History of VAZ 1111/11113 engines

The engineers who developed the Oka car faced a rather difficult task - to make a compact and affordable vehicle, made from common components and with good maintainability. Similar requirements were put forward for the engine - it had to be simple, reliable and easy to repair in the event of a breakdown outside specialized service stations with qualified personnel.

In the first versions of the Oka, the developers used a two-cylinder power unit from Daihatsu Quore with 30 horsepower. Several prototypes were made with this engine. But, although the engine had a well-functioning and reliable design, they refused to copy it, since the foreign power unit required high quality engine parts and assembly standards. In addition, copying required assembling engines from scratch and mastering the corresponding technical process, and this would make the car unacceptably expensive and seriously delay the production of serial samples.

Then the engineers turned to existing engine solutions in the domestic auto industry.

Interesting: the choice of engine was influenced by the launch of the VAZ-2108 on the assembly line of the Togliatti plant.

The G8 engine was already fully developed, so to equip the new compact youth car, it was decided to create a two-cylinder engine based on the G8 engine, which at that time was the main one in VAZ production. Through a series of technical manipulations, the 1111 engine was obtained, which they began to equip the Oka with.

VAZ 1111 engine - features and design

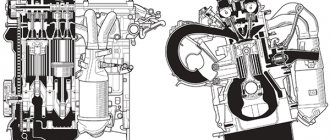

The 650 cc engine 1111 is “half” of the 2108 engine. To create it, they simply took half of the engine and cylinder block, since it was easier and cheaper to develop equipment for such a solution than for a new unit. Thus, the 1111th is a two-cylinder in-line petrol carburetor engine, with 2 valves per cylinder and an overhead camshaft configuration.

1111 assembled:

Main characteristics of the Oka engine:

- power - 30 forces;

- volume – 649 cubic meters. cm.;

- torque - maximum 44 Nm at 3400 rpm;

- recommended fuel is gasoline with an octane rating of 92;

- cylinders: 2;

- type of food – carburetor;

- valves – 4;

- fuel consumption – about 4.7 liters per 100 km;

- engine cooling – liquid;

- engine environmental standard: Euro-0.

Weight and dimensions of the Oka engine:

- weight – 66.5 kg without gearbox and clutch;

- overall dimensions – 550*640*670 mm.

The entire working process takes place in two revolutions of the crankshaft, due to which the engine experiences severe vibration loads. To compensate for them, two balancing shafts are provided to reduce motor vibration.

Interesting: in the VAZ 1111 engine, the fuel pump is not electric, but mechanically driven from the engine.

The supply of the fuel mixture is controlled by the carburetor. The lubrication system, as in 2108, is created with the installation of a gear pump. Engine oil is taken from the crankcase and supplied to the friction pairs of the camshaft and crankshaft. The cylinders are irrigated with oil mist generated during the operation of the crankshaft, and the engine gas distribution mechanism and valve rods are lubricated by gravity.

Car engine structure

The cars are equipped with two-cylinder, four-stroke carburetor engines model 1111 and 11113 with different cylinder capacities. They have an in-line arrangement of cylinders and a camshaft located on the cylinder head.

These two unified engines with a displacement of 649 and 750 cm 3 differ in pistons and cylinder block (different diameters of the intake ports and valves), cylinder head gasket (different diameters of the cylinder holes) and carburetors (different calibration data). In addition, there are differences in the magnitude of the balancing masses of the flywheel, generator drive pulley and balancing shafts.

Engines with a compression ratio of 9.9 run on AI-93 motor gasoline with a research octane number of at least 93.

High power and economic performance of engines is achieved through the use of a compact combustion chamber, a two-chamber carburetor, selection of adjustments to power and ignition systems, selection of the shape of intake and exhaust channels, valve timing, and reduction of mechanical losses in the engine as a whole.

The engine cylinders are combined with the upper part of the crankcase and form a single casting - the cylinder block. This arrangement ensures the strength of the structure, its rigidity, compactness, reliability, and also reduces the weight of the engine.

The crankshaft is mounted on three supports at the bottom of the cylinder block. The front and rear ends of the crankshaft are sealed with self-clamping rubber seals.

Each engine cylinder has one intake and one exhaust valve. Pistons 25 have two compression rings and one oil scraper ring with a spring. The piston is connected to the connecting rod by a piston pin pressed into the upper head of the connecting rod.

The camshaft 12 is mounted on the cylinder head and is driven by a toothed belt 10 from the crankshaft. The advantage of the drive is its simplicity of design and lower weight compared to other types of transmissions.

Two-cylinder engines (such as engines mod. 1111 and 11113) have worse balance of the moving masses of the crank mechanism compared to four-cylinder engines. Hence the level of engine vibration is higher. If appropriate measures are not taken, these vibrations will have a negative impact on both the car body and passengers. Therefore, to reduce vibrations on engines mod. 1111 and 11113, two balancing shafts 31 are installed on the right and left sides of the engine, which are driven by gears from the crankshaft. These shafts have unbalanced masses and, when rotating, compensate for the inertial forces from the piston and connecting rod. In addition, to reduce vibrations, one-sided tides are made on the flywheel 28 and the generator drive pulley 5. As a result of such design measures, engine vibration is reduced to an acceptable level.

Since engines 1111 and 11113 have different piston masses, they have correspondingly different imbalance values of the balance shafts, flywheel and generator drive pulley. Therefore, to distinguish these parts of the 11113 engine, there are marks. On the flywheel there is an annular groove with a diameter of 135 mm on the side where it is attached to the crankshaft. On the balance shafts there is an annular groove near the seating surface for the rear bearing. On the rear side of the generator drive pulley there is a circular groove with a diameter of 120 mm.

Motor VAZ 11113

This engine appeared later as a modification of the same engine from the V8, when the latter was brought to a volume of 1.5 liters (VAZ-21083). The engine was again “halved”, resulting in a 750 cc unit. The appearance of motors 1111 and 11113 is the same, the changes affected only the internal part. The car with this engine was called LADA OKA.

So, it was increased to 81 mm. motor piston diameter (from 76). Engineers installed an additional cooling system for the combustion chamber and made the inter-cylinder partitions thicker.

Additional cooling turned out to be necessary due to the increased heat generation of the new engine: without it, the pistons often jammed, the cylinder walls lifted, and other malfunctions occurred, typical of engine overheating.

The updated engine became 3-5 horsepower more powerful, although it remained carburetor-powered. Otherwise, the VAZ 11113 engine received technical characteristics almost no different from its “younger brother”, in particular, the eco-standard remained Euro-0, and the design of the fuel supply system (carburetor) remained the same. Main parameters:

- working volume – 749 cubic meters;

- power developed by the motor: 33 forces;

- standard torque: 50 Nm at 3200 rpm;

- fuel: 92 gasoline:

- fuel consumption: up to 6.2 l. by "hundred".

Interesting: Oka received the 11113 injection two-cylinder engine, such a project existed at the plant, and in 2005 a limited number of these cars were even produced. The injection version received the marking 11113-20. But the new product did not go into wide production due to many problems and the need for improvements, although today you can still buy a kit to convert the engine into an injection one.

This is what the factory injector kit looks like for the 11113th engine:

There are also “homemade” projects for installing an injector with subsequent modifications to the engine - a compressor, flashing the injector ECU, etc. In addition, the SeAZ plant, before the cessation of Oka production, produced a model with engine 11116 - a licensed three-cylinder injection engine of Chinese origin TJ 376 QE. This engine develops up to 53 horsepower and complies with Euro-2 standards.

Basket

Injection "OKA" with 3 cylinder engine

OJSC Serpukhov Automobile Plant produces the OKA SeAZ-11116 car with the Chinese TJ 376 QE engine, manufactured by TJ FAW under license from Daihatsu. The FAW Xiali car is also produced with this engine. The Chinese TJ engine is certified and has “Vehicle Type Approval”, and also complies with the EURO – 2 environmental standard.

Engine:

Type four-stroke, gasoline, with ECM Number and arrangement of cylinders 3, in line Cylinder diameter and piston stroke, mm 76 x 73 Displacement, l. 0, 993 Compression ratio 9, 5 Rated power at a crankshaft speed of 6000 rpm, kW (hp) 39 (53) Maximum torque at a crankshaft speed of 3000 rpm, N.m (kgf. m) 77 ( 7, 8 ) Minimum crankshaft rotation speed at idle speed, rpm 850 – 900 Cylinder operating order 1 – 2 ‑ 3 Mass fraction of carbon monoxide (CO) in exhaust gases at idle speed, no more, % 0.5

The TJ 376 QE engine has an electronic engine control system (ECM). The engine uses a Bosch control unit. When replacing the control unit, you can obtain exhaust emissions according to Euro-3 standards.

Technical characteristics of the OKA - 11116 car:

· Engine capacity increased to 0.993 l (TJ 376 QE) from 0.75 l (VAZ - 11113) · Engine power increased to 53 hp. (TJ 376 QE) with 32 hp. (VAZ – 11113) Fuel consumption decreased to 4.0 l (TJ 376 QE) instead of 4.6 l (VAZ – 11113) Acceleration dynamics improved: 18 s (TJ 376 QE) from 27.5 s (VAZ – 11113) · The maximum speed has increased to 150 km/h (TJ 376 QE) instead of 123 km/h (VAZ - 11113) · Installation of a 5-speed gearbox (OKA - 11116) instead of a 4-speed (OKA - 11113) · Service life of the OKA vehicle – 11116 compared to OKA – 11113 increased by 2 times to 200,000 km.

Additional materials:

* All technical parameters are manufacturer’s data.

Dimensions

Chassis

Fuel

Engine

The larger the engine capacity, the more powerful the car, and, as a rule, the larger it is. There is no point in installing a small-capacity engine on a large car, the engine simply cannot cope with its weight, and the opposite is also pointless - installing a large engine in a light car. Therefore, manufacturers are trying to select a motor. to the price of the car. The more expensive and prestigious the model, the larger the engine capacity and the more powerful it is. Budget versions rarely boast a cubic capacity of more than two liters.

Other Oka engine models

After AvtoVAZ practically curtailed its minicar production, the remaining ones attempted to install other engines:

- previously reviewed 11116;

- Korean Hyundai Atos unit (did not go into production);

- MeMZ 245 (went into small-scale production);

- MeMZ motor model 247.1 (can be found very rarely).

Created on the Oka platform, the all-terrain vehicle on tracks is equipped with a unit from the VAZ 2131, and the forced sports version is powered by engines from the Lada Priora.

Basic faults

In the early days of the 1111/11113's existence, Oka owners often complained about increased annoying vibration and noise from the engine compartment. The noise was especially loud when the engine was warming up; the balancer shafts mentioned above were to blame for it. This phenomenon worries car owners, but is not considered a malfunction. The engine may also be noisy due to too large valve clearances. The problem is eliminated by adjusting them. Vibration is a design feature, since the engine only has two pistons. A fairly common problem with engines is burnout of the cylinder head gasket. Its main reasons:

- factory production flaws, when the gasket was manufactured with inaccuracies;

- Incorrect tightening of the cylinder head, in which the gasket is not fully compressed.

If the motor is repaired, the seal is replaced and cannot be reused.

Important: if there are burrs on the new gasket, it is also not recommended to install it in the engine.

The Oka 11113 engine may have difficulty starting “hot” after a short stop. The reason for this is the layout of the engine compartment and problems with the fuel pump diaphragm. In a hot VAZ 11113 engine, fuel vapors are formed, including in the cavities of the fuel pump, and this unit is not intended for pumping gases and can “fail” when starting the engine before it cools down. The aperture can be changed.

Important: if a problem with the motor occurs on the road, you can simply place a damp cloth on the pump as a temporary measure. This will cool the unit somewhat and allow you to get to the place where the diaphragm can be replaced.

Other possible problems:

The ignition coils are located in such a way that water can enter them, for example, when the car crosses puddles. Water causes the voltage booster module to fail, and as a result, the engine cannot be started. There may also be general wiring problems associated with poor build quality and poor-quality wires, which are typical for VAZ engines in general.

- Damage to the engine cooling system.

Most often the pump fails due to poor assembly and low quality components. If the pump fails, the engine overheats and breaks down, so you need to monitor the temperature of the unit and change the pump promptly, if necessary. The engine thermostat is also not of high quality and may fail, with subsequent replacement.

- Electronic sensor failures.

Oka engines use domestically assembled electronics, which are not of the best quality, and sensor failures are not uncommon. In addition, they are not always properly secured to the unit body due to poor production standards.

Despite these problems, many repair operations, with the exception of complex specific breakdowns, can be performed by the car owner independently or in a “garage” car service. Spare parts from motors 21083, 21093 are suitable for repairs.

Engines of VAZ "Oka"

Let us immediately note that the Eye model received different power plants at different times. At the development stage, they planned to equip the car with a Japanese engine, which was intended for Daihatsu subcompacts. This power unit is 2-cylinder, power is about 30 hp. A little later, the first pre-production versions of the Oka, designed for testing and trials, appeared with such an engine.

Also, the car plant did not seek to launch production of a completely new engine, which would inevitably affect the final price of the Oka and delay the start of serial production of the car. The result is that the Japanese engine never made it under the hood of the compact.

The specified Oka engine has a displacement of 650 “cubes” and is actually half of the VAZ 2108 engine. This approach allowed us to avoid the costs of developing a new block and timing belt for a small-volume engine. So, the engine is in-line, gasoline, two-cylinder, with an overhead camshaft and 2 valves per cylinder.

It is noteworthy that the working process is implemented in 2 crankshaft revolutions, that is, such an engine is quite heavily vibration-loaded. To compensate for this drawback, as many as 2 balancing shafts were introduced into the design to reduce vibrations.

The power of such a unit is almost 30 hp, the torque characteristic is 44.1 Nm at 3400 rpm. Carburetor engine, mechanically driven fuel pump.

It is noteworthy that this engine, although it has become more modern and powerful, produces 35 hp. and 52 Newtons of torque, it also had cooling problems. After the appearance of the first versions, the pistons could jam from overheating, scuff marks appeared on the cylinder walls, etc.

Main malfunctions of VAZ Oka engines

As for the frequent problems of both the first and second versions (650 and 750 “cubes”), vibration and noise levels should be highlighted. In this case, noise is normal, especially on a cold engine when warming up. The valve mechanism is also noisy, especially if the thermal clearances of the valves are not adjusted.

Let's move on. On such engines, the cylinder head gasket often burns out. The problem is both in the quality of the gaskets themselves and in the incorrect tightening of the head during engine repair. There is also a problem with starting a hot 750 cc internal combustion engine, which is directly related to the fuel pump diaphragm and the layout of the engine compartment.

It is also noted on these engines that the ignition spark disappears. The reason is a contactless circuit with an ignition coil, and the coil is positioned in such a way that when driving through puddles, water can get in there.

As for the cooling system, the pump often fails and the engine overheats. The thermostat is also not very reliable. Failures of temperature and other sensors are also possible due to their poor quality and poor assembly, when the sensors are not securely attached to the engine.

Source

Maintenance

The declared resource of Oka engines under conditions of timely and correct maintenance is 120 thousand km. That is, these units, despite a number of inherent problems, can be called relatively reliable in their category.

The scheduled maintenance period is every 15 thousand kilometers. As part of the service, the oil is changed (it is advisable to use a synthetic lubricant; if semi-synthetics were poured into the engine, the interval is reduced to 10 thousand km). Therefore, when choosing which oil to pour into the Oka engine and when, you should clarify what liquid is already in the crankcase. When replacing, the oil system is washed and the oil filter is changed. Oil viscosity grade – 0W 40. 5W 40, 10W 40, depending on the season.

The lubricant volume in the 1111/11113 engine is 2.5 liters, the level is controlled by the oil dipstick. Overfilling liquid is strictly prohibited!

Valve clearance adjustment is supposed to be done every 30 thousand, but in fact it is carried out according to necessity and the actual condition of the engine. Also at this mileage you should clean the carburetor and adjust the idle speed.

After 60 thousand mileage, the fluid in the cooling circuit should be changed. If this is not done on time, the substance will degrade and lose its anti-corrosion and lubricating properties, reducing the life of the system as a whole. At this mileage, it is strictly necessary to replace a worn timing belt: if it breaks, the valves will bend, which will lead to the need to change the engine or make expensive repairs.

Engine oil change procedure

If it is necessary to change the type of engine oil in the VAZ Oka engine, the following manipulations are performed:

- Flushing oil is poured into the system to the minimum mark, after which the engine starts. The Oka engine should run in idle mode for 10 minutes - during this time the liquid will clean the system and remove accumulated dirt.

- The flushing fluid is drained and the oil filter is replaced. This is done so that dirt from the filter does not get into the new oil.

- New engine oil is poured into the Oka engine to the maximum level. After 10 minutes, lubricant is added if necessary.

Tuning the Oka engine

Since the power of the power unit is small, tuning as such does not make much sense: you can achieve an increase of up to 10%, especially with flashing the ECU of the injection version of the engine, but against the general background it will not be noticeable. The technical characteristics of Oka engines do not allow them to extract much power.

As a “custom project”, the owners of these cars can install an injector from a VAZ-21083i engine with improved characteristics, but this is a rather labor-intensive and financially expensive operation. In terms of cost, it is approximately equivalent to installing the Chinese TJ376QE mentioned above. To continue tuning and extract more power, a compressor can be installed on an injection engine and other modifications can be made as desired.

Performance characteristics of the VAZ 1111 Oka

Turning circle: 9.2 m Maximum speed: 130 km/h Acceleration time to 100 km/h: 24 s Fuel consumption per 100 km in the combined cycle: 4.3 l Gas tank volume: 30 l Curb vehicle weight: 645 kg Permissible gross weight: 975 kg Size tires: 135/80 R12

Engine characteristics

Location: front, transverse Engine capacity: 750 cm3 Engine power: 35 hp Number of revolutions: 5600 Torque: 52/3200 N*m Power system: Carburetor Turbocharging: no Gas distribution mechanism: OHC Cylinder arrangement: In-line Number of cylinders: 2 Cylinder diameter: 82 mm Piston stroke: 71 mm Compression ratio: 9.6 Number of valves per cylinder : 2 Recommended fuel: AI-92

Engine Modifications

| Engine | Box | Drive unit | Consumption, l | Acceleration to 100, s. |

| 0.6 29 hp petrol | Mechanics | front | 6.5/5.5 | 30 |

| 0.7 33 hp petrol | Mechanics | front | 6.4/5.4 | 24 |

| 0.7 35 HP petrol | Mechanics | front | 6.4/5.4 | 24 |

| 1.0 53 hp petrol | Mechanics | front | 7.4/5.0 | 18 |

| 1.1 49 bhp petrol | Mechanics | front | 7.4/5.1 | 18 |

Brake system

Front brakes: Disc Rear brakes: Drum

Steering

Steering Type: Rack and Pinion Power Steering: No

Transmission

Gear ratio of the main pair: 4.3 Drive: Front Number of gears: manual transmission - 4

Suspension

Front suspension: Shock absorber Rear suspension: Coil spring

Body

Body type: hatchback Number of doors: 3 Number of seats: 4 Vehicle length: 3200 mm Vehicle width: 1420 mm Vehicle height 1400 Wheelbase: 2180 mm Front track: 1210 mm Rear track: 1200 mm Ground clearance (clearance): 150 mm Maximum trunk volume: 630 l Minimum trunk volume: 210 l

The VAZ Oka model 1988 was equipped with a 0.65 liter engine. The first small car was initially developed at the Serpukhov Automobile Plant in austerity mode. Trial batches of small cars were planned to be produced in small quantities - 50 thousand copies per year, which significantly influenced the technical data of the car.

Technical characteristics of the Oka engine

Engine.

Transmission.

The clutch is single-disk, with a diaphragm spring, the clutch release drive is cable, with a backlash-free installation of the clutch release bearing. Gearbox – 4-speed, with synchronizers in forward gears. Send numbers: I – 3.7, II – 2.06, III – 1.27, IV – 0.90, 3X – 3.67. Main gear – cylindrical, helical, gear. number – 4.54. The wheels are driven by shafts with constant velocity joints.

Wheels and tires.

Suspension.

Brakes.

Steering.

Electrical equipment.

Filling volumes and recommended operating materials.

Fuel tank - 30 l, AI-93 gasoline. Cooling system – 4.8 l. antifreeze A-40;

Engine lubrication system – 2.5 l. Oils used: M-6/10G, at temperatures from plus 20 to minus 25 degrees C; M-6/12G, at temperatures from plus 45 to minus 20 degrees C; M-5/10G, at temperatures from plus 30 to minus 30 degrees C;

Gearbox housing - 1.8 l, see engine oils;

Hydraulic brake system - 0.55 l, Neva, Tom, Rosa fluids; Hydraulic struts for front suspension 2×0.27 l, MGP-10; Rear shock absorbers 2×0.143 l. MGP-10; Windshield washer reservoir – 2.0 l, NIISS-4 liquid and mixtures with water.

Luggage weight depending on the number of passengers: 4 people. 40 kg. 2 people 190 kg.

Curb weight 635 kg. on the front axle 395 kg. on the rear axle 240 kg.

Permissible gross weight 975 kg. Including: front axle 495 kg. on the rear axle 480 kg.

Max. speed 120 km/h. Max. climbability 30% Run-out from 50 km/h 500 m. Acceleration time to 100 km/h 30 s. Braking distance from 80 km/h 38 m.

Control fuel consumption, l/100 km: at 60 km/h 3.2 l. at 90 km/h 4.5 l. urban cycle 6.0 l. Turning radius on the outer wheel is 4.6 m.

Mod.VAZ-1111, petrol, in-line. 2-cyl.. 76×71 mm. 0.649 l, compression ratio 9.9, power 21.5 kW (29.3 hp) at 5600 rpm. torque 44.1 N'M (4.51 kgf-m) at 3400 rpm. Carburetor 1111-1107010. Air filter – with manual seasonal adjustment and replaceable filter element. The timing mechanism is driven by a toothed belt. The cooling system fan is equipped with an electric motor and turns on and off automatically.

The clutch is single-disk, with a diaphragm spring, the clutch release drive is cable, with a backlash-free installation of the clutch release bearing. Gearbox – 4-speed, with synchronizers in forward gears. Send numbers: I – 3.7, II – 2.06, III – 1.27, IV – 0.90, 3X – 3.67. Main gear – cylindrical, helical, gear. number – 4.54. The wheels are driven by shafts with constant velocity joints.

Piston dimensions

Defects of engine parts

When replacing parts of the connecting rod and piston group, it is necessary to select pistons to cylinders by diameter and weight, as well as piston pins to pistons by diameter and connecting rods by weight.

The following data is stamped on the piston bottom:

1

- piston class by pin hole (1, 2, 3)

2

- piston class by diameter (A, B, C, D, E)

3

- arrow showing the direction of installation of the piston

4

- weight group (normal - “G” , increased by 5 g - “+”, decreased by 5 g - “-“)

5

- repair size (diameter increased by 0.4 mm - D, by 0.8 - E)

The cylinder class (A, B, C, D, E) is stamped on the bottom plane of the block (the mating plane under the oil sump).

For the convenience of selecting pistons to cylinders by diameter, both are divided into five classes: A, B, C, D, E (every 0.1 mm). Spare parts include pistons of nominal sizes of three classes A, C, E and two repair sizes. The first repair size is increased by 0.4 mm, the second - by 0.8 mm.

Based on weight, pistons are divided into three groups: normal, increased by 5 g and decreased by 5 g. Pistons of the same group must be installed on the engine.

For repair size pistons, spare parts include repair size rings increased by 0.4 and 0.8 mm. The number “40” is stamped on the rings of the first repair size, and “80” on the second.

Nominal sizes of cylinder and pistons diameters, mm

When selecting pistons for cylinders, determine the gap between them as the difference between the measured diameters of the piston and cylinder.

The nominal gap is set to 0.025-0.045 mm, the maximum permissible is 0.15 mm. If the gap does not exceed 0.15 mm, you can select pistons from subsequent classes so that the gap is as close as possible to the nominal one. If the gap exceeds 0.15 mm, bore the cylinders to the next repair size and install pistons of the corresponding repair size. Both cylinders are bored to the repair size, even if the gap between the piston and the cylinder exceeds the maximum permissible in only one cylinder.

Piston pins are divided by diameter into three classes (1, 2, 3) every 0.004 mm. The class of the finger is marked on its end with paint. The piston pin class is stamped on the piston bottom, and the connecting rod pin class is stamped on the connecting rod cap.

Size classes of piston pins and pistons

Selection of crankshaft liners

Nominal diameter of crankshaft journals, mm:

main 50.799-50.819 connecting rod 47.830-47.850

The crankshaft journals can be ground to one of four repair sizes with a reduction in the nominal diameter of the journals, mm:

first by 0.25 third by 0.75 second by 0.5 fourth by 1.00

Nominal thickness of liners, mm:

main 1.824-1.831 connecting rod 1.723-1.730

The inserts are also supplied as spare parts in four repair sizes, increased thickness, mm:

first by 0.25 third by 0.75 second by 0.5 fourth by 1.00

Gaps between liners and crankshaft journals, mm:

for main bearings: nominal - 0.026-0.073, maximum permissible - 0.11; for connecting rod bearings: nominal - 0.02-0.07, maximum permissible - 0.1.

The crankshaft runout should be, mm:

along the middle main journal and the seating surface under the drive gear of the oil pump - no more than 0.03; along the landing surface under the flywheel - no more than 0.04; along the seating surface under pulleys and oil seals and under the drive gear of the balancing shafts - no more than 0.05.

Dimensions of half rings supplied as spare parts: nominal - 2.31-2.36 mm and repair (increased by 0.127 mm) - 2.437-2.487 mm.

Axial clearance of the crankshaft: nominal - 0.06-0.26 mm, maximum permissible - 0.35 mm.

Typical breakdowns of the VAZ 11113 OKA

- Starter problems

- Carburetor malfunctions

- Idle problems

- "Shots" from the exhaust pipe

- The smell of gasoline

- Increased fuel consumption

- Increased oil consumption

- The oil pressure warning light is on

- Engine overheating

- Extraneous noises when driving

- Problems with the brake system

Размеры поршневой

Дефектовка деталей РґРІРєріРєР°С‚еля

РџСЂРё замене деталей шатунно-поршневой РіСЂСѓРїРїС‹ РџСЂРѕР±С…Рѕ RґРѕРјРѕ RїРѕРґРѕР±СЂР°С‚СЊ RїРѕСЂС€РЅРё Rє S†Релиндра Рј РїРѕ диаметрСà массе, Р° также RїРѕСЂС€РЅРµРІС‹Рµ RїР°Р»СЃС†С‹ Рє РїРѕСЂС €РЅСЏРј РїРѕ диаметру Рё С€Р°С ‚СѓРЅС‹ РїРѕ массе.

РќР° днище поршня выбиты SЃР»РµРґСѓСЋС‰РёРµ данные:

1

— класс поршня РїРѕ отверстпод RїР°Р»РµС† (1, 2, 3)

2

— класс РїРѕСЂС€ РЅСЏ РїРѕ диаметру (Рђ, B, C, D, E)

3

- стрелка, РїРѕєР°Р·С‹РІР°СЋС‰Р°СЏ направленве SѓСЃС‚ановки РїР ѕСЂС€РЅСЏ 4 — РіСЂСѓРїРїР° РїРѕ

РјР

° СЃСЃРµ (нормальная - “Р“", увеличенная РЅР° 5 Рi — “+”, уменьшенная РЅР° 5 Рі — “-“) 5

—

ремонтРСС ‹Р№ размер (диаметр увеличен РЅР° 0.4 РјРј - D, РЅР° 0.8 - Р•)

Класс С†РеР»РеРЅРґСЂРѕРІ (Рђ, B, C, D, E) выбит РЅР° РЅРежней плоскости блокР° (РїСЂРёРІР°Р»РѕС ‡РЅРѕР№ плоскости РїРѕРґ масляный картер).

Подбор поршней

R»R»СЏ SѓРґРѕР±СЃС‚РІР° РїРѕРґР±РѕСЂР° RїРѕСЂС€РЅРµР№ Рє С†Релиндрам RїРѕ диаметру S‚Рµ Рь РґСЂСѓРіРёРµ делятся РЅР° пять РєР» ассов: A, B, C, D, E (через 0.1 РјРј). Р' запасные S‡Р°СЃС‚Рё RїРѕСЃС‚авляются RїРѕСЂС€РЅРё номинального SЂР°Р·РјРµСЂР° трех классов A, C, E Рё РґРІСѓС… ремонтных размеров. Первый ремонтный размер – увеличенный РЅР° 0.4 РјРј, вто СЂРѕР№ – РЅР° 0.8 РјРј.

РџРѕ массе RїРѕСЂС€РЅРё делятся РЅР° три РіСЂСѓРїРїС‹: нормальную, СѓР ІРµР»РёС‡РµРЅРЅСѓСЋ РЅР° 5 Рі Рі Рё SѓРјРµРЅСьшенную РЅР° 5 Рі. РќР° двигателе должны SѓSЃS‚анавливаться поршни РѕРґРЅРѕР№ РіС ЂСѓРїРїС‹.

R»R»СЏ RїRѕSЂS€РЅРµР№ SЂРµRјРѕРЅС‚ных SЂР°Р·РјРµСЂРѕРІ РІ запчасти RїРѕСЃС‚авля ются кольца СЂРµРјРѕРЅС‚РЅС ‹С… размеров, увеличенных РЅР° 0.4 Рё 0.8 РјРј. РќР° кольцаС... первого ремонтного SЂР°Р·РјРµСЂР° выбита цифр Р° in the 40th century, Р° РѕСЂРѕРіРѕ in the 80th century.

RќРѕРјРёРЅР°Р»СЊРЅС‹Рµ размеры диаметров цилиндрови RїРѕСЂС€РЅРµР№, RјRј

РџСЂРё РїРѕРґР±РѕСЂРµ поршней Рє цилиндрам RѕРїСЂРµРґРµР»РёС‚Рµ R·Р°Р·РѕСЂ меж РґСѓ РЅРеРјРё как разность RјРµР¶РґСѓ Р·Р°РјРµСЂРµРЅРЅС ‹РјРё РґРеаметрами поршня Рё С†Релиндра.

RќРѕРјРёРЅР°Р»СЊРЅС‹Р№ зазор SѓСЃС‚ановлен 0.025- 0.045 RјРј, предельно РґРѕР їСѓСЃС‚имый — 0.15 RјРј. Если зазор РЅРµ превышает 0.15 РјРј, можно RїРѕРґРѕР±СЂР°С‚СЊ RїРѕСЂС€РЅРё R ёР· последующих классов, чтобы зазор был как RјРѕР¶РЅРѕ Р±Р»Реже Рє Рє Рє Рє коминальному. Если зазор превышает 0.15 РјРј, расточите S†РёР»РёРЅрґСЂС‹ РїРѕРґ СЃР »РµРґСѓСЋС‰РёР№ СЂРµРјРѕРЅС‚РЅС ‹Р№ размер Ѓстановите RїРѕСЂС€РЅРё SЃРѕРѕС‚ветствующего S ЂРµРјРѕРЅС‚РЅРѕРіРѕ размера. РџРѕРґ ремонтный размер растачРевают РѕР±Р° цилиндра, дажРµ если зазор RјРµР¶РґСѓ RїРѕСЂС€РЅРµРј Ryo S†РёР»РёРЅРґСЂРѕРј RїСЂРµРІС‹С€Р°РµС‚ RїСЂРµРґРµР»СЊРЅРѕ РґРѕРї SѓSЃS‚имый только РІ РѕРґРЅРѕРј S†Релиндре.

Поршневые пальцы делятся RїРѕ диаметру РЅР° три класса (1, 2, 3) через 0.004 РјРј. Класс пальца маркируется РЅР° его торце RєСЂР°СЃРєРѕР№. Класс поршня РїРѕ пальцу выбит РЅР° днище RїРѕСЂС€РЅСЏ, Р° класс шатуна РїРѕ пальцу – РЅР° крышке шатуна.

Размерные классы поршневых пальцев и поршней

Подбор вкладышей коленчатого вала

RќРѕРјРёРЅР°Р»СЊРЅС‹Р№ диаметр S€РµРµРє RєРѕР»РµРЅС‡Р°С‚РѕРіРѕ вала, RјРј:

RєРѕСЂРµРЅРЅС‹С… 50,799-50,819 шатуРСРСых 47,830-47,850

Шейки коленчатого вала RјРѕР¶РЅРѕ RїСЂРѕС€Р»РёС„овать РґРѕ РѕРґРЅРѕР іРѕ РёР· четырех ремонтных размеров СЃ СГменСьшением номинального диаметра шеек, R јРј:

первого на 0.25 третьего на 0.75 второго на 0.5 четвертР*го на 1.00

RќРѕРјРёРЅР°Р»СЊРЅР°СЏ толщина вкладышей, РјРј:

RєРѕСЂРµРЅРЅС‹С… 1,824-1,831 шатуРСРСых 1,723-1,730

Р'кладыши поставляются РІ запасные S‡Р°СЃС‚Рё S‚акже S‡РµС‚С ‹ рех ремонтных размеров, увеличенной толщмны, РјРј:

первого на 0.25 третьего на 0.75 второго на 0.5 четвертР*го на 1.00

Зазоры между RІРєР»Р°РґС‹С€Р°РјРё Рё S€РµР№РєР°РјРё RєРѕР»РµРЅС‡Р°С‚РѕРіРѕ вала, РјР И:

для коренных подшипников: номинальный — 0.026-0.073, предел СЊРЅРѕ допустимый — 0.11; для шатунных подшипников: номнальный — 0.02-0.07, предель РЅРѕ допустимый — 0.1.

R'иение RєРѕР»РµРЅС‡Р°С‚РѕРіРѕ вала должно SЃРѕСЃС‚авлять, РјРј:

РїРѕ средней коренной шейке посадочной поверхностРе РїРѕРґ ведущую S€РµСЃС‚ерню RјР°СЃР»СЏРЅРѕРіРѕ насоса — РЅРµ более 0.03 ; РїРѕ посадочной поверхности RїРѕРґ RјР°С…РѕРІРёРє — РЅРµ более 0.04; РїРѕ посадочной поверхности RїРѕРґ S€РєРёРІС‹ Рё сальники РїРѕРґ С €РµСЃС‚ерню РїСЂРеРІРѕРґР° уравновешивающих валов — РЅРµ Р ±РѕР»РµРµ 0.05.

Р Размеры полуколец, поставляемых РІ запчасти: номинал ьный — 2.31- 2.36 RјРј Рё SЂРµРјРѕРЅС‚ный (увеличенный РЅР° 0.127 RјРј) - 2,437-2,487 RјРј.

Осевой зазор коленчатого вала: номинальный — 0.06-0.26 РјРј, РїС ЂРµРґРµР»СЊРЅРѕ допустимы R№ - 0.35 RјРј.

RўРёРїРёС‡РЅС‹Рµ RїRѕR»РѕRјРєРё R'RђR— 11113 RћRљRђ

- Проблемы со стартером

- RќРµРёСЃРїСЂР°РІРЅРѕСЃС‚Рё RєР°СЂР±СЋСЂР°С‚РѕСЂР°

- Проблемы S…олостого S…РѕРґР°

- В«Р'ыстрелы» РёР· выхлопной трубы

- Запах бензРеРЅР°

- RџРѕРІС‹С€РµРЅРЅС‹Р№ расход топлива

- RџРѕРІС‹С€РµРЅРЅС‹Р№ расход масла

- R“РѕСЂРёС‚ контрольная R»Р°РјРїРѕС‡РєР° давленоЏ масла

- RџРµСЂРµРіСЂРµРІ двигателя

- RџРѕСЃС‚РѕСЂРѕРЅРЅРёРµ S€СѓРјС‹ RїСЂРё движении

- Проблемы СЃ тормозной SЃРёСЃС‚емой

OKA 11113: injection two-cylinder engine

The subcompact compact car VAZ 11113 “Oka” is in some way unique - there are practically no such miniature cars in Russia anymore.

The VAZ car surprises with its technical characteristics - despite its more than modest size, the Oka accelerates quite quickly, has excellent cross-country ability, and at the same time is very economical in fuel consumption.

The VAZ 1111 family of cars has many fans, although many people laugh at the car, and many jokes have been written about it. Nevertheless, the car brand has the right to exist, and it’s worth stopping your gaze on this model and telling us more about it.

Engine assembly nuances

When assembling the Oka engine, you need to pay attention to some nuances:

"Oka" VAZ

At one time, the Serpukhov Automobile Plant produced the S-3D motorized wheelchair, which was mainly intended for people with disabilities, and was popularly called a “disabled car.” But the model was becoming outdated, a new car was needed that would meet modern requirements, and by the beginning of the 80s, the development of a new small-class vehicle began.

The Oka brand went into production in 1988; in its external design, the car was quite similar to the Japanese model Daihatsu Mira in the L70 body, which was produced from 1985 to 1990. However, the Russian brand had its own characteristic differences; at least the domestic car had a power unit and transmission of its own design.

Small KAMAZ

Although the development of the small car was carried out in Serpukhov, it was supposed to be launched into mass production in Elabuga, and since the city is located on the Kama River, the model was given the name “Kama” VAZ 1111. But due to the unstable economy then in the Soviet Union, there were no plans not destined to come true - the production of the brand in the planned volume (900 thousand cars per year) did not work out, and the Elabuga plant was repurposed. VAZ-1111 began to be produced in smaller volumes, and at other enterprises:

- at the Volzhsky Automobile Plant in Tolyatti;

- in Serpukhov (SeAZ);

- in Naberezhnye Chelny (ZMA).

In Togliatti, the production of a small car did not last long - its production on the main AvtoVAZ conveyor was unprofitable, and in 1995 the Oka was removed from the assembly line. The small car plant (ZMA) in Naberezhnye Chelny produced Oka until 2005, and the letters “KAMAZ” were proudly displayed on the nameplates of small cars.

"Oka" SeAZ

In 2006, the small car division in Naberezhnye Chelny was sold, and therefore the production of the “little Kamaz” was overthrown, and the Oka was now produced only at the Serpukhov plant. But the demand for an obsolete car was no longer the same, and in order to somehow arouse interest among buyers, SeAZ decided to modernize the brand.

In 2006, Oka began to be equipped with a Chinese-made 1.0 liter engine, the modification was named SeAZ-11116. But the demand for the car was falling, and besides, it was unprofitable to produce a small car, and in 2008, mass production of the model was discontinued.

Modifications

Over the years of production of the Oka model, many of its modifications were released. The car was produced with two main types of engines - 0.65 and 0.75 l, and depending on the installed power unit, it could have an index of 1111 (0.65 l) or 11113 (0.75 l). The factory designation of the model indicated the Volzhsky or Serpukhov Automobile Plant - VAZ or SeAZ, the cars were produced in various versions:

- for disabled people – SeAZ-1111-01/ SeAZ-1111-02/ SeAZ-1111-03 with a 0.65 l engine and SeAZ-11113-01/ SeAZ-11113-02/ SeAZ-11113-03 with a 0.75 l engine ;

- basic models - VAZ-1111 and VAZ-11113;

- a car with a 4-cylinder engine from Tavria - Astro-11301;

- model with a 1.0 liter engine in various modifications of SeAZ-11116, including pickups and vans.

VAZ 11113 Oka: technical specifications

The VAZ 11113 car is produced only in a hatchback body, in a three-door version, the car is designed for 4 people, including the driver. "Oka" has front-wheel drive, independent front and rear suspension, is equipped with a two-cylinder engine and 4-speed. manual transmission. The front suspension is standard for a car of this class, MacPherson type; a rigid beam with springs and shock absorbers is installed on the rear axle.

The brake system is hydraulic, with discs installed on the front axle and drums on the rear axle. Mechanical steering, hydraulic or electric power steering are not provided. The brakes have a vacuum booster and a master cylinder, a cable-type clutch without hydraulic release.

The engine of the VAZ-11113 model is two-cylinder, its location under the hood is transverse, some parts of the power unit are unified with the VAZ 21083 internal combustion engine (pistons, piston rings/pins). The cylinder block of the small engine is cast iron, the cylinder head is cast from aluminum. The timing drive is a belt drive, the camshaft is located at the top, in the bed of the cylinder head.

The VAZ 11113 “Oka” car has the following technical characteristics:

- dimensions (length/height/width) – 3.2 / 1.4 /1.42 m;

- wheelbase – 2.18 m;

- ground clearance – 15 cm;

- curb weight - 0.645 tons;

- maximum laden weight – 0.98 tons;

- wheel track (front/rear) – 1.21/1.2 m;

- ICE power – 35 hp. With.;

- ICE volume – 749 cm³;

- fuel system type - carburetor;

- fuel used - AI-92 gasoline;

- diameter of standard rims – R12

The Oka model with a 0.75 liter engine consumes 5 liters of gasoline fuel per 100 km on the highway; in urban mode, fuel consumption increases to 7.4 liters/100 km. The gasoline tank is designed for 30 liters, and on average the volume of the gas tank is enough for 400-450 km of travel. The VAZ-11113 does not accelerate quickly - in 24 seconds, but it is fast enough for city limits. But the Oka has an advantage in the city - the car is very maneuverable and can easily be parked anywhere.

Valve timing

1. Oil sump. 2. Right balance shaft. 3. Oil filter. 4. Cylinder block. 5. Rear oil seal holder. 6. Coolant pump supply pipe. 7. Inlet pipe. 8. Fuel pump. 9. Cylinder head cover. 10. Camshaft bearing housing. 11. Camshaft. 12. Cylinder head. 13. Spark plug. 14. Cylinder head gasket. 15. Piston. 16. Piston pin. 17. Connecting rod. 18. Left balance shaft. 19. Crankshaft connecting rod bearing shell. 20. Connecting rod cover. 21. Crankshaft. 22. Oil filter receiver. 23. Oil deflector cap. 24. Valve pusher. 25. Valve retainer. 28. Valve spring retainer. 27. Adjusting washer. 28. Internal valve spring. 29. Outer valve spring. 30. Spring support washer. 31. Retaining ring. 32. Valve guide. 33. Valve seat. 34. Inlet valve.

A - clearance in the valve drive mechanism on a cold engine: 0.15-0.25 mm for intake valves and 0.3-0.4 mm for exhaust valves. I - fuel mixture inlet II - compression III - power stroke IV - exhaust gas outlet

During one working cycle, four strokes occur in the engine cylinder: intake of the combustible mixture, compression, power stroke and exhaust gases. These strokes are carried out in two revolutions of the crankshaft.

The intake valve begins to open before the piston approaches top dead center (TDC), i.e., in the piston position corresponding to 26° of crankshaft rotation to TDC. m.t. This is necessary so that the valve is completely open (when the piston goes down during the intake stroke of the combustible mixture) and as much fresh combustible mixture as possible enters through the fully open inlet port.

The intake valve closes after the piston passes the bottom dead center (BDC), i.e. in a position corresponding to 60° of crankshaft rotation after BDC. m. t. Due to the inertial pressure of the jet of the sucked-in combustible mixture, it continues to flow into the cylinder when the piston has already begun to move upward, and thereby ensures better filling of the cylinder. Thus, intake practically occurs in a time corresponding to a crankshaft rotation of 266°.

The exhaust valve begins to open even before the full end of the working stroke, before the piston approaches the bottom. m.t., i.e. in a position corresponding to 50° of rotation of the crankshaft BC. m.t. At this moment, the pressure in the cylinder is still quite high and gases begin to flow intensively out of the cylinder, as a result of which their pressure and temperature quickly drop. This significantly reduces the engine work required to release gases and protects the engine from overheating.

The release continues after the piston passes through. m.t., i.e. when the crankshaft rotates 22° after c. m.t. Thus, the release cycle is 252°.

From the valve timing diagram it is clear that there is a moment (48° of rotation of the crankshaft at about VMT) when both valves - intake and exhaust - are open simultaneously, i.e. the exhaust and intake strokes are carried out with the valves overlapping. Due to the short period of time and small pressure drops, valve overlap does not lead to the penetration of exhaust gases into the intake pipe, but on the contrary, the vacuum in the cylinder due to the inertia of the exhaust gas flow causes the combustible mixture to be sucked into the cylinder and thereby improves its filling.

The described valve timing takes place at a gap A between the camshaft cam and the valve tappet on a cold engine.

To ensure that the opening and closing moments of the valves are coordinated with the corresponding piston positions determined by the angles of rotation of the crankshaft (i.e., to ensure the correct setting of the valve timing), there are marks on the engine parts (see Chapter 10):

- a - on the toothed pulley of the crankshaft drive;

- b - on the oil pump cover;

- c - on the generator drive pulley;

- g and e - on the front cover of the toothed belt;

- e - on the rear cover of the toothed belt;

- g—on the camshaft pulley.

If the valve timing is set correctly, then when the piston of the first cylinder is in V. m.t. at the end of the compression stroke, mark e on the rear cover of the toothed belt should coincide with mark w on the camshaft pulley, and mark a on the crankshaft drive toothed pulley should coincide with mark 6 on the oil pump cover.

When the camshaft drive cavity is closed by the front cover, the position of the crankshaft can be determined by marks c and d on the generator drive pulley and the front toothed belt cover. When the pistons are in position. m.t. mark c on the generator drive pulley should align with mark d on the camshaft drive cover.

Repair of VAZ 11113 Oka

The Oka car has high maintainability; servicing the car is very simple. But the disadvantage of the VAZ model is that it constantly requires repairs - something is bound to break. The reason for regular breakdowns is the short service life of many parts and the low quality of spare parts.

The most common chassis parts that fail are:

- ball joints;

- steering tips;

- hub bearings.

It is not so rare for CV joint boots to tear, both external and internal. If you don’t take care of the boot in time, the “grenade” begins to “crunch”, and the hinge also has to be changed. Brake hoses don't last long and the rubber on them cracks.

Electrical problems at Oka constantly arise:

- short the wires;

- the ignition coil fails;

- breaks through high-voltage wires;

- The electric cooling fan stops working.

Of course, all of the above applies to used cars with a solid mileage, but the car has not been produced for a long time, and it is difficult to buy a car in perfect condition.

The VAZ-11113 must be driven through puddles very carefully - if the ignition module gets wet, the car cannot be started. Many drivers try to isolate the reel from moisture, for example, by wearing a rubber glove. For such a “crumb”, the service life of its engine is not bad; during normal operation, the engine can be maintained for 120-150 thousand km without problems. It is important to monitor the performance of the electric cooling fan - if it fails, the internal combustion engine overheats, and then its service life is noticeably reduced.

Unlike the standard VAZ 4-cylinder engine, the Oka engine is equipped with balancer shafts for more stable operation. If for some reason the balancing goes wrong, the internal combustion engine begins to operate with terrible vibration.

The gearbox (4-speed manual) is quite reliable, and there are no chronic diseases. The only drawback is increased howling, but this defect is typical for many front-wheel drive VAZ cars and does not affect driving performance in any way.

Repairing a VAZ 11113 Oka is generally inexpensive, and spare parts for the car are cheap. It is relatively expensive for a car owner to repair a gearbox at a car service center - it is difficult to remove and install the gearbox.

Adjusting cylinder clearances

There is a gap between the valve stem and the valve cam in the Oka engine, which compensates for the expansion of parts during operation. The size of the gap affects the opening and closing of the valve, so this must be monitored every day.

Checking the gap is carried out only on a cold Oka engine - all parts in this case are in standard condition. The minimum exhaust valve clearance should be 0.35 millimeters, the intake valve should be 0.2 millimeters. If these parameters are not observed, unstable operation of the Oka engine is observed.

The valves are counted from the camshaft: the first and fourth valves are the exhaust valves, the second and third valves are the intake valves. The valves can be adjusted in any order - there is no need to follow the order.

Opinions about the Oka car

There are many conflicting opinions about the VAZ-11113 car - this car has many positive qualities, but the reputation of the vehicle is greatly spoiled by poor build quality and a high percentage of defective parts. Among the positive aspects, car owners note:

- excellent maneuverability - the car can be easily parked almost anywhere, in city traffic it is quite easy to change from one lane to another;

- surprisingly roomy trunk - with the rear seats folded down, a lot of things fit into it;

- good cross-country ability - thanks to the narrow wheel track, small size and light weight, the Oka does not get stuck in snowdrifts and confidently climbs out of shallow mud;

- low fuel consumption.

There are also a lot of disadvantages in a VAZ car:

- the suspension does not cope well with Russian rough roads - it is quite flimsy, the miniature R12 rims bend even from a small impact;

- the car does not have high anti-corrosion resistance; bodies and body parts rust especially quickly on cars produced after 1995;

- Okushka's security is low;

- You need to drive a car through water carefully - the ignition coil stops working if it gets wet, and in rainy weather the spark plugs become damp;

- the quality of spare parts is low, especially if they are non-original parts;

- The original mirrors are small and inconvenient - almost nothing is visible in them.

To summarize, we can say that the VAZ-11113 is a very good car, but it requires constant care, and it was created for people with “hands”. If you do not monitor the technical condition of the car, the Oka will quickly “crumble”.