What is DSG

The abbreviation DSG stands for Direkt Schalt Getriebe, or direct gearbox. The design of the unit uses 2 shafts, providing rows of even and odd speeds. For smooth and fast gear switching, 2 independent friction clutches are used. The design supports dynamic acceleration of the car while increasing driving comfort. Increasing the gearbox stages makes it possible to optimally use the capabilities of the internal combustion engine while simultaneously reducing fuel consumption.

History of creation

The idea of creating gearboxes with a preliminary selection of stages appeared at the beginning of the last century, the author of the design was Adolf Kegress. In 1940, a 4-speed gearbox developed by engineer Rudolf Frank appeared, which used a double clutch. The design of the unit made it possible to switch stages without interrupting the power flow, which was in demand in the commercial equipment market. The designer received a patent for his invention, and prototypes were made for testing.

At the end of the 70s. A similar design was proposed by Porsche, which developed the 962C racing car project. At the same time, the same gearbox with a dry double clutch was used on Audi rally cars. But further implementation of the units was hampered by the lack of electronics capable of controlling the operation of clutches and gear shifting.

The advent of compact controllers made it possible to begin the development of double-clutch transmissions for mid-price cars. The first version of the classic DSG gearbox with 2 clutches went into mass production at the end of 2002. Borg Warner and Temic took part in the creation of the unit, supplying clutch, hydraulics and control electronics elements. The units provided 6 forward speeds and were equipped with a wet clutch. The product received the factory index DQ250 and allowed transmission of torque up to 350 N.m.

Later, a 7-speed dry-type DQ200 gearbox appeared, designed for engines with a torque of up to 250 N.m. By reducing the oil sump capacity and using compact drives, the size and weight of the transmission have been reduced. In 2009, an improved wet-type DQ500 gearbox, adapted for use on vehicles with front-wheel drive or all-wheel drive, went into production.

The design of the unit is designed for installation of gasoline or diesel engines with a maximum torque of up to 600 N.m.

How does the DSG gearbox work?

At the moment, there are two transmission modifications: a six-speed with a “wet” clutch and a seven-speed. Each has some features or disadvantages, but more on them a little later. 7-speed consists of:

- First output shaft.

- Second output shaft.

- Main gear.

- Primary shaft.

- Mechatronic.

- Oil filter.

The first cars with DSG were cars from the Volkswagen AG line. They were the ones who came off the assembly line and announced this technology to the whole world. This gearbox is still manufactured at the plant to this day. So what is a DSG gearbox? It consists of 5 shafts, which are connected by gears and 2 clutches. With this technology they form a unique mechanism that is very different from classic gearboxes. It is he who is responsible for the rapid acceleration of the car and high speed, as in cars with mechanics.

DSG internals

Due to the fact that gear changes occur very quickly, DSG gearboxes have begun to be introduced into sports cars, where it is very important.

What is the difference between a dual-clutch transmission and a manual transmission?

The newest gearbox works very quickly and smoothly. All gears change instantly - this is a trump card for racing cars, where speed comes first. The transmission differs from the mechanics. Let's recall the operating principle of a manual transmission:

- When the driver engages the clutch, the engine is separated from the transmission, thereby stopping the flow of power to the gearbox.

- After moving the gearbox lever, the gear coupling moves from one gear to another, even though they are different in size.

- During this process, the rotation speed of the clutch is gradually equalized, which leads to the engagement of the next gear.

- When the clutch pedal is released, the transmission is reconnected to the engine, torque is released, which turns the car's wheels into rotation.

We recommend: How to check the engine oil level correctly

How DSG works

The fundamental difference between a preselective automatic transmission and others is in two clutches that quickly change gears. In a manual or robotic gearbox, to change gears, the clutch disc is disconnected from the flywheel, the driver or robotic computer selects the desired “speed”, and after that the disc snaps into place. During this time, torque is not transmitted to the box and the car loses dynamics.

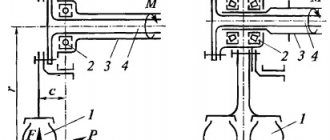

The DSG system allows you to get rid of power failures. The box is based on the operation of two shafts located coaxially: the first is hollow, and the second is inside it. The engine is connected to each of them through its own, separate multi-plate clutch - also external and internal. The gears of the even gears (2nd, 4th, 6th) are fixed on the primary, that is, the outer shaft, and the gears of the odd gears (1st, 3rd, 5th and reverse gear) are fixed on the inner shaft.

When the car starts, the odd-numbered disk is pressed against the rotating flywheel, while the even-numbered “speed” disk is open. During acceleration, the computer unit of the box gives the command to prepare the second gear, so that at the moment it is turned on, it disconnects the odd-numbered row disk and immediately puts the even-numbered disk into operation. Tuned shift control ensures no loss of torque.

The DSG 6 robotic gearbox entered the Volkswagen assembly line in 2003. The double clutch on it operated in an oil bath, receiving the name “wet”. The oil in such a box takes away some of the power, increasing fuel consumption. In 2008, the German automaker introduced a seven-speed DSG 7 with a dry clutch.

Varieties

Robotic gearboxes can be of two types - DSG 6 and DSG 7. The first appeared in 2003 and operates with a “wet” clutch. The main disadvantage of such a DSG is considered to be the loss of vehicle power due to transmission fluid. Five years later, DSG 7 appeared, operating on a “dry” clutch. Next, let's look at the structure, properties and differences between these two units.

DSG 6 box

DSG 6

As is already clear, the DSG 6 gearbox is an improved six-speed manual gearbox. Such boxes have two primary shafts and two secondary ones, one of them is external, and the other is internal, that is, located inside the first. Each of them is connected to the motor through a clutch. The outer shaft is responsible for even gears, the inner one for odd ones.

Direct gear shifting is controlled by an electronic unit. He does this, of course, automatically based on speed sensors, the position of the gas pedal, and other vehicle systems. Such units are much more economical and faster than conventional mechanical ones, and in terms of their dimensions, weight, smoothness of gear shifting and torque transmission, they are in no way inferior to automatic transmissions. Their main disadvantage is their high price. This also applies to repairs.

DSG 7 gearbox

DSG 7

This DSG box consists of four hundred parts, but its weight does not exceed 70 kg. The first way this unit differs from its predecessor is the dry clutch. This is not to mention the design advantages. DSG 7 significantly reduces the amount of oil needed for the box (about 1.7 liters compared to the standard - 6.5 liters). In the system, transmission fluid is used exclusively to lubricate gears and bearings (in traditional automatic transmissions, a lot of oil is used to cool the clutch). As a result, the car is provided with a higher efficiency of the gearbox, which allows reducing gasoline consumption.

All components of the DSG 7 system, including electronic control and shafts - primary and secondary - work harmoniously with each other, as a result of which each subsequent transmission speed is ready to switch and awaits only a signal. The process of changing gears occurs in an instant, and when driving fast this effect is especially noticeable (even with the most dynamic gear changes you will not notice an interruption in the flow of power). The main advantage is the relatively low cost for the consumer, but DSG 7 also has its drawbacks. In particular, jerks are noticeable at start-up, and if you often get stuck in traffic jams, then wear on the unit increases.

Automatic transmission DSG 6 disassembled

We recommend: What is the difference between an injector and a carburetor in a car?

DSG benefits

- The DSG box, due to the optimal modes of switching on the desired “speeds”, allows you to reduce fuel consumption. Cars with it consume about 10% less fuel than cars with a conventional gearbox.

- A distinctive feature of all such transmissions is dynamic acceleration. To shift up a gear, the box needs only 8 ms; it does not have the effect of rubber traction as on hydromechanical automatic transmissions.

- You can drive the DSG in manual mode, that is, change gears manually.

- This automatic transmission is 20% lighter than a similar hydromechanical transmission.

Typical breakdowns

If the diagnostic shows errors 21096 P073A, 21097 P073B, 21094 P072C or 21095 P073D, then this indicates problems in the mechanical part.

First of all, the gear forks fail. Here they move using a ball bearing bushing. And, as it turned out, it cannot withstand the load, because the hydraulics perform shifts very quickly and harshly. Once the bushing is damaged, its inner plate is sent floating around the box, causing damage to the gears and creating metal debris. The latter not only acts as an abrasive, but also clogs the Hall sensors, which are needed by the mechatronics to control the box. In case of serious damage, balls may fall out. They are more difficult to grind, but the box can handle it. But there will be even more losses.

It is not only the first and second gear shift forks that are damaged, as many people think. The sixth-rear fork breaks just as often. The design of the bushing bearings is fundamentally the same. After 2013, and on repair forks, the design of the bushings was completely replaced, they became solid. Nominally, the service life of such a design without a ball bearing is shorter, but it does not break, and purely resource problems have not yet manifested themselves. This is exactly the design installed on 0CW.

The remaining failures of the mechanical part of the box are in most cases considered secondary, associated with oil contamination due to broken rods. Thus, failure of the differential, chipping of gears, complete destruction of the seventh gear and overheating of the bearings in most cases are caused precisely by the presence of metal dust in the oil, a product of the destruction of the forks. By themselves, they rarely happen, and are usually associated with engine tuning or missed oil levels. Well, or unsuccessful assembly of the box: like any manual transmission, the DQ200 is sensitive to the accuracy of assembly and tuning.

Breakage of the differential can be a completely independent problem: the satellites are welded to the axle under increased load due to an unsuccessful design, and not due to any other problems.

Fault numbers P175 21062/21184 and P176E 21063/21185 indicate problems with clutches and their wear.

Failures of the clutch block and dual-mass flywheel are considered by many to be beyond the list of failures of the DSG itself, but in fact, these are its integral parts. The flywheel wears out during serious torsional vibrations, during starts, slipping of clutches and wheels, when driving over uneven surfaces under traction, and similar situations. Wear accelerates overheating and contamination of the structure.

314424 9 45 08/13/2014 Articles / Practice What’s wrong with the DSG gearbox? There are many different horror stories circulating among motorists. One of the most popular today is about DSG robotic gearboxes on Volkswagen cars. Jerks, failures in traction and...

The clutch block also does not like dirt, but the complex design has many more vulnerable points. But the main thing for us is that with a replacement price of about 50 thousand rubles, new versions of this unit are simply more reliable and better maintain gaps during operation. Since 2012, installing a shield on the hole for the release rods has made it possible to significantly reduce contamination of the clutch housing and their wear. Adjustment of the working gap is the responsibility of the master, and the general list of typical violations during assembly is almost a dozen items.

Also, the clutch unit suffers greatly if the driver does not work properly with traction in traffic jams and on rough terrain. By the way, both clutches are normally open, so there is absolutely no need to put the box in neutral to reduce the load on the mechatronics and clutch in traffic jams. But the knot still remains quite complex and expensive. And very vulnerable to driver and technician errors.

However, the service life of even the first versions of the unit can be a very respectable 150-250 thousand kilometers or more. And in terms of service life stability, the latest versions have greatly improved: after 2012, there are almost no cases of clutch block wear before a mileage of 100 thousand.

What is the difference between DSG6 and DSG7?

There are two types of DSG. The first, in 2003, was the six-speed DSG6 gearbox. The double clutch in it was “wet”, that is, it worked in an oil bath. The main disadvantage of the box is significant power loss due to oil. Therefore, in 2008, Volkswagen introduced a new version - DSG7. This box uses a dry clutch. It was this box that became problematic. When choosing a car with DSG, always pay attention to whether it uses a six- or seven-speed unit. DSG6 can be taken without a doubt, but DSG7 is better left to those who are not well versed in technology.

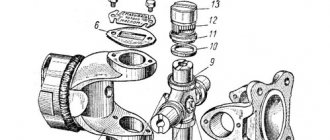

Diagram of DSG 6 (Fig. 1) and DSG 7 (Fig. 2)

The transmission is equipped with five shafts, gears and 2 clutches. This dual-circuit transmission system allows you to transmit torque smoothly and without loss. That is why cars equipped with this gearbox pick up speed much faster than cars with manual transmissions. Today, this automatic transmission is widely used in many sports cars. Also, thanks to the presence of the Tiptronic system, DSG technology allows manual gear shifting.

Overview of the box and the principle of its operation

The DSG gearbox switches gears without loss of power flow, which greatly improves its purchasing qualities compared to other robotic gearboxes. In particular, we are talking about such qualities as excellent car dynamics during acceleration, gas savings, etc.

Continuous supply of torque from the motor to the drive axle was achieved thanks to two clutches and two rows of speeds corresponding to them. The “seven-speed” (seven-speed gearbox), as a rule, is installed on passenger cars of classes B and C. In turn, the “six-speed”, thanks to the achievement of a torque of 350 Nm (on seven-speed gearboxes this figure is 250 Nm), is installed on more powerful auto.

Automatic transmission DSG 6

As for the design of such a gearbox, it includes:

- dual-mass flywheel;

- double hitch;

- two speed ranges;

- main gear;

- differential;

- control system.

All structural components are located in the DSG housing. The operating principle of the unit is described below.

In the case of a robotic gearbox, the first clutch of the two operates in reverse gear and the rest are odd. Only even-numbered gears operate through the second clutch. This arrangement of the box between the stages allows for a smooth transition from one gear to another. When a car accelerates, the acceleration itself, of course, occurs at first speed. At this moment, the second gear gear is engaged.

The very moment of the gear change is determined by the computer. When it switches, the DSG wires simultaneously release the first clutch and close the second tightly. There is a transition of torque moving from the engine to second gear. This process is repeated until sixth gear, after which everything happens in reverse. When the last speed (sixth or seventh) is turned on, the gear of the previous one (fifth or sixth) simultaneously begins to rotate.

We recommend: The radiator fan is the creator of the wind under the hood of the car

DSG 7

DSG-7 was developed in 2006 specifically for economy class cars. The DSG box weighs 70-75 kg. and contains an oil volume of less than 2 liters. This gearbox is installed on budget cars with an engine torque of no more than 250 Nm.

At the moment, DSG-7 is mainly installed on the following cars:

- Audi (TT, Q3, A3);

- Seat (Leon, Ibiza, Altea);

- Skoda (Octavia, Fabia, SuperB);

- Volkswagen (Tiguan, Golf, Jetta, Passat).

The main difference between the DSG-7 and the DSG-6 is the presence of 2 dry clutch discs that are not in the transmission fluid. Such changes made it possible to reduce fuel consumption and reduce the cost of service.

How to use the DSG box correctly

Let's start with the fact that DSG provides excellent acceleration dynamics and fuel efficiency inherent in a manual transmission, as well as the comfort of a “classic” hydromechanical automatic transmission. As a result, the preselective robot has become one of the most promising types of gearboxes.

Moreover, even taking into account the similarity with an automatic transmission in terms of operation, as well as with a manual transmission in design, the operation of a car with a DSG is somewhat different from an automatic, manual and simple single-disc robots (AMT gearbox).

Moreover, some nuances arise even depending on what type of DSG is installed on a particular car model. For example, the DSG-6 box is “wet” (the clutch operates in an oil bath), while the DSG-7 is “dry”.

- At the same time, the clutch discs, both in the first and second cases, wear out, and in the case of the DSG-7 this happens faster. This means that an aggressive driving style, sudden acceleration from a standstill, slipping, etc. for DSG-6 are still acceptable, but the same cannot be said about DSG-7.

The fact is that a clutch in an oil bath is more protected from wear and overheating than its “dry” counterpart. Also, the DSG-6 was initially designed for higher torque (about 350 Nm), while the 7-speed version “digests” no more than 250 Nm.

In practice, this means that chip tuning and harsh operation will quickly damage the DSG-7. It is worth mentioning cases when such a gearbox did not last more than 50-70 thousand km. from the moment of purchase and required expensive repairs.

- It is important to understand how to use DSG in a traffic jam and operate a car with this gearbox within the city. First of all, in order to save fuel, the DSG in automatic mode usually quickly switches from first to second gear. Moreover, if the driver further presses the brake or does not accelerate, the transition to first gear occurs again.

It turns out that with such jerky driving, accelerated wear of the gearbox and clutch occurs, the clutch overheats, etc. To avoid this, it is optimal to switch to manual control using the semi-automatic mode of the box. To put it simply, the driver independently engages first gear and does not switch to second if such a situation arises on the road.

- Another thing to note in the list of rules that can increase the life of the DSG is the need to actively press the brake pedal when switching modes. If the brake is not fully depressed, the DSG does not fully open the clutch discs, thereby increasing wear.

Also, the rule of switching to “neutral” when stopping, which is relevant for “single-disc” robots, affects the DSG to a lesser extent. In other words, switch to N mode at traffic lights and when idle for up to 60 seconds. there is no need, since frequent switching only increases wear. Moreover, when the brake is fully pressed, the box itself opens the clutch.

You need to know that the DSG gearbox (especially the 7-speed gearbox) is “afraid” of slipping even more than an automatic transmission. This means that slipping in mud, on ice, when starting from a standstill in manual mode, etc. forbidden.

We also recommend reading the article about how the DSG gearbox works. From this article you will learn about the design of the DSG gearbox, as well as the operating principles and features of this type of gearbox.

Also, when setting the vehicle to “parking” mode, it is necessary to use the parking brake in order to extend the life of the limiter (locking mechanism), which prevents the vehicle from rolling back. Switching between modes should be smooth, with a slight delay of about 1 second. During this time, the electronics will have time to “adjust.”

- It should be added that a car with a DSG should not be overloaded by towing a trailer or other vehicle, as well as by transporting various cargoes in the car itself. In practice, an initially heavy car with DSG-7 (for example, a Skoda Superb) with a full passenger compartment and additional cargo can weigh about two tons. Given that the box is not designed to withstand heavy loads, such a robot may unexpectedly fail.

As for the DSG-6, this gearbox is more durable and is installed in conjunction with powerful engines. However, this does not mean that a car with such a transmission can be constantly used as a tow vehicle.

Main problems of DSG7 - video

Weak points of mechatronics

The weakest points are the mechatronics and clutch.

DSG 7 - disadvantages

There are car enthusiasts who are not 100% satisfied with the performance of this transmission. What could they not like and what problems arise in the DSG ?

Is the DSG7 gearbox that good?

— The appearance of jerks and vibrations in the DSG when changing gears. This drawback is caused by the fact that DSG clutch begins to wear out. The result is the same effect if you do not depress the clutch pedal when changing gear in a car with a manual transmission. In a word, the vibration spreads throughout the entire body, depending on the state of the clutch, and progresses until the gearbox completely fails.

— Extraneous noises under the hood. Mainly metal parts when driving over speed bumps.

— Reduced traction when accelerating the car. This problem is known to the developers and they promise to fix it soon.

DSG 6 device

DSG 6 (model DQ250) was developed in 2003. At the factory, the box is labeled as VW02 E, a distinctive feature of this box from the 7-speed “older friend”, released three years later, is the so-called “wet clutch”. This means that the gearbox disc packs are constantly immersed in an oil bath and operate under conditions of constant lubrication and cooling. This significantly increases the resource of both the discs themselves and the box as a whole.

Schematic structure of the box:

Main building blocks:

- double clutch box;

- crankcase;

- differential box;

- two rows of gears;

- control unit of the Mechatronic box;

- main gear.

The double clutch transmits torque to the gearbox's rows of gears. The drive disk of the box is connected to the friction clutches and the flywheel by a special hub, which also combines the gears.

The first row of gearboxes operates with odd gears and reverse gear. The second, accordingly, serves the remaining stages of the transmission.

The ECU is located in the box body, in the crankcase.

An equally important element is the electro-hydraulic unit, which carries out all the physical operations of changing gear ratios in the box. Its main components:

- control and solenoid valves of the box;

- multiplexer generating a control signal;

- box distribution spools.

When the driver moves the gearbox selector to one of the positions, the gearbox distributors are activated. Gears are changed using solenoid valves, and the clutch clutches are adjusted by pressure valves. Therefore, these valves can be called the “heart” of the box, and “Mechatronic” - its “brain”. The DQ250 box multiplexer controls the hydraulic cylinders. In DSG 6 there are 8 of these, but a maximum of 4 box valves are activated at the same time. When the multiplexer uses one mode or another, different cylinders are activated, depending on the gear selected on the gearbox.

Typical DSG gearbox selector:

Thus, the DSG 6 box operates on fairly simple shifting algorithms, changing gears cyclically. At one point, two rows of gears are engaged, but the second (currently inactive) is still working, just not being used. If the gearbox changes the gear ratio, the row is engaged without restarting, entering the activity phase. This allows you to reduce the gear shift time literally to a fraction of a second, making the car move smoothly and accurately, without the “thoughtfulness” typical of “slower” gearboxes. And this approach made it possible to give the box the name “preselective”, since the desired gear is always ready for work.

An important point is that gearboxes built on DSG technology are equipped with the Tiptronic system, which allows you to switch the gearbox to manual control mode.

Operating instructions for DSG 6

You need to understand that DSG, both six- and seven-speed gearboxes, are relatively new transmission models. Even if the switching occurs in automatic mode, we cannot say that this is a familiar “automatic” or even something as close as possible to it. Therefore, there are a number of rules that drivers of cars with a robotic gearbox should know. Compliance with them will increase the life of the system and protect it from breakdowns. This is extremely important, since repairing a DSG 6 is not a cheap pleasure.

How to change the gearbox oil yourself

The process consists of several stages.

- Lifting the car onto a lift or driving into a viewing hole.

- After this, the engine should be turned off and the gearbox selector should be moved to the Parking position.

- Next, the drain plug of the box is unscrewed.

- After this, about a liter of old transmission fluid will pour out of the transmission pan. Next, use a hex wrench to remove the control tube, and the remaining oil from the automatic transmission will begin to flow.

Important: you should visually check for the presence of foreign matter in the oil, for example, metal shavings. If they are present, the box is in poor condition and will soon break; an early visit to the service center is advisable.

- Next, you will need to remove the oil filter of the box, for which you will have to dismantle the battery and its mounting platform, and for convenience it is better to remove the air filter with air ducts.

The box filter cover is unscrewed two turns, then you should wait until the remaining liquid drains into the crankcase cavity, remove the entire cover and replace the filter.

- The next step is to fill the box with new oil.

You can do this directly through the filter housing, but the process will then take quite a lot of time; a liter of liquid will be poured into the box for about 10 minutes.

You can do it differently by purchasing in advance an adapter for the hole in the oil drain plug with a transparent hose about 2 meters long. One end is screwed into the hole in the box, and a funnel is attached to the other, which should be secured, for example, to a side mirror to create a height difference. You need to pour 5-6 liters.

- Then you should start the engine and warm up the box by sequentially switching the accelerator modes.

This is necessary so that the oil in the box warms up and the driver can control its level. Next, the funnel is unscrewed and the remaining oil bottle/canister is placed in its place. The container is placed below the box - that is, on the floor. Excess liquid will flow into the vessel. When the flow stops and only small drops remain, the adapter is unscrewed and the plug returns to its place.

There is no need to tighten it tightly just yet. Engine transmission modes, selector returns to Parking.

- Next, the plug is unscrewed again; if there is excess oil left, it must be allowed to drain to the level of the overflow hose.

If they are absent, the adding procedure is repeated until the desired level is reached. Once completed, the DSG plug, together with the seal, is screwed into its standard position.

According to official recommendations, it is extremely important that the oil temperature during checks is 35 degrees. This is why you need to “warm up” the DSG box.

In car services, the temperature parameters of the fluid are controlled by a special device, another car computer/program with a VAG-Com communication interface:

Without the device, you will have to rely solely on tactile sensations, which, in theory, can lead to over- or underfilling of oil, which are equally harmful to the DSG. In practice, many car owners carry out the procedure themselves, without damaging the automatic transmission.

As you can see, the DSG 6 transmission, despite its rather complex technical design, shows fairly high reliability if proper operating rules are observed, and the oil change service procedure is accessible even to a simple car enthusiast without special knowledge. The DSG box provides high dynamic performance of the car and a level of user comfort.

Changing the oil in DSG 6

Finally, we’ll briefly talk about how the oil is changed in DSG gearboxes. The process looks unusual from the outside, although it is not difficult.

Mechanics use a special large syringe designed for working with robotic boxes. Oil is poured into the gearbox from below, having first checked the oil for the presence of chips. It is noteworthy that changing the oil in a robot box yourself is almost impossible without special tools.

The effect after changing the oil is very noticeable. If you've been driving with a DSG for at least a year, then after replacing it feels like you've literally been given a new gear shift system. The car moves much more smoothly, and various braking and jerking, which may sooner or later appear when using DSG 6, disappear after changing the oil for a long time.