Steering rack device

Rack and pinion steering transmits the rotational movement of the steering wheel into the translational movement of the steering rods, which turn the wheels to the required angle. For this purpose, the design uses a gear and a rack with a constant or variable pitch.

The unit is housed in an aluminum housing, which is attached to the car body or subframe. At the edges there are travel limiters, seals and steering rod boots. Depending on the design of the car, amplifiers of various types can be installed. They not only make the steering wheel lighter and control precise, but also dampen uneven road surfaces.

Types of passenger car steering racks:

- mechanical;

- with hydraulic booster (power steering), reducing steering effort;

- with electric power steering (EUR), powered by an additional electric motor.

Despite the differences in design, the mechanical part fails most quickly. This is due to the following reasons:

- driving on poorly paved roads;

- aggressive driving style;

- untimely maintenance of the node;

- wheel alignment violation;

- installation of larger wheels and offset;

- wear of oil seals, anthers, hydraulic valves.

Important! The loaded area is the contact patch between the gear and the gear bar, so wear most often begins in this part of the mechanism.

Characteristic

The steering has several functions:

- Increases the effort applied to the steering wheel.

- Transmits torque to the wheels through the drive.

- Automatically returns the steering wheel to the neutral position.

The main component of this mechanism is the gearbox. It has its own gear ratio (this parameter is different for each car). At the moment, a rack and pinion assembly is used. Previously, manufacturers used a worm and screw assembly. Why is rake so popular? This mechanism is characterized by a simple design and high efficiency. Due to its design features, it can be installed on cars with front-wheel drive and also on cars with independent suspension.

Steering rack diagnostics

To check the steering rack play, it is not necessary to contact a diagnostic service at a special stand. Primary signs of breakdown can be easily identified on your own. First of all, pay attention to the following changes in the behavior of the car:

- the steering force increases noticeably;

- a drop in the fluid level in the power steering reservoir or an error on the instrument panel (for power steering);

- knocking and vibration when driving on uneven roads;

- hum from the rack with a large turn of the steering wheel;

- the steering wheel slowly returns to its original position;

- the car does not maintain a straight line.

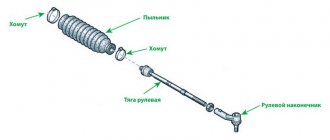

The next step is a visual inspection. To do this, it is advisable to hang the car on a lift to provide access to the steering rods, boots, and rack housing. Such diagnostics will help identify the following defects:

- torn anthers of the rod ends, as a result, their wear;

- excessive wheel play in the horizontal direction due to severe wear of the gear bar;

- fluid leakage from under the steering rack seals;

- radial play of internal rods caused by wear of guide bushings;

- rotational play of the gear-rack pair;

- play of ball pins and silent blocks of suspension;

- traces of corrosion on the rods or rack and pinion housing.

Advice! You can check the steering rack for extraneous noise as follows. Place your hand or stethoscope on the body, and ask an assistant to rotate the steering wheel. All unnecessary sounds will be clearly audible.

Principle of operation

The steering rack is the main unit of the steering system. Through it, force is transmitted from the steering wheel to the wheel rods. When you turn the steering wheel, the car's wheels turn horizontally. Progress, as always, has not stood still, so today many versions of rack and pinion mechanisms are produced.

w[n] = w[n] || []; w[n].push(function() { Ya.Context.AdvManager.render({ blockId: “RA-676344-20”, renderTo: “yandex_rtb_R-A-676344-20”, async: true }); }) ; t = d.getElementsByTagName("script")[0]; s = d.createElement("script"); s.type = "text/javascript"; s.src = "//an.yandex.ru/system/context.js"; s.async = true; t.parentNode.insertBefore(s, t); })(this, this.document, "yandexContextAsyncCallbacks");

Checking and troubleshooting the removed rack

You can try to disassemble the knocking unit and replace the problematic part. Some manufacturers allow this and produce ready-made repair kits for the steering rack. The steering mechanism should be disassembled after removal from the vehicle and thorough cleaning of the outside.

After disassembly, all components must be washed and inspected for wear. Most often, support bushings fail. They are made of plastic or soft metal and are therefore the first to be washed. This occurs due to the ingress of moisture and dirt due to torn anthers and heavy loads on the steering wheel. Replacing with metal ones helps solve the problem. The seals need to be replaced along with the bushings.

Interesting articles:

What to glue molding to on a car

How to increase endurance in running?

The most worn place in the rack and pinion mechanism is the central part of the gear bar. Chipping of teeth, scuffing, and damage to the rack profile cannot be repaired. Such a unit is replaced with a new one or an entire rack assembly removed from another car. On the other hand, you can try to correct a slight play in this connection with an adjusting nut. The tightening torque must be such that the rack can move freely in both directions without snagging.

After assembly, it is advisable to check it on a special stand. This is especially true for a rack with power steering, when the force depends on the precise adjustment of the bypass valves.

Underwater rocks

What problems may a motorist encounter when performing operations to tighten the steering mechanism? The first is the rotation angle. The tighter the rack is tightened, the lower the degree of rotation of the front wheels. Accordingly, the maneuverability of the vehicle decreases. The second point is the effort required to rotate the steering wheel. The tighter the nut is tightened, the tighter the steering wheel. This is especially noticeable on cars with a mechanical drive type (these are domestic “tens”, “trainers” and foreign cars of the early 90s). As for cars with hydraulic booster, the load on the pump increases. The fluid pressure inside the system will increase. The hose or cuffs may leak. If you feel that the steering wheel has become very tight and is difficult to return to the neutral position, you need to loosen the nut. It is not recommended to ride on a heavily tightened rack. This will entail wear and tear on a number of other elements.

Steering rack repair or replacement

Some automakers make the inner tie rod ends permanent. They are integral with the steering rack and can only be replaced as an assembly. The cost of replacing the entire assembly with an original one is high, and the ball joints cannot be repaired. In this case, it is recommended to regularly inspect the boots for cracks and promptly update the lubricant.

In other cases, car enthusiasts can only repair the steering mechanism or replace the unit with a contract one. Repair kits can be found for almost any popular model, and their choice depends on the price and quality of the supplied parts. This kit includes repair bushings, seals, oil seals, and anthers. With good components, this unit can perform no less than in the factory version.

The second way is to install non-original spare parts or those removed at a car disassembly. In this case, the car owner receives the entire assembly at a price 2-3 times lower than the original. The residual life of such a steering rack is unknown and can only be estimated indirectly by appearance. However, this service is in demand because it does not require specialized stands for disassembly and diagnostics. All work comes down to a simple replacement and checking the wheel alignment.

We wrote more about knocking in the Lada Kalina steering rack here.

Is it effective?

Statistics say that tightening the steering rack gearbox really helps eliminate play. However, in 20 percent of cases the problem is not solved. First of all, this is due to the high wear of the drive transmission pair itself.

This is a rack and pinion. Also, the causes of play may be wear of the steering rod joints or loose mounting of the steering bipod. Therefore, adjusting the staff does not always give an effective result. So, if such symptoms are present, experts recommend checking the condition of the front suspension components. There should be no play on the tie rods, ball joints or suspension arms. At the same time, it is recommended to check the shock absorber. Its rod should move properly. On a MacPherson type suspension, its replacement is complicated by the fact that the element is assembled with a spring. A special press is used to dismantle it.

VESKO-TRANS.RU

AutoNews / Reviews / Tests

Tighten the Steering Rack of VAZ 2109

Replacing the steering rack of VAZ 2113, 2114, 2115

We correctly pull the control rack on a VAZ-2114 with our own hands: tips and the process itself No one disputes the fact that a working steering wheel in any car guarantees not only the safety of the driver and passengers, but also uninterrupted operation in principle. Regardless of the type of drive, be it worm gear, rack gear or non-assisted, they all require a lot of maintenance. The VAZ-2114 and all second-generation Samara generators received a fairly reliable and familiar mechanism for managing repairs and adjustments. It does not have hydraulic booster, so it is easier to maintain and adjust.

Why pull the rail on a VAZ-2114

Diagnostics of rail control and control mechanisms

Before you tighten up the control bus on your VAZ-2114, you should consider the preconditions that will tell you when it's time to start repairs or lifting.

First of all, this is a free game.

Basically, AvtoVAZ guarantees a fairly long service life of the steering mechanism, namely ten years. However, you must understand that these are ideal working conditions. This assumes a smooth asphalt road, a constant supply of high-quality lubricant in the trunk pan and a gentle driving style.

Under normal operating conditions, this period is practically unattainable

It doesn’t matter whether the roads, the quality of spare parts and the often harsh conditions of the car lead to the fact that the mechanism makes itself felt much earlier

The first symptoms of a rail malfunction or the need for tightening are obvious:

Test drive - checking the steering by ear

To do this, you need to drive the chosen car a little, and not only on smooth asphalt, but also on a dirt road. You need to turn off the music and focus entirely on extraneous sounds. Any observed noises, squeaks, knocks, crunches and clanks may indicate a problem with the steering.

- A knocking sound from the steering rack indicates wear. Probably, the car was often driven on bad roads, or its owner is a fan of low-profile tires;

- Noises when turning the wheels indicate wear of the steering cardan, its crosspieces, and steering tips. Operating a machine in such a technical condition is simply dangerous;

- Noises and humming from the hydraulic booster indicate its imminent failure. The reason for this is untimely replacement of hydraulic fluid or its poor quality.

More about the design

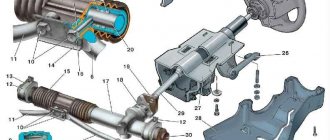

The steering rack consists of the following elements:

- Carter, also known as a protective aluminum housing;

- A worm or gear that rotates when the steering column moves, to which it is connected by a bearing;

- A toothed section engaged with a gear using several springs;

- Range of motion limiter, consisting of a power cuff and a tie rod bushing on opposite sides of each other;

- Seals, hydrobarrier rings, support bushings and other parts included in the repair kit.

The entire structure is made of aluminum and high-strength steel . There seemed to be nothing to break. Let's try to understand this statement.

How to check tie rod ends?

The first method is for an assistant to sit behind the wheel and turn the steering wheel left and right.

And at this moment you crawl under the car and look from under the car to see if there is play on the steering tips.

If there is no assistant, you can crawl under the car yourself and pull all the steering ends, rods - everything you can.

If the play of the steering tip is already significant, then it will be impossible not to notice it.

Look how my tie rod is hanging out. It can be seen that it is broken and dangling very much.

While driving, a strong roar can be heard from inside the car.

If you have neither a pit nor an assistant, then this is not a problem.

The steering tip can be checked by simply jacking up the front wheel and shaking it from side to side.

We take the suspended wheel with both hands and push it first with one hand, then with the other. With these movements we check the backlash.

As you can see, there is a huge gap here, you also saw it from the pit. If you talk too much, you can even hear the tapping of the steering tip.

After you have discovered the play, remove the wheel and get to the very tip.

It is necessary to find out what specific type of tip is installed on your car, since there are two types of steering tips on the Chevrolet Aveo in the T250 body.

After dismantling the wheel, you can clearly see how the steering tip dangles. The play is already quite significant, which means that it needs to be changed urgently.

You cannot drive with such a tip, because it may even tear off. If you suddenly fall into a hole, the wheel will jerk and the impact may cause the steering wheel ball to fall off.

That is why you should never drive for a long time and severely break the steering tips. If you hear something rattling, go immediately and check where it’s rattling.

So that after replacing the steering tip there are no problems with toe-in and camber - by the way, there is no camber here.

It is factory-made and not adjustable, but the toe-in is adjusted using the same steering tip and tie rod - we take a tape measure and measure from some fixed part.

In this case, I measure from the boot clamp to the center of the bolt, or to the edge of the bolt, if convenient, I measure along the edge of the bolt on this side.

Here I get 25 cm and 8 mm. I write down this value so as not to forget, and remove the steering tip.

Some repairmen advise counting the thread revolutions - how many revolutions the tip itself has been unscrewed.

But you yourself understand that the tips are always bought from an unknown company, it is not clear who made them and where, for what car.

In this case, you can see the letter L on this steering knuckle. This means that this steering knuckle was installed on some car on the left side.

But it fits the Chevrolet Aveo and is installed here on the right side, so I believe that the length of the tip itself - from the bolt to its threaded edge - may be different.

And if you count on the old tip how many times you unscrewed it, then on the new tip everything may not match.

You can tighten it, correctly calculate how many turns, but in fact the wheel alignment will come apart and you will not be able to drive normally.

Using a 19mm socket, unscrew the steering tip nut.

The steering tip pin began to rotate, now there is no way to unscrew it, since there is nothing to grab from below to hold the steering tip bolt itself.

Conclusion

If handled properly, steering racks do not often fail. The lion's share of problems with them can be eliminated with one trip to the service station. Irreversible changes are mainly observed in rubbing parts, such as teeth, which simply wear out. In this case, only buying a new rack helps. Considering the high cost of this part for new cars, buying used parts is especially popular. We can neither recommend nor discourage car enthusiasts from purchasing a non-new rack. If it was used correctly, its resource is not exhausted, and the former owner of the car monitored the condition of consumables, such a rack can serve. However, there is always a risk. It is safe to buy an OEM part or one of those manufactured by the companies listed above.

Do not forget also that after replacing the rack it is necessary to adjust the wheel alignment. Follow the work of the master: initially he will loosen the boot clamps, and then he must tighten them. Sometimes people forget to do this, as a result of which the rack wears out very quickly.

Spare parts for Mazda 626

Steering rack

626 V sedan (GF) (05.97 - 12.02)

A wide circle of motorists have been talking about restored steering racks for several years, but the attitude towards such units is radically different. Some believe that buying a restored rack is much more profitable than paying for a cheap analogue or forking out for a new expensive original. Others act on the principle of distrust of something new and, on the contrary, put Chinese copies in first place. Why is the vast majority of our country’s population not ready for change?

Restored steering rack for a Fiat car

What causes distrust in restored racks

Knowing that everything is a deception, a Russian person sets himself up for negativity in advance.

Let’s say it’s quite possible and safe to buy “used” tires, the condition of which can be assessed by a simple inspection. In addition, the cost of used tires is significantly lower than new ones.

A rebuilt steering rack is a little more complicated: you can't test it yourself before purchasing, but it costs more than a new analogue. After these words, “consumer surprise” may arise: “Why should I buy a refurbished rack, which will cost more than a new rack?”

And here we need to explain briefly and clearly: “More expensive than the new analogue from China.” Do I need to go on and repeat that at the moment, spare parts from China are like playing roulette?

You never know how long this or that “new” Chinese spare part will last on your car.

Non-original steering rack for Renault car

Therefore, car owners are perplexed why they will have to pay a decent amount of money for a unit that they have already used and are guided by proven, but often biased opinions, buying inexpensive analogues.

It is clear that it is difficult to convince with words, but for those still in doubt, we can suggest re-reading “articles from the people”, where car owners share their ordeals with fake spare parts: “Original and non-original spare parts - which is better?” “Unblowable fuses” “Fake fuses-2 (word to the representative How do refurbished steering racks differ from new, contract and repaired ones"

1. New steering racks.

There are two types: · original - made for assembling a car on the assembly line of a manufacturing plant.

· non-original (analogs) – products from independent manufacturers specializing in the production of spare parts for different brands of cars. Originals are branded, but expensive spare parts and sometimes you have to wait up to several weeks for them. Analogues are 30-40% cheaper than the original ones, freely available, but inferior to them in terms of workmanship. 2. Contract steering racks.

These are used original units in working condition, removed from cars to be scrapped at dismantling yards in America, Europe and Asia.

Their cost is lower than new branded slats, but their service life is reduced several times. 3. Repaired steering racks.

We are talking about inexpensive used units in which broken parts are replaced with serviceable ones and sometimes the body is cleaned of dirt.

If a person buys such a rail, then the maximum he can count on is a guarantee of 14 days to 1 month. 4. Restored steering racks.

This category includes used units that have been restored using factory “REBUILT” technologies (common name) and have a service life no lower than that of new spare parts.

When restoring a unit, a whole range of work is carried out: processing of the housing, complete replacement of rubber products and faulty components, labeling and packaging. Most often, hydraulic steering racks are restored.

They are characterized by high reliability, good resistance to climate changes, and are easy to maintain. What are the benefits of buying remanufactured power steering racks?

1. Saving money and time. Purchasing and installing a restored steering rack will take several hours, which is much faster than repairing a “native” unit and waiting for original expensive spare parts from abroad.

Diagnostics of the steering rack for a Skoda car

2. Resource saving and environmental protection: · restoration of the hydraulic steering rack involves 5 times fewer technological processes, and, accordingly, reduces the emission of harmful substances into the atmosphere and saves 70% of the metal used in production; · All metal parts that will no longer be used are recycled.

Disassembling a steering rack for a Daewoo car

How a hydraulic steering rack is restored using REBUILT technology

1.

The unit is restored under factory conditions. First, the rail is completely disassembled. Then the body is thoroughly sandblasted, washed under ultrasound, and a new protective coating is applied. Only the unit body and unworn components that are free of mechanical damage can be reused.

2.

In a clean and dry room, a new repair kit is selected from the catalog of components for repairing the ORPAV steering control. This catalog is used by most of the world's manufacturers of steering units, as it is very convenient and has no analogues.

3.

After assembling the steering rack, the operation of the unit is checked on a special diagnostic stand under different modes and loads. This guarantees the reliability and long service life of the restored mechanism.

4.

The final stage is to pack the steering rack in a branded box, complete with installation instructions and a warranty card.

The process of restoring a steering rack for a Daewoo car

As you can see, buying a refurbished spare part is a pretty good idea, because it saves money, time and natural resources, giving in return comfortable and safe movement in your own car every 80-100 thousand kilometers.

Moscow, 2nd Kotlyakovsky lane, 1 building 99 +7

Adjustment

So, the situation is such that tightening the steering rack can still give a positive result. Therefore, you need to find out how to tighten the knot and what is required for this.

You can adjust the rack through the bottom of the car, removing the engine protection, or through the top. In the second case, the work will have to be done by touch. So decide for yourself what is more convenient for you.

- To adjust the steering rack, you will need to tighten the adjusting screw. You can find it in the steering mechanism. To be more specific, in the end cap.

- It is optimal to have an overpass or a pit at your disposal in the garage. If there are no such conditions, you can get by by raising the car with a jack. Only in this situation will it be necessary to additionally secure the car in order to avoid it sliding off the jack and the likely consequences.

- Before lifting the body with a jack, be sure to align the front wheels straight.

- You can measure the backlash using a backlash meter. Moreover, they can be old or electronic. The latter are more relevant and convenient to use, but some people don’t have to choose. What you find is what you will use.

- According to current norms and standards, for the VAZ 2109 the steering wheel play should not exceed 10 degrees.

- Find the adjusting screw and begin to tighten it gradually. The operation is carried out slowly. Periodically check the steering wheel movement and any play or knocking in the steering column.

- Use a special key for adjustment. It is available at any auto parts store.

- The key is inserted into the adjusting screw and turned counterclockwise. Scroll a little and check the result.

- The procedure may take a long time. Still, take your time.

- When you feel that the adjustment has reached the desired level, take a test drive in your car, feel how the steering wheel moves, whether the knocking or play has disappeared, how hard the steering wheel rotates.

- If the steering wheel has become too tight, you will have to slightly loosen the tension on the adjusting screw.

Special key

If there is no positive result after the adjustment, you will have to eliminate play and knocking by dismantling, repairing or completely replacing the unit. Now decide for yourself.

You should not rely solely on reiki adjustments as a cure for all its ills. But you shouldn’t rush to conclusions about the need to replace the rack. Try to adjust, and then act according to the situation.