Which way does the hub nut unscrew?

Yes, you may very well be one of the lucky ones who won't need any extra effort as the problem with unscrewing the hub nut may simply be a matter of going in the wrong direction.

So, we take the wrench and, when your car is far from new, try, if the nut does not lock, on the left wheel, unscrew the nut counterclockwise, and on the right wheel, unscrew it clockwise. In modern brands, it is usually necessary to unscrew the hub counterclockwise .

Before you start unscrewing the hub nut, do not forget that it comes off when the car is standing on the wheels and the stops are placed under them. On the side from which the nut will be unscrewed, a stop is securely installed.

Although if the nut is located deep and the brake disc is ventilated, then you can try to unscrew it (fixing it with a powerful screwdriver) and only after making sure that the car is securely secured. Remember about personal safety precautions: protect your eyes, do not overdo it, because in the spirit of enthusiasm you can accidentally get hurt or damage the car body.

Unfortunately, in most cases, it is not enough to use a wrench with a large lever; you have to use additional tools and special mixtures. Let's consider the other options.

Briefly and clearly

Which way should I unscrew the hub nut?

On the left wheel - counterclockwise. On the right wheel - clockwise.

On modern cars, the hub nut is most often unscrewed counterclockwise.

Five ways to unscrew a car hub nut

This method involves replacing the hub nut; you will have to buy a new one. It is necessary to drill the nut along the groove in order to loosen it, and then use a chisel and hammer to break it. To do this you will need a drill, drill, chisel and hammer.

2. Humane way

It is necessary to treat the hub nut with Vedashka penetrating lubricant (WD-40), wait a little for the rust to soak. Next, you need to install the wrench head on the nut and make a few blows. After that, try to unscrew the nut. For this method, you will need a hammer, a heavy-duty screwdriver, WD-40, and a heavy-duty tubular socket wrench.

3. Method “Use force”

We install a wrench of the required size on the nut, and a long pipe on the wrench itself. We tear off the structure by force and pull the pipe down and gradually increase the pressure on the pipe. For this method you will need a powerful and high-quality socket wrench and a long pipe.

4. Heating method

This method is very dangerous for the bearing and hub. A burner will be required

It is important to understand that if you do not change the hub after unscrewing the nut, then this method is not applicable for you. Those

After using this option, you will need to change the hub. When the nut heats up, the metal expands and, accordingly, the nut will be easier to unscrew.

5. Chemical method

This method will require kerosene, a hammer and mineral spirits. The point of this method is to allow the soured nut to soak a little and acidify for 8 to 12 hours. You need to soak a swab in kerosene and apply it to the nut. After the nut has soaked a little, your hub nut should loosen a little and come loose. The second option for the chemical method is that instead of a solvent you need to take water, sulfuric acid, zinc, plasticine (to fix the tampon to the nut). You need to wait a day for the chemical reaction to produce results. You need to understand that the chemical method is applicable only when the nut is tightly stuck and cannot be unscrewed.

I once changed springs and at a service station they told me that I needed to replace the hub bearings, well, I happily gave up on this matter and drove until they started to make noise. And yesterday I changed them, I’ll tell you, it’s not a quick job and there’s no swearing here it will cost.

So I’ll tell you step by step how it’s done.

It is better to do this in 2m. Doing this on a lowered car in 2 is not inconvenient (((

First, you need to place and strengthen the front axle of the car in a suspended state, this is the main disadvantage of a lowered car, because the jack does not fit under the bottom, you had to drive onto the boards to raise the car higher and then jack it up. Also, for greater safety, we place houses or pyramids under the bottom, as anyone calls them.

Next, you need to knock out the locking clip on the hub nut, for this we take some kind of nail and knock it out, and then with the help of a partner we twist this nut (the partner presses on the brake pedal) I can tell you that an incredible amount of force was applied to unscrew it.

This is the 30 nut in the middle of the hub

Due to the increased loads on the suspension of modern models of Lada family cars, the front wheel bearing on VAZ 2113, 2114 and 2115 often fails, replacing which requires a certain skill and the use of some special tools. In addition to all of the above, an important point here is the correct selection of high-quality spare parts, which determines the long, trouble-free operation of the vehicle.

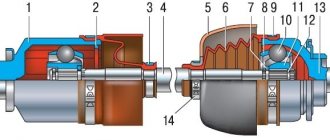

Design features of the hub nut

The hub nut is located in a unit whose operation occurs under conditions of high temperatures, mechanical and external influences. Therefore, alloy steel with anti-corrosion coating is used for manufacturing.

The part, in addition to the standard nut elements, has grooves. After reaching the required torque, a locking pin is inserted into them or mechanically fixed with a chisel. The outside of the nut is surrounded by 6 standard edges. We gain access to the locknut after removing the protective cap.

Possible problems for VAZ owners and not only

With long-term exposure to tools and repeated attempts to remove the nut, “force majeure” situations occur, which include:

- the edges are licked off;

- wear of the union head;

- does not withstand the ratchet mechanism;

- the thread on the shaft or locknut is knocked out;

- violation of adjustment, tightening torque;

- the bearing is damaged.

We buy a spare locknut and cotter pin in advance. It is also advisable to have a spare set of special keys before dismantling.

It is not recommended to unscrew

Don’t try to “discover America” again; the methods listed above will help break the locknut in 99% of cases. The following methods should not be attempted:

- Cut using argon, oxygen or electric welding;

- Strong blows with a hammer or sledgehammer on the end surface;

- Jumping on a lever;

- Impacts on the side, edges, base;

- Exposure of the part to open flame (for example, pour kerosene on it and set it on fire).

There are many ways to fix threads:

Before unscrewing the hub nut, it is advisable to read the instructions for routine maintenance of your car. It indicates the method of fixation, the direction of the thread and other nuances.

- Changing the geometry of the nut (one side is oval). Anyone who has repeatedly unscrewed such a nut has seen that the threads gradually become unusable;

- Punching after tightening. This solution is not suitable for replaceable units, since this will damage the screw part. However, many car manufacturers fix the hub nut in this way so that it does not unscrew while driving;

- Hairpin. The most reliable method of fixation. The nut does not unscrew on its own, and the thread does not deteriorate. For some reason, not all car designers use this simple method;

- The retainer is a “shoulder-groove”. A common method, more reliable than core punching, but detrimental to carvings. Longitudinal grooves (one or two) are made on the threaded connection of the axle shaft. The CV joint nut has the same number of collars, which bend into grooves after tightening. It is almost impossible to unscrew the nut without damaging the thread;

- A variety of fixing paints and adhesives. Not used on hub connections.

Since the connection is in unfavorable conditions (especially if the boot cap is lost), the nut does not unscrew the first time. An inexperienced driver panics, starts turning the nut in the wrong direction, uses attachments on the wrench in the form of a meter-long pipe, and as a result breaks the thread. The consequences are a forced replacement of a still-living CV joint.

How to unscrew the CV joint nut if a fixing collar is used

It is this method of fixation that most often leads to “licking” of the thread. VAZ drivers know what they are talking about. An inexperienced master, delighted at the easy movement of the nut, will ruin your grenade in 2-3 turns of the key.

For proper release, you need a special punch that exactly matches the size of the spline collar. You won’t find them during the day with a fire, so it’s wise to make a useful tool yourself. For example, from an old file. With its help, you can unscrew the nut while maintaining the threads on the axle shaft.

After disassembly, it is necessary to slightly grind the shoulder to remove burrs.

Types of fasteners

Here are the types of fasteners needed for alloy wheels:

- Bolts are metal rods with a screw thread at the end. Used to connect detachable elements.

- Nuts are round-shaped parts designed to fasten elements by screwing a metal die onto threaded rods.

Steel, aluminum or titanium alloys are used to produce products.

Titanium bolts are distinguished by high quality indicators. Black bolts for alloy wheels are made from steel with the addition of molybdenum or steel with a chrome or nickel coating.

Recommendations

In order to no longer be tormented by the question of how to unscrew rusted nuts, when installing them, it is important to treat the threads with a special lubricant. You can use graphite, silicone or Teflon

Many craftsmen do not recommend using lithol or grease. Such products are more suitable for dynamic rather than static nuts and bolts. Choosing them will lead to the fact that such a lubricant will soon ossify and will interfere with the rapid unscrewing of parts.

Experts recommend working by heating the part. A change in temperature leads to expansion of the metal and, as a result, to the destruction of the corrosion layer and loss of strength of the thread connection. For heating, it is better to take a blowtorch. A hair dryer or lighter will also work.

You can unscrew the rusty part using a wax cup. To do this, you need to take a little wax or children's plasticine and mold the product in the form of a mini cup. The height of the sides of such a product must exceed the height of the nut. Sulfuric acid is poured into an improvised cup and some zinc is added. Due to the interaction of the components, a galvanic effect will occur, and the rust will begin to break down. After carrying out such an operation, unscrewing the nut will become much easier.

Using one of the listed options, you can easily unscrew a stuck nut. More attention should still be paid to prevention and the use of special means to prevent metal corrosion.

How to unscrew the nuts, see below.

Classic methods

Essentially, standard dismantling methods involve two main methods.

You will need:

- jack to remove the wheel

- tool kit

- hydraulic jack to lift the engine, or replacing it with a “stump”

First way

In the first case, we will have to make significant physical efforts, therefore, you need to clearly focus on your own strength. We are talking about the need to put stones or special stops under the wheels that would not allow them to move during operation. The gearbox should, if possible, be set to maximum gear. The higher it is, the easier it will be for you to cope with the task. In third and lower gears, it will be almost impossible to make a turn with your hands. But everything is unscrewed by hand. To make this task easier for yourself, it is appropriate to use a lever that will reduce the necessary effort. In some cases, the length of the lever can reach one and a half meters.

Read more: Conditions for the use of firearms by police officers

Getting to the bolt is not always easy

Second way

As for the second method, it involves placing the vehicle in neutral gear. Next, you need to install a suitable sized head on the bolt with a piece of pipe, which, in turn, rests on asphalt or concrete. Ordinary soil will not be able to hold it. But the bolt itself is already loosened by the starter.

This saves a lot of effort and makes it possible to complete the task the first time. The main thing is to take into account the reliable fixation of the pipe so that it does not jump out and damage anything around it.

Be careful not to lose the pulley key

But, in any case, the threads in this nut are correct, so you need to unscrew it counterclockwise, with some exceptions, which we will now look at.

How to change a wheel

The wheels, as always, break at the most inopportune moment. Therefore, you must always be prepared for this trouble. I think there is no point in saying that there should be a working and inflated spare tire in the trunk. Driver's actions to change a wheel:

- Block the car's wheels to prevent it from moving.

- If the car wheels are equipped with hubcaps, then using a screwdriver or the flat end of a wheelbrace, you need to pry and remove the hubcap from the damaged wheel.

- Remove the spare tire from the trunk of the car.

- Using a wheel wrench, loosen the mounting bolts that hold the wheel. In this case, you need to know which bolts you have - left-handed or right-handed. The type of thread determines which direction the wrench should be turned. Typically, right-hand threaded bolts (which should be unscrewed counterclockwise) are used, but sometimes, on the left side of the vehicle there may be left-hand threaded bolts (which should be unscrewed clockwise). Look carefully at the bolts - if the letters “R” and “L” are visible in the center of the bolt, then: R (right) – right-hand thread; L (left) – left-hand thread.

- Place the wheel wrench on the bolt and loosen it until it can be turned freely by hand. Do this operation in a circle with all the bolts. The bolts can be very tight, so if you can't loosen it with your hands, you can use your feet or improvised means (a piece of pipe) to increase the strength or length of the lever.

- Place the jack in its designated location and lift the car so that the wheel rotates freely in the air.

- Install supports and lower the car onto them (the wheel should still rotate freely).

- Unscrew the loosened bolts by hand and remove the broken wheel from the studs.

- Roll the broken tire to the trunk and put it in place of the spare wheel.

- Place the spare tire on the studs and secure it with the bolts.

- Lightly tighten the bolts with a wheel wrench until the wheel is securely in place.

- Raise the car on a jack and remove the jack stands.

- Lower the car to the ground and remove the jack.

- BE SURE to tighten all the wheel bolts! Pull with all your strength - don’t be afraid, you won’t break the thread, but the wheel will be securely fixed.

- Reinstall the wheel cover. To do this, place it opposite the hooks and drive it into place with the back of your hand. Tap it a couple of times in several places to make sure it sits evenly and securely. If this cannot be done, then this can be done later. The cap mainly plays a decorative role, and it is quite possible to drive without it. But it is highly recommended to install the cap in the near future, because... it protects the brake pads and bearings from dirt and dust.

- Don't forget to take all tools and wheel blocking chocks with you.

- Don’t delay repairing a flat tire, otherwise if you have another accident, you will have nothing to replace the flat tire with. A broken tire can be repaired at any tire shop. Depending on the damage, the technician will offer you repair options.

Top of page

The easiest way to unscrew/tear off a hub nut

The easiest way can be considered the following, but it involves completely replacing the nut. Don't worry, any method does not guarantee the safety of this part. To easily unscrew or tear the hub nut out of place (an option for all brands - from VAZ to foreign cars with a groove on the shaft), you need to take:

Unscrewing the VAZ hub nut using a drill

- New nut.

- Drill or screwdriver.

- Drill up to 3 mm.

- Chisel.

- Hammer.

Process.

- You need to drill the nut along the groove to counteract it.

- Using a chisel and hammer, simply break the nut and remove it, then replace it.

- If throwing away the nut is not possible, then you will have to sweat - and in the literal sense of the word too.

But this method should be used only as a last resort; first try using more or less simple and humane methods.

Chemical

Now we will consider methods for those who do not rely on the help of physics, but want to solve the problem with the help of chemistry. Your laboratory should have: kerosene, white spirit, acidified sulfuric acid, zinc, plasticine, hammer, water, sandpaper, wrench, chisel.

Attributes of the chemical method for unscrewing the nut

We moisten the nut and bolt with kerosene (experienced people recommend making a mixture of White Spirit and kerosene), applying a swab to them, it doesn’t matter whether it’s cotton or gauze. After some time - from an hour to a day, and with repeated attempts, you may find that the hub nut can be easily unscrewed. But even here you cannot do without force: at a minimum, you will probably have to work with sandpaper to clean the parts from rust. If even after this things don’t work, you should help with a hammer: tap it on the edges of the hub nut.

If in this case you are not successful, make a small container out of plasticine, secure the hub nut on top, pour water with sulfuric acid into it, and put zinc in the container. A chemical reaction begins that does a very good job of removing rust. Usually a day is enough for even advanced corrosion to go away from a part. Finish the job with a wrench. But this method is valid only in the case when the reason is that the nut is tightly stuck and/or rusted, and if it was simply tightened, neglecting the required tightening torque (to “be sure”), then you just need to tighten it.

What is the result..

As you can see, unscrewing the hub nut is not an easy task, but it can be solved. Please note that the first step is to try to preserve the hub nut by using penetrating fluids such as Vedeshka. Physical efforts to twist the hub should be moderate. And, of course, you should refrain from strong blows and heating with a torch, as methods that can render not only the nut, but also the bearing unusable.

The spline connection of the outer CV joint is a critical unit. It is this part that bears the torque load. It is no wonder that the grenade nut, which holds the floating axle shaft in the drive wheel hub, should not unscrew on its own.

Wheel nuts

Wheel nuts, like bolts, are distinguished by 4 main parameters: diameter and thread pitch, profile of the clamping part, nut height, wrench size.

Wheel nut diameter and thread pitch

The diameter and thread pitch of the nut must match the stud, i.e. car make and model. Possible wheel nut thread options for passenger cars and light commercial vehicles: 12 x 1.5, 12 x 1.25, 14 x1.5, 16 x 1.5, as well as inch threads. Determine the diameter and thread pitch of the wheel nut using the selection by car function in our online store.

Profile of the wheel nut clamping part

The profile of the clamping part of the wheel nuts can be conical, spherical, or flat. As with bolts, wheel nuts are selected solely according to the profile of the well in the wheel rim. The consequences of incorrect selection are described in detail in the previous article.

When making your own selection, you need to take into account the following facts:

- spherical nuts

- only for original Honda, Rover and several older VW models; - flat nuts

- only for original alloy wheels of Toyota, Mitsubishi, Hyundai, some global models of Peugeot and Citroen; - cone nuts

- for original wheels of those car brands that are not mentioned in the previous paragraphs; - Third party discs are designed to use flare nuts only.

Nut height, spanner size, form factor

The height of the wheel nut is not of fundamental importance. The main thing is that the nut is not lower than the original sample, otherwise there is a risk that the wheel stud will rest against the “bottom” of the nut. As a rule, for disks with deep wells, nuts are installed higher.

Wheel nuts come in open and closed types. In most cases, steel disks are fastened open because it is assumed that such a disk will be covered with a cap, and a high closed nut can prevent this. Secondly, saving money, because... open wheel nuts are significantly cheaper.

Choose wheel nuts that match the size of your original wheel wrench. This must be done for several reasons. Firstly, in the future this will eliminate confusion when selecting a nut based on the car model. Secondly, you don't have to buy a new wheel wrench.

Further sequence of actions

So, the hub nut was successfully unscrewed. What to do next?

- First of all, an external inspection is carried out to determine the integrity of the threaded elements. Using fine sandpaper, improvised materials, kerosene or solvent, the entire surface of the thread on the stud is thoroughly cleaned to bare metal. Order factory hub nuts in advance.

- The tightening is carried out under load control. We use a torque wrench.

- To prevent this part and contact from sticking again, we use a special deep penetration lubricant WD-40 or thick graphite lubricant.

- Don't forget to lock or install a cotter pin.

Security measures

To safely unscrew the hub nut, the following requirements must be met:

- Use proper tools and accessories;

- Firmly fix the body in its original position (handbrake, heel);

- Use special anti-slip gloves;

- If excessive force is used, do not place body parts under the car body if the wheel is jacked up;

- First we try to unscrew it using more gentle methods, trying to preserve the original locknut;

- The sequence of actions is defined in the operational map. It must be followed.

How to unscrew a hub nut - the delicate way

What do you need:

- Tubular socket wrench - “wrench”. The tool must be made of high-strength steel.

- Powerful screwdriver.

- Iron pipe.

- WD-40.

- Wire brush.

Process.

- Clean the threads from dirt using a brush with metal bristles. Now you should soak the hub nut with penetrating lubricant. For example, WD-40.

- We impregnate the hub with the penetrating mixture. You can rest for 10-15 minutes, and then you should put the wrench head on the nut and hit it with a hammer several times, gradually increasing the force of the blow. Just don’t overdo it: the point of this action is to slightly deform the nut, which will make it easier to remove. And immediately after the impacts, you should try to unscrew the hub nut on a VAZ or a car of another brand.

Remove the nut from the car: force method

What do you need:

- Lever made of pipe (length of at least one and a half meters).

- Powerful socket wrench (450 mm).

- Head of the appropriate size.

Process.

Place the head of the wrench on the hub nut, insert the wrench and place the pipe on the handle. Gradually increasing the applied effort, we unscrew the part.

As experienced car enthusiasts say, few hub nuts can resist for a long time if you use a Zilov cylinder!

How to unscrew a broken bolt

What to do, what to use and how to unscrew it if a pin or bolt is torn off. Video tips on how to independently unscrew a broken bolt/stud in an engine or manifold. A reliable way to unscrew if the head of a bolt has been torn off Read more

Replacing the rear wheel bearing of a VAZ 2111

To replace the rear wheel bearing on VAZ 2110, 2111, 2112 cars you will need: a “30” socket, “10” and “15” keys, a hammer, duckbills and a long pipe as a lever. See details clearly Read more

Hub

A wheel hub is a part designed to mount a car wheel on an axle called an axle. Hub bearings are a key element not only of the hub, but also of the entire chassis of the machine. Read more

How to measure yourself

Measurements must be as accurate as possible, since the indicators differ in close values with a distance of a couple of millimeters, for example, 98 and 100 or 110 and 112, and they are not interchangeable. To eliminate errors, it is recommended to use a caliper or ruler.

Adjacent holes

Here's how to determine the distance between bolt holes. The dimensions of the circle on which the holes are located are taken. The diameter is determined using compatibility tables or by measuring using a ruler. The resulting distance between adjacent fasteners should be multiplied by a factor that depends on the number of holes. The circumference of a VAZ is 9.8 cm, and that of passenger cars is 139.7 millimeters.

Far holes

A simple measurement method is carried out on models with an even number of recesses - for 4, 6, 8 fasteners. Parallel Hole Distance – PCD.

And here’s how the far holes of disks with five bolts are measured: the calculation is made between non-adjacent recesses, the resulting figure should be multiplied by 1.051.

Hub window diameter

Indicative data for the central hub window are indicated in the table and in the complete bolt pattern formula. In the absence of information, readings are measured with a ruler or caliper. The diameter of the hub area on the VAZ 2110 = 58.6 mm.

The bolt pattern is carried out taking into account the relative size of the vertical axis of symmetry of the disk to the area adjacent to the hub.

Where to turn?

For many beginners who are faced with the problem under consideration, the pressing question is which way to unscrew the hub nut - clockwise or counterclockwise? It should be noted right away that everything depends on the age of the car. On new cars, the hub usually unscrews counterclockwise. If we are talking about old VAZs and other cars, then on the right side you need to unscrew the nut clockwise, and on the left - counterclockwise.

Before you begin the repair, you need to take into account that the nut can only be removed if the vehicle is standing on wheels, and with pre-installed stops.

In some cases, you can try to unscrew the nut without installing the stop. But this option is only possible if we are talking about a ventilated brake disc, and the nut itself must be deep. In any case, the vehicle must be insured. You should also not forget about personal safety. It is not recommended to use unnecessary force, as many motorists receive minor injuries or damage to the vehicle body.

Practice shows that even a large lever is not always enough to unscrew. Therefore, to complete the work you will need to use special mixtures and other tools. We will also talk about them. Below is a video instruction on how to unscrew the hub nut.

Dry residue

The result is a wear-resistant thread of the same diameter with a strong fit, resistant to corrosion and temperature influences, while the load on the threads is distributed more evenly due to the design features and profile of the insert. Read a detailed overview of technologies from the manufacturer: at the bottom of the page there is all the necessary technical documentation, or just flip through the brochure (available on the manufacturer’s website), where all aspects of the inserts are discussed very compactly.

The costs of time and consumables for thread restoration are available in the “Services” section.

Restoring threads in the wheel hub

The thread in the front wheel hub broke.

Unread message by lynxear » Mon Nov 24, 2008 06:39:23 PM

Unread message by lynxear » Tue Nov 25, 2008 9:12:58 AM

Unread message by lynxear » Tue Nov 25, 2008 9:26:59 AM

Unread message VladiZlav » Tue Nov 25, 2008 12:14:17

Unread message nezznaika » Sun Apr 12, 2009 19:46:38

Unread message by DonPedro » Sun Apr 12, 2009 07:54:26 PM

Unread message nezznaika » Sun Apr 12, 2009 20:22:48

Unread message Mr_Ice » Mon Apr 13, 2009 9:30:35 AM

Unread message by VladiZlav » Mon Apr 13, 2009 10:06:55

Unread message SMSha » Mon Apr 13, 2009 14:22:44

There was PARADISE in the USSR - wherever you look, there was a DISTRICT Council, a DISTRICT executive committee, a DISTRICT committee, and so on. And in this state, wherever you spit, there is an Administration.

All current life in three sentences: On a warm and sunny May day on the high bank of the river, a team of workers was building a cowshed. They worked fervently, cheerfully, with fire and swearing. It turned out shitty.

Unread message Mr_Ice » Mon Apr 13, 2009 14:26:19

Unread message SMSha » Mon Apr 13, 2009 18:02:29

Mr_Ice I agree that you shouldn’t underextend, in fact - I wrote that I set 70 N * m - although it was possible to set 63. But on the other hand, over-tightening is also scary. When the bolt snaps, it’s in half.

balaganoff Regarding “which key to take” - I would definitely take one “with an exit” to a standard square, where you attach any head. Actually, I took one for myself. With torques from 42 to 210 N*m. And I will take a second one just like it - but with fewer moments.

There was PARADISE in the USSR - wherever you look, there was a DISTRICT Council, a DISTRICT executive committee, a DISTRICT committee, and so on. And in this state, wherever you spit, there is an Administration.

All current life in three sentences: On a warm and sunny May day on the high bank of the river, a team of workers was building a cowshed. They worked fervently, cheerfully, with fire and swearing. It turned out shitty.

Bicycle repair: How to install pedals

Installing pedals is not a tricky matter. The main thing you need to know is which way to unscrew the right pedal and which way to unscrew the left. Today we cover the main aspects when removing and installing pedals. How to do this as simply and safely as possible.

Tool

Installation algorithm

conclusions

As always, let's start with the tool. You will need:

Grease

To install new pedals, you usually need to remove the old ones first. Although uninstallation of pedals may be required if there is a suspicion of a bent pedal axis, a simple inspection of the pedal or for its service. So we'll start with how to remove the pedals.

First of all, decide what tool you need. Often this is a flat 15mm open-end wrench, or a 6-8mm hexagon, or maybe both, depending on the pedal model. If possible, we recommend using a hexagon, as it is more difficult to lick off the edges, and it is guaranteed to help you unscrew the pedal

Attention! Never use adjustable wrenches, they can tear off the edges of your pedal.

- Rotate the connecting rods so that the connecting rod from which the pedal is unscrewed is at the bottom. Hold the other connecting rod and unscrew the pedal. The easiest way to do this is to apply the force downwards from yourself, so you will not get hurt by the sprockets, chain or cranks themselves.

- The pedal on the leading side (marked R - right) is unscrewed counterclockwise. The pedal on the driven side (marked L - left) has a “left” thread and unscrews clockwise. This is done so that while riding, while you pedal forward, the pedal axle does not twist out of the connecting rod under load.

- If you try to unscrew the pedal in the correct direction, but it still does not budge, then spray WD-40 or any other degreaser on the pedal axle where it screws into the crank arm

- After unscrewing the pedal, remove any remaining old grease and dirt from the threads in the connecting rods, and from the threads on the pedal if you plan to use it further.

- Hold the pedal, check for play and turn the axle several times with your fingers to make sure that the pedal axle does not move left and right, that is, it is not bent.

- If you use plastic shields for the ends of the connecting rods (great stuff, they cost a pretty penny and protect your connecting rods), then remove them and remove any remaining dirt. She really likes to get in there.

- Lubricate the threads on the pedal axle. Install the pedals according to the marks, on the corresponding side (L/R). Otherwise, you may lose the threads on both the pedal and the connecting rod. Remember! The pedal on the leading side (marked R - right) is twisted clockwise. The pedal on the driven side (marked L - left) is twisted counterclockwise.

- Don't over-tighten the pedals! You shouldn't put a lot of effort into installing the pedals; all that's left is to tighten them slightly. Otherwise, unscrewing the pedal next time can be very problematic.

Replacing pedals can be tricky if they were over-tightened during a previous installation or if you forgot to lubricate the axles with grease and they became stuck. In this case, you may have to tinker. Don’t forget the simple rules listed above, as well as the directions for unscrewing and tightening the pedals, and you will succeed!

How To Change Pedals- Remove and Replace Your Pedals

What is a guitar truss rod used for?

Many beginning guitarists who do not understand how the instrument works generally misunderstand its structure. The neck of the guitar is not at all horizontally straight, as many people think. Moreover, it is not so much a perfectly even beam as an arc onto which the strings are stretched, like a string on a bow. If this part of the guitar were perfectly level, then the strings would lie on it and it would be impossible to clamp them. The anchor performs two tasks at once - it takes on the enormous load that a stretched string puts on the tree, and also keeps the neck in one position for more comfortable playing.

Accordingly, if changes occur to the guitar rod, this directly affects the ease of play, as well as the ability to perform songs in general. Two very common problems are directly related to a crooked neck

- This is one of the reasons why the strings rattle - that is, they ring against the saddles, and instead of giving an even, ringing sound, they get along, and sometimes don’t play at all.

- It becomes very difficult to clamp the strings - this is especially felt at the 5th fret and above. It becomes extremely difficult to play with the barre technique - the guitarist begins to spend much more effort than is required. This situation is also directly related to the fact that the guitar truss rod is overtightened and compresses the neck much more than required.

At the same time, the instrument may stop tuning and produce a note a little higher or lower than it should be.

How to fix this? This is exactly what this article is dedicated to.

The steering rack of the VAZ 2110 is knocking, why and how to fix it

Lada Granta Liftback Logbook Clutch cable

A knock in the steering rack of the VAZ 2110 is quite the most common malfunction. Where does it come from? Let's look for the root cause. Yes, the steering rack is a simpler system than the outdated worm type. As noted above, even on Russian cars it “goes” 80-100 thousand km without causing problems for motorists. But premature knocking, alas, sometimes occurs. The reasons are:

- On VAZs, for example, knocking in the steering rack is often caused by insufficiently tightened mounting bolts. No, they were tightened in good faith, it was our amazing roads, creating vibrations, that eventually unraveled them. The knocking noise here is easy to eliminate - you just need to tighten all the fasteners.

- On the VAZ-2110 and all cars in the tenth row family, the support bushing on one side of the rack often wears out. Since the support bushings are made here from plastic, their rapid wear does not become a miracle when traveling along our ideal, so to speak, roads. Irregularities contribute to the free movement of this element, causing wear to occur at an accelerated pace.

- The situation is much more serious when the covers protecting the steering rack are torn. Then dust and dirt have access to its jagged surfaces, which without unnecessary drama looks like a disaster. The rack will not work for a long time without protection, which is why the unfortunate knock appears.

- Corrosion of a part is generally a fatal problem, because the steering rack will definitely have to be replaced. It is expensive, but not more expensive than finances and, most importantly, life with health.

- Rarely, but there is a manufacturing defect. Here the rack most often knocks on a new car. Fortunately, if the vehicle is listed under warranty, then replacement of a low-quality component can be achieved through the “establishment” of the manufacturer of the car. Factory damage and poor workmanship are the most common cases of manufacturing defects.

- Lath material. As a rule, it is soft and designed for driving on quality roads. When driving through our pits and as a result of constant vibration, metal is gradually removed from the surface of the rack, layer by layer, micron by micron, and this leads to premature wear of the support sleeve. In this case, the problem can be solved in two ways. Either buy a new rail or order the production of a similar one from a more durable metal. Usually people who do this will recommend you the right material.

Types of Guitar Anchors

First of all, it’s worth understanding what kind of guitar rods there are, and how they generally work. This is important because each type has its own adjustment mechanism.

Contracting

The most popular type of truss rods, which is installed on almost every acoustic guitar. Its principle of operation is to compress the neck as you scroll the rod with the key. Conventionally, it consists of two parts - the first, static, which is responsible for holding part of the tool in one position, and the second, which can be twisted, and which regulates the degree to which the tree is compressed.