

After this, reverse the assembly procedure according to the dismantling steps. Refill the system with coolant and check that the new damper is in place. It is important to ensure that there are no leaks and that the hose connections are not tight.

Turn on the stove and check how the heater behaves. If everything is normal, you have carried out competent and successful work, for which we congratulate you.

Adjusting the heater dampers

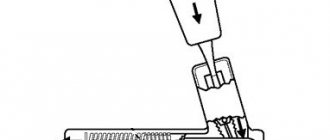

By adjusting the dampers with your own hands, you eliminate the supply of part of the air “to the glass” when the lever that controls the air flow is installed in the heater in the “chest” or “legs” position. The photo shows the damper adjustment control units.

2 – adjustable rod for installing the damper “in the chest” – “in the legs” 3 – fastening the rod “in the chest” – “on the glass”. To do this, it is necessary to shorten the adjustable rod by three divisions, and use side cutters to bite off the tip protruding on it. After performing such operations, the heater damper will be in the desired position, and the heat from the stove will flow better in the given direction.

Assembly of the unit

Interchangeability of gearmotors

When work on restoring the functionality of the MMR is completed, install it in place. For this:

- Insert the pin of the micromotor-reducer lever into the slot of the lever. It is located on the damper drive;

- If the lever is not turned properly, apply 12V voltage to the motor connector pins using two wires. We are talking about yellow wires here. This way you can return the lever to the correct position;

- Having installed the micromotor-reducer, check it for operability, plus watch how the damper drive of your heater moves, whether the heater control lever “plows” properly to regulate the temperature.

We will repair or replace the damper and heater drive, you will be able to return the heater to its previous functionality and independently determine what temperature regime will be set inside the cabin of your VAZ 2110.

Functions

In simple terms, without terminology unnecessary for most motorists, the throttle valve is nothing more than the gas pedal of your car.

By pressing or releasing this pedal, you thereby close or, on the contrary, open this damper.

The device provides a path for additional air to enter. When you press the gas pedal to the floor as much as possible, you open the throttle fully, so the engine speed increases.

Ventilation and heating systems of the VAZ 2110 car

To find out whether the VAZ 2110 heater generally needs to be replaced, you should first consider the system as a whole. The ventilation and heating system of the VAZ 2110 car model consists of:

- The controller's automatic control system is an automatic system that controls the heater;

- a special sensor that regulates the interior air temperature;

- micromotor gearbox.

To increase the accuracy of maintaining normal temperature in the cabin, it is possible to adjust it to the sensor. The device is called a potentiometer and is located under a slot on the side of the controller itself. Simply remove the controller from the socket and adjust the setting using a trim potentiometer based on the following calculation:

- 0.2 gr . Celsius - if the potentiometer rotates clockwise, this leads to a decrease in temperature (referring to the controller per revolution 2110-8128020-01 ;

- 0.3 gr . Celsius – if rotating the potentiometer leads to an increase in temperature ( 2110-1303.3854 ).

Potentiometer regulating interior temperature

Stove design

A special sensor sends a corresponding signal about the temperature in the cabin to the heater system unit, which instantly responds and compares it with the temperature set by the driver. If the difference exceeds two degrees, the ACS controller transmits a control signal to the micromotor gearbox, which, in fact, controls the heater damper. In other words, this same micro-gearbox closes or opens the access of hot air to the cabin.

micromotor gear unit of the heating system VAZ 2110

The drive of the heater damper of the VAZ 2110 must be carried out in such a way that the damper in the extreme temperature positions on the ACS unit moves independently of the readings given by a special sensor. In this diagram everything looks in more detail.

diagram of the operation of the stove on a VAZ 2110 car

Causes of breakdown or malfunction of the stove

Often, stove malfunctions occur due to the fact that there is a lack of a certain amount of coolant in the cooling system. What to do in this case?

- check the level of antifreeze or antifreeze in the barrel;

- check the level of contamination of the entire system.

Another reason why the heater may not work well is a “sick” radiator. To recognize this you should:

- make sure the car radiator is hot;

- carefully check the operation of the air plug.

Troubleshooting a stove malfunction associated with improper operation of the radiator is corrected as follows:

- the car drives its front wheels onto some hill;

- the engine turns on and the driver keeps it at medium speed for several minutes;

- the stove should work, if not, then you need to check the radiator for leaks and replace it.

Principles of interior ventilation

Before you figure out the causes of the malfunction, you should know the principle of the device and the rules by which ventilation is carried out. So:

- Air is supplied to the passenger compartment through the holes in the trim on the windshield: when the car is moving voluntarily, or forcibly with the help of a heater fan.

- Air escapes through the gaps between the inner door panels and between the upholstery, then through the holes located at the ends of the doors. The thermal insulation of the interior is improved by valves built into the openings, which allow air to pass out and prevent it from entering the inside of the car.

- The main part of the air is directed to the windshield; flows are directed to the central part and side windows through deflectors blocked by flaps.

- Air is supplied to the driver’s feet and the passenger sitting next to him through two pairs of deflectors: one pair is located near the floor, the other at knee level.

- Through a lining located on the floor tunnel and two air ducts built under the front seats, air is supplied to the feet of passengers in the rear.

- To prevent the entry of outside air, especially if the road section is polluted, smoky or very dusty, there is an air recirculation system. When the recirculation button is recessed on the instrument panel, the electro-pneumatic valve opens. In this case, under the influence of the vacuum that occurs in the intake pipe, the access of outside air is blocked by the recirculation system flap into the vehicle interior.

- The air temperature is regulated by the controller handle from 16°C to 30°C.

- Information about the temperature is read from its sensor by a unit with a microfan located on the ceiling. The unit turns on the micromotor when a temperature difference occurs, which controls the heater dampers. When the damper reaches the desired position, a signal is sent from the sensor to the control unit, which turns off the micromotor.

VAZ 2110 heater blows cold, reasons

Many owners of “ten” complain that at some point the stove constantly blows cold air and no amount of turning the handles of the automatic heater control system can save the situation. There can be a lot of problems and malfunctions. For example, the ACS controller itself is faulty, the ceiling sensor or micro-geared motor is faulty and simply does not open or close the damper. Another reason is the air (air lock) in the heater radiator, which is simply not capable of heating the air passing through it.

Heater dampers VAZ 2110

Often the cause of poor performance of the “ten” heater is the damper of the VAZ 2110 stove. The damper may not close tightly or open poorly. The heater flap itself is made of plastic, which can become warped and perform poorly over time. Many car owners buy a metal damper and change it themselves. How to check the functionality and evaluate the condition of the heater damper? Everything is quite simple, remove the central air duct deflector and there you have it - a damper!

Next, carefully inspect the damper, turn on the stove, turn the controls on the ACS unit and see if the damper works at all. How does it move, does it fit tightly. If she does not respond to commands, then the problem may not be her at all. For one thing, you can see if the lever for redirecting the air flow from the glass to the feet works.

Signs of a clogged element

You can independently verify that the damper needs cleaning based on several signs:

- car acceleration dynamics decreases;

- engine operation becomes unstable;

- when moving, peculiar jerks are observed;

- there is no smooth running.

If the above symptoms appear, the damper should be cleaned of dirt as quickly as possible. Cleaning, as we noted earlier, is quite simple, and besides, it will be much cheaper than purchasing a new element.

Checking the functionality of the manual heater damper of the VAZ 2110

If a car enthusiast simply does not have the funds for professional car repairs, you can try to fix the problem yourself.

But before that, you should check the functionality of all elements of the stove separately. This is the only way to understand what exactly is not working. To do this you need to perform these steps:

- Turn on the ignition;

- After this, check the regulator by switching it in different directions;

Diagnostics

To diagnose, you need to try to manually move the heater damper. This is necessary in order to check whether it is jammed. This will also help return the damper to its original working position. This will solve problems with the damper if it has been misaligned and is simply stuck.- But to gain access to the damper itself, you will need to remove the deflector. If after all these manipulations the damper started working, that was the problem.

- But this was an inferior way to fix the stove. After all, after this, the stove will still not be able to work as before. After all, the nest will already be worn out. If you constantly use this method, the stove may completely break down at any moment. To completely get rid of problems with the damper in the 2110 stove, you need to completely replace it.

- The main thing is not to forget to pay attention to how exactly the damper is controlled. If it is controlled only manually, the problem is in the micromotor gearbox. Also, all problems may be associated with a malfunction of the microfan. Also, the problem may lie in the control unit. That is why you need to check all components of the stove. If any of these devices does not work, you need to urgently replace this part. Due to these violations, the damper of the VAZ 2110 stove will not open. If this defect is not corrected in time, the entire stove may have to be replaced. And this is already several times more expensive than replacing the damper.

Normal operation

Air enters through the gap formed by the damper, but the regulator does not work. A mixture formation process occurs in the fuel rail - gasoline is suspended (like fog) under high pressure. Its value is constant and is regulated using a sensor and an overpressure valve. After the mixture is formed, fuel is injected into the combustion chambers - the injectors open one by one (in fact, these are electromagnetic valves). They are controlled by an electronic unit. Their operation completely depends on the readings of the sensors and the fuel map (firmware of the microcontroller control system).