Each type of transmission (automatic and manual) has both its pros and cons. For example, during operation of a car, an automatic transmission provides maximum comfort, but such a gearbox is less reliable and more expensive to maintain and repair.

As for the manual transmission, this gearbox is more reliable and has a simpler design. However, the constant need to change gears yourself can be a problem for cars that are used in large busy cities.

It is not surprising that many car owners, for one reason or another, wonder whether it is possible to change a manual transmission to an automatic one and vice versa, as well as how to install an automatic transmission in a car equipped with a manual transmission, etc. Let's figure it out.

Read in this article

Option to replace “automatic” with “manual”

As a rule, the reason for such a replacement is the failure of a rather expensive automatic transmission. The second reason is simple fuel economy. Please note that if the machine is in working order, it may not be advisable to invest money in re-equipping a car with a non-guaranteed result of a noticeable improvement.

- Lifting the car on a lift and dismantling the internal combustion engine components that prevent the dismantling of the automatic transmission.

- Removal of interior panels and instrument panels, which also interfere with conversion work.

- De-energizing the power supply system by disconnecting the battery.

- Removing the starter if it is located in the lower part of the engine compartment.

- Disconnecting the automatic transmission electrical wires from the gearbox casing, disconnecting the cable or gear shift lever drive, as well as disconnecting the speedometer cable.

- Next comes the transmission fluid radiator tubes from the automatic transmission. They are disconnected, then the transmission oil is drained.

- Fixing the internal combustion engine, unscrewing the connecting bolts between the automatic transmission and the engine.

- Disconnecting the intermediate shaft from the gearbox and dismantling the support and automatic transmission mounting brackets.

- The automatic transmission torque converter unit is dismantled, after which the automatic transmission is disconnected from the engine using jacks.

- After complete dismantling of the automatic transmission components, install the flywheel on the crankshaft and the mechanical drive cables.

- The automatic transmission selector is being replaced with a manual transmission selector.

- This is followed by installation of the clutch pedal and clutch master cylinder.

- Next, the manual transmission is installed.

- In parallel, after complete assembly, the ECU is often flashed.

List of main parts that are primarily needed when replacing an automatic transmission with a gearbox:

- Transmission;

- gear selector;

- selector drive cables;

- flywheel (with fastening);

- clutch disc and basket;

- engine and gearbox mounting brackets and pedal assembly;

- clutch master and slave cylinders and CV joint drive suspension;

- Manual transmission ECU, wiring.

It is necessary to take measurements and select suitable brackets, drill additional holes necessary for installing the gearbox. It is often necessary to approach the issue from the perspective of an engineer, since after replacing an automatic transmission with a manual transmission, the box must be reliable and operational.

Let us add that there are cases when, when installing a manual transmission in a car that is equipped with an automatic transmission, the electronic control unit (ECU) does not require replacement or flashing. This feature is due to the fact that on cars of the same brand, the ECUs for automatic transmissions and manual transmissions can be identical.

In this case, there will be no need to completely change the wiring harness going to the vehicle's attachments. However, complete identity is extremely rare. As a result, difficulties arise, so without proper experience it is better to contact specialized service stations that provide services for replacing automatic transmissions with manual transmissions and vice versa.

For example, the minimum prices for reinstalling a transmission on a VW Passat B5 start at $700. The contract transmission itself will cost, on average, another $500. If we consider the Passat B3, the work of replacing an automatic transmission with a manual transmission will cost 400-500 dollars, a used transmission will cost from 200 US dollars.

Steps to replace a manual transmission

- First of all, you need to take care of safety.

All work must be performed exclusively on a cold box, since it contains oil, which also heats up when the engine is hot. It will be very difficult to drain it without getting burned. After all units have completely cooled down, it is necessary to disconnect the battery terminals, since the sensors on a manual transmission may differ for different car models. Then the motor protection is removed. An assistant is required to dismantle the gearbox. It will be difficult for one person to hold this unit, despite its light weight. It is better to carry out this procedure at an inspection station, where it is possible to lower the gearbox under the car. Next, the oil is drained from the box. Wait a while until all the lubricant has completely drained out and begin removing the wheel and drive nuts. If the car is parked in a pit, it should be slightly raised from the front with a jack, and then, while removing the fasteners, hold the front part of the manual transmission to prevent the mechanisms from falling. - The next step is to dismantle the clutch block. The speedometer cable is often located near the gearbox, so it should also be disconnected. Next you need to remove the ball joints. Before doing this, make sure that the car is raised at the front. Then you should remove one or more longitudinal braces that may interfere with dismantling the box. On rear-wheel drive models, the cardan is additionally removed.

It is recommended to carry out the process of removing a manual transmission for replacement with an assistant, since both drives will need to be removed. In this case, while one person is using a pry bar to pull off the internal grenade, the second needs to remove the drive from the gearbox by the wheel.We recommend

“Replacing automatic transmission clutches: how to do it yourself” Read more

- Having pulled out the internal grenade, carefully and without knocking, insert a plug (special stopper) or another already used part in its place so that the box does not turn during operation and the differential is not damaged. Otherwise, you will have to resort to completely disassembling the gearbox and placing the elements in the required position.

- After this, remove the remaining components and mechanisms that interfere with the normal descent of the manual transmission. The starter can interfere, and in off-road cars, the air conditioning compressor. Often, a mass drive can get in the way of moving the box. In this case, it must also be removed. Next, disconnect the reverse gear sensor, remove the housing with the flywheel and the gear shifting gears. Pre-mark the positions of the parts.

Next, you need to unscrew the mounting bolts of the manual transmission. In this case, it is important to support the engine with a jack or support it on the spar cups with a jumper above the engine so that the engine does not fall out during operation.

- Then the mounting supports to the body are unscrewed and removed. The box must also be held with the help of a partner. To remove the gearbox, shake it a little and try to move it away from the engine. It is enough to move the assembly 10 cm so that the input shaft leaves the disc and clutch basket. When removing the manual transmission, try not to damage the petals on the basket. After removing the box, you can lower it under the bottom of the car. If you plan to stop work for a while, it is advisable to cover areas vulnerable to dust and dirt.

- Removing a manual transmission is only half of the replacement work completed. It is equally important to correctly install the new or repaired unit back. The repair procedure itself will not be discussed here - this is the topic of a separate article. Moreover, each malfunction requires an individual approach to elimination, be it late switching or the resulting crunching noise. During the repair or replacement process, you need to carefully inspect all clutch components for serviceability. It often becomes necessary to change the clutch disc, release bearing and basket.

- Before installing a new or repaired mechanism, lubricate the connection between the input shaft and the release bearing flange. Installation is also carried out with an assistant. First of all, the car should be lowered slightly on the jack. Next, manually, always without the help of tightening bolts, insert the manual transmission until it stops. Make sure the box is installed close to the motor.

- The next step is to tighten the main manual transmission bolts to the engine. Install the gearbox support pads and clutch cable. The latter must be adjusted so that the clutch pedal is approximately 1 cm higher than the brake pedal. Then mount the reverse sensor, remove the starter and finally connect the box. Adjustment of the installed gearbox should be carried out according to the previously applied marks.

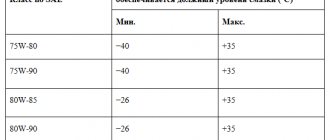

- Next, the chassis of the car is assembled. Insert the drives carefully and without knocking, being careful not to disturb the position of the differential. Then connect the ball joints and braces and tighten them with the mounting bolts. After this, you can lower the car and remove it from the jack. At the end of the replacement work, fill the system with transmission oil to the level specified in the vehicle’s service manual.

This completes the replacement of the manual transmission. Check the unit by shifting gears several times with the engine off. In this case, there should be no crunching, and switching speeds should be easy. Then test the operation on the go, driving about 1 km in low gears. This way you can feel the operation of the car’s components, and the oil will have time to pass through the entire system. After this, check the ride at higher speeds (4th-5th gears and higher).

It is also worth considering replacing a manual transmission with an automatic transmission, namely the pros and cons of this solution, since a certain part of car owners are interested in just this option.

Replacing the gearbox: manual transmission with automatic transmission

Having studied the information on replacing an automatic transmission with a manual transmission, you might think that the reverse process of replacing a transmission with an automatic transmission follows the same principle. Let us immediately note that in practice this is not the case.

The process of replacing a manual transmission with an automatic one is much more labor-intensive and expensive. Dismantling the gearbox and all equipment is the beginning of a long and technically complex operation. In order to change a manual transmission to an automatic transmission, it is necessary not only to replace the instrument panel and wiring, but also to purchase a large number of spare parts.

A basic list of required parts includes:

- Automatic transmission, automatic transmission radiator and hydraulic pipes to the radiator;

- Automatic transmission selector with cables, one or two “braids” of wires (virtually a complete replacement of the wiring);

- control unit (ECU) for automatic transmission, relays, fuses;

- instrument panel, speedometer sensor;

- reverse “frog”, pedal assembly, starter;

- mounting pads (not always, depends on the car);

- cardan (not always, depends on the car);

- torque converter (if not included with automatic transmission).

The order of technical operations performed when replacing a gearbox with an automatic transmission:

- The manual transmission is dismantled and the clutch assembly parts are disconnected.

- Disconnecting the rocker and dismantling the pedal assembly.

- The flywheel is removed, after which the cardan or axle shaft is dismantled (depending on the drive).

- Disconnect and remove the hydraulic pipes of the clutch drive, then install the disk with the crown on the crankshaft.

- The automatic transmission cooling radiator is installed and the rear support for the internal combustion engine is additionally installed.

- The starter and cardan are replaced (if necessary, depending on the car).

- Replace all electrical wiring connected to the instrument panel with replacement of the instrument panel itself.

- The ECU for the automatic transmission is being installed.

How to replace an automatic transmission with a manual one and vice versa

Today, this problem often becomes a subject of discussion among many motorists. So is it really possible to change an “automatic” to a manual and a manual transmission to an automatic? From the very beginning, it is worth identifying the reasons that may force the car owner to think about such a replacement. The key reason is often the failure of the gearbox, the second most important reason is savings, which happens if the owner seeks to switch from an automatic transmission to a manual transmission in order to reduce fuel costs, and sometimes even improve acceleration dynamics. There are more such car enthusiasts than those who want to get rid of “mechanics” in order to install an automatic transmission to improve driving comfort in city mode. Replacing an automatic transmission with a manual transmission This replacement is much simpler than the procedure for replacing a manual transmission with an automatic one. All car enthusiasts are individual in their own way, so they need a special approach, but still, there are certain rules, as well as the necessary operations to carry out such a replacement. The technological process is quite labor-intensive and looks something like this: 1. The front part of the vehicle is lifted and secured, the engine panels at the bottom are dismantled, as well as instruments are dismantled, the list of which directly depends on the vehicle and the dashboard. 2. The battery terminals are disconnected and the starter is removed, but only when it is located at the bottom of the engine. The wires must be disconnected from the gearbox housing. 3. The speedometer sensor and the automatic transmission shift lever cable are disconnected. 4. The transmission fluid radiator tubes and transmission fluid drain are disconnected from the gearbox. The motor must be secured to spacers. 5. The mounting bolts that connect the gearbox to the power unit are dismantled. The intermediate shaft is disconnected from the gearbox. 6. The gearbox brackets and supports, and the torque converter are dismantled. The machine should be dismantled using a jack. 7. The drive cables of the manual gearbox and the flywheel are installed. The automatic selectors are changing. 8. The clutch master cylinder and clutch pedal are installed, after which the “mechanics” can be installed. 9. The electronic control unit is changed only after the interior has been assembled. These are the basic steps for replacing an automatic transmission with a manual one, but this does not mean that you will not have to do anything else, additionally. It must be said again that everything depends only on the make of the vehicle, its model and even on the configuration. You should also not think that such procedures as “installation” and “dismantling” are very easy; in fact, they involve many different actions. For example, in order to secure the clutch, gearbox and other necessary parts, you will have to very carefully rethink the space that you have, as well as look for the necessary cushions and fasteners. You will also have to drill new holes more than once. We emphasize that sometimes the electronic control unit does not need to be replaced, this happens if it is identical for the versions with “mechanics” and “automatic”, however, this happens only in rare cases. Very often it is necessary to change the electronic control unit along with the “braid” (this is a harness of wires that goes to the processor from sensors located on the attachments and the motor). There are service stations where mechanics carry out the procedure of replacing an “automatic” with a “manual”, but this pleasure has a different cost depending on the year of production, model and brand of the car. But so that you can roughly estimate the price, we inform you that for a Volkswagen Passat B5 car, replacing an automatic transmission with a manual transmission will cost 1-2 thousand dollars, it all depends on the type of drive and motor. A used gearbox costs $500-600 (it must be taken into account that all its parts are not new). The more modern the car is from a technological point of view and the newer it is, the more expensive such an alteration will cost and vice versa. For example, for a Volkswagen Passat B3, the price of replacing an automatic transmission with a manual transmission will be in the range of $600-900, while a used gearbox costs from $250 to $350. For an average car, the list of essential parts for such a replacement looks like this: Manual transmission; Flywheel together with fastening; Selector; Clutch basket and disc; Fastening the gearbox and motor; Electronic control unit for “mechanics”; Clutch slave and master cylinders; Clutch and brake pedals; Suspension of the CV joint drive; Selector drive cables.

Replacing a manual transmission with an automatic one At first glance, it seems that rearranging the terms will not change the sum. But not in this case. Dismantling the “mechanics” and all those elements that relate to it is only a small part of the entire complex process. Then the most interesting part begins - you need to completely change all the wiring, this even applies to the wiring of the instrument panel. The car owner will also have to buy a huge number of necessary spare parts, namely: Automatic transmission; Hydraulic tubes to the automatic radiator; Automatic transmission radiator; Fuses and relays; Control unit for automatic transmission; Automatic selector along with cables to the ignition switch; Speedometer sensor; Instrument panel; One or two “braids” of wires, because the wiring actually needs to be completely replaced; Mounting pads (not always necessary, it depends on the machine); Reverse frog; Starter; Pedal assembly (if the extra pedal doesn’t bother you, you can leave the old one); Cardan (not always necessary, depends on the model); Torque converter (if it is not included with the automatic transmission). The sequence of actions aimed at replacing a “mechanical” with an “automatic” is more difficult to describe, but in fact this procedure is in many ways similar to replacing an “automatic” with a “mechanical”, especially installation and dismantling, but laying out the wiring and setting up the brains is already exception. Let us describe the principle of replacing a manual transmission with an automatic transmission, focusing on the main points: 1. The “mechanics”, clutch parts, pedal assembly, rocker, flywheel are dismantled. 2. Depending on the drive of the vehicle, the axle shafts or cardan should be removed. The hydraulic clutch release tubes are dismantled. 3. Install the radiator for the automatic transmission, rear engine mounts, and a disk with a crown on the crankshaft. 4. The starter and cardan are replaced (if necessary, it all depends on the car). 5. The wiring under the panel and the entire “braid” are changed. 6. The instrument panel is completely changed (if you have specialists among your friends who can remake the old one, then go ahead). 7. An electrical control unit for the automatic transmission is installed. In an attempt to find out the approximate cost of replacing a manual transmission with an automatic transmission, the service station employees did not react quite adequately, stating that it was already easier to change the car or that it would be twice as expensive as the cost of the car itself. They say that with such a replacement, the wires and electronics are considered the most difficult. It will be very difficult and expensive to implement the plan, especially if there is no comprehensive information on the vehicle and spare parts, and there are no diagrams. The main difficulties are hidden in the little things, but, nevertheless, these little things play a fundamental role. It is best if you consider a car that was equipped with the same engine, but received different gearboxes. Otherwise, you will have to spend a long time selecting an electronic control unit, drilling the floor of the car and making fasteners. Moreover, according to the mechanics, the meaning of this modification is very controversial, since the cost of a used gearbox is high, and on the secondary market, vehicles with automatic transmissions usually cost 10-15 percent more than the same models with manual transmissions. But in any case, if you have hands and free time, then you can do anything. Good examples of this are those vehicle owners who have already carried out such a replacement, they claim that in reality everything is not that complicated. It should be emphasized that when replacing a manual transmission with an automatic transmission, the model, make, and year of production play a more important role than when replacing an automatic transmission with a manual transmission. In the second case, there is a complication, while in the first there is a simplification, this is precisely what explains the unpopularity and high cost of replacing an “automatic” with a manual transmission.

What's the result?

As you can see, the decision to make changes to the design and remodel the car, changing a manual transmission to an automatic transmission and vice versa, is not always justified in practice. As for replacing an automatic machine with a manual one, this approach is more common, especially taking into account the availability of units and spare parts, as well as if the work is done with your own hands. The fact is that the final amount may be the same as repairing/replacing an automatic transmission with a contract one.

It is necessary to study the data related to the electrical and mechanical parts of the car being converted, and also start with the selection of the necessary parts for such a car conversion, familiarize yourself with the prices, etc. This approach can be considered a guarantee that the modification of the car will not drag on indefinitely, and the owner himself will ultimately get the desired result.

Checking the oil level in an automatic transmission: how to check the ATF level. What else to pay attention to: color, smell, ATP contamination, etc.

How to change gear oil in a gearbox: changing oil in manual and automatic transmissions. When to change the oil in automatic and manual transmissions. Useful tips.

How to service an automatic transmission: changing the automatic transmission oil and oil filter, the cost of changing the oil in an automatic transmission. Methods for replacing ATF, recommendations.

Choosing oil for a manual transmission: types of gear oils, features and differences. What kind of oil is best to fill in a manual transmission, what needs to be taken into account.

Is it possible to mix oils in a gearbox: what you need to know, the possible consequences of mixing gear oils for a gearbox. Useful tips.

How to change gear oil in a Lada Largus gearbox. Procedure for replacement, selection of oil at the Largus checkpoint. Tips and tricks.

Please tell me whether it is possible to replace the automatic transmission with a manual transmission? I am interested in the approximate price of the issue, and will anyone take on such a modification? Thank you all in advance!)

Types of gearboxes in a car

Let's look at the distinctive features of each type.

- A manual transmission , or, in other words, manual, is a classic type of gearbox. However, it has proven itself to be excellent among car owners who prefer maximum control over the car.

- Automatic transmission has also been known since relatively ancient times. The gears in this gearbox change automatically, but driver intervention is still required to change direction. The disadvantage of automatic transmission is higher fuel consumption and slow acceleration compared to manual transmission. Although in new automatic transmission models the acceleration is improved.

- The robotic gearbox is a manual gearbox with integrated automatic control. This variety combines the capabilities of an automatic (no need to monitor engine speed) and manual (for those who like fast acceleration).

The robotic (variable) gearbox has a significant drawback - the possibility of full use only on small cars. However, there are known cases when a CVT was installed on crossovers such as the 2015 Honda CR-V with a 2.4-liter engine. The variable transmission design allows you to change the gear ratio thanks to continuously variable gear shifting or through electronic control. By changing the diameters of the pulleys, the speed of the car increases or decreases.

see also

Comments 67

There are still some things that need to be changed in the interior... The gear knob, the leather crap, the tunnel, and the instrument cluster (not necessary, but for Feng Shui it is necessary).

I changed the handle, the tidy - why? There, the automatic transmission display just goes out and that’s it. Tonel - why? Everything fits perfectly.

I thought the automatic transmission handle wouldn’t fit into the old tunnel... Does the speedometer show correctly with the new gearbox? Does the gear board just go dark? I thought they remained, so it was for Feng Shui to change...

Everything works fine, the mechanical speedometer shows correctly, the digital speedometer shows fuel consumption, etc. lies, or rather doesn’t work at all

I modified my golf course like this, look in my magazine, I can give you the contacts of someone who will send the kit for modification, but it’s up to you to decide where to do it