The fuel pump plays a vital role in the fuel system of any car. The main task of the device is to supply fuel from the fuel tank to the engine. The fuel pump also regulates the amount of fuel supplied through the fuel pump reducer.

We also recommend reading the article about the design of the fuel pump. From this article you will learn about what types of fuel pumps are used in gasoline cars, as well as about the features of their design and operating principles.

What does the fuel pump look like?

External view of the fuel pump on Lifan Solano (also suitable for Breeze)

The pressure in the fuel system (rail) of the machine is an important parameter that should be monitored regularly once every few months. This is a simple procedure that is carried out first, after which they begin to eliminate other shortcomings. The quality of engine functioning in all operating modes depends on the correct pressure.

Possible options

You can use several methods to check. The simplest option would be to purchase a special device, which includes a pressure gauge and some other elements. The price of such a set is about forty dollars, depending on the manufacturer (we specifically indicate the price in dollars, since the price in rubles now fluctuates greatly due to fluctuations in the exchange rate).

If you turn to a service station for help, then for a one-time measurement you will be asked for an amount equal to one fifth of the price of the finished device.

Let's have fun

You can use special means

But, there is a more affordable option, where we will use improvised means. We are talking about a standard pressure gauge that allows you to measure tire pressure. Almost every car owner has it. But here you need to remember that air pressure gauges are designed to measure pressure with large values, about sixteen atmospheres, while models for fuel are limited to six atmospheres.

What devices are used

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Several instruments can serve as devices for taking pressure readings.

- A special device purchased from an auto parts store. It comes complete with an adapter, drain hose and pressure gauge. Costs about 1.5 thousand rubles.

- Converted tire pressure gauge. The instrument scale and tube are subject to modification. As you know, the air pressure gauge shows a value of up to 20 atm, and the fuel measurement limit is around 5-7 atm. For this reason, reading errors may occur, and the device is modified to take this into account. Regarding the tube: you need to change it to a gas-resistant version.

Pressure check

The first sign that should hint at a malfunction in the engine power system is its unstable operation; the engine may stall or stall.

Even those who lack the appropriate skills can figure out how to measure the pressure of a fuel pump. So, you will need to find a special plumbing-type tape, which is used to seal threaded connections, as well as the pressure gauge itself, which is a special measuring device with a pipe on which the specified tape should be wound.

The diameter of the pipe should be nine millimeters. To ensure fire safety, it is necessary to cover the generator with heat-resistant film or other object. Next, we approach the ramp (read how to measure the pressure in the fuel rail here), the location of which is different for all cars. Focus on the specific model of your vehicle and its instructions.

You can also use a regular air pressure gauge.

Step by step details

This procedure can be carried out both in your garage and in the field, when there are no additional tools at hand.

As for the pressure on different car models, it can be completely different. Check the exact values on websites with car instructions. For example, on domestic VAZ cars, where the engine volume is 1.6 liters, the fuel pump pressure should be about four atmospheres.

Main characteristics of the Bosch model

The VAZ 2110 gasoline pump has a performance in the range of 3-3.8 bar.

For each type of fuel system, the manufacturer produces a separate device. Many car enthusiasts replace a broken mechanism with a Bosch model with high pressure. The pressure of the VAZ 2110 fuel pump does not affect consumption, because the cars are equipped with a return line and excess fuel is returned to the tank. There is also a fuel pressure regulator. Fuel consumption may increase if the rail is not at optimal pressure. After which the nozzles do not spray, but pour gasoline, which does not have time to burn.

Instructions for diagnosing pressure and repairing a fuel pump

In this situation, the absence of a vacuum effect in the pipe will indicate that the diaphragm or discharge valve has been damaged.

And, if there is no vacuum or discharge pressure, then in addition to the indicated possible breakdowns, it may turn out that a foreign object is stuck in the fuel pump filter.

Don't forget to wash the filter

To eliminate it, it will be enough to rinse the filter with regular gasoline, and then blow it with compressed air or a compressor.

If the filter is excessively deformed or cannot be cleaned to the required level, it must be replaced with a new one.

Different measuring methods

In addition to measuring against the wall, there are many other ways to measure yourself. One of the options for checking the fuel supercharger is the “plug” diagnosis. In this case, the return line is clamped for two seconds, the engine starts, and the pressure reading is taken.

Another testing option. The speed of the power plant increases to three thousand revolutions per minute. At the same time, you need to monitor the instrument readings. If the pressure drops to 0, this is a sign of a “dead” pump.

The pressure on the ramp is measured as follows:

- fum tape is wound around the pipe;

- the device hose is reinforced with a clamp (if homemade);

- a rag is placed on nearby parts to prevent fuel from spilling (especially carefully you need to close the generating device in order to avoid a fire hazard in the engine space);

- there is a cap on the fuel rail that needs to be unscrewed;

- access to the hole with the nipple is opened - the latter is unscrewed with a cap from the car wheel;

- To prevent gasoline from splashing too much, it is necessary to release the pressure in the vehicle in advance;

- the end of the meter hose is threaded into the ramp hole and is also secured with a clamp;

- The rag is removed, the engine starts, and readings are taken.

Checking the serviceability of the fuel pump on the injector

When, when you turn the ignition key, you hear a slight buzzing, a slight hum, this is how the fuel pump works, pumping gasoline creates pressure in the system. If, when you try to start, there are no such signs of the fuel pump working, then you can assume a malfunction of the electrics, the pump itself or its individual parts. Therefore, let’s look at how you can check the operation of a gas pump using a step-by-step logical chain. Starting from whether power is supplied to the fuel pump and ending with whether the fuel pump pumps at all, and if so, what pressure is created in the fuel rail.

Step 1: Checking the fuse

Checking the fuel pump fuse involves inspecting the integrity of the conductive plate and, if broken, replacing it. But if there is no new fuse, then wind one strand of copper wire around the fuse contacts. If it burns out again, it means the problem may be in the wiring.

Stage 2: Checking the relay

To check the fuel pump relay, remove it from the socket and connect a 12 volt light bulb according to the diagram. If the light bulb works, the relay itself is also working properly. An alternative is to use a multimeter in ohmmeter mode to measure the resistance of the relay coil winding. One probe is connected to terminal 85, and the other to 86. The device will show a break if the relay has failed.

Make sure that the terminals are not oxidized - this will negatively affect the power supply to the fuel pump engine!

Stage 3. Checking the power supply to the BN

Checking the fuel pump voltage is done using a multimeter . The probes of the measuring device in voltmeter (from 0-20 volts) must be connected to the power terminals of the fuel pump. Turn on the ignition and take readings on the device. 12-12.5 volts is normal operating voltage. If there is voltage, but the pump does not work, check the electric motor.

Stage 4. Checking the fuel pump motor

To prevent damage to the electric motor, we supply 12 volts directly from the battery to the fuel pump terminals. It works - we check its performance, check valve, measure the pressure with a pressure gauge. If it doesn’t work, check the coil for a break.

When voltage is applied to the terminals of the gasoline pump, does it not work? Let's check the stator winding: take a tester (multimeter) and switch it to ohmmeter mode, it should show resistance, otherwise there is a problem with the winding and it needs to be replaced. If there is a resistance reading, the problem may be that there is a short winding on the fuel pump body. The tester probe goes to the positive terminal, the second one goes to the body. If it shorts, there will be no break.

Step 5. Checking the coarse filter

By removing the coarse filter (see vehicle technical documentation) from the fuel pump, you can even visually determine how dirty it is. If there is a large amount of deposits, it is recommended to replace the filters; if the problem occurs on the road, use a brush and gasoline to clean it.

Step 6: Check the check valve

The check valve must constantly prevent the movement of liquid in the opposite direction. During operation, its performance decreases, which reduces its technical characteristics.

1 way . Checking the check valve involves measuring the pressure with a pressure gauge. It needs to be connected to that part of the system that is directly involved in supplying fuel to the internal combustion engine. Pressure readings should not exceed 3 kg/sq.m. see (true for passenger cars). And when the engine is stopped, the pressure should not drop sharply.

Checking and cleaning the check valve

Method 2 . To check the operation of the fuel pump check valve without a pressure gauge, you need to clamp the return line and watch how the engine operates. If the check valve is faulty, the internal combustion engine will operate at higher speeds (provided there are no other problems).

3 way . Combines diagnostics and cleaning of the check valve at the same time. Remove and inspect it—clogging that requires cleaning can be seen with the naked eye. You can blow out the valve with a dense stream of air, but it is better to pass water through it under pressure. This way you combine checking the valve with cleaning it. If after this the valve does not work, it needs to be replaced.

Step 7. Pressure check

In order for diagnostics to correctly determine pressure readings, you need to reset the initial fuel pressure by turning off the fuel pump fuse.

Checking with a pressure gauge how the fuel pump pumps

How to check a fuel pump with a pressure gauge

You can check the fuel pump with a pressure gauge for serviceability as follows: connect the device to the fuel rail. The output is through the edge of the hood onto the windshield, where we install the device securely.

We record measurements in:

Static position . Turn the ignition key and look at the pressure gauge readings, they should not exceed 3.7 atm .

Dynamics . We turn on third gear (speed about 50 km/h), observing the pressure gauge data. When driving, if the problem is pressure, the readings will be either below 3 atm. , or above 3.7 atm .

Low pressure in the fuel system may be due to a fuel leak. The passage of fuel will show a decrease in pressure below 1.6 atm. Fault location: injector or fuel regulator.

It should be noted that, despite all the similarities (principle of operation, purpose), the methods for diagnosing a mechanical fuel pump differ, and in what way we will consider in more detail below.

Parameters of the Bosch model 0580453453

If you are interested in a VAZ 2110 Bosch fuel pump, the characteristics of the models will differ in the length and sometimes in the diameter of the body. The diameter of the body is adjusted using a gasket made of gas-resistant rubber. Also, devices may differ in pressure, placement of chips on the terminals. The device grid does not differ in the number of seats, but may vary in shape. You can remake the chip for a terminal or install it from a VAZ car. The length of the fuel pump determines its performance when the volume of fuel in the tank is low. If it is located in a module, then compliance is required to install it. The length of the Bosch model 0580453453 is 105 mm, 0580453449 is 65 mm, and for Bosch 0580453465 this figure is 90 mm. The pump is located in the car tank, it is immersed in fuel. It contains an electric motor that drives the pumping element. A combination of these components supplies fuel under high pressure. As a result, the fuel pump is noisy and needs cooling. Therefore, the equipment is immersed in a tank of fuel, as it serves as a coolant and noise-insulating compound.

Checking the fuel pump of a carburetor car (mechanical)

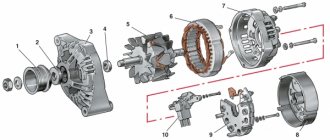

Mechanical fuel pump - diagram

To check the operation of the fuel pump, you should:

Delayed jet output is not a sign of a breakdown, especially if the car has been parked for a long time. As a rule, diaphragms eight and nine are the main cause of malfunction.

Be that as it may, you need to inspect both the strainer and the inlet/outlet valve.

Even if the gaskets are replaced, fuel may leak. In this case, the problem lies in the tightness of the fuel pump housing due to deformation during repairs.

Let's summarize:

The causes of fuel pump problems, both electrical and mechanical, are varied, and the need to find/fix a breakdown may take you by surprise along the way. By following the above recommendations, you will be able to independently carry out the entire necessary set of measures to diagnose this device. And you should start with the power supply (if it is an electric fuel pump) and the operation of the diaphragm when checking a mechanical fuel pump. Very often, the unstable operation of a fuel pump is not due to its breakdown, but to related parts - a filter, check valve or injectors.

Source

Determination of RTD performance

An RTD is a sensor that, if faulty, affects pressure readings in the entire system. To determine the performance of an RTD, 2 main methods are used.

- Close the nearby contacts on the diagnostic block near the gearshift lever if the pressure with the engine stopped is below 2.8 atm. A short circuit will allow the fuel pump to bypass the engine.

- Stop the fuel pump. Measure the pressure, which under normal conditions should drop to 0.7 atm and remain at this level, without varying. On the contrary, if the indicator instantly drops to 0, either the sensor is faulty or there is a problem in the pump return system. Fuel leaks, poor condition of injection elements, etc. are also possible.

Fuel tank

The fuel tank must be made of corrosion-resistant material and not leak at twice the operating pressure and. in some cases, at 0.3 bar. Timely opening or safety valves must be ensured or secondary measures must be taken to ensure the release of excess pressure. Fuel must not leak through the tank cap or pressure compensation devices. This is true when the vehicle is subjected to minor mechanical stress, such as when turning or stopping, or driving over rough terrain. The fuel tank and engine must be sufficiently separated from each other that there is no risk of fire in the event of an accident. Moreover, for open-body vehicles, tractors and buses, special regulations regarding the height of the fuel tank and its protection must be taken into account.

Main malfunctions of the fuel injection system and their symptoms

Before moving on to malfunctions of the “Seven” fuel system, let’s consider what symptoms may accompany them. Signs of a system malfunction include:

- difficult starting of a cold power unit;

- Unstable engine operation at idle speed;

- “floating” engine speed;

- loss of engine power;

- increased fuel consumption.

Naturally, similar symptoms can occur with other engine malfunctions, especially those related to the ignition system. In addition, each of them can simultaneously indicate several types of breakdowns. Therefore, when conducting diagnostics, an integrated approach is important here.

Difficulty starting when cold

Problems with starting a cold unit can occur when:

- fuel pump malfunction;

- reducing the throughput of the secondary filter;

- clogged injectors;

- failure of the lambda probe.

Unstable motor operation without load

Irregular engine operation at idle may indicate:

- malfunction of the XX regulator;

- fuel pump failure;

- clogged injectors.

"Floating" speed

Slow movement of the tachometer needle, first in one direction, then in the other, may be a sign of:

- malfunction of the idle speed sensor;

- failure of the air flow sensor or throttle position sensor;

- malfunctions in the fuel pressure regulator.

Power Loss

The power unit of the injection “seven” becomes significantly weaker, especially under load, with:

- malfunctions in the operation of the injectors (when fuel is not injected into the manifold, but flows, as a result of which the mixture becomes too rich, and the engine “chokes” when the gas pedal is sharply pressed);

- failure of the throttle position sensor;

- interruptions in the operation of the fuel pump.

All of the above malfunctions are accompanied by an increase in fuel consumption.