If you are the owner of a car with an injection engine, you should know that for the injection system to work properly, it requires working injectors. You can check the operation of the injectors of an injection engine and troubleshoot problems with their operation yourself; you don’t have to immediately rush to a service station.

The concept of injector nozzles and the principle of their operation

Injectors are required to dose fuel into the combustion chambers of the engine. In the fuel system, they allow gasoline to be mixed with air. Thus, a flammable mixture is formed, which then ignites.

The injectors are:

• Electromagnetic - the valve monitors fuel access and regulates the atomization of the fuel mixture using the electronic engine control unit. There is a valve on the central distribution system in front of the throttle valve.

• Mechanical – they do not dose the fuel supply, but only allow it access under pressure.

The principle of operation of the nozzles: an electronic sensor analyzes the volume of air supplied under pressure. The information received by the sensor enters the computer unit for further analysis (for example, engine temperature, air temperature). After this, the computer calculates the size of the volume of air in the fuel mixture required to ensure that the output coefficient of performance (efficiency) from the operation of the engine is as high as possible.

Why and when to check injectors

If you decide to buy a used car, or your car has already driven about 100 thousand km, then you should check the performance of the injectors or replace them.

Remember! The performance of the engine directly depends on the operation of the injectors (they supply fuel to the system).

The injectors (their condition) are affected by the quality of the fuel consumed. If low quality fuel is regularly poured into the tank, the injectors will not last long. They will have to be changed sooner than after 100 thousand km.

Symptoms of faulty injectors can be noticed. He will tell you about them:

• Unstable engine operation at idle.

• Increased fuel consumption.

• The engine does not start well.

• Exhaust gases have become more toxic.

• The ignition skips at idle.

• The car accelerates worse (even though the gas is squeezed to the max).

• If you notice at least one of the above symptoms, you should check the injector nozzles.

To extend the life of the injectors, it is advisable to:

• Fill the tank only with high-quality fuel.

• Regularly add various additives to the tank (sold in auto chemical departments).

• Clean the injectors every 40 thousand km (because they get clogged).

We look for faults and make repairs

Before checking the injector nozzles, pay attention to the fuel filter (it must be clean), the gas tank and the fuel pump screen (they may be clogged and deposited). Similar inspections are required after 30 thousand km for preventive purposes. If everything is in order with this part of the fuel system, proceed to check the injectors.

You can stop by the service station, where there is a special stand. The liquid is supplied to the nozzles under pressure, and on the stand you will be able to see the operation of each sprayer (what spray dose it produces).

To diagnose injectors, use a multimeter or ohmmeter (these are devices for measuring resistance of injectors). To determine the condition of the injector, you need to disconnect it from the high voltage wire. Now we check the injector with the device. There are low and high impedance injectors (the manufacturer's instructions will tell you about the type of injector). The resistance should be 2-5/12-18 ohms.

We recommend: When to change the fuel filter

Attention! If you hear a dull hum in the engine, then the injectors are acting up.

You can also check the injector nozzle at home. You can do this in several ways:

Start the engine. Touch the working nozzle with your hand - it should pulsate. If the shaking is not felt, it means that the injector has failed. At idle, add speed and let the engine run a little. If you loosen the cap nuts that hold the injectors one by one, the engine speed will decrease. If the speed does not change, then the injector requires cleaning or replacement.

Diagnostic tool

Checking gasoline injectors yourself is possible if you have a diagnostic tool:

• On-board computer of the car (will help determine malfunctions in the engine control system).

• Pressure gauge (determines fuel pressure). Helps identify problems with the fuel pump pressure regulator and clogged fuel filters.

• LED for determining the polarity on the injectors (you can also determine the polarity on the ignition modules and coil).

• Ohmmeter or multimeter (determines the resistance of the injectors).

Checking power supply to injectors

If the ignition is turned on and one of the injector nozzles does not work, then check the presence of power to the injectors. To do this, you need to disconnect the wire block from the non-working injector. You need to attach the two ends of the wires to the battery, and touch the injector contacts with the other side of the wire. Now turn on the ignition.

Attention! If this injector begins to spray fuel, then problems must be looked for in the electrical circuit of this injector.

Checking the windings

The nozzle on the injector requires immediate replacement if its resistance is higher or lower than 11-15 Ohms. This is determined using an ohmmeter.

How to check the resistance on the injector windings?

1. Remove the negative terminal from the battery.

2. Disconnect the block with wires from the injector.

3. Connect the ohmmeter leads to the electrical connector of the injector.

4. Compare the ohmmeter readings with the standard values (this is indicated in the manufacturer’s instructions).

On-ramp diagnostics

You can also check the injector nozzles on the ramp. For this:

1. Remove the ramp along with the injectors.

2. Get her out of an awkward position.

3. Remove the negative terminal.

4. Connect the wire block to the ramp harness.

5. Replace the minus terminal.

Connect both fuel pipes and tighten the fittings that hold them with a wrench. Place a container with a measuring scale under each injector (there should be 4 containers). Turn the engine over with the starter.

Attention! Fuel should flow smoothly and evenly from the injector nozzles into 4 containers.

Turn off the ignition. When at rest, no liquid should leak from the nozzles.

If leaks are noticeable, then the fuel injector is leaking and therefore needs to be replaced. Compare the amount of leaked fluid in the measuring containers. If the amount of fluid leaked out is different, then one of the nozzles requires cleaning or replacement.

Don't forget to inspect the injectors for defects. If you find something, change the nozzle. Put the ramp in place.

Did you know? If the injector nozzles are checked and everything is in order, but the car continues to act up, then check the pressure in the fuel rail. Most likely the reason is pressure.

Subscribe to our feeds on social networks such as Facebook, Vkontakte, Instagram, Pinterest, Yandex Zen, Twitter and Telegram: all the most interesting automotive events collected in one place.

Electro-hydraulic fuel injector

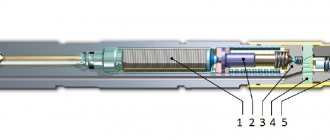

The electrohydraulic type of injector is most often used in diesel engines. Structurally, it consists of a control chamber, an electromagnetic valve and two throttles: for inlet and outlet. The operation is based on the principle of applying fuel pressure during injection and stopping it. At the beginning, injection does not occur because the solenoid valve is closed and de-energized, and due to the fact that fuel pressure is exerted on the piston located in the control chamber, the fuel injector needle is pressed against the seat.

The difference in contact areas corresponds to the fact that the pressure on the piston is greater than the pressure on the needle. The valve is activated by a signal from the electronic unit. This valve, in turn, opens the drain throttle. Through it, fuel enters the corresponding line from the control chamber. Moreover, the intake throttle does not allow the pressures in the intake line and the control chamber to sharply equalize. As a result, the pressure exerted on the piston decreases, while the pressure on the needle remains unchanged, it begins to rise and fuel is injected.

Here you see the arrangement of electro-hydraulic injectors. Photo: carnovato.ru

The accuracy of the fuel dosage is checked using the response time. During injection, the valve will be open for only 1-2 milliseconds.

Electromagnetic injector

This type of injector is usually used on gasoline engines.

The design has a nozzle and an electromagnetic valve with a needle. Photo: Childhood-empire.ru

Due to a predetermined algorithm, the control unit transfers voltage to the exciting winding of the solenoid valve at the required moment. As a result, an electromagnetic field appears that can overcome the spring force. It also draws an armature with a needle into the free nozzle and fuel is injected. After the voltage supply is completed, the fuel injector needle moves back into the seat with the help of a spring.

Piezoelectric injector

The most advanced type of such devices today is the piezoelectric type of injector, which is installed on diesel engines. Structurally, the nozzle consists of a pusher element, a piezoelectric element, a needle and a switching valve. The operation of such a nozzle is based on the hydraulic principle. Initial position: the needle is on the seat due to high fuel pressure. When an electrical signal is applied to the piezoelectric element, it grows in length and delivers the required force to the pusher piston. When the switch valve opens, fuel begins to flow into the drain line. The pressure begins to decrease above the needle. In this case, the pressure below raises the needle, due to which fuel is injected.

Operating principle of a mechanical nozzle

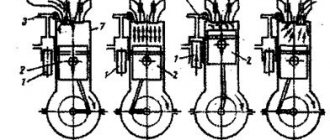

The operating principle of a diesel power system with mechanically controlled injectors is as follows. The high pressure fuel pump (HPFP) is supplied with fuel from the fuel tank. The feed pump is responsible for the supply, which creates the low pressure necessary to pump diesel fuel through the fuel lines.

Next, the fuel injection pump, in the required sequence, distributes and pumps fuel under high pressure into the lines leading to the mechanical injector. Each nozzle of this type opens for the next injection of diesel fuel into the cylinders under the influence of high fuel pressure. The decrease in pressure causes the diesel fuel injector to close.

A simple mechanical injector has a body, a nozzle, a needle and one spring. In the device, the shut-off needle moves freely along the guide channel of the sprayer. The injector nozzle closes tightly at a time when there is no required pressure from the injection pump. At the bottom, the needle rests on the atomizer seal, which has a conical shape. The needle is pressed using a spring attached to the top.

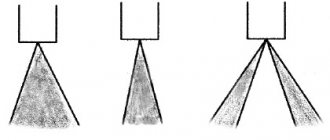

Simple diesel engines that have a split combustion chamber often have a single-hole atomizer with a needle. Diesel engines, which are based on direct fuel injection, are equipped with injectors with several spray holes. The number of holes in such a sprayer ranges from two to six.

The fuel supply is regulated depending on the design of the atomizer, since there are two main types of such solutions:

- sprayer with the ability to block channels;

- sprayer with overlapped volume;

In the first case, the injector needle shuts off the fuel supply by blocking each hole. The second type of nozzle means that the needle covers a kind of chamber at the bottom of the atomizer.

The fuel pressure pumped by the injection pump forces the needle to rise due to the presence of a special step on the surface of such a needle. Diesel fuel penetrates the housing under the specified step. At the moment when the fuel pressure is stronger than the force created by the pressure spring, the needle moves upward. This opens the nozzle channel. Diesel fuel under pressure passes through the atomizer and is sprayed in the form of a torch. This is how fuel injection is implemented.

Next, a certain amount of fuel, which is supplied by a high-pressure pump, will pass through the atomizer and enter the combustion chamber. After this, the pressure on the needle step begins to decrease, as a result of which the needle, under the force of the spring, returns to its original position and tightly closes the channel. Then the supply of diesel fuel to the sprayer stops completely.

What types of injectors are there and their location?

There are several types of kit in question. This:

- low-resistance with performance indicators 1-7 Ohm. The circuits may have additional resistance from 5 to 8 ohms;

- high-resistance with indicators of 14-17 Ohms.

- In a four-cylinder in-line engine, one injector nozzle is used - this is mono injection.

- In a V-shaped engine with six cylinders, two injectors operate while dividing the process - this is double mono injection.

- When one injector operates per cylinder, this is distribution injection.

- When one injector is located, the working part of which is located inside the cylinder - this is direct injection.

- One injector per power unit with the working part located in the intake manifold is the starting injector.

- Location.

The starting nozzle, located in the intake manifold, is installed in such a way that a wide spray of atomized fuel (up to 90 0) reaches the intake valves of all cylinders.

The mono injection nozzle can be found at the carburetor installation site. Fuel enters the intake manifold.

Distributive injection nozzles are located on the intake manifold (the intake valve area of each cylinder). If there are 2 valves, therefore, the spray of atomized fuel consists of 2 parts. The supply is directed to each valve.

Depending on the operation of the engine, the fuel entering it is regulated by 80-130 operating atmospheres. We are talking about direct fuel injection.

It does not matter what type of fuel, diesel or gasoline, a self-propelled vehicle runs on. Technical problems with injectors often arise. This part, responsible for high-pressure fuel injection due to poor quality fuel, regularly sends the car to repair bays. Drivers should know how to check the operation of the injector nozzle if starting the engine is difficult.

Why are fuel injectors needed?

In the photo: Electromagnetic injectors of a diesel engine

Electrohydraulic injectors

This type of injector combines two previous technologies and is fully adapted for use on diesel engines. The high pressure in the fuel system is equalized by the fact that pressure on the needle occurs from above and below. Thus, the same pressure is formed in the upper chamber and in the lower one. But into the lower chamber, fuel enters through a narrow channel, increasing the time for balancing the pressure in the two chambers.

In the photo: Electro-hydraulic injectors of a diesel engine

When the solenoid valve is activated, due to equal pressure - no more power is required, the needle opens access to the nozzle and allows fuel from the lower chamber to enter the cylinder. But the upper chamber is directly connected to the fuel line and fills quickly, increasing the pressure on the needle. After closing, the lower chamber is filled with fuel through a narrow channel and the pressure is equalized.

Injectors have proven to be a reliable mechanism, effective when used on any engine, but are used on modern diesel engines. Since, on gasoline systems, electromagnetic injectors are sufficient. In addition, electrohydraulic injectors are used in engines with a direct fuel injection system into the cylinders.

Piezoelectric injectors

Piezoelectric injectors are the most modern invention used in the mass production of modern diesel engines equipped with a direct injection system into the cylinders. According to the principle of operation. They completely replicate electrohydraulic injectors, with the only exception - not an electromagnet, but a piezoelectric crystal is used as a valve drive.

What is an injector

An injector is a special nozzle installed on an internal combustion engine, or is part of an entire injection system. It performs the function of a fuel atomizer (liquid or gaseous).

Bosch specialists first introduced this development into production when they equipped the Goliath 700 Sport coupe with a two-stroke engine with it. This happened in 1951, and just 3 years later Mercedes did the same (Mercedes-Benz 300 SL). However, at first such components were quite expensive, so the widespread use of injectors began only in the 70s. The injection system quickly replaced carburetors (especially in Europe, America and Japan) and today most car models are equipped with this particular device.

The Fuel Injection System is distinguished by the fact that it performs direct injection directly into the cylinders or into the intake manifold. This is done using the same nozzle, which, in turn, are divided into 2 categories, differing in the location of the injector installation, as well as the principle of its operation:

- Mono-injection – it is also called central fuel injection. In this case, the injector is only one nozzle that supplies fuel to all cylinders of the engine. With this approach, the injector itself is mounted directly on the intake manifold. It is worth noting that today this work scheme is outdated and is practically not used by automakers.

- Distributed injection means that each individual cylinder has its own injector.

In addition, there are several types of distributed injection:

- direct (direct) - with it, fuel is injected directly into the combustion chamber of the engine;

- simultaneous - in this case, all injector nozzles operate synchronously, supplying fuel to all cylinders at the same time;

- pair-parallel – the injectors are opened in a pair pattern. That is, the first one opens before the inlet, and the second one opens before the outlet. However, this approach only takes place when the motor is started, while in motion a phased pattern is implemented;

- phased injection - this means that each individual injector nozzle opens just before the intake.

Cleaning the fuel injector

This procedure is nothing more than an imitation of the operation of an injector on an engine, with the only difference being that flushing liquid is supplied to the injector under pressure in place of the fuel.

After pressing the spray gun, the flushing liquid is supplied under pressure to the nozzle and does not pass through it until we open the nozzle. We apply current to the nozzle by pressing the button so that it opens. The nozzle will open and liquid will begin to spray out from the back of the nozzle due to pressure.

Pay attention to the nozzle spray. It should be uniform

If a stream flows from the nozzle, run the flushing liquid until the stream turns into a uniform spray. If the spray was initially of the correct geometry, this indicates that the nozzles were clean. Surprisingly, my injectors turned out to be clean, although their initial appearance allowed me to doubt this.

We rinse each nozzle in this way for 2-3 minutes with short breaks. After all nozzles have been cleaned, repeat the procedure for each nozzle again. While the remaining nozzles are being cleaned, the residual liquid in the first cleaned nozzle eats away unwashed deposits and during the next flush, all residues are washed out.

Uniform torch

Perhaps this is all that can be said on this topic. After washing the injectors, we assemble everything in the reverse order. If the rubber injector seals are in good condition, put them back after lubricating them with engine oil. Otherwise, stock up on a set of new rubber seals, preferably in advance. Deformed rubber bands can cause fuel leaks or air leaks into the intake manifold.

Having finished assembling the disassembled one, without starting the engine, turn on the ignition in order to activate the fuel pump for a couple of seconds and increase the pressure in the power system. We repeat turning the ignition on and off several times to build up more pressure. Then we check the fuel line and injectors for fuel leaks. It would be a good idea to replace the fireproof injector washers (relevant for diesel engines) and rubber seals, if any. If no leaks are found, you can safely start the engine. Typically, cleaning fuel injectors is combined with cleaning the throttle valve. In the next article we will discuss exactly this.

| Vehicle air and fuel systems. Theory: Cleaning the throttle valve. Roll up your sleeves ECU: fuel injection control, fuel maps |

Methods for cleaning and flushing the injector

The most widely used methods for flushing the injector are:

- Washing with special detergent additives for gasoline.

- Cleaning and washing the injector without removing the injectors from the engine.

- Washing injector nozzles in an ultrasonic cleaning stand.

We recommend: Modification of the VAZ 2110 thermostat

Let's take a closer look at each of them.

Gasoline additives for injector flushing

Additives for flushing the injector are the cheapest and easiest way to clean it from contaminants. Such additives are available in the range of many auto chemical manufacturers. They are most effective when added regularly to the gas tank.

When the first signs of injector contamination appear, you can apply a shock dose of such additives, but provided that the gas tank and pipelines are relatively clean. Otherwise, all the dirt will end up in the electric fuel pump and fine fuel filter, which obviously will not add durability to these components.

Flushing the injector without removing the injectors from the engine

Cleaning and washing the injector without removing the injectors from the engine is carried out using a simple washing unit:

- to do this, the engine is disconnected from the standard power system;

- instead, a unit for washing the injector is connected;

- after which the motor is forced to run for 20-30 minutes using a special solvent.

The washing ability of this composition is very high and it easily washes away all deposits (for an example, see the video at the end of the article).

Washing and cleaning the injector with ultrasound

Ultrasonic injector cleaning is by far the most effective cleaning method. To do this, the injectors are removed from the engine and placed in an ultrasonic unit with a special solvent.

The operating principle of the installation is as follows:

- In order to help the solvent wash out toxins, it is forced to vibrate using ultrasound.

- Liquid vibrations have virtually no effect on the nozzle, but cause slags to resonate, which peel off from the metal and become easy prey for the solvent.

The time for such injector flushing usually ranges from half an hour to an hour. The advantages of this method include the uselessness of an expensive solvent, however, a fairly large amount of work is required to remove and reinstall the injectors on the engine.

Injectors with throttling vibrating needle

A standard nozzle assembly with holder for engines with a prechamber and a swirl chamber consists of a nozzle (type DN...SD) together with a holder (type KSA with thread). The regular version of this holder has a thread size of M24x2 and a spanner size of 27 mm. Typically, DN O SD nozzles are used, which have a spray needle diameter of 6 mm and a jet angle of 0° (straight jet). Much less commonly used are nozzles with a specific spray angle (for example, 12° for a DN 12 SD nozzle). For limited cylinder head space, more compact injector holders are used (for example, KSE).

One of the characteristic features of a throttling needle injector is the control of its cross-section, in other words, the amount of fuel flowing through it depending on the rise of the needle. While in the case of a pinhole nozzle (i.e. an injector with holes) the cross-section increases sharply as soon as the needle opens, a throttling needle nozzle has a very flat cross-section characteristic in the region of small needle strokes. In this region, the rod-shaped throttling needle remains inside the nozzle orifice and only the small annular shaped surface between the nozzle orifice and the needle acts as a cross-section for the fuel flow. With large needle strokes, it rises completely from the nozzle hole and the cross section increases sharply.

To a certain extent, this change in cross-section as a function of needle stroke controls the discharge rate curve, in other words, the amount of fuel injected per unit time. At the beginning of injection, only a small amount of fuel can exit the injector, while a large amount exits at the end of the injection process. First of all, this characteristic has a positive effect on engine noise from the combustion process.

It should be noted that if the cross-sectional values are too small and the needle lift is insufficient, then the injection pump moves the needle in the opening direction more quickly than it could be and the needle leaves the nozzle hole earlier, i.e. The throttling action will stop faster. As a result, the amount of fuel injected per unit time increases rapidly and the combustion noise also increases. Excessively small cross-sections at the end of injection have a similar negative effect due to the fact that when the needle closes again, the fuel exit is obstructed through the restricted cross-section while simultaneously delaying the end of injection

What are the dangers of injector malfunctions, and what are the signs of possible problems?

If the electric injector is leaking, the efficiency (efficiency) of fuel atomization decreases. In other words, the shape of the flame dissipates. This problem is indicated by black or gray smoke. The car is reluctant to start. When the injectors are leaking, engine power may be lost.

If the injector is leaking, fuel consumption increases. A dirty filter can be a problem. The injector may not flow, and malfunctions may occur due to bad spark plugs. The culprit may be the fuel pump or timing belt. The difficulty of starting the engine is 90% of the injectors are not working.

Often, when a car does not have a fine fuel filter installed, dirt accumulates on the injector mesh, which does not allow fuel to pass through and, as a result, there is a lack of fuel atomization, and in the worst case, the engine may even start to misfire!

Problems while driving may be indicated by jerking of the car, in particular when accelerating. After switching gears and gaining speed, the car may jerk. Accelerating a vehicle and performing maneuvers is very difficult. If you drive with injection problems, which, by the way, is not recommended by experts, the operating time of the engine can be significantly reduced.

Defects must be corrected immediately. It's scary to think what could happen on a steep climb or dangerous descent if an injector fails.

Main types of injectors produced by Siemens

Siemens injectors have a greater variety compared to Bosch. The main criterion that determines the possibility of installing a particular model is the number of valves in the engine. Depending on this, the design changes. The nozzle can be:

- single-flare, designed for precise dosing and injection of fuel at one point;

- two-flare, spraying fuel into each inlet channel separately.

Generalized table of installed injectors for various models of VAZ car engines.

High manufacturing precision is manifested in the good quality of Siemens products. Different colors for each model increases convenience when selecting nozzles. Despite its high reliability, the injection system is sensitive to fuel quality. It is enough to refuel with bad gasoline once, and replacing the elements of the fuel system will not take long.

Purpose of injectors in engine operation

Metered supply makes it easy to operate the machine thanks to carefully calculated portions of fuel. The purpose of such a system allows not only to reduce the emission of harmful substances, but also to make driving safe. The microprogram embedded in the control unit makes the car responsive to the slightest changes in movement. In this case, the engine gains power more dynamically, which makes it possible to take into account the slightest features of the road.

Each high pressure injector is an important part of the fuel system. Precisely calculated fuel supply is of great importance for the power plant of the machine and allows you to increase its service life. In modern cars, the injector (nozzle) is controlled electronically and comes in several types. Such equipment is successfully used on gasoline and diesel internal combustion engines, which makes this technology the most promising. Depending on the type and characteristics of the engine, injectors differ in injection method, each of which has its own characteristics.

Advantages and disadvantages of fuel injectors

Fuel supply systems using injectors have certain advantages over carburetors, namely:

- fuel consumption is lower due to precise dosage;

- exhaust toxicity is reduced;

- the power of the power unit increases to 10 percent;

- the car starts easily in any weather;

- improved by car dynamics;

- replacement and cleaning are done much less frequently.

But such systems also have disadvantages, namely the high quality of the fuel used. Because if the chemical composition of the fuel is disrupted due to the ingress of water, dirt and other particles that are often found in diesel fuel, this will have a very negative impact on the injector mechanism.

Another disadvantage of a distributed injection system is the high cost of replacement and repair.

In order to clean injectors, two methods are used - ultrasound and dry cleaning. Each of these methods can be used in different situations. For example, contamination of fuel injectors is accompanied by the formation of soft and hard deposits. First of all, soft deposits appear, which are washed off by dry cleaning. When soft deposits compact, they become hard. In this case, only dry cleaning can help.

It is optimal to perform dry cleaning after every 20 thousand kilometers traveled. Ultrasonic testing is carried out no more than 2 times during the entire period of use of the nozzles, since there is a serious risk for the insulation of the windings.

With a mileage of more than 100 thousand kilometers, dry cleaning of injectors is not only not advisable, but will also lead to unfavorable results. The reason is that hard deposits break off over time and clog the injector needle. This is especially true for injectors where there is direct fuel injection.

Cleaning injectors

Ultrasonic cleaning requires knowledge of what the actual operating voltage for the nozzle is. Because a normal voltage of 12 volts cannot provide significant speed and closing of the nozzle. As a result, a number of modern manufacturers are seeking to use lower voltage. For example, Toyota uses injectors with an operating voltage of 5 volts, and Citroen has injectors with an operating voltage of 3 volts. This eliminates the use of an operating voltage of 12 volts due to the fact that they will simply burn out.

The voltage at the injectors is the subject of a separate article, which you can read about on the relevant websites. Photo: drom.ru

The best cleaning involves consistent use of chemical and ultrasonic cleaning methods. That is, first, hard deposits are softened using ultrasound, and at the next stage they are removed using chemicals.

In addition, there are special additives required to be added to the fuel tank. Their function is to wash the injectors when fuel, which contains a cleaning agent, is transported through them.

The period between periods of using such additives varies and depends on the specific brand of car and the fuel used. However, it is necessary to understand that this method is not as effective as the previously described methods. It should be used when changing fuel filters or periodically after several thousand kilometers.

Find out how to wash injectors with your own hands in this video:

How to check the performance of injectors on injection engines

Today, there are several ways to check injectors without removing them from the car engine. You can do this yourself in a garage. Although, for a more accurate and complete diagnosis, it is better to contact a car service specialist or service station. Below are the verification methods with step-by-step instructions.

Checking with a multimeter (ohmmeter)

You can check the injectors without removing them from the car using the resistance measurement method. First, you will need to find out what type of injectors are installed on your car - high or low impedance (electrical resistance of the environment). This information will be needed during the diagnostic process. To check the injectors using a multimeter, you should perform the following algorithm:

- the high voltage wire is disconnected from the injectors;

- switch the tester switch to resistance measurement mode to a value of 0-200 Ohms (different devices may have different upper limits);

- turn on the ignition and disconnect the negative terminal from the battery;

- disconnect the connector from the injector being tested;

- connect the multimeter wires to the injector contacts and check the readings.

On injectors with a high winding resistance it should be in the range of 11.2-16 Ohms, for low ones - 2-5 Ohms. If it is very different, this indicates an injector failure. In this case, it should be removed and a more detailed diagnosis should be carried out.

Remember, you should check all the injectors one by one, so you can find out which one has failed.

It is worth considering that the voltage from the electronic unit to the injector is supplied in pulses and not constantly. Therefore, it is important to check not only the resistance of the circuit, but also the oscillogram of the pulse voltage supply, this way you can determine the peak voltage at the node.

Checking the power supply to the injectors

We will consider a way to check the power supply to the ramp using the example of a VAZ 2110. The terminal block has five contacts: four of them are intended to supply power to the injectors, and the fifth (pink wire with a black stripe) is their mass. The check is carried out in the following sequence:

- the power supply is disconnected;

- the tester or ohmmeter is moved to the position for measuring resistance;

- one tester probe is connected to the common ground, and the second one is connected in turn to each of the four remaining contacts.

Under normal conditions, the resistance indicator should be at the level of 11.8-15.3 Ohms. This way you can find out the resistance of each injector on the ramp.

The proper operation of the injector can also be determined by vibration. An intact injector vibrates slightly when the engine is running. If this does not happen, it should be replaced.

Checking the power supply from the electronic control unit is a fairly simple process. To do this you need to do the following:

- the terminal block is disconnected from each injector in turn;

- using two wires, the injector contacts are connected to the battery;

- the ignition is turned on.

If the injector works well and fuel atomizes within normal limits, then the wiring is faulty. When using this method, be careful not to get any fuel on you or the open flame area. It is better to place the nozzle in a closed vessel.

Checking the starting injector (single injection)

Before we begin, a few words about monoinjectors, also known as monoinjection. Today they are used less and less, as they are considered an outdated system, but are still found on some older cars, such as VW, Audi, Skoda and others. Its design provides only one injector in front of the throttle valve. The serviceability of the monoinjector is checked using the following algorithm:

- the contacts on the injectors are checked in pairs using a multimeter or ohmmeter (the values should be in the range of 1.2-1.6 Ohms);

- when checking contacts 1 and 4, you should make sure that the intake air temperature sensor is working properly (normal values can be found in the car’s registration certificate);

- If discrepancies are detected in the readings, it is necessary to carry out a more detailed check of the injector.

Often on monoinjection engines, in addition to the valve injector, there is also a starting injector. Its task is to ensure the injection of additional fuel during engine starting, especially at low temperatures and high speeds, to facilitate starting. The period of operation of this unit is determined by the control unit (or rather the thermal relay), usually it is no longer than a few seconds. After starting the engine, it turns off as unnecessary.

It works on the same principle as injection nozzles. Naturally, when using a car, sooner or later it can also fail partially or completely. A clear symptom of a faulty starting injector is that a cold engine immediately stalls after starting. You can check it as follows:

- select a small measuring vessel (for example, a glass);

- the injector is removed from the engine and installed in this container;

- “plus” from the car battery is added to one contact of the injector, and “ground” to the second;

- connect to the “plus” of the battery, and the fuel pump relay (this way you put it into operation).

When checking the serviceability of the injector, it is important to pay attention to both the angle of fuel spray and its quantity. You can find out the exact reference information in the technical documentation for the model installed on your car. As an example, let's look at the indicators in the K-Jetronic system. Its spray angle under normal conditions will be 80°, and the amount of injected fuel will be 70-100 cm3/min. Accordingly, in other types of systems these indicators may differ.

After checking the functionality of the injector of a mono-injector device, you need to disconnect the wires from it, and wipe the assembly dry with a clean rag. A working nozzle should be completely sealed, without visible signs of damage. In other words, no fuel should leak from it during operation. Wait a few minutes and see if traces of fuel appear on the body.

Checking injectors by ear

Motorists with extensive experience can easily determine the serviceability of the injector with the engine running by ear. For this purpose, use a regular rectangular board or, even better, a stethoscope.

One end of the board or the sensitive element of the device is applied to the nozzle being tested, and the other to the ear. If the unit is fully operational and in good condition, then there should be no extraneous noise or vibration, only uniform clicking sounds. In the case of uneven clicks or their complete absence, as well as in the presence of strong vibrations and knocks, it can be judged that the nozzle is clogged. The higher the level of noise and knocking, the greater the blockage.

You can check the injectors by ear without using a board or a stethoscope, but this will require experience. In the event of a faulty unit, muffled high-frequency sounds similar to a whistle or squeak can be heard from the cylinder block. If these appear on a running engine, it is recommended to conduct a more detailed diagnosis of the injectors on a stand or ramp.

Checking the injector balance

As an example, let's look at how the balance of injectors on a VAZ is checked. The sequence of actions is as follows:

- the fuel pump turns off;

- the engine starts - this removes excess pressure in the fuel system (the car will run for a few seconds, after which it should stall);

- a pressure gauge and a fuel pump are connected to the fuel system;

- A PC with the appropriate diagnostic program is connected to the car’s on-board computer.

Next in this program the fuel pump and injectors are turned on and off. Actions are performed in the following sequence:

- the ignition is turned on;

- the pressure gauge readings are checked (the value should be within 2.8-3 atmospheres);

- using the program, the fuel pump relay is turned off;

- the pressure gauge should record a slight pressure drop (up to about 2.8 atmospheres);

- the first injector turns on;

- readings are taken from the pressure gauge (the pressure should not drop much);

- the fuel pump turns on again to restore the pressure to the original one;

- Then the procedure is repeated with all nozzles in turn according to the same pattern.

Under ideal conditions, all injectors will show the same pressure drop. If the readings of any of them differ sharply from the rest, then it is most likely faulty and additional diagnostics are required.

Checking injection nozzles for overflow (backflow) for diesel engines with Common Rail

During operation, injection nozzles may experience a problem due to the fact that the fuel from them flows back into the fuel system. This leads to the fact that the pump cannot create the required operating pressure. As a result, problems arise when starting the engine and during its operation.

To carry out the test, you will need to buy 20 ml medical syringes and a dropper system from the pharmacy (to connect the syringe, a 45 cm long tube is enough). To detect a nozzle that throws more fuel into the return line than it should, you can follow the following algorithm of actions:

- the plunger is pulled out of the syringe (it is not required);

- with the engine running, connect one end of the hose to the nozzle of the syringe, and the other to the “return” of the nozzle;

- wait two minutes while fuel is drawn into the syringe (if it is filled);

- the procedure is repeated on each nozzle, or you can make a structure from syringes and hoses for all nozzles at once.

Based on the data obtained on the presence and quantity of fuel collected in syringes, the following conclusions can be drawn:

- the syringe is empty - the nozzle is in working order and fully operational;

- the volume of collected fuel fluctuates between 2-4 ml - the injector is working;

- if the volume of fuel exceeds 10-15 ml, the nozzle has failed completely or partially; in any case, it will require repair or replacement;

- over 20 ml - the valve seat is badly worn, so the injector is considered completely faulty and cannot be repaired, since it will not be able to maintain the operating pressure of the fuel system.

But you should understand that with such a simple check you will not get complete information. The amount of fuel that is discharged into the return line when the engine is running is influenced by many variables. Perhaps the injector is simply clogged and requires cleaning, or it is simply hanging and needs repair or complete replacement. Therefore, this method of checking a node allows you to find out only about its throughput. Under normal conditions, the volume of fuel passed through the injectors should be approximately the same and range from 2-4 ml within two minutes.

More accurate data on the amount of fuel passed through the injectors can be found in the data sheet for your car or power plant.

To extend the life of the injectors, refuel your vehicle only with high-quality fuel. Do not forget to change fuel filters in a timely manner (use only original products from trusted suppliers). The operation of all machine systems greatly depends on this.

Checking the injectors on the ramp

To do this, you will need to disconnect the fuel rail from the engine along with the injectors installed on it. Then all disconnected electrical contacts are reconnected to the ramp and injectors. After disconnecting the negative terminal from the battery, it must be returned to its place. Next, the algorithm of actions is as follows:

- the ramp is placed in the engine compartment in such a way that it is possible to place a container with a measuring scale under each injector;

- the fuel supply hoses to the ramp are connected, after which the reliability and tightness of all connections is checked;

- the ignition is turned on and the engine is cranked slightly using the starter (it is better to do this with an assistant);

- While an assistant is cranking the engine, you should check the quality of operation of all injectors - fuel should be supplied equally to all injectors;

- The ignition is turned off and the fuel level in the containers is checked - it should be approximately the same in each container.

Different volumes of fuel in the measuring vessels will indicate the need to clean or repair a particular injector. If there is obvious underfilling, the nozzle should be cleaned or replaced with a new one. If, after turning off the engine, you see fuel leaks on the injector body, it means it has lost its tightness, and accordingly it needs to be replaced.

In addition to self-checks, you can contact car service or service station specialists. Using special equipment, our technicians will conduct a full diagnostic and provide more detailed data on each component - you will receive information not only about the efficiency of fuel supply, but also about the shape of the torch when sprayed in the combustion chamber.

Electromechanical diesel injector

Further development of fuel supply systems for diesel internal combustion engines led to the appearance of injectors in which diesel fuel is supplied to the cylinders using electromechanical injectors. In such injectors, the nozzle needle opens and closes access to the nozzle not under the influence of fuel pressure and counteracting spring force, but using a special controlled solenoid valve. The valve is controlled by the engine ECU, without a corresponding signal from which fuel will not enter the nozzle.

The control unit is responsible for the start of fuel injection and the duration of fuel supply. It turns out that the ECU doses diesel fuel by supplying a certain number of pulses to the injector valve. The pulse parameters directly depend on the frequency at which the engine crankshaft rotates, in what mode the diesel engine operates, what temperature the internal combustion engine is, etc.

Diagnostics as prevention and problem solving at an early stage of a “technical disease”

In a modern, “properly” equipped service station, it is possible to diagnose injectors without removing them. Testing goes very quickly. The emphasis is on noise analysis. High-frequency muffled noise is a direct path to cleaning the injectors. When diagnosing, attention should be paid to the fuel supply. Checking the power supply begins by disconnecting the injection system block. Two ends of the wire are connected to the battery, and the others are secured to the injectors. The engine is started and the supply of incoming fuel is monitored. The results are recorded, processed and appropriate conclusions are drawn:

- If fuel leaks, there may be problems with the car's electrical network.

- If fuel does not leak out, then everything is fine with the injectors.

When you need to measure the resistance at the injector, you can resort to using an ohmmeter. Next, compare with the recommended values. If deviations from the norms are detected, the non-working nozzle is dismantled. It is replaced with a good one. Next, the resistance is checked again and the engine is started. The work involves removing the fuel rail, and the injectors are removed along with the rail.

Basic faults

Faulty injectors are the main cause of car engine stalls and breakdowns. When the engine is running, such malfunctions are very easy to notice.

Signs of injector failure:

At partial loads, a smoky exhaust appeared (toxicity increased).

Engine power has decreased.

High temperature and knocking of exhaust gases.

With increased loads, jerks and dips in engine operation appeared.

At low speeds, engine operation became unstable.

A malfunction of the injectors can lead to a loss of its properties: the tightness will be broken, leaks will appear, the fuel spray angle will change, any supply of fuel to the combustion chamber will stop, and the fuel will be unevenly distributed in the chamber.

Operational faults are divided into two categories:

Malfunctions are caused by the use of low-quality fuel, which disrupts atomization and causes overheating (wear of injector elements, needle sticking, metal melting, etc.).

Malfunctions caused by incorrect assembly of the equipment or its incorrect installation (misalignments of parts, blockage of fuel channels, lack of tightness of connecting parts, pinching of the needle, etc.)

Let's look at the main options for injector malfunctions.

The most common malfunction of injectors is their contamination. Since they are exposed to high temperatures, when low-quality fuel is used, solid deposits form on them, blocking the holes and breaking the seal. General contamination of the fuel system leads to clogging of the filter and injector channels. To restore normal operation of the injectors, they should be washed.

Failure of the needle seal is also a fairly common cause of injector failure. It is caused by needle wear. This problem can be solved by replacing the needle and sprayer.

Violation of pressure regulation - occurs due to wear of the spring and its weakening or wear of the needle and rod. This problem can be eliminated by changing the spring tension using the adjustment screw.

A stuck needle is a consequence of overheating or working with a needle that does not close tightly. Therefore, gases from the cylinder enter the nozzle space. To solve this problem, either clean the parts or replace the needle.

It is recommended to replace injectors after every 100-150 thousand kilometers. But, as a rule, they can still work for 30-50 thousand km after the official warranty expires.

To ensure that the injectors do not become clogged and work properly, they must be serviced periodically. The maintenance intervals for diesel injectors vary for different engines and range from 500 to 5000 hours.

How to check injectors without removing them from the engine using a multimeter

The diagnostic device multimeter is a faithful assistant to any motorist. It allows you not only to check fuses or the battery, but also to diagnose injector malfunctions. To check the injectors with a multimeter you need to do the following:

- Remove the high voltage wires from the injectors and consult your vehicle's manual to determine whether your engine has high impedance or low impedance injectors - this will be necessary for accurate diagnosis;

- Set the multimeter to resistance measurement mode and connect the diagnostic wires to the injector terminals, then take the measurement;

- If your vehicle has high impedance injectors, the measured resistance should be between 12 and 17 ohms. In the case where low impedance injectors are used on a car, their resistance lies in the range from 2 to 5 ohms.

In a situation where the indicators differ from the recommended ones, you should remove the injector from the car and check it in more detail, and if necessary, replace it.

Injector with two springs

The efficiency of fuel supply and subsequent fuel combustion in diesel cylinders can be influenced by changing various characteristics of the injector, such as the structure and number of nozzle channels, spring force, etc. One of the design solutions was the introduction of a special needle lift sensor into the injector device. This rise is taken into account by special electronic control units that interact with the injection pump.

A special feature of the operation of these injectors is a two-stage needle lift. It turns out that the fuel pumped by the injection pump first exceeds the pressure force of the resistance of one spring, and then the other. In idle mode and with light loads on the engine, injection is carried out only through the first stage, supplying a small amount of diesel fuel to the engine. When the engine reaches load mode, the pressure of the fuel pumped into the injection pump increases, and the fuel is supplied in two metered portions. The first injection is a small volume (1/5 of the total amount), and then the main one (about 80% of diesel fuel). The difference in injection pressure for opening the first and second stages is not particularly large, which ensures smooth fuel supply.

This approach made it possible to increase the uniformity, efficiency and completeness of combustion of the mixture. The diesel engine began to consume less fuel, and the amount of toxic impurities in the exhaust gases decreased. Diesel injectors with two springs were actively used on units with direct fuel injection until the advent of power systems called Common Rail.

Bottom line

Thus, the injector is one of the most advanced mechanisms for fuel injection. With proper care and repair, it can last for quite a long time. It is most advisable to take cars with diesel engines, since the piezoelectric injectors used there have a more advanced design compared to other types of injectors. Moreover, after 100 thousand kilometers the nozzle needs to be replaced, since by this point its cleaning and other repair work becomes harmful.

- Next Selecting a carburetor cleaning fluid and its correct use

- Back The car jerks when driving: what could be the reason

- News / Ratings

Oct 3, 2019

- Oct 3, 2019

- Oct 2, 2019

- 1 Oct, 2019

- BMW Crossovers / News

Sep 30, 2019

- Sep 30, 2019

- April 13, 2019

- March 12, 2019

- Feb 17, 2019

- News/Reference information

Jun 22, 2019

- April 11, 2019