How does a differential work?

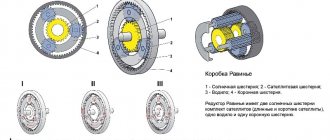

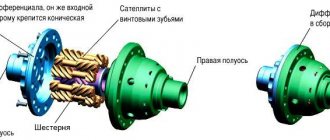

The operating principle of the differential is simple. It is based on a planetary gear, which consists of semi-axle gears, satellite gears, driven and drive gears (rotation transmission is carried out through the drive gear).

There are 3 modes:

- Driving on a straight road. The wheels of the car encounter the same resistance - because of this, the satellite gears are not set in motion. Therefore, the power is distributed in a 50/50 ratio - equally to each wheel. In this case, the period of rotation of the wheels is equal to the period of rotation of the driven gear.

- Turn. A different situation arises when turning. Due to different resistance, the angular velocity of one of the wheels decreases, as a result, the axle gear also slows down. It sets the satellites in motion. Their rotation ensures an increase in the rotation speed of the second gear of the axle shafts. That is why the ratio of wheel rotation speeds changes (torque is distributed in equal proportions), but there is no rotation of them.

- Slipping. If the car gets stuck or hits the surface, one of the wheels may slip. A sliding wheel encounters almost no resistance, but for a stuck wheel it is maximum. Due to the differential located in the car, power is redistributed. The ratio can go up to 0/100 (one wheel is stationary, and the second rotates at double speed). Then the car stops and cannot move. That's why many modern cars are equipped with differential locks.

Based on the type of gear transmission, the types of automobile differentials are as follows: cylindrical, bevel and worm. The last type is the most universal - it is installed both in all-wheel drive systems and on vehicles with a single drive axle. Cylindrical is more suitable for installation between the axles of an all-wheel drive vehicle. And front- and rear-wheel drive cars are equipped with conical ones.

Differential lock

The locking is most important in a car with all-wheel drive. And the reason is not only that they are more often used off-road. Due to the design features of such cars, if one wheel loses traction, torque may be reduced on the other three. Because of this, the car will not move.

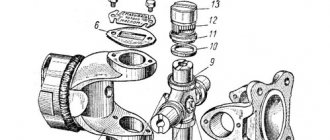

Blocking occurs due to “disabling” the satellite gears or transferring power to the loaded axle shaft. Depending on the method of redistribution, blocking mechanisms can be complete or partial. Self-locking differentials are common - they are installed on crossovers. Their work allows optimal distribution of torque.

The most complex device has an electronic lock. It is combined with a directional stability system. In this case, the vehicle's movement parameters are determined by sensors. And the car’s computer is responsible for power distribution.

Why is a differential needed in a car?

The node performs 2 tasks:

- splits one energy flow into two different ones;

- ensures rotation of the driving wheels of the vehicle at different frequencies.

With the first point, everything is clear: there is one source of rotation in the vehicle, there are two driving wheels (in the case of all-terrain vehicles or all-wheel drive vehicles, even more). Why do we need different rotation speeds? This is necessary primarily when turning. If the wheels rotated equally when performing them, the car would simply tip over. The differential breaks the rigid connection between the two parts of the drive axle and thereby:

- increases vehicle efficiency;

- reduces fuel consumption;

- prevents the phenomenon of parasitic power circulation, which occurs if the wheel speed is not consistent;

- makes the grip of the drive wheels and the road surface more reliable.

In other words, the node provides different rotation of two elements or divides 1 rotation flow into 2 or more. Hence its name - the word “differentia” translated from Latin means “difference”.

Location

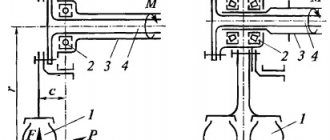

There are 2 types of differentials: center and cross-axle (located in the drive axle housing). These types of differentials have a number of differences. The location of the unit depends on the type of vehicle drive.

Popular brands:

Nissan Almera Classic, Toyota 4Runner, Volkswagen Passat

The interwheel is installed on cars with both one and two driving axles. On front-wheel drive cars, due to the lack of a cardan transmission, the unit is located immediately behind the gearbox (or they are combined in one housing). On rear-wheel drive vehicles it is installed in the gearbox.

The center wheel is installed on cars with all-wheel drive. It no longer distributes power between the wheels, but between two axles. This unit is used during ascents and descents. Due to the tilt of the car, the mass is redistributed and one of the axles is loaded more.

Most all-wheel drive cars are equipped with 3 differentials at once (2 inter-wheel differentials and 1 inter-axle differential). At the same time, for a machine with one drive axle, only 1 inter-wheel unit is sufficient.

Differential operating modes

It is impossible not to tell us about the operating modes of the differential. Let us immediately note that differentials are divided into symmetrical and asymmetrical. A symmetrical mechanism is capable of transmitting torque to the axes in equal proportions. Their work does not depend on the angular speeds of the drive wheels . An asymmetrical mechanism can “share” the torque, as a result of which it can be installed between the drive axles of the vehicle. The symmetrical cross-axle differential operates in one of three modes:

- Rectilinear movement;

- Entering a car into a turn;

- Driving on atypical surfaces, somehow slippery.

In the first mode, both car wheels overcome the same road resistance. From the main gear, torque is transmitted to the differential housing (cup). The satellites shift without engaging with the semi-axial gears and transmit torque to the drive wheels. There is no difference in the torque perceived by the wheels. In the second mode, the following is observed: the outer wheel, i.e. distant from the center of rotation, encounters much less resistance than internal. internal semi-axial gear of the differential slows down, which leads to rotation of the satellites against its axis. As a result, the rotation speed of the outer side gear will become higher. Note that the sum of the side gear speeds is always twice the speed at which the final drive gear rotates.

The third operating mode of the differential is especially interesting. When driving on a slippery surface, one of the car's usual wheels encounters a lot of resistance, and the second one even begins to slip. In this case, the differential will increase the rotation speed of the slipping wheel, and reduce the speed of the second one. This leads to a stalemate: one wheel has no traction and its torque is increased by the differential, and the second wheel, which has traction, receives no torque at all. Because of this, a car caught, for example, in a swamp, will not move - only the suspended wheel . The problem can be solved by locking the differential.

Types of automobile differentials

The types of differentials based on their operating principle are as follows:

- With full blocking. The blocking is performed by the driver forcibly. Due to the fact that the angular speed of the wheels becomes equal, when cornering, handling deteriorates and tire wear increases. VAZ-2121 cars were equipped with a similar blocking.

- LSD (Limited Slip Differential). This type of node is self-locking. If the difference between the rotation speeds of the two wheels becomes too large, automatic locking occurs (that is, a situation where all the power goes to 1 wheel is impossible). This type of design allows you to successfully overcome slippery areas or off-road conditions.

- Viscous coupling (viscous coupling). A type of self-locking differential in which the locking is performed due to the physical properties of certain substances. Typically, a dilatant liquid based on silicone is poured here. At normal temperature and without stirring, it remains liquid. However, when heated, it expands and takes on the consistency of glue. This design is very simple and cheap, so it is installed on most SUVs. However, this unit is not repairable, is unstable to long-term operation and cannot be connected manually. Complete wheel locking is only possible with very strong slipping.

- Torsen (eng. Torque and Sensing). Another type with self-locking. The design and operating principle of the Torsen differential is somewhat different from previous models. The principle of operation is due to the property of the worm gear to jam at a certain ratio of torques. This type of unit is used on many all-wheel drive vehicles (for example, Audi models). The advantage of Torsen is its simplicity and reliability. It operates purely mechanically and is not associated with electronics. This unit is more stable than a viscous coupling. The main disadvantage of the design is that the car cannot be moved if 2 wheels of the same axle slip at once. In addition, Torsen products are quite expensive.

- Electronic. The blocking is performed automatically using the on-board computer. The main advantage of this design is the ability to adjust the degree of blocking. This unit also stabilizes the car well when excessive “steer” occurs. However, the torque here is always shifted to the wheel with a lower rotation speed.

- Multi-disc. The design features spring-loaded friction discs. Mechanisms of this type are rarely used because they wear out quickly. They are most often used in motorsports.

Advantages and disadvantages

The use of a differential mechanism has both advantages and disadvantages. The main advantages include the following.

- Ability to make turns safely and efficiently. If there was no device in the car’s design, the vehicle would slip on them. This would lead to a significant reduction in maneuverability, as well as a significant increase in the load on the transmission and other components of the machine.

- Reliability. The device can withstand significant loads.

And these are the disadvantages of the node.

- Need for locking in some travel conditions. It has already been said that when slipping, the differential can almost stop the wheel, which has retained reliable grip on the surface. This requires blocking it under certain conditions. These include movement on ice, snow, and difficult roads.

- The need to monitor the condition of the node. The structure experiences significant loads during vehicle movement. Therefore, over time, its elements wear out. This requires the driver to constantly monitor their condition and replace them with new ones if they are severely worn.