Trying to meet the stringent economic and environmental requirements dictated by the market, developers of modern vehicles provide them with a large number of complex devices and mechanisms. One of the most complex units installed on a car is an automatic transmission.

The service life of the part, depending on the model, is 100,000 - 700,000 kilometers, some break down more often, once every 1-3 years. Unfortunately, a breakdown or failure of the box requires expensive repairs or replacement entirely. Not every owner can afford this, the way out of the situation is a contract automatic transmission.

Contract automatic transmission - what does it mean?

When using an automatic transmission, a situation often arises when, if the mechanism breaks down, it is not advisable to replace the failed part, since the gearbox mechanism has significant wear and requires complete replacement. A new gearbox is expensive, so it’s not surprising that the concept of a contract automatic transmission is popular.

A contract box is a restored, functional product that was serviced in a factory environment in compliance with the requirements, tolerances and fits laid down by the developer during the design. Boxes are restored by manufacturers; such units are covered by a warranty, which minimizes the risk of receiving a low-quality product.

When accepting a used box for restoration, the workshop carries out a full diagnosis of the product, components and assemblies. Defects are identified, tests are carried out, on the basis of which a decision is made whether the box is suitable for restoration or not. Only serviceable units are restored using original factory parts.

When choosing a remanufactured automatic transmission, it is recommended to follow the following rules:

- The room where the box is stored is clean, dry, ventilated;

- There are no mechanical damages on the box: dents, cracks, chips, etc.;

- The box contains a standard sample probe;

- Working lubricant of the box: the color of the oil is not black, the viscosity meets the established standards, there is no burning smell.

- Technical openings are hermetically sealed.

Contract automatic transmission: subtleties and nuances

First of all, the basis for unit replacements are usually serious breakdowns, when repair of a particular unit is simply impossible or the feasibility of repair is called into question, it is extremely unprofitable to carry out repair operations economically, it is difficult, etc.

Also, units are changed for the purpose of modernization, tuning the car, as part of various complex modifications (for example, replacing the engine with a more powerful one, replacing a manual gearbox with an automatic one and vice versa, etc.).

So, contract automatic transmissions are used automatic transmissions that were removed from various cars for one reason or another. Often we are talking about units that come to the territory of the CIS countries from Europe, Japan or the USA.

Typically, such boxes are much cheaper than new automatic transmissions. Also, often the cost of such units is comparable to the cost of high-quality repair of an automatic transmission, which makes this solution quite popular among car enthusiasts.

Moreover, replacing an automatic transmission with a contract automatic transmission in some cases is faster and easier than repairing an automatic transmission.

- As it may seem, the advantages are obvious, since if an expensive overhaul of the old box is necessary, you can simply replace it with a contract one. However, in practice, it is imperative to take into account a number of nuances associated with the acquisition of contract gearboxes, engines and other components and assemblies.

Let's start with the fact that large sellers who sell contract spare parts usually value their reputation by purchasing used spare parts only from trusted suppliers abroad. As a rule, the accompanying documents contain information about the mileage of the car from which the unit was removed.

Then the automatic transmission is carefully checked by the dealer himself, after which it is sold officially, since all the accompanying documents (customs declarations, etc.) are available. A warranty is also provided (especially in the case of installation in a service that is a dealer, that is, a partner).

As a rule, such parts usually have a fairly large residual life and can work properly and efficiently for more than tens of thousands of kilometers, which is especially important in the case of automatic transmissions.

Moreover, often such boxes have not been repaired and consist 100% of original spare parts, which is an advantage compared to automatic transmission repair, when some parts can be replaced with analogues from third-party manufacturers (not always of high quality).

- Now about the nuances, since there are also disadvantages to buying a contract automatic transmission. First of all, even thorough checks may not reveal hidden defects, which means there is still a possibility of the box failing.

However, this is not even important. Please note that when purchasing contract spare parts, you should not chase the lowest price, and you also need to pay increased attention to the integrity and professionalism of the dealer who selects and sells contract units.

You will also need to separately clarify details regarding the warranty policy, conditions for return or repair under warranty, replacement in case of serious defects, etc. The fact is that a situation often occurs when the automatic transmission was initially incorrectly selected, since the type of automatic transmission was incorrectly determined.

Another problem can arise as a result of the fact that when trying to install a contract automatic transmission, mistakes are made due to the unprofessionalism of the installer, which leads to breakdowns and malfunctions of the unit.

Also, unscrupulous dealers can sell a reconditioned automatic transmission, that is, such a transmission was first repaired (not always efficiently), after which it is sold as a contract one in excellent condition at a bargain price.

Often units with high mileage are sold at a low cost, the resource of which is almost exhausted, that is, expensive repairs will soon be required. The main advantage of such automatic transmissions is their affordable price. Remember, a contract transmission with a guarantee in good condition cannot cost much less than a major overhaul of an automatic transmission.

Let us also add that in pursuit of profit, unscrupulous suppliers who do not have their own spare parts warehouses may quote short selection and delivery times. However, in reality, delivery in this case takes 1.5 - 2 months or more.

Contract automatic transmission or repair

When buying a remanufactured transmission, you need to take into account all the positive and negative aspects. When trying to find an alternative to a damaged mechanism, the vehicle owner has the following options:

- Used automatic transmission.

- Repaired automatic transmission;

- Contract automatic transmission.

Considering the cost of a contract automatic transmission, service life, and quality of factory assembly, it is the best option. The contract box is of better quality than unknown analogues; its parts and mechanisms are of original origin and in good condition, since low-mileage cars are sent for disassembly. The key to long and correct operation of the unit is its correct selection, in accordance with the characteristics of the originally installed original.

Choosing the right contract automatic transmission is difficult, since various modifications differ in parameters; only experienced specialists can determine the reason why the gearbox, with other similar characteristics, is not suitable.

For correct selection, the product labeling is studied. This will help determine whether the product is compatible with a specific car brand, and will also provide information about the parts and lubricants used. The marking is applied directly to the box or to a metal plate attached to the product.

If the information on the box and plate is not visible, they resort to searching by the car’s VIN number. By decoding this number, complete information about the car and equipment will be available. This coding is popular among vehicles produced in Europe and the USA; a contract automatic transmission from Japan may not be equipped with a VIN number. In this case, the selection is carried out according to brand, modification, engine size and other parameters.

What is a contract detail

In Europe there is a practice for recycling cars. Not all elements of a written-off car are hopeless. Let’s take a closer look at what happens to written-off cars:

- Each car is completely disassembled and parts are removed.

- They identify elements that have not exhausted their resource.

- Suitable parts are diagnosed.

- Based on the results, rapid restoration is carried out using factory equipment.

- Remanufactured parts are tested at different levels.

- Functional parts with a manufacturer's warranty are either installed in cars by manufacturers, or go on sale renamed as a “contract part.”

There are both automatic transmissions (automatic gearboxes) and manual transmissions (manual gearboxes).

Advantages of contract boxes:

- The box consists of original parts installed at the factory, which guarantees the quality of the mechanism;

- Since contract parts are removed from cars with low mileage, the service life of the box is high, information about mileage is available in the accompanying documents;

- The product was assembled in a factory environment, which also speaks about the quality of the box;

- Gain in time. By changing the entire box, there is no need to figure out what caused the breakdown of the previous box, look for the necessary parts, or repair the unit;

Replacing the gearbox

Before replacing the gearbox, you should decide whether you will install an automatic transmission or the choice will fall on a contract manual transmission. For some time, contract gearboxes were at the peak of popularity; now both types of boxes are equally chosen for installation in cars.

Replacing an automatic transmission with a contract one is carried out for the following reasons:

- it is more profitable to buy a replacement instead of repairing an installed gearbox,

- desire to modernize your car,

- gearbox failure.

In cases where it is possible to repair an existing gearbox at low cost (the damage is minor), then there is no need to look for a contract replacement. Diagnostics of the box will help with this.

Prices for contract automatic transmissions

The advantage of a contract box over a new one is its price. There is no point in selling such a product for a lot of money, since at a high price it would be more expedient to repair a failed unit. This is why contract transmissions are much more affordable and preferable.

In addition, contract products are removed from the car long before the need for major repairs, unlike restored and repaired analogues, so they can be safely ordered, having selected the required option in advance. In order for the automatic transmission to work better, complete maintenance must be carried out before installation on the car.

Contract engine and gearbox - all your risks. Expert advice

We often hear that instead of repairing a unit, the owner prefers to buy a contract unit. Not everyone knows what lies behind this name. “Behind the Wheel” helps you figure it out and choose the best option for purchase.

What is a contract engine or gearbox?

A contract engine or gearbox is a unit that has been removed from a damaged or scrapped car and put up for sale for further use for its intended purpose.

Another source of such units is the dismantling of stolen cars.

However, it is often difficult to trace the entire history of an acquisition.

Is a contract unit legal?

Recently, engine replacement does not need to be approved by the traffic police. The registration certificate does not indicate the number stamped on the cylinder block. Now replacing the motor is much easier. Well, gearboxes could have been changed before without approval from the traffic police.

In what case should you think about a contract unit?

While the car is protected by a warranty, there is no talk of a contract engine or gearbox. The malfunction will be repaired by official dealers. But the years go by, the car gets old, sometimes it changes owners, and then one of the two main units, the engine or the gearbox, fails. We are talking about a major breakdown, one might say, an accident of the unit. For example:

- A broken connecting rod, accompanied by a broken cylinder block wall, is the “hand of friendship”

- “Defreezing” of the engine, which is caused by freezing of water in the cooling system. When defrosting, cracks occur in the cylinder head and block.

- Cracks and warping of main parts, for example as a result of an accident.

- Scuffing of the crankshaft main liner, accompanied by damage to the bed in the cylinder block.

What's the result?

As you can see, contract automatic transmissions are a worthy alternative if serious repairs to the automatic transmission are necessary. Such units often come from developed countries, undergo customs clearance and are legally sold in the CIS.

Also, time costs when choosing a contract unit are minimized, since suppliers’ warehouses usually always have in stock almost all types and types of automatic transmissions for most popular cars of various models and brands.

Finally, we note that the successful purchase and installation of a contract automatic transmission directly depends on the choice of installation service and the supplier of such automatic transmissions. For this reason, the choice of dealer and specialists should be approached with maximum responsibility.

Which automatic transmissions are considered the most reliable: automatic transmission rating with a large margin of safety and a service life of 500 thousand km. and higher.

New automatic transmission: what to consider when purchasing. Why is automatic transmission repair in some cases more optimal than replacing the unit with a new one or a contract one?

What kind of resource do different types of automatic transmissions have: the average service life of an automatic transmission, a robotic transmission with one and two clutches, as well as a variator.

Noise or hum of an automatic transmission, howling of an automatic transmission: what malfunctions are indicated by various extraneous sounds during operation of an automatic transmission, diagnostics.

Automatic transmission for SsangYong Actyon: features, types of automatic transmission. Malfunctions of the Aktion BTR M11 automatic transmission: signs of problems, diagnostics, repair.

Pros and cons of a contract engine or gearbox. Advantages of contract units, possible nuances and disadvantages after purchasing a contract engine and gearbox.

Principles for selecting automatic transmissions

Finding a contract automatic transmission is more difficult than choosing a new one; sometimes there is no exactly the same model, so you have to look for a substitute. Selecting a suitable model is the seller’s task, and the buyer must accurately indicate which automatic transmission is installed on his car, since different modifications of the unit differ in a number of parameters. There are several ways to determine the type and modification of the “native” automatic transmission.

The easiest and most reliable way is to study the markings. The data given in the markings will help you buy the same or compatible gearbox, and select parts for its repair, as well as oil for maintenance. The marking can be applied to the automatic transmission itself or to a metal nameplate that is attached under the hood (underhood plate), or it can be duplicated here and there:

- on Toyota the marking is on the nameplate in the TRANS/AXLE line, it consists of 5 characters; The 1st character (letter A) means automatic transmission type, the 2nd (number) - series, 3rd - number of gears, 4th - gear ratio, 5th (letter) - model features. D – overdrive mode, L – lock-up clutch, E – ECT with lock-up clutch H or F – 4WD with lock-up clutch;

- On Honda, you need to look for the marking on the automatic transmission itself, on a sticker under the barcode, usually it has four characters. Marking allows you to distinguish a simple automatic transmission from a variator, a cable transmission from an electronic one;

- on Mitsubishi, the markings are duplicated on the automatic transmission itself and on the engine compartment plate, but there are only 5 characters on the plate. 1 – type of drive (F – front, W – full), 2 – number of speeds, 3 (letter A) – automatic, 4-5 – model. The full labeling contains information about compatibility with the motor, gear ratio;

- Nissan – the marking is also duplicated and contains information about the drive, gear ratio, number of steps;

- On Subaru, the marking is applied to the box itself, starting with the letters TZ, the presence of the letter B in the first part of the marking indicates a model with tiptronic.

Each manufacturer uses its own code system when compiling markings; the car owner does not need to be able to decipher the markings, but for a spare parts sales specialist, these numbers and letters will tell a lot and help him choose a suitable contract automatic transmission.

Sometimes the markings on the sticker are so worn out that they cannot be read. In this case, the search is carried out using the VIN number of the car, which encodes the most complete information about the vehicle’s configuration. But this coding is in use in Europe and the USA; a Japanese car may not have a VIN. It is also possible to select by make, model and modification (you must specify the engine size).

When determining the type and modification of an automatic transmission, in addition to the markings, you should pay attention to the following external features:

- number of pallets and their location;

- number of wires leading to control chips;

- location of sensors.

Automatic transmission - general principle of operation

In Europe, about 80% of cars sold are equipped with an automatic transmission. In the US this figure is even higher. In our country in 2015, 48% of cars with automatic transmission were sold. Moreover, only 10% of budget cars are equipped with an automatic transmission, while in the premium segment such cars are 80%. It follows from this that automatic transmission is very popular all over the world, so motorists need to learn more about the features of this box.

Before moving on to considering the pros and cons of automatic transmissions, you need to understand the nuances of the design and operation of an automatic transmission, as this affects its advantages and disadvantages.

In an automatic transmission, speeds are switched without driver intervention (in automatic mode). The “heart” of the machine is a hydraulic transformer. It is the box with this device that can rightfully be called an automatic machine. This is how it happened historically. The first automatic transmission appeared in the 30s of the last century. Naturally, modern “automatic machines” are very different from the boxes of the middle of the last century, but the principle of their operation remains the same.

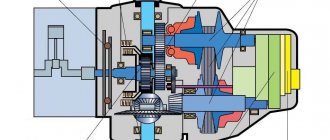

Any automatic transmission consists of the following elements:

- A hydraulic transformer that transmits forces from the motor to the drive wheels. This is the main element of any “machine gun”.

- Planetary gear, which transmits the torque of the power plant to various parts of the box.

- A friction clutch that changes gears when it receives a signal from the electronic control unit.

- Overrunning clutch, which protects automatic transmission parts from impacts, jolts and protects the friction clutch from vibration when shifting gears.

- Connecting mechanisms (various shafts, drums and gears).

The hydraulic transformer includes a centrifugal pump connected to the engine crankshaft and a turbine connected to the box crankshaft. These elements, working together, perform clutch functions.

On early automatic transmission models, gear shifting depended entirely on the position of the accelerator pedal, but on modern gearboxes, an electronic unit is responsible for this. Naturally, the position of the gas pedal is important, but the electronic unit additionally processes information from various sensors and makes appropriate decisions about changing gears.

When the driver presses the gas, the engine torque is transmitted to the torque converter. The electronic unit processes the available information and turns on the necessary transmission.

When we understand the general structure and operating principle of the “machine”, we can move on to considering its advantages and disadvantages.