Malfunctions of the torque converter and its blocking

Having considered what the operation of the gas turbine engine is based on and how the torque converter is blocked, it is not difficult to guess that the presence of friction linings (rubbing pairs) means a decrease in service life.

Moreover, these friction pairs actively wear out due to heavy loads and early locking. Also, their wear products contaminate the gas turbine engine itself from the inside; transmission oil is also subject to severe contamination. The result is active wear of all parts without exception, not only of the “donut” itself, but also of the automatic transmission. The first to suffer from the presence of abrasive in the oil are the turbine wheel blades and bearings, then the gaskets and rubber seals fail, then the dirty oil damages the automatic transmission valve body channels, solenoids, etc.

We also recommend reading the article about why the automatic transmission slips. From this article you will learn about the reasons why automatic transmission slips.

Simply put, the main source of ATF contamination in modern automatic machines is the torque converter. The worst thing is if the material of the locking friction linings is structurally glued to the base. This means that as a result of inevitable wear, not only abrasive, but also glue particles get into the oil. The adhesive base contaminates the oil even faster.

It becomes clear that the “donut” with worn-out locking elements needs to be changed or repaired, and in many cases already by 100-150 thousand km. Precisely because old automatic transmissions rarely had locking or did not have it initially, the oil change intervals were long, and the service life of the automatic transmission and gas turbine engine itself was also impressive. Unfortunately, this cannot be said about modern analogues.

Removing the torque converter from an automatic transmission: main faults and options for their elimination

A torque converter is one of the components of an automatic transmission that transmits torque from the power plant to the gearbox. Acting as a clutch with some additional functions, the torque converter allows the transmission to provide smooth and timely gear changes.

This automatic transmission element is widely used in both automatic and CVT gearboxes. In this article we will take a closer look at the simplest torque converter, its operating principle, common faults, and also how to remove the torque converter from the automatic transmission for repair.

Device, principle of operation, modes

DIY xenon ignition unit repair.

Possible breakdowns. Replacing the block The design of the torque converter includes only a few elements:

- Pump wheel;

- Turbine wheel;

- Stator, also known as a reactor;

- Frame;

- Locking mechanism;

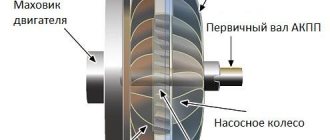

The torque converter is mounted on the engine flywheel, but one of its components has a rigid connection with the gearbox shaft.

If we compare this type of transmission with a conventional friction-type clutch, then the pump wheel acts as a drive disk (rigidly connected to the engine crankshaft), and the turbine wheel acts as a driven disk (attached to the gearbox shaft). But there is no physical contact between these wheels.

It is noteworthy that even the location of these wheels is identical to the friction clutch - the turbine wheel is located between the flywheel and the pump wheel.

All components of the torque converter are enclosed in a sealed housing filled with a special working fluid - ATF oil. Due to its shape, this transmission element received the popular name “donut”.

The essence of how a torque converter works is very simple. The wheels of the device have blades that redirect the liquid in a certain direction.

Rotating together with the flywheel, the pump wheel creates a fluid flow and directs it to the turbine blades, thereby ensuring the transmission of force.

If the design included only these two wheels, then the torque converter would be no different from a fluid coupling, in which the torque on both components is almost the same.

But the task of the torque converter is not only to transmit force, but also to change it.

So, at the start, it is necessary to ensure an increase in torque on the driven wheel (at the start of movement), and during uniform movement, to eliminate the so-called “slippage”.

To perform these functions, the design includes a reactor and a locking mechanism.

The reactor is another impeller, but of a much smaller diameter, and it is located between the turbine and the pump; the reactor is connected to the latter by means of an overrunning clutch.

The task of this element is to increase the speed of fluid flow, which leads to an increase in torque.

The reactor works like this: if there is a large difference between the main wheels of the torque converter, the overrunning clutch blocks the reactor, preventing it from rotating (because of this, another name for the component is the stator).

At the same time, its blades, which have a special shape, increase the speed of the fluid flow that hits it after passing the turbine wheel, and direct it back to the pump.

Thus, the reactor significantly increases the torque required to create sufficient force when starting to move.

With uniform movement, the torque converter is blocked, that is, a rigid connection appears in it, and this is done by the locking mechanism used in the design.

Previously, in automatic transmissions, this component only worked at high speeds. Now, the electronic transmission control systems used block the torque converter at almost all stages.

That is, as soon as the torque for a certain gear approaches the required parameters, the mechanism is activated.

When changing gears, it turns off to ensure smooth shifting and turns on again. This eliminates the possibility of the torque converter “slipping,” which increases its service life, reduces effort losses and reduces fuel consumption.

It is noteworthy that the locking mechanism is essentially a friction clutch, and it works on the same principle. That is, the design has a friction disk that is attached to the turbine.

When the locking mechanism is turned off, this disk is in a depressed state. When the lock is turned on, the clutches are pressed against the torque converter housing, thereby achieving rigid transmission of torque from the engine to the gearbox.

In general, if we consider the functioning of the torque converter, then there are three modes of its operation:

- Transformation (turns on when an increase in torque is required to create more force. The reactor operates in this mode, providing an increase in the flow speed);

- Fluid coupling (in this mode the reactor is not involved and the torque on the drive and driven wheels is almost the same);

- Blocking (the turbine is rigidly connected to the housing to reduce losses due to “slippage”).

The electronic system used to control the operation of the torque converter ensures a very quick change in its operating mode, adjusting the functioning of this element to the emerging conditions.

Description of the torque converter design

The torque converter is located in the automatic transmission housing and is connected to the oil pump through the transmission input shaft. On the opposite side, the “donut” is attached to the engine flywheel through threaded bosses.

The automatic transmission torque converter parts are located in a sealed casing, where they are immersed in ATF fluid. Due to the toroidal shape of the torque converter housing, it was nicknamed the “donut”. To get to the filling, you need to carefully cut the weld along the equator of the casing.

In cross-section, the automatic transmission torque converter is a set of bladed wheels and couplings mounted on one axis:

- pump wheel;

- turbine wheel;

- reactor wheel;

- overrunning clutch;

- locking clutch.

The pump wheel is welded to the housing cover, which is connected to the engine crankshaft. The turbine wheel is structurally similar to the pump wheel and is installed opposite with a small gap. The turbine is rigidly connected to the transmission input shaft.

Between the pump and the turbine there is a reactor. It is fixed to the freewheel, which is mounted on the input shaft bushing. The lock-up clutch is located behind the turbine.

The kinematic diagram shows how the main parts of the torque converter are located and shows the trajectory of the fluid flow. Structurally, the automatic transmission torque converter is a direct drive device, when the blade wheels force the fluid to circulate in the following order: pump - turbine - reactor - pump.

Torque converters with an overrunning clutch are called complex ones.

Components of the torque converter

The basis of the pump and turbine wheels of the torque converter is a bowl cast from a light alloy. Grooves are cut out on the inner and outer surfaces of the bowl, between which the blades are located. The blades are made by stamping and connected to each other by a toric disk using bending tendrils. Additionally, the blades on the bowl are secured with a ring.

The curvature of the bowl and the complex shape of the blades are designed to meet the requirement to increase the efficiency of liquid circulation. Thus, the design of the wheels provides the necessary speed and direction of oil movement.

The turbine wheel rests on the shaft by means of a hub and plain or rolling bearings. The bearing absorbs radial and axial loads.

The pump hub is typically used to drive the oil pump located behind the torque converter. The drive is activated when the end splines of the hub enter the corresponding grooves of the pump drive gear.

Causes of automatic transmission malfunction

Possible gearbox malfunctions, their causes and solutions

The most common cause of automatic transmission breakdowns is non-compliance with vehicle operating rules. For example, the cause of a breakdown may be a sharp increase in speed or prolonged slipping in one place. In addition, driving at speeds above 150 km/h can significantly reduce the service life of the automatic transmission. But if you can’t imagine your life without racing, then change the oil in the box more often, because at high speed the oil quickly loses its properties. You should not tow another car, because this will lead to additional load on the automatic transmission components. In addition, the additional load always makes itself felt in snowy weather or when you drive through sand or mud.

Signs of automatic transmission failure

The smell and color of the oil can indicate that there is a malfunction in the automatic transmission. If the oil is black or dark brown in color, and there is a characteristic burning smell, this is a sure sign of a malfunction. Indicators of serious automatic transmission malfunctions include suspicious noise, jerking and a long time between gear shifts.

How to remove a torque converter from an automatic transmission

Often, specialists and amateurs who have experience working with a manual transmission do not take into account some features of the automatic transmission, as a result of which quite annoying mistakes are made during the removal and installation process.

Thanks to illiterate dismantling, the amount of work of repair specialists increases and, accordingly, the cost of repair itself. Violations of the technology for installing a box that has already been repaired can often negate the results of the work on its restoration, and clients who are not sufficiently knowledgeable in this matter tend in such situations to make unreasonable demands and claims against repairmen.

But installing and removing an automatic transmission is not a big problem, and both an auto mechanic and an experienced car enthusiast can handle it. You can also avoid troubles if you approach this matter thoughtfully and responsibly.

- First, we want to tell you a few general details. If you nevertheless decide to remove the automatic transmission yourself, then this should be done on an overpass, on an inspection pit or in a special room equipped with a car lift. Since the automatic transmission has quite a good weight, you need to think about how you will correctly lower the box when undocked from the engine. You should know that rough handling of an automatic transmission will inevitably lead to its complete breakdown, so we recommend using a special device such as, for example, a transmission jack. You will need to stock up on the necessary tools for the car in advance.

- Before removing the automatic transmission, inspect it carefully and unplug everything that can connect it to the vehicle system: oil system pipes, mechanical control and adjustment rods, various electrical cable connectors.

- Some cars require socket sockets or internal hexagons to unscrew the box mounting bolts. If this procedure is performed using tools that are not provided in the instructions (chisel or sledgehammer), then it cannot lead to anything good. You need to plan the work so that it is done as carefully as possible, without rushing.

Most often, removing an automatic transmission is similar to dismantling

an automatic transmission, however, it is necessary to take into account some nuances that are determined by the designs of automatic units and their features:

- Before you remove the gearbox, it is not necessary to drain the oil from it, but it is necessary to

- Before you start lifting weights, you will need to carry out some preparatory operations. It is necessary to check whether there are two centering pins on the mating flange in the engine crankcase. If one of them is missing, then there is no way to install the automatic transmission. The fonts can be made on a lathe, providing a press fit in the engine crankcase and a gap of 0.03-0.05 millimeters in the box body. The length of the pin can reach from 20 to 25 millimeters. Having dealt with the “pin” problem, you need to check the membrane for end runout, to which you will then attach the torque converter. End runout should not exceed 0.15 millimeters. When checking, it is necessary to use precise measuring instruments, such as an indicator head. The membrane must be replaced if the runout is above the permissible level.

- Having started installing the box, you need to check the presence of the engine crankcase and two pins on the flange. If they are missing, you cannot install an automatic transmission.

- The internal surfaces of the automatic transmission must be thoroughly cleaned during any type of repair, since in the event of a malfunction, wear and partial destruction of the clutches and brake bands, as well as other metal parts, will begin.

- For the correct operation of an already repaired gearbox, it is necessary that the runout of the flywheel membrane does not exceed 0.15 millimeters. You can check them using an indicator head.

So now you have received a clean refurbished box from repair. If your time, money and specialist labor are valuable to you, spare no effort in cleaning the line and radiator in the oil cooling system. Cleaning must be carried out under the strictest fire safety precautions.

- First, drain the remaining old oil from the radiator and flush the radiator with gasoline under pressure in two directions or by gravity. This procedure must be repeated until clean gasoline flows from the oil tube. Next we blow out the line and the oil cooler with compressed air. Then we get down to cleaning the torque converter. We wash the insides of the torque converter with gasoline, draining it until the gasoline is clean. Next, fill it with about a liter of ATP gear oil.

- Drain the remaining dirty oil from the cooling system. We wash the line and oil with gasoline

If you did it easily, it means that everything was done correctly. Let's move on:

- We tighten each standard bolt and nut securing the box. Don't forget also about the torque converter, which is hidden inside the crankcase. The torque converter must be firmly attached to the diaphragm in the engine flywheel. You need to remember what you undocked from the box when you removed it, since now everything needs to be returned to its original position.

- Many parts must be color coded or specially marked. Vacuum lines must not be swapped under any circumstances. It is necessary to check and, if necessary, adjust the consistency of the position of the selector and the automatic transmission shift lever.

- If you have a mechanical connection between the throttle valve (or fuel injection pump rack for a diesel engine) and the automatic transmission throttle lever, then it is advisable to check its adjustment according to the instructions for its operation, since poor adjustment will shorten the service life of your automatic transmission.

- After the adjustment work, fill the box with ATF oil through the control plug or dipstick tube. Add oil until the level exceeds the upper mark on the dipstick 3-5 centimeters. If the dipstick is missing, it is necessary to add until oil begins to flow out of the control plug.

- With the transmission in a horizontal position, slide the torque converter onto the input shaft shank. It is necessary to ensure that it is completely seated on the shaft splines by rocking it with your hand.

- We start the engine and make sure that the crankshaft speed does not exceed 2000 rpm. Next, we need to add oil to the required level according to the mark on the dipstick or according to the level of the control plug.

- When you lift and install the automatic transmission, you will need to ensure that its longitudinal axis always has a slight slope. This should prevent the loose torque converter from moving or falling.

- When braking the car, pressing the pedal, it is necessary to sequentially turn on all modes in the gearbox, after which we check the oil level again and top up if necessary.

- We make a test drive and avoid movements with sudden gas changes. Then you need to let the car cool down and check the oil level again.

- If the oil level drops, do not worry, as this is a common occurrence. This is because the lines, torque converter and gearbox have many hidden cavities, from which air will be removed during a test drive and filled with oil.

Identifying the main faults of the automatic transmission torque converter

Automatic transmission for Jaguar S Type: design and operation

We list the signs of a faulty automatic transmission torque converter. As a rule, this installation loses its operating functions due to the natural wear of its components, for example, the clutch. The main manifestation of the fact that there is a breakdown with this element is the appearance of characteristic vibrations

In this case, the driver should pay special attention to the valve body valves

The presence of vibration is also evidence that the oil filter is clogged. With the replacement of this consumable, an oil change is also required. Checking the oil on each version of the car is individual. Thus, according to technological regulations, it can be carried out at 30,000, 45,000, 60,000 km.

It is necessary to pay attention to the integrity of the bearings if a characteristic sound begins to appear, which goes away when the speed increases. As a rule, disassembly of the torque converter is required

It is important to replace the automatic transmission torque converter oil seal after approximately 175,000 km. By this time, this consumable begins to leak due to a violation of its elasticity. Often, leaks occur not because the oil seal has lost its state of aggregation, but because the gearbox housing has become deformed.

The smell of melting plastic began to be felt inside the car. This is evidence that the torque converter is experiencing enormous loads, resulting in overheating. In this case, you need to check the amount of lubricant, oil level, and the cooling system of the speed box. There is no need to replace the automatic transmission torque converter.

Replacing the control unit is important if the automation fails. At the same time, when changing speeds, the engine stalls.

What is an automatic transmission torque converter - photo and description

This blade system allows the transmission of torque from the internal combustion engine to the gearbox. In addition, it makes it possible to modify the rotation speed and torque supplied to the driven shafts of the vehicle without driver intervention. As a rule, this mechanism is recommended for use with CVTs or automatic transmissions.

Automatic transmission torque converter design

It consists of a stator (also called a reactor), a pump wheel, a locking mechanism, an overrunning clutch and a turbine. All of these elements are located in one housing, which is mounted on the flywheel of the car engine. A special transmission compound is poured inside the mechanism.

The operating principle of an automatic transmission torque converter

The overrunning clutch connects the pump wheel to the device body, inside which an oil flow is formed. It begins to rotate the stator wheel, and then the turbine. The reactor is blocked automatically when a significant difference in the speed of the pump and turbine occurs. At this moment, the required fluid flow enters the wheel. When the engine speed increases, the stator controls the increase in torque.

Having figured out how the torque converter works in an automatic transmission, you can understand that torque is transmitted “softly” inside it. Due to this, it is possible to avoid shock loads on the transmission, and also achieve noticeably smooth movement of the vehicle. At the same time, locking the automatic transmission torque converter “saves” fuel when the car is moving on the highway. It turns on automatically at speeds over 60 km/h.

Purpose

To clearly imagine what role the torque converter plays in an automatic transmission, it is worth remembering the purpose of an ordinary clutch, which is universally installed on manual transmissions.

The clutch acts as a link between the engine and transmission. In other words, if the clutch is not disengaged, then one hundred percent of the motor is transferred to the gearbox, and, consequently, to the wheels. In addition to everything, the manual transmission itself allows the driver to choose the gear himself and change the torque, which allows him to achieve maximum engine efficiency when driving and simply prevent it from stalling in place when the wheels are not rotated.

The main disadvantage of manual transmissions over automatic transmissions is that in addition to constantly selecting the speed manually, you need to depress the clutch pedal. If this is not done, there is a risk of damaging the extremely expensive clutch and burning it, which will lead to the need to replace it.

It was for these purposes that the transformer began to be used. This element is much more complex than the clutch on a manual transmission, which consists of only two discs - a drive and a driven.

Then the question arises: is it possible to use an ordinary clutch on an automatic transmission instead of a torque converter, as on a manual transmission? The answer is incredibly simple - the automatic transmission itself selects the moment when the gear needs to be changed, and the driver does not know this moment in advance. Consequently, there is no way to press the clutch pedal in time. Hence the need arises to introduce a torque converter into the automatic transmission, which greatly facilitates the interaction between the driver and the box.

Repair instructions

Before you begin repairing a vehicle, you should diagnose it. I consider it necessary to distinguish 3 stages in it.

- Quick view. It is often free at many service stations. It consists in the fact that the driver talks about the problems he noticed and, if they indicate a simple malfunction, specialists check the automatic transmission oil level or replace it.

- Tactile stage. If the steps described above do not help, the vehicle is inspected. At this stage, the cost of diagnostics is low. This includes “removing the pan.” Specialists will most likely remove fault codes, check pressures, conduct a bench test, and check the electrical wiring for faults to determine the fault without dismantling. The solution to the breakdown is an oil change.

- Those cars with a mileage of more than 150 thousand km will most likely need to disassemble the machine to determine and eliminate the cause of the malfunction. In this case, it is worth replacing the GTF clutch.

We recommend: Caution: painted! Preparatory work and organization of make-up

As for repairing the automatic transmission torque converter, it is better to contact specialists at the first sign of a malfunction, then less serious problems with the operation of the entire system await you. Repair of the gas pump consists of disassembling it, identifying defects in parts and replacing them. It is disassembled by cutting off the weld seam of the body. After the spare parts are checked for defects, they are replaced if necessary. After assembling the hydraulic pump, its body is welded. At this stage, an important point is to check the housing for leaks. I also always advise you to check whether the parts are securely attached and whether there is an internal thermal gap.

I would like to note that when repairing automatic transmission faults, the gas transmission unit must also be repaired.

It is almost impossible to repair an automatic transmission torque converter yourself in your garage, if only due to the lack of necessary equipment. Which, by the way, is not always available in auto repair shops. Not to mention that this procedure requires certain knowledge and skills. If repaired incorrectly, the torque converter will cause even more problems than if it were faulty.

Automatic transmission torque converter repair

The gas turbine engine is a reliable unit and can operate for a long time without complaints. Its service life should coincide with the service life of the automatic transmission itself. However, it happens that this part is sent for urgent repair. The main failures that can befall your gas turbine engine are wear of parts such as the pump wheel hub, locking clutch, cracks or kinks in the wheel blades.

If you repair the automatic transmission torque converter in a timely manner, it will not cost much. A problem that is not corrected in time usually leads to the need to replace the entire gas turbine unit.

Since the automatic transmission torque converter and gearbox have a common fluid circulation, wear products of various parts affect the operation of the entire unit as a whole. Therefore, when planning engine and automatic transmission repairs, you also need to carry out a preventive inspection and check of the torque converter.

It is impossible to remove wear products, as well as inspect the integrity of the wheels of the gas turbine engine without depressurizing it. Therefore, after the body is cut, the repair continues by thoroughly washing the parts and examining them for wear: any cracks, chips, deformation or missing teeth on the wheels - all this requires immediate replacement of parts.

You can diagnose possible problems yourself, based on standard signs of automatic transmission torque converter breakdowns.

For example, if when you engage a gear you hear a slight rustling noise, which then disappears, then, most likely, the problem is the wear of the thrust bearing connecting the pump wheel and the reactor or the turbine bearing with the gas turbine engine cover.

If you hear a loud metallic knock when you engage the gear, then repairs may be needed for worn-out blades that have fallen out, become deformed, or chipped.

If aluminum powder settles on the oil dipstick, this indicates wear on the freewheel end washer.

The appearance of the smell of melted plastic indicates the need for urgent repair of the torque converter. When overheated, parts made of polymer materials failed.

If the engine begins to stall when changing gears, it means that the automatic transmission torque converter locking system has activated due to a failed control system. Well, stopping the car may mean that the splines on the turbine wheel have been cut off.

After replacing worn parts, the repair of the torque converter ends with the assembly and welding of the gas turbine housing. After welding, the body must be checked for tightness, correct fastening of all internal elements and their runout. Lastly, the internal thermal gap is checked for compliance and balancing is performed.

It is almost impossible to repair an automatic transmission torque converter efficiently and accurately at home. A poorly repaired gas turbine engine is just as dangerous as the one before the repair. It is better to repair your car by taking it to a specialized service center.

General characteristics

Hydrodynamic transformer

The hydrodynamic transformer is a hermetically sealed unit. It transmits torque from the drive to the box. Obviously: the torque converter replaces the clutch. Let's get acquainted with the principle of operation of the GT.

The drive crankshaft interacts with the pump wheel, whose task is to accelerate the mixture, then direct it to the turbine. The automatic transmission interacts with the turbine. The incoming liquid is pumped by a turbine and then returned to the pump. Before the pump, the mixture flows onto the reactor blades, whose task is to accelerate the flow of the mixture and direct it in the direction of rotation.

According to the specified cycle, the mixture is accelerated until the rotation speeds of the pump and turbine wheels are equal, after which the hydraulic transformer stops converting torque, and the reactor rotates freely, without interfering with the flow of liquid.

The difference in the rotation speeds of the pump and turbine wheels determines the acceleration of the working mixture, which, while rotating, begins to heat up, the efficiency of the hydrodynamic transformer decreases - a large amount of energy is spent on heating. When equalizing wheel speeds, there is no need to transmit torque using fluid due to large losses. Therefore, to the GT design, engineers decided to introduce a GD lock (elements whose operation is based on the action of friction), connecting the input and output shafts so that torque is transmitted directly. On modern cars, the locking is electronically controlled and controlled by a separate valve. There are many locking designs, but they have the same meaning - connecting shafts to temporarily exclude the transmission mixture from the torque transmission chain.

We recommend: How to change the brake drum on a VAZ 2107

The operation of the torque converter is monitored using a special control unit, which is an automated system that receives data from sensors located on the hydraulic transformer and automatic transmission. When a malfunction is detected in the operation of these units, the electronics signals an error. On some car models, the operation of the torque converter can be completely blocked - this leads to the engine turning off when there are changes in the operation of the automatic transmission. Many GT failures occur on the part of mechanical elements, so when carrying out diagnostics it is difficult to determine the location of the malfunction; you need to disassemble the damaged unit and perform a visual inspection to understand why the GT stopped working.

We recommend watching a video about repairing a GT automatic transmission:

Correspondence of signs and causes

Here is a table of common automatic transmission breakdowns.

| Signs | Causes |

| Reverse gear does not work. Only speeds 1 and 2 function, but speeds 4 and 3 do not work. | The friction discs are worn out, the piston cuffs are broken, the sealing rings are destroyed. |

| The car does not move forward, it slips, reverse gear works. | Worn discs, front clutches, broken cuffs, worn clutch rings, stuck valve body. |

| The car does not move back and forth. Strong shocks when switching. | The torque converter is faulty; oil needs to be added and the filter needs to be replaced. |

| You can only drive in third gear. | Wear of friction discs, front clutches, breakage and wear of piston cups, wear of clutch rings, valve sticking. The electronic unit has switched the box into emergency mode; diagnostics and repairs are required. |

| Shifts on a cold box are made with jerks. | Dirty solenoids or hydraulic plates. Consumables need to be replaced and the valve body needs to be cleaned. |

| No reverse. | Worn brake band, broken cuffs, brake band, broken piston rod. |

| The car is unable to move in any direction. Switching is carried out without jolts. | Malfunction of the torque converter, pump drive gear, no gear engagement with the torque converter. It is necessary to add oil and clean the filter. Wear of the brake band, clutch and disc, as well as piston seals. Wear and breakage of O-rings. The valve body solenoid or valve is faulty. |

| The increasing rumble of the box, vibration when driving, intensify with increasing engine speed. | Bearing wear. |

| There is reverse gear, forward gears - only first and second. When the box warms up the problem goes away. | A dirty solenoid or valve body is stuck. |

| The car drives in neutral. | Incorrect adjustment of the gearbox lever or cable. Clutch piston jamming. Welding friction clutches. |

| Speeds are included at high speeds | Incorrect throttle cable adjustment, clogged filter, faulty throttle valve. |

| The car drives normally, but on an ascent the automatic transmission slips and switches to a reduced speed. | Low oil level, wear of friction discs, brake band. The oil pump and valve body solenoids are faulty. |

| A sudden press on the gas does not switch to a lower speed, and the kickdown does not work. | The button or sensor under the pedal is faulty, the switch valve is stuck, the damper cable is faulty, there is no power to the sensor. |

| When starting from a stop, it slips, but when the speed increases, it drives normally and the gearbox shifts properly. | Worn turbine wheel splines, broken cuffs. |

| When switching, slippage occurs. | The oil pump is faulty, the filter is clogged. |

| No forward or reverse. | The splines on the turbine wheel hub were cut off. |

| Significant shocks occur when changing speed. | Wear of the brake band, friction discs, clogged solenoids or valve body channels. |

| The car slips when driving and jerks when shifting. | Clutch failure. |

| No movement in both directions, no oil pressure. | Oil pump splines cut off. |

| The car moves normally until the oil warms up. Then slipping occurs and the car stops. | Faulty friction discs. When the oil is cold, its pressure and viscosity are higher compared to hot oil; worn discs are pressed better and form traction. Friction wear, oil contamination, filter mesh. |

| Noise in the form of metal beating at idle. | Severe wear on drum discs. |

| The transmission does not switch to a lower speed when the pedal is depressed, there is no kickdown. | Engine malfunction. |

| The transmission does not switch to a lower speed when the pedal is pressed all the way. The car moves normally until the oil warms up. Then the car slips and does not move. The car accelerates slowly. No reverse. | Violation of the tightness of the fan blades of the turbine and pump. Broken blades. |

| There are large metal shavings in the tray. | Severe wear on the planetary gear. |

| The oil in the box foams and slippage occurs. | Water penetration into automatic transmission. |

| Low oil pressure. | Dirty solenoids or valve body. It is necessary to check the oil level and the relief valve in the pump. |

| When the gear is engaged, the car stumbles and stalls. As the rpm increases it moves normally. | The speed clutch valve needs to be checked. The torque converter is faulty. |

| Aluminum shavings in a tray. | Wear of the plain bearing and planetary gear. |

| The tray contains plastic elements. | Broken plastic part. |

| Metal scraping. | Wear of differential bearing, gears. |

| Magnetized rollers were found in the automatic transmission tray. | Broken roller thrust bearing. |

Signs of breakdown

It is important to notice transmission problems at the earliest stage. Then, with proper diagnosis, complex repairs can be avoided. Quiet and smooth operation of the automatic transmission is considered normal. There are a lot of signs that something is wrong with the box. Most often these are extraneous sounds when changing gears or during transmission operations. It may be crunching or clicking. An unpleasant odor also indicates problems. It can appear during long-term or short-term operation of the box. It’s worse if the gear shift slows down, or one of them doesn’t work at all. Then immediate intervention is required.

Don't be lazy to look under the car, it should be clean. Red spots will indicate an oil leak from the gearbox. Regularly checking the oil level is a must. Normally, it should be translucent and reddish in color. No burnt smells or cloudy overtones! If they appear, it's time to change the oil.

Recommended: 15 Best H11 Bulbs

Main causes of breakdowns

Automatic transmission malfunctions often occur due to improper operation. The transmission becomes unusable due to insufficient oil level or overheating. For this reason, gears wear out, and the machine may jerk when changing gears. As a result, any part of the automatic transmission can fail. Shocks when driving indicate overheating of the oil and problems in the valve body.

Aggressive driving with sudden acceleration and braking leads to abrasion of parts. Driving in traffic jams and slipping does not add durability to the box. All this leads to overheating of the box and has a bad effect on its general condition.

All faults are divided into two subgroups. They can occur in

- electronic control system,

- mechanical and hydraulic parts of the gearbox.

If a malfunction occurs, the automatic transmission goes into emergency mode, that is, it switches to third speed and does not shift. The corresponding icon appears on the display.

If problems arise with the electronics, they cannot be eliminated by repairing the automatic transmission. Therefore, it is important to understand the nature of the faults.

The torque converter consists of the following parts

- pump (pump wheel);

- reactor;

- turbine (turbine wheel);

- overrunning clutch.

How does a torque converter work?

The pump must be connected to the engine crankshaft, while the turbine is connected to the gearbox shaft. The freewheel reactor rotates in the fluid flow when switching to fluid coupling mode. While driving, the torque converter experiences hydraulic and thermal stress. A special radiator cools the working fluid. If it is faulty, coolant may enter the transmission.

In what cases is torque converter repair necessary?

The most common reason is wear of the locking clutch. There are cases when repair of automatic transmission torque converters (repair of gas turbine engines) is necessary due to wear of the pump wheel hub or breakage of wheel blades. Other options are rare.

When repairing torque converters, the equipment must be cut, faulty and worn parts must be replaced. After this, the torque converter is welded again. Repair of automatic transmission torque converters (repair of gas turbine engines) cannot be carried out without opening the housing.

Repair of torque converters is carried out as an independent troubleshooting or as part of a comprehensive automatic transmission repair. Since the torque converter is subjected to significant thermal loads during operation, its parts wear out prematurely.

Malfunctions that the torque converter is susceptible to:

- unlocking the overrunning clutch;

- wear of the locking clutch;

- breakdown of wheel blades;

- overrunning clutch jamming;

- wear of the pump wheel hub.

Timely repair of automatic transmission torque converters allows you to extend the service life of the units. Do not delay repairing the gas turbine engine if there is the slightest sign of malfunction (jerks when shifting gears, vibrations)

Your attention to your car will help you avoid such an unpleasant extreme as replacing the torque converter. If minor problems are not corrected on time, not only torque converters will be required to be repaired, but also other parts.

Remember that repairing a donut will cost you less than replacing a torque converter. Car service center Lider Motors, carrying out repairs of automatic transmission torque converters, performs troubleshooting and replacement of failed parts. To disassemble the unit, it is necessary to cut the weld seam. Replacement of parts is possible only after depressurization. Repairing the donut also includes welding the body, checking for leaks and balancing.

Often the torque converter needs to be cleaned of automatic transmission wear products. In this case, the torque converter must also be opened. Whenever the torque converter is opened, the seals and O-rings must be replaced.

Torque converter repair is an important part of automatic transmission repair work. The consequence of their close relationship is that the failure of one node leads to the failure of another

Therefore, diagnostics of the gas turbine engine followed by repair, if necessary, is an integral part of automatic transmission diagnostics.

At the Lider Motors car service center, torque converter repairs are carried out using high-quality specialized equipment. A complete repair of torque converters can be carried out in a short time.

Our craftsmen guarantee that the restoration of torque converters (repair of gas turbine engines) will be performed flawlessly. They know well how specific the torque converter is, and therefore, accurately identifying problems, they quickly eliminate them.

Unfortunately, there are situations when repairing a gas turbine engine does not make sense. In such cases you will have to buy a torque converter

Please note that the sale of gas turbine engines is also included in the range of our services. From us you can buy a torque converter for all types of automatic transmissions serviced by our service center. Replacing the torque converter should also be carried out by professionals

So, if you need qualified torque converter repair or other services related to this unit, we are waiting for you.

The design and principle of operation of the torque converter

The design of the torque converter consists of two wheels: pump and turbine, as well as a stator (the name “reactor” is also widely used) and a special locking mechanism. Inside the entire unit there is oil, which can move freely throughout the mechanism to minimize friction of parts. However, many designs have their exceptions. For example, in the transmission of the DT-175S tractor, the connection between the engine and the torque converter can be provided by a cardan shaft. The same applies to the LiAZ-677 bus.

The pump wheel is connected to the engine and when the flywheel rotates, it moves oil through the mechanism, which, in turn, causes the turbine and reactor wheel to rotate as a result of the flow. The turbine transmits rotation to the automatic transmission shaft.

Typical torque converter malfunctions

Having examined the principle of operation of the torque converter, everyone could understand that this mechanism is loaded only when the car accelerates to a certain speed. At these moments, the hydromechanical device consumes the energy received from the motor to spin the control blades, thereby reducing the efficiency of its operation to 80-85%. It is at this moment of operation that the torque converter elements experience enormous loads and quickly wear out.

Conventionally, breakdowns of the hydromechanical mechanism can be divided into two large groups:

- Wear and failure of the components of the torque converter itself;

- Malfunctions of the hydraulic block plate in contact with it.

It is worth noting that the torque converter, unlike the valve body, is a non-separable unit and, accordingly, cannot be repaired. Despite this, in the auto repair industry it is common to simply cut off the weld seam connecting the two halves of the mechanism, repair it and re-weld it. Often one of the following malfunctions occurs with the torque converter:

- Wear of friction clutches;

- Looseness or wear of input and output shafts;

- Clogging or wear of the oil supply channels, which causes overheating of the device.

In addition, the valve body is important in the operation of the entire automatic transmission, in particular in the operation of the torque converter. The hydraulic plate most often has breakdowns of the following types:

- Clogged hydraulic filter or oil supply channels;

- Malfunctions of solenoids and sensors responsible for supplying lubricant to the torque converter;

- Incorrect operation of the oil pump.

Any malfunction of the automatic transmission torque converter and valve body manifests itself in the form of three main symptoms: overheating of these components, vibration and incorrect operation of the box. The appearance of such signs requires the motorist to take some measures, since speed is important when repairing a quickly killed machine, and you cannot hesitate when organizing it.

What is a torque converter used for and how does it work?

A torque converter is necessary to eliminate the clutch pedal, smooth acceleration, and increase torque during it. Thus, it protects the engine from extreme load. The clutch of the automatic transmission to the engine is ensured by a torque converter, transmitting torque between the shafts due to oil pressure. Very often I come across the fact that automatic transmission means the torque converter and the gearbox itself. The GTF consists of 2 bladed machines (a centrifugal pump and a centripetal turbine), between which there is a reactor, which is a guide vane.

The principle of operation of the GTF: when the rotation speeds of the output and input shafts are equalized, the torque converter is locked (the efficiency is equal to 100%!), the oil rotation stops, the engine shafts and transmissions are connected. This procedure is very similar to changing gears on a manual transmission. The advantage of a torque converter transmission is the ease of control of the machine's traction.

Repair and restoration work

You should entrust the repair of a torque converter breakdown to mechanics who work in a professional service center. They will help not only with disassembling the torque converter, but also with its assembly, which requires welding. Finally, the restored device is checked for leaks.

Replacing the torque converter must take place in specially created conditions. Professional equipment for repairing torque converters is available only at trusted stations. In particular, it is imperative to use an automatic machine that can carry out welding work when a torque converter repair is needed. You should not delay repairs if the torque converter is slipping.

When repairing a torque converter with your own hands, this device must be removed from its original location. It requires washing and troubleshooting. A special solvent should be used as a detergent. In this case, the car owner must not only have relevant experience, but also have special tools and work equipment. It should be noted that independent repair of a torque converter may involve replacing oil seals, bushings, and friction linings.

How to remove and install automatic transmission

Removing and installing an automatic transmission is a complicated matter. There are many nuances that you need to pay attention to if you are removing the machine from your car for the first time. Therefore, if you do not have an experienced mechanic friend nearby, and you yourself are weak and know little about the structure of gearboxes, then it is better to send the machine to a service center for repair.

Well, for those who are familiar with the design of automatic transmissions, the instructions given below will be a good help in their work. Before removing the machine, perform computer diagnostics. You may not need to completely remove the machine, but only remove the old valve body and install a new one, or replace the solenoids on it.

Write in the comments, have you removed the box from the car yourself?

We check the automatic transmission transformer ourselves

A torque converter (hydrodynamic transformer) is installed on cars with an automatic transmission and serves to transmit torque from the engine crankshaft to the drive shaft of the gearbox and transform the torque (about 2-3 times).

It frees the driver from constantly using the clutch pedal when changing gears and when suddenly braking the car, and there is also no constant mechanical connection between the engine and the gearbox. The connection is maintained hydrodynamically, carried out by fluid supplied by the oil pump, turbine and pump wheels.

The torque converter ensures smooth gear shifting (relieves shock loads) and smooth acceleration (prevents wheel slipping).

Torque converter malfunctions

The hydrodynamic transformer includes: turbine wheel, pump wheel, reactor, locking mechanism, overrunning clutch, bearings, oil seals, housing parts.

This transformer is a closed type, welded structure, all parts are located inside a sealed housing. Oil is pumped by an oil pump into the housing cavity, ensuring its constant circulation, due to which heat removal (cooling) of hydrodynamic transformer parts is achieved, removal of mechanical and abrasive particles formed as a result of wear of rubbing parts, as well as lubrication of parts.

The pump wheel has a rigid connection with the engine crankshaft. The turbine wheel is connected to the automatic transmission through a shaft. A wheel (reactor) with an overrunning clutch is installed between them, ensuring rotation in only one direction.

When starting, the engine begins to spin up. The pump wheel spins simultaneously with the crankshaft. It captures oil with its blades, which, under the influence of centrifugal forces, is pushed to the periphery. There the oil swirls and hits the turbine wheel blades. Possessing excess speed, the liquid acts on the blades of the turbine wheel, gradually beginning to spin it.

As the engine speed increases, the pump wheel speed increases. The liquid receives greater acceleration - accordingly, the revolutions of the turbine wheel increase - passing its blades, it receives additional acceleration and ends up on the reactor blades. The reactor, due to the fact that its blades are installed at a certain angle, corrects the direction of the liquid strictly to the blades of the pump wheel. The pump wheel receives additional acceleration and the process repeats.

When the engine is running at idle and the accelerator pedal is slightly moved, the turbine wheel has enough torque to start the car moving. While the car is moving, the working process in the torque converter proceeds in a similar way, but until the revolutions of the turbine wheel exceed the revolutions of the pump wheel. Thanks to the presence of the overrunning clutch, the reactor begins to spin up, stopping the flow of liquid to the pump wheel blades, eliminating the additional increase in speed. The locking mechanism comes into operation.

With the help of a piston, the locking ring is pressed against the annular surface by a friction layer, ensuring a rigid connection between the pump and turbine wheels. Thanks to this operation, the engine does not consume excess fuel to overcome internal losses. The operation of the hydrodynamic transformer is constantly under the control of the on-board computer and is automatically controlled by the electronic control unit.

Design bureaus and engineers are constantly working to improve the torque converter, increasing its reliability. However, during operation, malfunctions arise that require routine repairs or replacement of the entire unit. Such malfunctions are caused by violations of manufacturing technology, the use of materials that do not meet technical specifications, the presence of residual stresses at welding points (due to local overheating leads to breakage of the blades), poor-quality gluing of the friction layer (leads to premature destruction).

Operational faults: use of oil that does not comply with specifications, untimely replacement of oil and oil filter, poor quality control of oil and oil filter cleanliness, untimely replacement of parts that have become unusable.

Malfunctions in the operation of a hydrodynamic transformer can be caused by various types of mechanical damage, sealing failures, as well as malfunction of the electronic control unit.

Checking the automatic transmission torque converter.

To check the performance of the torque converter, primary diagnostics, in-depth diagnostics and analysis of indirect signs of malfunction by service station specialists, dismantling, disassembly and detailed diagnostics are performed, followed by repair and instrumental testing.

If there is a suspicion of malfunction of the hydrodynamic transformer, the driver performs initial diagnostics, collection of information, initial analysis and conclusion.

Before starting the engine, check the amount and cleanliness of oil in the gearbox (on a dipstick or a drop of oil on white paper), warm up the engine and check again. With the engine running, pay attention to the absence of extraneous noise (listen carefully in the area of the automatic transmission), as well as odors associated with transformer overheating. Check how the car behaves during gear shift on/off, acceleration, make sure that the engine does not stall during gear shifting, there is no vibration or knocking in the automatic transmission.

Check the acceleration time of the car to 100 km/h, make sure that the acceleration time is within the limits allowed by the technical operation conditions of the vehicle. If problems arise with the oil, it is necessary to check that there are no leaks in the area of the gearbox, and if necessary, refill or replace the oil and filter. If the cause has been eliminated, you can continue to operate the machine, keeping the operation of the gas turbine engine under constant control.

If, when performing control checks, the cause has not been eliminated, and changing the oil and filter has not given any results, you must contact a service station. After confirming indirect faults, specialists remove the gas turbine engine, disassemble it, carry out detailed diagnostics and repairs.

What is needed to check the automatic transmission torque converter.

To assess the performance and determine the failure of gas turbine engines, extensive experience in carrying out this work is required. Specialists read codes, check oil pressure, conduct tests, remove the pan, check for the absence of large metal particles, dirt, abrasives, and impurities from the destruction of the friction lining. To perform the above work, no special equipment is required. A standard tool is required to perform dismantling and installation work.

How to remove automatic transmission

Now I will describe how to remove the automatic transmission. Removing the machine consists of several stages. This is the preparation and the procedure itself. Preparations for removal include: draining the oil, inspecting the connections of the electrical cables to the box and disconnecting them from the connectors, as well as separating them from the vehicle engine.

Attention! I recommend draining the oil before starting to remove the machine, although you will find a lot of information on the Internet that you don’t have to drain the lubricant. And by draining the oil, you won’t stain either yourself or your partner when you unscrew the hoses from the radiator pipes.

Basic points of automatic transmission dismantling

So, let's start removing the box:

- Unscrew the drain plug and place an ATF drain container under the hole.

- Wait until all the oil has drained from the automatic transmission.

- Unscrew the pan bolts and remove it. Remove the filter.

- Unscrew the valve body bolts, disconnect the wires connecting it to various sensors.

Why I advise doing these things is that the box will become a little lighter. Yes, and it will be more convenient for you to remove it. If you disassemble the box, you will still have to remove the hydraulic plate. You can return the tray cover to make it easier to attach the holding mechanism.

Carry out all work with gloves. Remove components carefully so as not to damage them.

Procedure for removing an automatic transmission

Now the steps for the dismantling procedure are:

- Disconnect the hoses from the cooling system pipes. If you did not drain the oil, then plug the pipes with a rag so that the lubricant does not spill out.

- Disconnect the mechanical control rod fasteners.

- Disconnect the vacuum lines up to the vacuum corrector, if the machine has one.

- Disconnect all connectors that connect it to the electronic control.

- Perform the automatic transmission removal procedure only together with the torque converter, so as not to damage the input shaft splines or bend the diaphragm. To do this, you will need to disconnect the torque converter through the engine flywheel housing window. When removing the automatic transmission, a partner must support the torque converter.

- Walk around the box and see if everything is disconnected, repeat the procedure in two directions.

- Carefully inspect all shaft connections and drive connections.

If everything is unscrewed and ready to be removed, then you can begin the procedure. The removal procedure itself is difficult, so be careful not to damage the soft parts.

How to remove the torque converter

The difficulty is that many people do not know how to remove the torque converter from the car along with the automatic transmission. The fact is that the mounting bolts with the motor are located in different parts of the device. It all depends on the design of the device.

If you did not find the automatic transmission housing in the window, then perhaps the mounting bolts with the motor membrane are located in the hatch in the crankcase. In other devices, you will have to remove the starter to get to the gas turbine engine bolts.

Attention! Tilt the automatic transmission so that the torque converter does not slip off the spline of the input shaft.

Before you begin the procedure for removing the automatic transmission, carefully inspect again whether everything is disconnected, so that you don’t get a surprise from broken wires, torn pipes and other unpleasant moments.

The gas turbine engine must work properly after installation. This is an important part of the whole box.

During disassembly, clean each part of the automatic transmission with compressed air, kerosene or carbocleaner. Don't forget to mark the parts you pulled out. This will save you from unnecessary problems during the assembly of the machine, when you cannot remember where one of the parts came from.

Installation of the box

Before installing the automatic transmission, you must wash all components from carbon deposits, old oil, chips and metal dust. This way you will get rid of additional repairs for at least 100,000 kilometers. And the oil will be clean and not quickly contaminated.

Do not forget to fill the torque converter with oil before installing it on the input shaft. Do this procedure with the box in a horizontal position. Rotate the gas turbine engine until it sits tightly on the shaft. Because if the fit is insufficient, the pump wheel gear may fail.

Basic moments

It is also better to have an experienced mechanic or at least a knowledgeable person install the automatic transmission. However, if you have ever installed an automatic transmission, then you roughly know what this procedure is.

Attention! Before installation, be sure to clean all internal openings of the automatic transmission. Any rust or build-up will cause its particles to peel off and quickly clog the filter device and oil. And this is fraught with overheating and repetition of the procedure for disassembling the machine and cleaning it.

Therefore, if you decided to repeat it, then here are my instructions for you.

- Attach the automatic transmission to the puller mounts.

- Raise the machine to the level of the hole where the automatic transmission should be located.

- Check the two alignment pins on the motor mating flange. Check the end diaphragm for runout. If any of these parts is faulty or missing, install a new one.

- Diaphragm runout is checked using an indicator head. It should not exceed 0.15 millimeters.

After these procedures, you can couple the automatic transmission to the engine.

Installation procedure

Installing the automatic transmission is done as follows:

- Use the centering pins to align the automatic transmission with the motor.

- Join until you achieve complete abutment of the crankcases.

- Tighten the bolts that connect the automatic transmission to the engine.

- Check through the hatch that the connection is correct and tight by turning the torque converter. It should fit tightly and spin without play.

- Tighten the automatic transmission mounting bolts and nuts.

- Adjust the position of the selector and the automatic transmission shift link.

- If you have a diesel engine, then check the throttle adjustment with the automatic transmission throttle lever.

- Connect all electronic sensors and connectors to wires. Reinstall the bolts and nuts. Follow the marks you left on them with a marker.

- Now pour lubricant through the filler hole and check the level on the dipstick. If there is no dipstick, then fill until it flows out of the control hole. Screw in all plugs. Using the dipstick, determine the level at o. Since the oil is not heated.

- Lower the vehicle from the lift if the vehicle was still raised.

- Start the engine and wait until the rpm reaches 2000.

- Add oil again.