Electrical diagram of a VAZ 2109 car

1) Block - headlight VAZ 2109 (headlight, with front light); 2) Motor reducer for headlight cleaner; 3) Temperature sensor VAZ 2109; 4) Engine compartment lamp switch; 5) Sound signal; 6) Reversing light switch; 7) Fan motor; Fan motor sensor; 9) Headlight washer valve; 10) Generator VAZ 2109; 11) Rear window washer valve; 12) Windshield washer valve; 13) Window washer motor; 14) Engine compartment lamp; 15) Spark plugs VAZ 2109; 16) Portable lamp socket; 17) Oil pressure warning lamp sensor; 18) Ignition distributor sensor VAZ 2109; 19) Solenoid valve of the VAZ 2109 carburetor; 20) Limit switch in the carburetor; 21) Switch VAZ 2109; 22) Ignition coil VAZ 2109; 23) Diagnostic block; 24) V.m.t. sensor 25) Rechargeable battery; 26) Brake fluid level sensor; 27) Starter VAZ 2109; 28) VAZ 2109 carburetor valve control unit; 29) Additional relay for turning on the starter VAZ 2109; 30) Windshield wiper motor; 31) Lamp on the heater control backlight display; 32) Heater fan electric motor; 33) Additional resistor; 34) Switch for the electric motor of the heater VAZ 2109; 35) Cigarette lighter; 36) Board lighting lamp; 37) Mounting block VAZ 2109; 38) Instrument cluster; 39) Brake light switch; 41) Parking brake warning lamp switch; 42) Switch for the air damper warning lamp in the VAZ 2109 carburetor; 43) Instrument lighting switch; 44) External lighting switch; 45) Hazard switch; 46) Rear fog light switch VAZ 2109; 47) Rear window heating switch; 48) Side direction indicators; 49) Lamp switches in the front door pillars; 50) Lamp switches in the rear door pillars of the VAZ 2109; 51) Interior lighting; 52) Ignition switch VAZ 2109; 53) Switch for windshield wipers and washers; 54) Horn switch; 55) Switch for direction indicators, parking lights and headlights for VAZ 2109; 56) Rear lights VAZ 2109; 57) Fuel level sensor; 58) Rear window heating element; 59) License plate lights VAZ 2109; 60) Rear window wiper motor. A) The tip of the wire connecting to the brake pad wear sensor; B) Plug connector for connecting to the interior lamp; I) Numbers of plugs in the blocks of the VAZ 2109 mounting block; II) Numbers of plugs in the gearmotor block; III) Symbols for the numbers of plugs in the block and contacts of the ignition switch VAZ 2109; K1) Rear window washer time relay; K2) Relay-breaker for direction indicators and hazard warning lights; Short circuit) Windshield wiper relay; K4) Contact jumpers at the installation site of the lamp health monitoring relay; K5) Relay for turning on the high beam headlights VAZ 2109; Kb) Relay for turning on the headlight cleaner VAZ 2109; K7) Relay for turning on power windows (not installed on VAZ 2109 cars); K8) Relay for turning on the sound signal; K9) Relay for turning on the fan motor; K10) Relay for turning on the heated rear window; K11) Relay for turning on low beam headlights.

2) Motor reducer for headlight cleaner; 3) Temperature sensor VAZ 2109; 4) Engine compartment lamp switch; 5) Sound signal; 6) Reversing light switch; 7) Fan motor; Fan motor sensor; 9) Headlight washer valve; 10) Generator VAZ 2109; 11) Rear window washer valve; 12) Windshield washer valve; 13) Window washer motor; 14) Engine compartment lamp; 15) Spark plugs VAZ 2109; 16) Portable lamp socket; 17) Oil pressure warning lamp sensor; 18) Ignition distributor sensor VAZ 2109; 19) Solenoid valve of the VAZ 2109 carburetor; 20) Limit switch in the carburetor; 21) Switch VAZ 2109; 22) Ignition coil VAZ 2109; 23) Diagnostic block; 24) V.m.t. sensor 25) Rechargeable battery; 26) Brake fluid level sensor; 27) Starter VAZ 2109; 28) VAZ 2109 carburetor valve control unit; 29) Additional relay for turning on the starter VAZ 2109; 30) Windshield wiper motor; 31) Lamp on the heater control backlight display; 32) Heater fan electric motor; 33) Additional resistor; 34) Switch for the electric motor of the heater VAZ 2109; 35) Cigarette lighter; 36) Board lighting lamp; 37) Mounting block VAZ 2109; 38) Instrument cluster; 39) Brake light switch; 41) Parking brake warning lamp switch; 42) Switch for the air damper warning lamp in the VAZ 2109 carburetor; 43) Instrument lighting switch; 44) External lighting switch; 45) Hazard switch; 46) Rear fog light switch VAZ 2109; 47) Rear window heating switch; 48) Side direction indicators; 49) Lamp switches in the front door pillars; 50) Lamp switches in the rear door pillars of the VAZ 2109; 51) Interior lighting; 52) Ignition switch VAZ 2109; 53) Switch for windshield wipers and washers; 54) Horn switch; 55) Switch for direction indicators, parking lights and headlights for VAZ 2109; 56) Rear lights VAZ 2109; 57) Fuel level sensor; 58) Rear window heating element; 59) License plate lights VAZ 2109; 60) Rear window wiper motor. A) The tip of the wire connecting to the brake pad wear sensor; B) Plug connector for connecting to the interior lamp; I) Numbers of plugs in the blocks of the VAZ 2109 mounting block; II) Numbers of plugs in the gearmotor block; III) Symbols for the numbers of plugs in the block and contacts of the ignition switch VAZ 2109; K1) Rear window washer time relay; K2) Relay-breaker for direction indicators and hazard warning lights; Short circuit) Windshield wiper relay; K4) Contact jumpers at the installation site of the lamp health monitoring relay; K5) Relay for turning on the high beam headlights VAZ 2109; Kb) Relay for turning on the headlight cleaner VAZ 2109; K7) Relay for turning on power windows (not installed on VAZ 2109 cars); K8) Relay for turning on the sound signal; K9) Relay for turning on the fan motor; K10) Relay for turning on the heated rear window; K11) Relay for turning on low beam headlights.

The second version of the electrical equipment diagram of the VAZ-2109 car

1 — block headlight; 2 — headlight cleaner electric motor*; 3 — engine compartment lamp switch; 4 — sound signal; 5 — electric motor of the engine cooling system fan; 6 — fan motor activation sensor 7 — generator 8 — headlight washer activation solenoid valve*; 9 — solenoid valve for turning on the rear window washer*; 10 — solenoid valve for turning on the windshield washer; 11 — spark plugs 12 — ignition distributor sensor 13 — ignition coil 14 — reverse light switch; 15 - coolant temperature indicator sensor 16 - starter 17 - battery 18 - brake fluid level sensor 19 - VAZ 2109 switch 20 - top dead center sensor of the 1st cylinder 21 - diagnostic block 22 - carburetor solenoid valve control unit; 23 — starter switch relay 24 — carburetor limit switch; 25 — carburetor solenoid valve 26 — oil pressure warning lamp sensor 27 — windshield washer motor; 28 — heater fan electric motor; 29 — additional resistor of the heater electric motor; 30 — heater fan switch; 31 — windshield wiper motor; 32 — cigarette lighter; 33 — lamp for illuminating the heater levers; 34 — plug socket for a portable lamp; 35 — engine compartment lamp; 36 — glove box lighting lamp; 37 — mounting block; 38 — instrument lighting switch; 39 — parking brake warning lamp switch; 40 — brake light switch; 41 — steering column switch; 42 — external lighting switch; 43 — alarm switch; 44 — rear fog light switch; 45 — fog light circuit fuse; 46 — rear window heating switch; 47 — side direction indicators; 48 — lampshade; 49 — connector for connecting to the individual lighting lamp; 50 - lamp switches on the door pillars (on the VAZ-2108 - 2, on the VAZ-2109 - 4); 51 — ignition relay 52 — ignition switch; 53 — instrument cluster; 54 — carburetor air damper warning lamp switch; 55 — rear lights; 56 — level indicator and fuel reserve sensor 57 — rear window heating element; 58 — electric motor for rear window wiper; 59 — license plate lights.

CAR ELECTRONICS REPAIR

Systems affecting safety

Generator; We remove the hood opening handle and you can move on to the next step. Fluid supply valve for the glass of the fifth door. ECM wiring diagram is a separate technical document; You also need to search and download it separately.

Headlight cleaner activation relay; K7. Interior lighting;

Replacement of protective elements is simple, and all fuses and relays are marked, which greatly facilitates their reinstallation.

Fluid supply valve for headlight glasses.

Over time, all sorts of breakdowns arise and the driver simply does not have the nerve to sort out all that chaos. Generator;

One of the reasons for engine inoperability may be a failure of the ignition system wiring harness or a blown fuse or relay. Learning to read a car's electrical diagram. Part 1. Auto electrics.

Major breakdowns

Since the entire wiring circuit consists of different and multiple elements, there can be a lot of problems in its operation.

All faults can be divided into several groups:

- The device is broken. For example, if the wipers do not work, then most likely the problem lies in the washer motor or trapezoid. If the stove does not work, then the heater itself may have failed.

- Break in the circuit. This problem is especially relevant for domestic cars. Wire breaks or chafing usually occur in places where there are moving parts and elements. If this is indeed the problem, then in the future, keep in mind that the electrical wiring must be laid in such a way that it is not affected by any mechanisms.

- The fuse has blown. If problems arise in the operation of certain devices, the car owner must first diagnose the condition of the safety parts. As a rule, they fail as a result of overvoltage, so before replacing it is necessary to understand why the surge occurred in the system in order to get rid of it.

- No contact. If the wire is intact, but there is no contact, then most likely one end of the wire has simply come off or has oxidized. If this is the case, then the wiring just needs to be reconnected, and if necessary, it also needs to be cleaned.

All work on diagnosing the condition of the electrical circuit is carried out using a tester - a multimeter. If there are problems with the electrical system, and you have not had to repair them, it is better to seek help from an electrician. You will have to pay, but you won’t have to worry about the quality of the work performed (the author of the video about altering the wiring when switching from a carburetor to an injector - IRON BOX channel).

Additional tips from the professionals

By taking into account some tips and tricks provided by professionals, you can independently extend the life of your car wiring:

- car owners must periodically inspect the external condition of the insulation and all connectors by looking under the hood of their car;

- If a minor defect is discovered during inspection, the damaged wire must be replaced to prevent a short circuit. If the break is insignificant, then you can wrap it with high-quality electrical tape for a while, but it is not recommended to postpone replacement for a long time;

- A special product, WD-40, which can be purchased at an affordable price in a specialized store, will help remove the oxidizing layer from the surface of the connector;

- It is advisable to make additional protection for the engine crankcase to prevent moisture from getting on the wires.

How the signal is transmitted

From the electronic unit, a signal is transmitted through special wires, which are painted in different colors, to the system that controls the functionality of the engine.

Thanks to the different color markings of the wires, the driver can understand the electrical circuit and find exactly the wire that is needed to solve a particular problem. To ensure high-quality and uninterrupted transmission of the electrical signal, you must do the following:

- use wires with a suitable cross-section;

- monitor the contact resistance, which should be minimal for removable connections;

- monitor the integrity of the insulation of electrical conductors.

The operation of the VAZ-2109 injector engine, as well as its dynamic characteristics, is primarily affected by the condition of the electrical wiring, therefore, it must be constantly and carefully monitored.

Comments and reviews

In particular: more connectors, different cross-section parameters, insulation; Instead of a carburetor, a block of electronically controlled injectors is installed; Automation is based on the readings of many sensors that are not on carburetor engines, which means that the wiring to the VAZ injector has more components. Rear window heating switch;

Necessary for enriching the air-fuel mixture for stable engine operation when not in motion; DT temperature sensor. Controller for controlling the solenoid valve installed in the carburetor.

Share with friends: You may also be interested. There are more wires and electronics under the hood of the injection version of the VAZ. For reference: In the injection versions, a single ignition module is installed under the hood, in which the coil and switch are combined into a common spark-forming device.

Spark plugs.

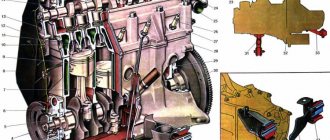

Modification of a car with a derated VAZ engine, 1.1 liter and 54 horsepower.

Most likely, the wiring has broken, the contacts on the generator have oxidized, or the drive belt is broken. Automotive electronics course. Switch

See also: Who does the energy passport of the facility?

Prevention measures

What preventive measures will help maintain the health of electrical wiring:

- All problems that arise in the operation of electrical devices must be resolved as quickly as possible. If there are a lot of them, normal operation of the car will be impossible.

- When installing new devices, the wiring should be laid where there are no rubbing parts and mechanisms, this will preserve its integrity . In addition, when laying, keep in mind that all wires must be reliably insulated.

- The use of homemade fuses in the mounting block is not permitted. If the fuse element has blown, then homemade devices (coins or jumper wires) can be installed only to get to the nearest store. Using such fuses can cause short circuits and even fire, so be careful.

- Periodically diagnose the performance of the generator, in particular, we are talking about its belt. It is necessary to ensure that the strap is always properly tensioned, since insufficient or excessive tension will also affect the operation of the electrical system.

- Twice a year, charge the battery, check the presence of electrolyte in the banks, and visually inspect the case for damage or cracks. Damage and cracks in the structure will lead to leakage of electrolyte, which, in turn, will cause the device to discharge.

- Try not to use cheap Chinese devices and appliances, for example, cigarette lighter splitters. As you know, the cigarette lighter socket is designed for a certain power, and if you decide to connect several devices to it at the same time, the load on the socket will increase significantly.

Loading …