An internal combustion engine has a large number of rubbing parts. Lubricant is supplied to them in one way or another to reduce the friction force and remove wear products that inevitably form during operation. To prevent removed dirt from returning to the parts, the oil must be cleaned, for which a special filter is used. The design of the oil filter may be different, but its purpose remains the same - constant cleaning of the lubricant.

As the vehicle is used, the filter gradually becomes clogged and needs to be changed from time to time. As a rule, the replacement is carried out simultaneously with the oil change. Automobile manufacturers themselves determine the frequency of replacements, depending on the engine design and operating conditions. For modern gasoline engines, the interval is usually about 15,000 km, for diesel engines - half that.

Oil filter design

Oil filters used on passenger cars have a similar design. Inside the glass-shaped housing there is a filter element, a spring, a bypass valve and a check valve. It has several inlet holes located around the perimeter of the upper part, and one outlet. The outlet has a thread for mounting an oil filter. There is also a rubber O-ring located outside, the sole purpose of which is to prevent oil from leaking through the connection.

The filter element is usually made of special impregnated cardboard, which is folded like an accordion and rolled into a roll. This is done in order to increase the working surface area, because the larger it is, the better the oil is cleaned and the longer the filter will last.

Many people are not even aware of the presence of a bypass valve in the filter, but it is a necessary element. It is needed in order to directly direct raw oil into the lubrication system under certain conditions. For example, when starting the engine in severe frost, when it thickens and cannot pass through the filter element (otherwise the flow of thick oil will destroy the filter). Thanks to this, the engine will not be left without lubrication during operation.

The purpose of the check valve is to prevent lubricant from draining from the oil line into the crankcase of a stopped engine. Otherwise, the next time you start the motor, it will be without lubrication, which will not prolong its life. How well the check valve works can be judged by how long the oil pressure indicator on the dashboard remains lit after the engine is started (picture of an oil can). Ideally, it should go out immediately, but up to seven seconds is considered the norm.

Ways to distinguish a fake from an original filter

Despite the low quality of the original oil filter, installing a fake can lead to serious consequences and a significant reduction in the life of the power plant. The reason for this is the production of counterfeit consumables without complying with any norms and standards. Therefore, installing counterfeit products is extremely undesirable. A counterfeit can be identified by a number of characteristic features.

First of all, the packaging must be visually inspected. The original is made using rich colors, which the counterfeit cannot boast of. At the same time, counterfeit products may contain spelling, typographical and other errors.

You can identify a fake by looking at the o-ring. The original rubber has sufficient elasticity. The ring sits securely in the seat. In a fake filter, the seal is made of rubber, which quickly hardens. In some cases, the ring does not match the size of the seat, so it falls out of it freely.

You can identify a fake by the quality of the body paint. The original coating has no flaws and has a uniform color. In counterfeit products, when examining the case, shagreen is often noticeable. If you carefully examine the quality of paint application, you may find traces of dust. In counterfeit goods you can also see differences in shade and other defects. The inscriptions and fakes are less readable.

To complete the identification of a fake, it is recommended to look inside the filter. The original has no visible signs of corrosion or protruding sealant. When examining a fake, carelessness in the manufacture of the consumable is often revealed.

Types of Oil Filters

There are three types of oil filters:

- full-flow;

- partial flow;

- combined.

They differ in the way they filter.

- A full-flow oil filter is connected to the lubrication system in series, and passes through itself the entire volume of oil that is pumped by the oil pump. Its design is the simplest. The main advantage is the high speed of oil purification, but the disadvantage is that it clogs quickly. The greatest attention in such a filter is paid to the bypass valve. When the filter becomes heavily clogged, the pressure in it increases and the valve opens. Thus, the oil stops being purified, but overheating of the engine as a result of oil starvation is avoided.

- The partial flow filter is connected to the lubrication system in parallel. Unlike full flow, only part of the oil passes through it. Thus, the cleaning speed is significantly reduced, but filtration is better. In general, the degree of protection of the power unit from wear products is the same for a partial-flow oil filter and a full-flow one. True, the first reduces the risk of a sharp pressure drop due to critical contamination.

- A combined type oil filter is characterized by the presence of both full- and partial-flow filters in the lubrication system. The principle of its operation is as follows: 90% of the lubricant passes through the full-flow filter, and the remaining 10% passes through the partial-flow filter. This solution makes it possible to achieve almost complete oil purification, increase its service life and more reliable engine protection. This type of filter is usually used on diesel engines of trucks and construction equipment.

Design and principle of operation of settling filters

It should be noted right away that settling filters are not used as independent elements for oil purification, but are usually included in the FGO. The basis of this device is a housing, in the lower part of which a glass is installed, and in the upper part there is a plate-type FGO, consisting of a number of metal plates. When oil passes through such a filter, contaminant particles are separated on the plates and settle in the glass. As the glass becomes dirty, it is removed and cleaned of sediment, and the collapsible plate-type FGO is also cleaned.

What is an oil centrifuge

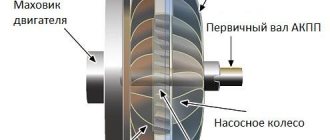

A centrifugal oil filter, or centrifuge, is a filter in which oil is purified from impurities under the influence of centrifugal forces. Its main components are a rotor and an axis, screwed into the filter housing with the lower part.

The principle of its operation is as follows. The oil pump pumps oil into the rotor through longitudinal and radial holes in the axle. Next, it enters the nozzles through the tubes, passes through them at high speed and hits the filter cover; reactive forces cause the rotor to rotate. As a result, the impurities contained in the lubricant settle on the cover, and the purified oil flows into the oil line.

A centrifugal oil filter is used in truck and tractor engines. Previously, it was also installed on passenger cars, but this practice was later abandoned due to increasing requirements for the quality of engine oil purification, as well as due to the need to remove deposits from the walls of the oil filter at least once every 2000 km.

Choosing which oil filter is better for the VAZ-2114

The ideal place to buy an oil filter is a certified VAZ service center, but given the realities of our country, it is best to buy such things from friends, although they can deceive.

Oil filters for VAZ 2114

In order not to purchase a frankly low-quality product, you should pay attention to the following nuances of the product:

- the quality of the packaging and the presence of spelling, grammatical or semantic errors on the packaging, if any - the filter is a fake of the worst quality;

- the presence of burrs on the filler holes - the original filter does not have them;

- the presence of “VAZ stripes” on the side ring;

- elasticity of the sealing gum – it should be high;

- the product body must be durable and free from defects;

- the paper must be glued carefully, and there must be no streaks or other traces of glue;

- the thread must be of high quality and not have any visible defects.

We recommend: A practical guide to replacing the clutch on a Chery Amulet car

Fulfilling all the conditions will not be able to protect you from buying a fake with 100% probability, but at least it will be of high quality.

How often should you change the oil filter?

As mentioned at the beginning of the article, how often a car needs to change the oil filter and oil is determined by the manufacturers. This takes into account the characteristics of the engines, operating conditions and climate of the country in which the machine is used. Of course, the more intense the operating conditions of the engine (mountainous terrain, very dusty roads, high temperatures, traffic jams in large cities), the more often the filter should be changed. Manufacturers recommend in such situations to reduce maintenance intervals by 30 - 50%. How often the car needs to be serviced also depends on your driving style - if it is aggressive, it is better to change consumables at shorter intervals.

Some motorists prefer to change them even more often, on average once every 5 – 7 thousand km, based on the color of the oil. However, this is exactly the situation when more often does not mean better, because by this moment the engine oil has a full range of performance properties. The fact that it quickly darkens does not mean that it is time to change it, but only about its good cleaning properties.

Many car owners are concerned about the question of whether it is possible to change the filter without changing the oil. The answer is simple: you can. Since almost all the lubricant in an idle engine is in the crankcase, and its level is below the pipe onto which the oil filter is screwed, when performing such an operation, only what is in the removed filter is lost (for passenger cars, approximately 200 ml). If the oil level is normal, then after changing it you won’t even have to add it to the engine.

This procedure can be carried out, for example, if there are doubts about the quality of the filter. If after 2-3 thousand you also have to change the oil, then it is better to do everything at once. » alt=»»>

During engine operation, the fine filter constantly removes abrasive particles from the lubrication system that can cause increased wear of rubbing parts.

Not only the oil change interval, but also the engine life depends on the quality of cleaning.

Getting ready for replacement

Before you start replacing, you need to learn a few simple rules. Changing the fluid should be carried out on a warm engine, when the fluid has better fluidity. If the engine is cold, start it and wait until it warms up to operating temperature. If you are thinking of changing the brand of oil, then you should wash the engine with a special cleaning compound.

The replacement will have to be carried out twice - first drain the waste, and then pour in the flushing fluid (fill the entire volume) or flushing lubricant - but the oil filter should not be replaced. We start the engine for ten to fifteen minutes, then turn it off and drain the flushing oil. We proceed to the procedure of filling with fresh oil, and the oil filter must be changed.

MAIN FILTERS MANUFACTURERS

Due to the peculiarities of their production, oil filters are mainly manufactured by specialized companies. They use high-quality filter paper, which only a few companies in the world can produce. In recent years, relatively new enterprises located in Asian countries have mastered the production of filters. In addition, a number of European and American companies have their branches in these countries.

The most well-known manufacturers of automotive oil filters are currently:

- European countries: Sogefi

Mann + Hummel Pro Tec Gmbh (trademark "MANN FILTER"); MAHLE (trademarks "Mahle" and "Knecht"); Hengst Filterwerke (trademark “Hengst Filter”); UFI filters (trademark "SOFIMA"); SCT-Vertriebs Gmbh (trademark "SCT"). - USA

: Donaldson; Wix (Wix-Filtron); Fleetguard; Federal Mogul (this transnational company is known under the “Champion” brand). - Japan –TSUCHIYA

MFG Co; Nippon Micro Filter Co. - China –

NAFIL Filter Co; QAP Automotive Industries Ltd. - Taiwan –

PEKO Inc. Ltd. - South Korea –

KANGNAM Filter Co; SE-KWANG Ind. Co. - Turkey –

Fil Filter Ltd; ASAS Filter Ind.

In Russia

, along with long-standing filter manufacturers - LAAZ, EZTF, CHAZ and ZARYA, in recent years about 50 new companies have appeared, such as NPF Nevsky Filter, Industrial and Trade Group BIG (trading brand “BIGfilter”), “Salyut-filter”, “CITRON”, “J-CARS”, etc.

GENERAL INFORMATION

Automotive oil filters

must meet the following requirements:

- have sufficient dirt holding capacity - the ability to retain and accumulate a significant amount of oil contaminants, which mainly depends on the size of the filter element and determines the service life of the filter;

- ensure optimal fineness of screening out contaminants - determined by the pore size of the filter element;

- have a small hydraulic resistance - to facilitate the supply of thickened oil to the rubbing vapors during a cold start of the engine;

- have sufficient strength of the housing and a reliable seal at the connection to the motor - in case of an emergency increase in pressure in the lubrication system or external mechanical influences.

Oil purification in the engine lubrication system can be carried out according to two main schemes:

– full-flow

– including one filter through which all the oil supplied by the oil pump is pumped;

In Fig: Full-flow diagram of the lubrication system of a car engine 1 – engine oil sump (pan); 2 – oil pump; 3 – full-flow oil filter

– combined

– including, in addition to a full-flow filter, a partial-flow filter or, in some cases, a centrifuge;

In Fig: Combined diagram of the lubrication system of a car engine 1 – engine oil sump (pan); 2 – oil pump; 3 – full-flow oil filter; 4 – partial flow filter

Oil contaminants

, depending on their origin, there are:

- organic - products of incomplete combustion of fuel and a small amount of motor oil that inevitably enters the combustion chamber (this is due to the phenomenon of oil “burnout”);

- inorganic - dust and metal particles of wear parts formed during running-in and subsequent operation of the engine.

The intensity of engine oil contamination depends on the design and technical condition of the engine, the quality of the fuel used, operating conditions and many other factors.

FILTERS DEVICE

Oil filter

consists of a housing in which there is a filter element and, if necessary, bypass, anti-drainage and anti-drain valves.

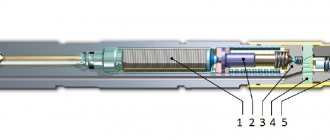

Depending on the housing design, filters can be of two types: – non-separable (spin-on)

, which are currently most widespread due to their compactness, low cost and ease of replacement;

– dismountable (replaceable cartridge)

with a replaceable filter element, used less frequently, as they have increased dimensions and are less convenient to maintain.

In Fig: Non-separable oil filter 1 – housing; 2 – filter element (curtain); 3 – bypass valve; 4 – anti-drainage valve; 5 – anti-drain valve The filter element (“ curtain

This paper has high porosity, and thanks to its impregnation, it is durable, water- and oil-resistant.

To achieve the maximum possible filter surface area with minimal filter dimensions, the paper is laid in a special way, usually in the form of a multi-beam “star”. Volumetric filter elements made of cotton, synthetic and artificial fibers are used less frequently. A bypass valve

is sometimes called a safety valve, bypass valve, or bypass valve.

Its purpose is to ensure a guaranteed supply of engine oil to the engine lubrication system in the event that it cannot pass through the filter element if it is completely clogged or the oil viscosity is too high at low temperatures. The response pressure of the bypass valve is set depending on the engine design and is in the range of 0.55–2.6 kg/cm2 for different models. valve

prevents oil from draining from the filter and oil passages into the crankcase after the engine is stopped.

This eliminates the possibility of a delay in the supply of oil to the lubrication system due to the formation of an air lock during subsequent start-up. The most common design of an anti-drainage valve is a spring-loaded rubber disk that closes the inlet holes in the filter housing from the inside. An anti-syphon valve

is usually installed in permanent filters in combination with a bypass or anti-drain valve and prevents oil from pouring out of the housing through the outlet when replacing a used filter.

The absence of some valves in the filter

- the filter is placed on the engine so that oil cannot leak out of the housing, so there is no need for anti-drainage and anti-drain valves;

- The bypass valve is installed outside the filter directly on the engine.